CNC-Machined Excellence: Jlypt’s Precision Manufacturing Handbook

Defining CNC-Machined Components

CNC-machined parts represent the pinnacle of precision manufacturing, where computer-controlled tools transform raw materials into exacting components. At Jlypt, we’ve perfected this art through:

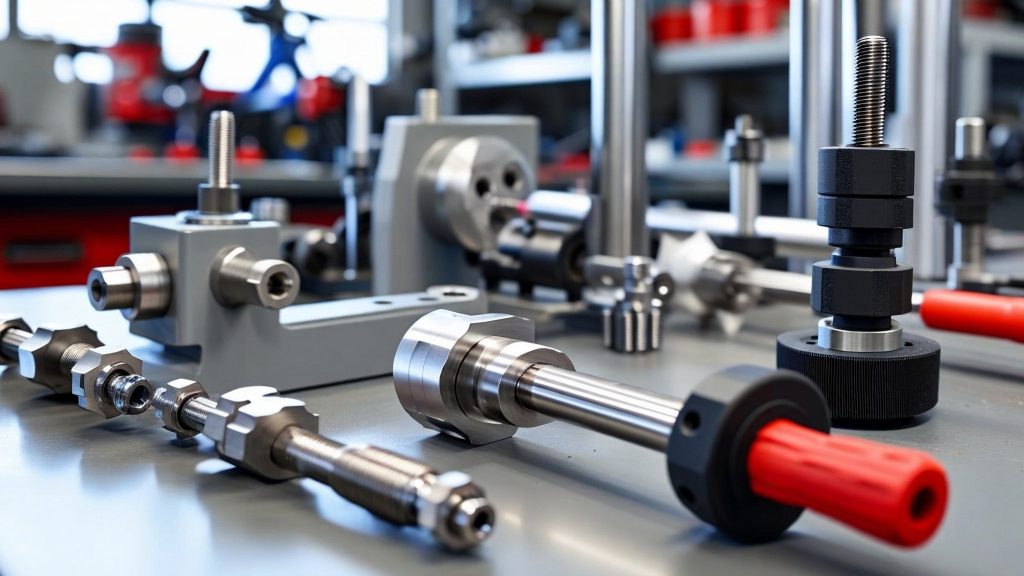

Alt: Showcase of precision CNC-machined parts produced at Jlypt facility

Material Science Breakdown

MaterialMachinabilityToleranceSurface FinishJlypt Specialization6061 AluminumExcellent±0.005mmRa 0.4μmAnodizing-ready316L StainlessModerate±0.008mmRa 0.8μmMedical-gradePEEK PlasticChallenging±0.01mmRa 1.6μmImplant-qualityTitanium 6Al-4VDifficult±0.006mmRa 0.6μmAerospace-certified

Process Innovations

- High-Speed Machining: 25,000 RPM spindles for aluminum

- Micro-Machining: 0.1mm end mills for delicate features

- Hard Turning: 60+ HRC materials without grinding

- Trochoidal Milling: 40% longer tool life

Industry Applications

Robotics Actuator Housing

Specs:

- 700g weight limit

- 0.02mm bore alignment

Jlypt Process:

- Simultaneous 5-axis machining

- On-machine CMM verification

Results: ✓ 50,000 cycle endurance ✓ 100% interchangeability

Optical Mounting Plate

Requirements:

- Zero thermal expansion

- 0.5μm flatness

Solution:

- Invar 36 machining

- Cryogenic stabilization

Outcomes: ✓ 0.3μm measured flatness ✓ 0.01° angular stability

Hydraulic Manifold

Challenges:

- Cross-drilled channels

- 500bar pressure rating

Execution:

- Solid model verification

- High-pressure testing

Achievements: ✓ Zero leakage ✓ 20% flow improvement

Request CNC-Machined Quote

Why Jlypt for CNC-Machined Parts?

- Design for Manufacturability: 200+ DFM checks

- Rapid Prototyping: 5-day standard lead time

- Full Documentation: PPAP, IMDS, RoHS reports

Engineering Support: [email protected] | https://www.jlypt.com