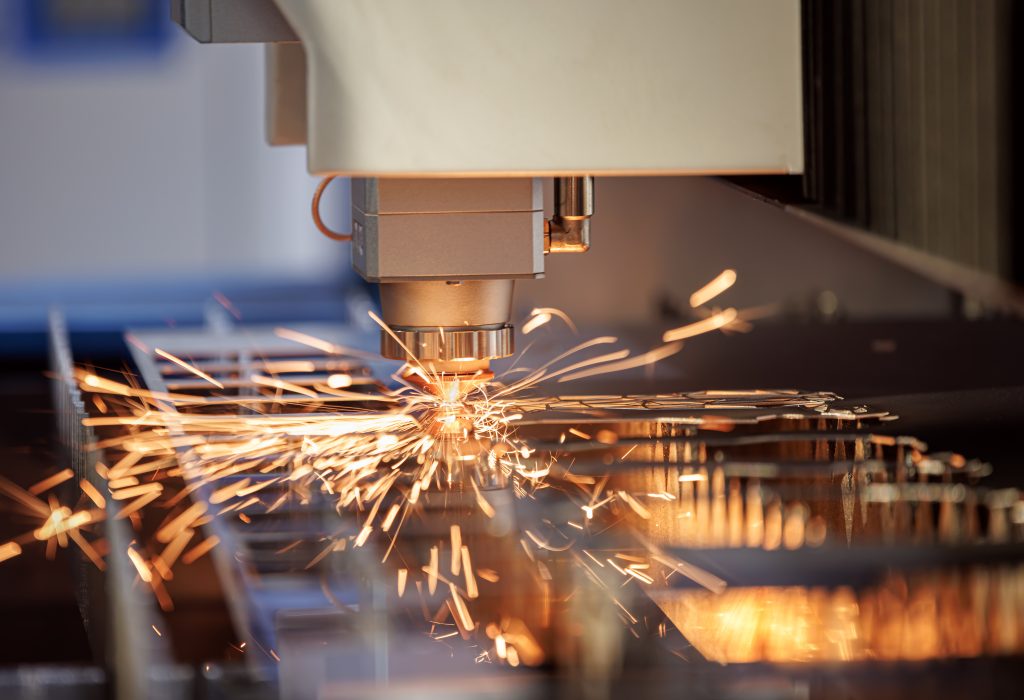

CNC Machine Company: Delivering Precision and Innovation in Modern Manufacturing

In an era where precision and efficiency define industrial success, partnering with a trusted CNC machine company is critical for businesses aiming to stay competitive. Companies like JLYPT Machining Solutions combine cutting-edge technology, material expertise, and rigorous quality control to produce components that power industries ranging from aerospace to healthcare. This article explores the role of CNC machine companies in modern manufacturing, their capabilities, and how to choose the right partner for your project.

What Defines a Leading CNC Machine Company?

A top-tier CNC machine company offers more than just machining—it provides end-to-end solutions tailored to industry-specific needs. Key attributes include:

-

Advanced Technology: 5-axis CNC mills, Swiss-style lathes, and EDM (Electrical Discharge Machining) for complex geometries.

-

Material Mastery: Expertise in titanium, Inconel®, PEEK, and carbon fiber composites.

-

Certifications: ISO 9001:2015, AS9100 (aerospace), and ISO 13485 (medical) compliance.

-

Scalability: Support for prototypes (1–10 units) to mass production (10,000+ units).

For example, JLYPT’s CNC machining services reduced lead times by 40% for a satellite component project through AI-optimized toolpaths.

Why Partner with a CNC Machine Company?

-

Unmatched Precision

Achieve tolerances as tight as ±0.0005″ for critical applications like jet engine components or surgical robots. -

Cost Efficiency

Automated workflows and bulk material sourcing reduce production costs by 20–35%. A 2023 industry report found that 78% of manufacturers saved costs by outsourcing to specialized CNC firms. -

Speed-to-Market

Rapid prototyping and 24/7 production capabilities help companies like VoltAuto launch EV battery enclosures 12 weeks ahead of schedule. -

Sustainability

Leading CNC machine companies like JLYPT recycle 95% of metal waste and use energy-efficient machines powered by renewable energy.

Industries Transformed by CNC Machine Companies

-

Aerospace & Defense

-

Turbine blades, UAV frames, and radar housings.

Case Study: JLYPT produced 200 Inconel 718 fuel nozzles for a jet engine OEM, achieving zero defects in FAA audits.

-

-

Medical Devices

-

Titanium spinal implants with porous surfaces for bone integration.

-

Surgical robot arms with 0.002″ positional accuracy.

-

-

Automotive

-

Lightweight EV battery trays from aluminum 6061.

-

High-strength transmission gears from 4340 steel.

-

-

Energy

-

Wind turbine hubs and corrosion-resistant nuclear valve systems.

-

Technologies Powering Modern CNC Machine Companies

-

5-Axis Machining

Create intricate geometries like impellers or orthopedic implants without multiple setups. -

AI-Driven Optimization

JLYPT’s SmartCut AI software reduces tool wear by 25% and cycle times by 15%. -

Hybrid Manufacturing

Combine 3D printing and CNC machining for lightweight aerospace brackets. -

Digital Twin Simulation

Test machining processes virtually to eliminate errors, reducing scrap rates by 18%.

How to Choose the Right CNC Machine Company

-

Verify Certifications

Ensure ISO 9001:2015 or AS9100 compliance for aerospace projects. -

Assess Material Expertise

Confirm experience with challenging materials like magnesium or PEEK. -

Evaluate Lead Times

Prioritize companies offering rush services. JLYPT delivers prototypes in 3–5 days. -

Review Quality Control

Look for in-house CMM (Coordinate Measuring Machines) and laser scanners. -

Transparent Pricing

Use JLYPT’s instant quote tool to avoid hidden fees.

The Future of CNC Machine Companies

-

Nanomachining

Produce micro-components with sub-micron tolerances for semiconductors and optics. -

IoT-Enabled Factories

Real-time machine monitoring via 5G reduces downtime by 30%. -

Circular Manufacturing

Recycle end-of-life parts into raw materials for sustainable production. -

AI-Powered Supply Chains

Autonomous systems predict demand and optimize inventory.

Why JLYPT Stands Out as a CNC Machine Company

-

Zero MOQs: Order 1 prototype or 10,000 parts with no minimums.

-

Global Reach: Facilities in the U.S., Europe, and Asia ensure localized support.

-

Eco-Conscious Operations: 100% renewable energy and zero waste to landfill.

Client Testimonial:

“JLYPT’s CNC services machined 500 drone motor mounts with flawless precision. Their team became an extension of our engineering department.”

– Alex Carter, CEO of Skyward Drones

Conclusion

Choosing the right CNC machine company is pivotal for businesses seeking precision, speed, and scalability. By partnering with JLYPT, industries can leverage advanced technologies like AI-driven machining and hybrid manufacturing to stay ahead in a competitive market. Explore JLYPT’s CNC capabilities to transform your next project from concept to reality.