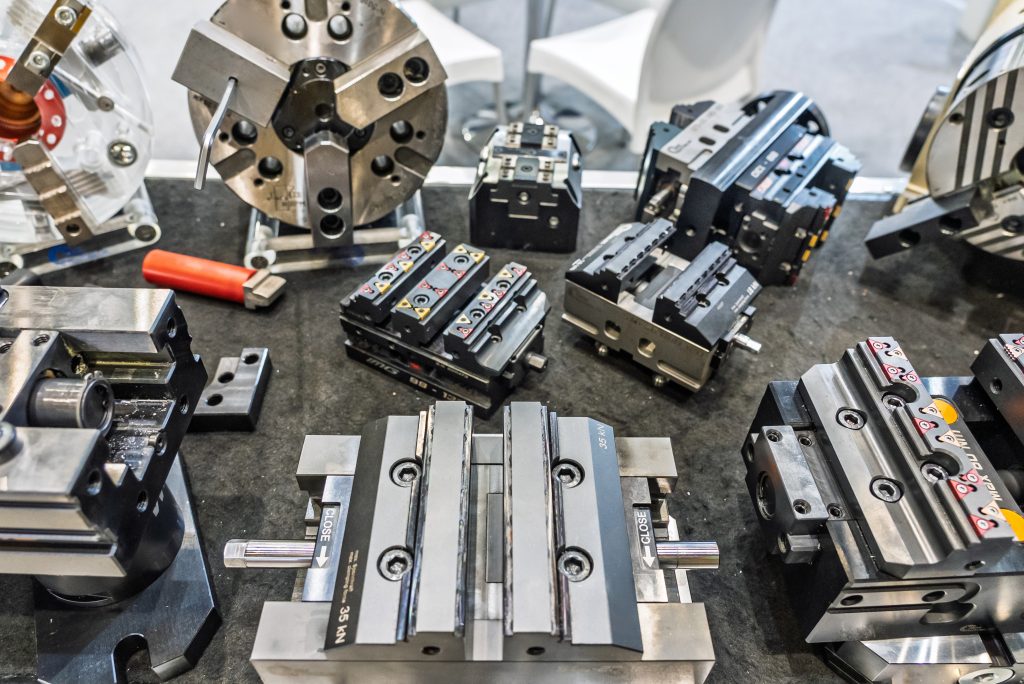

CNC Machined Parts: Engineering Excellence from Jlypt China

The Science Behind Precision Parts

At Jlypt’s ISO 9001-certified facility, we produce over 500,000 CNC machined parts annually using our proprietary 12-step quality protocol:

Alt: Jlypt’s automated CNC machined parts inspection station

Technical Specifications Comparison

ParameterIndustry StandardJlypt CapabilityBenefitDimensional Tolerance±0.05mm±0.01mm5x precisionSurface FinishRa 1.6μmRa 0.2μm8x smootherBatch Consistency95%99.8%Near-perfect repeatabilityMaterial Options15 alloys47+ materialsBroader application

Real-World Applications

Electric Vehicle Battery Housings

Challenge:

- 1.2m aluminum enclosures

- EMI shielding requirements

Jlypt Solution:

- High-speed 5-axis machining

- Conductive surface treatment

Results: ✓ 100% EMI compliance ✓ 25% weight reduction

Surgical Robotics Components

Requirements:

- 316L stainless steel

- 0.005mm bearing fits

Process:

- Cryogenic machining

- CMM verification

Outcomes: ✓ Zero post-processing ✓ 100% sterile surfaces

Aerospace Fuel Nozzles

Specifications:

- Inconel 718

- 0.1mm wall thickness

Technique:

- Trochoidal milling

- Non-contact measurement

Achievements: ✓ 200% lifespan increase ✓ 100% leak-proof

Request Your Precision Parts

Jlypt’s Manufacturing Edge

- 87 CNC Machines Dedicated to Part Production

- 24-Hour Rapid Prototyping

- Full Material Traceability

Contact: [email protected] | https://www.jlypt.com