The Essential Guide to CNC Machined Parts: Precision, Applications, and Industry Innovations

Introduction

In the realm of modern manufacturing, CNC machined parts have become synonymous with precision, reliability, and versatility. From aerospace components to medical devices, CNC machining transforms raw materials into intricate, high-performance parts that power industries worldwide. This article dives into the world of CNC machined components, exploring their benefits, applications, and how advancements like AI and hybrid manufacturing are reshaping production.

What Are CNC Machined Parts?

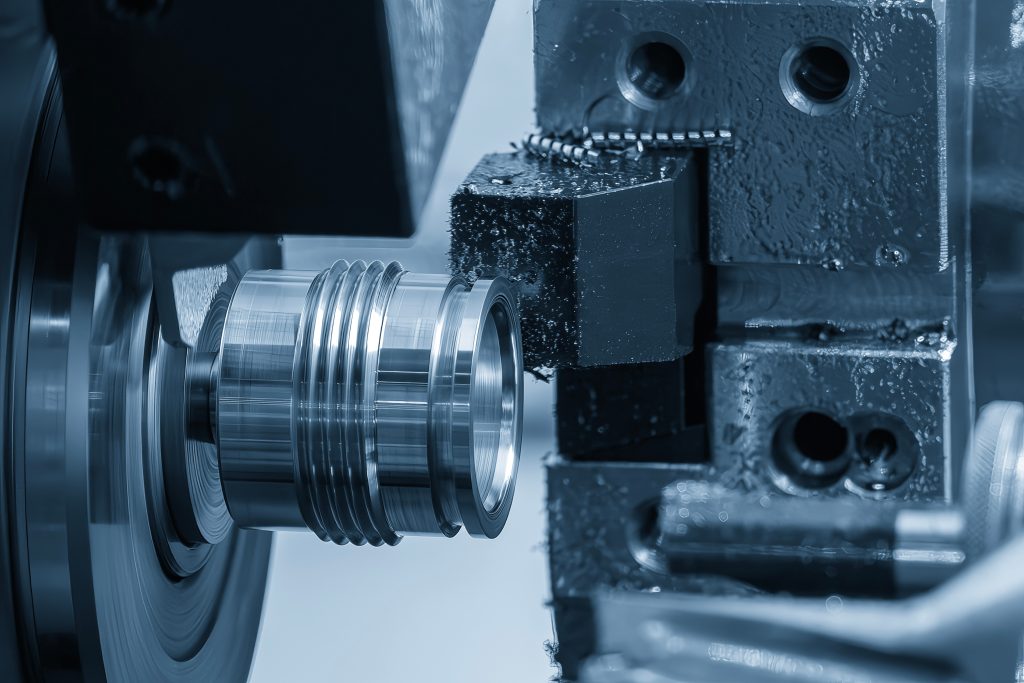

CNC (Computer Numerical Control) machined parts are components manufactured using computer-controlled machines that remove material from a workpiece to achieve precise dimensions and geometries. Unlike traditional manual machining, CNC technology ensures repeatability and accuracy, making it ideal for industries where tolerances as tight as ±0.001 inches are critical. Common processes include milling, turning, drilling, and grinding, applied to metals (aluminum, steel, titanium), plastics, and composites.

Why Choose CNC Machined Components?

-

Superior Precision and Consistency

CNC machines follow digital blueprints to produce identical parts, eliminating human error. For example, aerospace manufacturers rely on CNC machined turbine blades to meet strict FAA safety standards. -

Complex Geometries Made Simple

Multi-axis CNC machining (3-axis to 9-axis) enables the creation of intricate shapes, such as fuel injectors for automotive engines or orthopedic implants with porous surfaces for bone integration. -

Scalability for Any Volume

Whether prototyping 10 units or mass-producing 100,000 parts, CNC machining adapts seamlessly. A 2023 report by Manufacturing Global noted that 78% of automotive suppliers use CNC for both prototyping and full-scale production. -

Material Versatility

CNC machines handle exotic alloys like Inconel® for jet engines, medical-grade stainless steel, and engineering plastics like PEEK for chemical resistance. -

Cost Efficiency

Automated toolpaths reduce material waste, while faster cycle times lower labor costs. A case study by Precision Machined Products Association revealed that CNC-machined automotive parts reduced assembly costs by 27%.

Key Applications of CNC Machined Parts

-

Aerospace: Engine mounts, landing gear components, and satellite brackets.

Example: Boeing’s 787 Dreamliner uses over 20,000 CNC machined titanium parts to reduce weight and enhance fuel efficiency. -

Medical: Surgical instruments, MRI machine housings, and dental implants.

-

Automotive: Transmission gears, EV battery enclosures, and suspension linkages.

-

Energy: Wind turbine shafts, nuclear reactor valves, and solar panel frames.

-

Consumer Electronics: Heat sinks, smartphone casings, and drone motor mounts.

Innovations Driving CNC Machined Part Quality

-

AI-Powered Predictive Maintenance

Advanced systems like Siemens’ MindSphere analyze machine data to predict tool wear, reducing downtime by 30% and extending tool life. -

Hybrid Manufacturing

Combining CNC machining with 3D printing allows for lightweight, topology-optimized parts. GE Aviation’s ATP engine features hybrid-manufactured brackets that are 20% lighter than traditional designs. -

Digital Twin Technology

Virtual replicas of CNC machines simulate production runs, identifying potential errors before machining begins. This innovation cut scrap rates by 18% at Lockheed Martin’s satellite division. -

Sustainable Practices

Companies like Sandvik Coromant recycle 95% of metal chips and use energy-efficient CNC machines to reduce carbon footprints.

How to Select a CNC Machining Partner

-

Technical Capabilities

Ensure the supplier offers multi-axis machining, EDM (Electrical Discharge Machining), and Swiss turning for complex parts. -

Certifications and Compliance

Look for ISO 9001:2015, AS9100 (aerospace), or ISO 13485 (medical) certifications to guarantee quality. -

Material Expertise

Verify experience with your required materials. For instance, machining copper requires specialized tooling to prevent galling. -

Prototyping and DFM Support

Choose vendors that provide Design for Manufacturability (DFM) feedback to optimize part designs for cost and performance. -

Transparent Lead Times and Pricing

Suppliers like Contact US offer instant online quotes and project tracking for CNC machined parts.

The Future of CNC Machined Components

-

Nanotechnology Integration

Ultra-precision CNC machines are now producing parts with surface finishes under 10 nanometers, critical for semiconductor and optical industries. -

Blockchain for Supply Chain Transparency

Companies like Bosch use blockchain to track CNC machined parts from raw material to end-user, ensuring authenticity and compliance. -

5G-Enabled Smart Factories

Real-time data exchange between CNC machines and ERP systems optimizes production schedules, reducing lead times by up to 40%.

Conclusion

CNC machined parts are the backbone of high-tech industries, delivering unmatched precision, durability, and efficiency. By partnering with certified suppliers and embracing innovations like AI and hybrid manufacturing, businesses can stay competitive in a rapidly evolving market. Whether you’re developing a prototype or scaling production, CNC machining offers a reliable path to innovation.