Understanding CNC Machines: Definition, Evolution, and Industry Impact

The term CNC machine definition refers to Computer Numerical Control (CNC) technology—a manufacturing process where pre-programmed software dictates the movement of machinery and tools. This innovation has revolutionized industries requiring micron-level precision, from aerospace turbines to medical implants. At JLYPT, we harness CNC machining to transform raw materials into high-performance components, blending decades of expertise with cutting-edge technology.

This article demystifies the CNC machine definition, traces its evolution, and showcases its critical role in modern manufacturing.

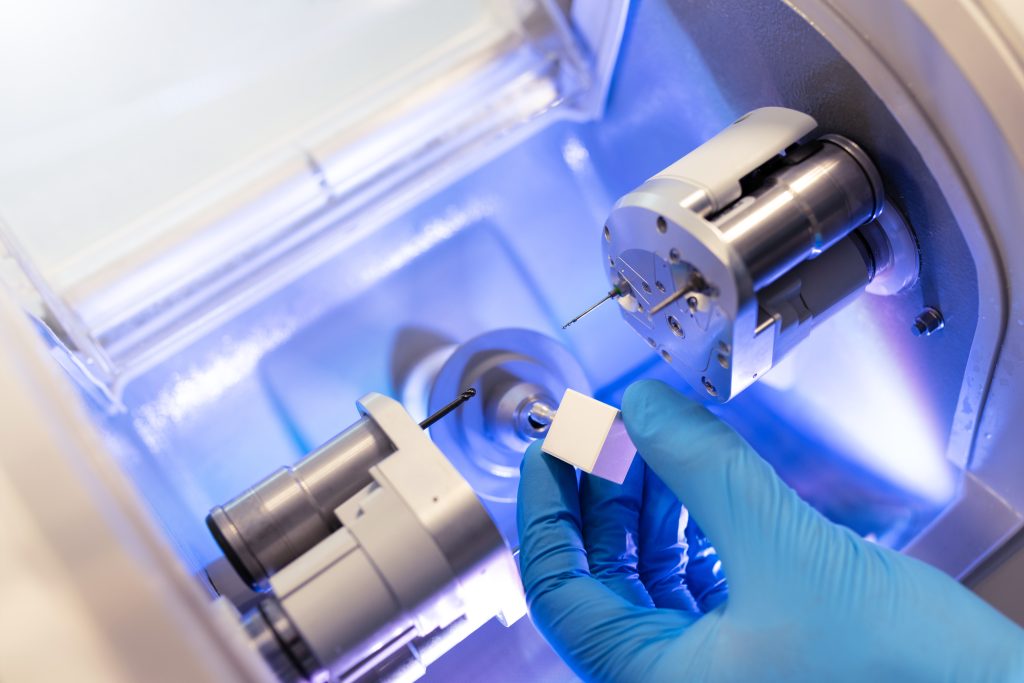

What is a CNC Machine? Breaking Down the Definition

The CNC machine definition centers on automation: computerized systems replace manual control to execute complex sequences with unmatched accuracy. Key elements include:

-

Control System: Converts CAD/CAM files into G-code instructions.

-

Drive System: Servo motors and ball screws ensure precise axis movements (X, Y, Z).

-

Tooling: High-speed spindles (up to 30,000 RPM) and multi-axis capabilities.

For example, JLYPT’s 5-axis CNC mills produce titanium aerospace brackets with ±0.002 mm tolerances—a feat impossible with manual machining.

Historical Evolution: From Punch Cards to AI

The CNC machine definition has evolved dramatically since the 1940s:

-

1940s-50s: MIT’s punch-tape systems for helicopter blade production.

-

1970s: Introduction of CAD/CAM software, enabling 3D machining.

-

2000s: IoT integration for real-time monitoring and predictive maintenance.

JLYPT’s facilities utilize AI-driven CNC systems that self-optimize toolpaths, reducing cycle times by 22% in aerospace projects.

Core Components of a CNC Machine

Understanding the CNC machine definition requires dissecting its anatomy:

-

Controller: JLYPT uses Siemens Sinumerik for real-time adjustments.

-

Machine Bed: Granite beds dampen vibrations during high-speed milling.

-

Tool Changer: 120-tool magazines enable uninterrupted 24/5 operations.

Industry Applications of CNC Machines

1. Aerospace: Precision Under Pressure

-

Jet Engine Blades: CNC-machined from single-crystal superalloys (CMSX-4®) to withstand 1,200°C.

-

Satellite Components: Aluminum 6061-T6 frames with 0.005 mm positional accuracy.

2. Medical: Life-Saving Accuracy

-

Spinal Implants: Ti-6Al-4V ELI machined to Ra 0.4 µm for biocompatibility.

-

Surgical Robots: Stainless steel 316L arms with 0.01 mm repeatability.

3. Automotive: Speed Meets Precision

-

EV Motor Housings: Waterproof aluminum A380 enclosures (IP67) in 10-day lead times.

-

Transmission Gears: 8620 steel gears hardened to HRC 60 with AGMA Q12 specs.

Technical Advantages of Modern CNC Machines

1. Multi-Axis Capabilities

-

5-Axis Simultaneous Machining: Achieve complex geometries like impellers in a single setup.

-

Swiss-Type Lathes: Machine Ø0.2 mm Nitinol guidewires for medical devices.

2. Material Versatility

From Inconel 718 to PEEK polymers, CNC machines handle:

-

Metals: Titanium, stainless steel, magnesium alloys.

-

Composites: CFRP for lightweight aerospace structures.

3. Sustainable Practices

-

Energy Recovery: Regenerative drives cut power use by 25%.

-

Recycling: 95% of aluminum chips reused.

Case Study: Redefining Medical Implant Manufacturing

Challenge: A client needed 500 porous titanium spinal cages (Ra < 0.8 µm) in 15 days.

JLYPT’s CNC Solution:

-

Tooling: Diamond-coated end mills for burr-free edges.

-

Process: Adaptive toolpaths to maintain surface integrity.

-

Result: Delivered in 12 days, achieving 100% FDA compliance.

The Future of CNC Machines

Emerging trends reshaping the CNC machine definition:

-

AI Integration: Self-correcting systems reduce scrap by 18%.

-

Hybrid Manufacturing: Combine 3D printing and CNC finishing.

-

Nano-Machining: Sub-micron accuracy for optical components.

Why Partner with JLYPT?

-

Certifications: ISO 9001, AS9100, ISO 13485.

-

Global Reach: 50+ countries served with DDP shipping.

-

Expert Support: DFM consultations to slash costs by 30%.

Explore JLYPT’s CNC Capabilities

Conclusion: The CNC Machine Defined

The CNC machine definition encapsulates more than technology—it’s the backbone of precision manufacturing. From its punch-card origins to AI-driven futures, CNC machining continues to push boundaries. At JLYPT, we blend this legacy with innovation to deliver components that power industries where failure is not an option.

Ready to leverage CNC excellence? Contact JLYPT for a consultation.