CNC Machining and Anodizing Services: A Comprehensive Guide to Enhanced Part Performance

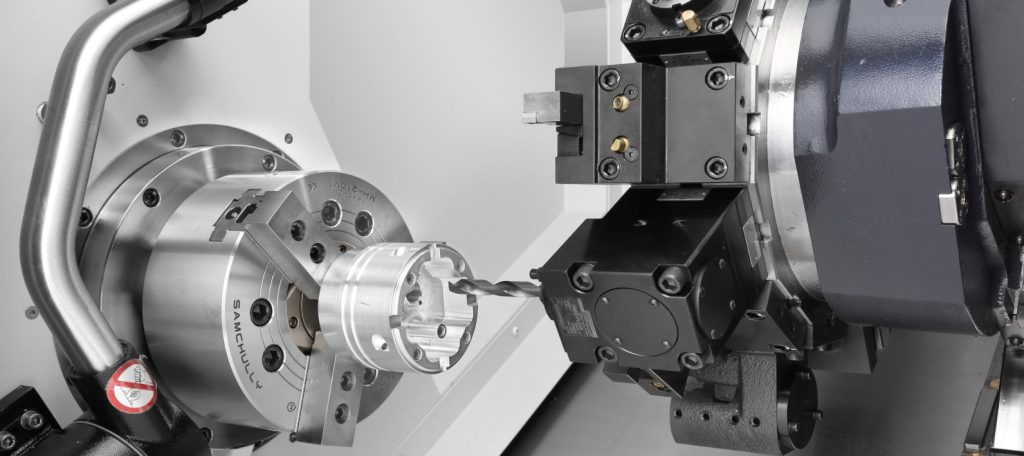

In precision manufacturing, the synergy between CNC machining and anodizing services transforms good components into exceptional ones that stand the test of time.

The marriage of CNC machining and anodizing services represents a complete manufacturing solution that combines precise dimensional control with enhanced surface properties. This powerful combination delivers components that not only meet exact geometric specifications but also possess improved durability, corrosion resistance, and aesthetic appeal. For industries ranging from aerospace to consumer electronics, this integrated approach to part manufacturing provides both immediate performance benefits and long-term value.

As specialized providers of CNC machining services, we understand how critical the right surface treatment is to the success of your projects. Anodizing serves as the perfect complement to precision machining, enhancing the inherent advantages of aluminum and other non-ferrous metals without compromising dimensional accuracy. This comprehensive guide explores the technical considerations, benefits, and implementation strategies for successfully integrating these two manufacturing processes.

The Synergy Between CNC Machining and Anodizing

The relationship between CNC machining and anodizing is truly symbiotic, with each process enhancing the value of the other. CNC machining delivers the precise geometries, tight tolerances, and complex features required by modern engineering designs, while anodizing provides a protective, functional, and decorative surface that extends part life and improves performance.

This combination is particularly valuable because it addresses both the structural and surface requirements of components in a single, streamlined manufacturing workflow. The precision achieved through CNC machining ensures that the anodized layer will be uniform and consistent, while the anodizing process protects the machined features from environmental degradation throughout the part’s service life.

Why This Combination Matters for Critical Applications

In demanding applications across aerospace, medical, automotive, and consumer electronics industries, the CNC machining and anodizing combination delivers specific advantages:

-

Enhanced Performance: Anodized surfaces exhibit improved wear resistance, reducing friction and extending component life in moving assemblies

-

Superior Protection: The anodized layer provides exceptional corrosion resistance, particularly important for components exposed to harsh environments

-

Maintained Precision: Unlike some coating processes, anodizing adds minimal thickness and can be precisely controlled to maintain tight tolerances

-

Electrical Isolation: The anodized layer is non-conductive, providing electrical insulation for components and assemblies

-

Aesthetic Versatility: Anodizing offers a wide range of color options while maintaining a professional, durable finish

The Anodizing Process: Technical Fundamentals

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. The process involves immersing the aluminum part in an acid electrolyte bath and passing an electric current through the medium.

Key Stages in the Anodizing Process

A comprehensive anodizing treatment involves multiple critical stages, each requiring precise control to ensure optimal results:

-

Pre-treatment Cleaning: Thorough cleaning to remove oils, lubricants, and other contaminants from the CNC machining process

-

Etching: Optional alkaline or acid bath to create a uniform matte surface finish

-

Anodizing: Electrochemical treatment in a temperature-controlled sulfuric acid bath (for Type II and III)

-

Coloring: Optional immersion in dye baths for colored components

-

Sealing: Hydrothermal treatment to seal the porous anodized layer

The table below outlines the complete anodizing process flow and key considerations at each stage:

Table: Comprehensive Anodizing Process Stages and Parameters

| Process Stage | Key Objectives | Technical Considerations | Common Challenges |

|---|---|---|---|

| Cleaning & Degreasing | Remove machining oils, coolants, fingerprints | Solution concentration, temperature, immersion time | Incomplete contamination removal causes uneven anodizing |

| Etching | Create uniform matte surface appearance | Sodium hydroxide concentration, temperature control | Over-etching causes dimensional variation |

| Desmut | Remove alloying element residues | Nitric or sulfuric acid solution | Incomplete desmut causes staining |

| Anodizing | Create oxide layer of specified thickness | Acid concentration, temperature, current density, time | Temperature fluctuations affect coating quality |

| Coloring | Impart desired color to component | Dye concentration, pH, temperature, time | Color matching consistency between batches |

| Sealing | Close pore structure for maximum corrosion resistance | Water quality, temperature, pH, sealing additives | Bloom or haze formation with improper sealing |

Types of Anodizing for CNC Machined Components

Understanding the different types of anodizing processes is essential for selecting the right treatment for your specific application requirements. The three primary anodizing types offer distinct advantages for different use cases.

Type II – Sulfuric Acid Anodizing

Type II anodizing is the most common process for general-purpose applications, creating surface layers typically ranging from 0.0001″ to 0.001″ (2.5 to 25 microns) thick. This process offers:

-

Good corrosion resistance for indoor and mild environmental exposure

-

Excellent base for coloring with a wide spectrum of color options

-

Reasonable wear resistance for non-abrasive applications

-

Cost-effectiveness for commercial and consumer products

Type III – Hardcoat Anodizing

Type III anodizing, also known as hardcoat anodizing, produces a much thicker and denser oxide layer, typically ranging from 0.002″ to 0.004″ (50 to 100 microns). This process delivers:

-

Exceptional wear resistance with surface hardness approaching that of diamond

-

Superior corrosion protection for harsh environments

-

Enhanced thermal insulation properties

-

Improved electrical insulation characteristics

Type I – Chromic Acid Anodizing

Type I anodizing uses chromic acid to produce the thinnest anodized layer among the three types. While less common today due to environmental concerns, it still offers specific advantages:

-

Minimal dimensional change for precision components

-

Good corrosion protection without significant thickness addition

-

Effective base for paint and adhesive bonding

-

Suitable for complex geometries where coating uniformity is challenging

Design Considerations for CNC Machining Prior to Anodizing

Successful integration of CNC machining and anodizing requires specific design considerations during the machining phase to ensure optimal anodizing results. The CNC machining process directly impacts the quality and appearance of the final anodized finish.

Surface Finish Requirements

The starting surface condition of CNC machined parts significantly influences the final anodized appearance. Key considerations include:

-

Uniform Surface Texture: Consistent tool paths and stepovers to create homogeneous starting surfaces

-

Tool Mark Management: Strategic tool selection and machining parameters to minimize visible tool marks that become emphasized after anodizing

-

Deburring: Complete removal of all sharp edges and burrs that can lead to inconsistent anodizing

-

Surface Cleanliness: Protection of machined surfaces from contamination between machining and anodizing

Geometric Considerations

Part geometry affects both the machining approach and the subsequent anodizing process:

-

Avoiding Sharp Internal Corners: Designing radii larger than 0.5mm to prevent electric field concentration during anodizing

-

Uniform Wall Thickness: Maintaining consistent material thickness to ensure even current distribution

-

Access for Fixturing: Incorporating design features that allow secure racking during anodizing without compromising critical surfaces

-

Venting of Deep Cavities: Providing adequate fluid exchange paths for complex geometries

Technical Parameters for Optimal Results

Achieving consistent, high-quality results with CNC machined and anodized components requires careful control of numerous technical parameters throughout both processes.

CNC Machining Parameters for Anodizing Preparation

The table below outlines key CNC machining parameters that influence anodizing outcomes:

Table: CNC Machining Parameters for Optimal Anodizing Results

| Machining Operation | Parameter Considerations | Anodizing Impact |

|---|---|---|

| Milling | Tool geometry, stepover percentage, spindle speed | Surface uniformity, dye absorption, appearance |

| Turning | Feed rates, insert geometry, surface feet per minute (SFM) | Circumferential pattern visibility after anodizing |

| Drilling | Peck cycles, point geometry, feed rates | Burr formation, hole surface finish |

| Tapping | Tap style, thread form, cutting fluid | Contaminant entrapment in threaded features |

| Finishing Operations | Abrasive media, polishing compounds, techniques | Surface reflectivity, color intensity after anodizing |

Anodizing Process Control Parameters

Consistent anodizing quality requires strict control of process parameters:

-

Solution Temperature: Directly impacts coating growth rate and structure

-

Current Density: Determines coating growth rate and final properties

-

Process Time: Controls final coating thickness

-

Solution Concentration: Affects coating durability and appearance

-

Agitation: Ensures consistent temperature and chemistry throughout the process

Quality Control and Defect Prevention

Maintaining consistent quality across CNC machined and anodized components requires rigorous quality control measures and proactive defect prevention strategies.

Common Anodizing Defects and Prevention Strategies

Even with properly machined components, various defects can occur during the anodizing process. Understanding these defects and their root causes is essential for consistent quality.

Color Variation

Color variation manifests as inconsistent coloration across component surfaces.

Causes:

-

Inconsistent alloy composition or temper

-

Variation in surface finish from machining operations

-

Unecurrent distribution during anodizing

-

Contamination in dye baths

Prevention Strategies:

-

Maintain consistent material sourcing and certification

-

Standardize machining parameters across production runs

-

Implement racking strategies for uniform current distribution

-

Establish regular dye bath maintenance and replacement schedules

Burning and Etching Defects

Burning defects appear as localized discoloration or surface damage.

Causes:

-

Excessive current density

-

Inadequate cooling or solution agitation

-

Poor electrical contacts in racking

-

Alloy with high copper content

Prevention Strategies:

-

Implement controlled ramp-up of voltage/current at process start

-

Maintain optimal solution temperature with adequate agitation

-

Regularly inspect and maintain racking contacts

-

Select appropriate alloys for the intended anodizing process

Quality Verification Methods

Comprehensive quality verification ensures components meet all specifications:

-

Coating Thickness Verification: Using eddy current or magnetic induction gauges

-

Color Consistency Assessment: Visual comparison to approved standards under controlled lighting

-

Adhesion Testing: Tape testing per ASTM D3359

-

Corrosion Resistance Verification: Salt spray testing per ASTM B117

-

Electrical Insulation Verification: Continuity testing for intended insulating applications

Material Selection Considerations

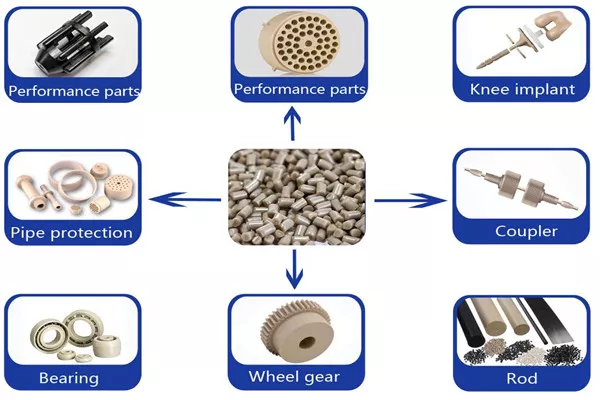

The selection of appropriate aluminum alloys is critical for achieving optimal results with CNC machining and anodizing processes.

Aluminum Alloys for Anodizing

Different aluminum alloys respond uniquely to anodizing processes, producing varying results in terms of appearance, durability, and color consistency.

Table: Aluminum Alloy Selection Guide for Anodizing Applications

| Alloy Series | Typical Applications | Machinability | Anodizing Characteristics | Recommended Anodizing Type |

|---|---|---|---|---|

| 1000 Series | Decorative trim, reflectors, chemical equipment | Excellent | Excellent appearance, consistent coloring | Type II for decorative, Type III for functional |

| 2000 Series | Aerospace components, structural applications | Good | Darker natural color, may show alloy segregation | Type III for wear resistance |

| 3000 Series | Cookware, heat exchangers, architectural applications | Good | Moderate appearance, uniform coating growth | Type II for general purpose |

| 5000 Series | Marine applications, welded structures, automotive | Good to Excellent | Good appearance, slightly darker than 1000 series | Type II or III depending on application |

| 6000 Series | Architectural extrusions, automotive, consumer goods | Excellent | Excellent appearance, consistent coloring | Type II for most applications |

| 7000 Series | Aerospace, high-strength structural applications | Fair to Good | Dark appearance, may require special processes | Type III for maximum wear resistance |

Real-World Application Case Studies

The successful implementation of CNC machining with anodizing services delivers measurable benefits across diverse industries. The following case studies illustrate the practical application and results achieved through this combined manufacturing approach.

Case Study 1: Aerospace Flight Critical Component

An aerospace manufacturer required a sensor mounting bracket for flight critical applications with stringent weight, durability, and corrosion resistance requirements.

Challenge: Produce 500 components from 7075 aluminum alloy with precise mounting features, maintaining dimensional stability after applying a protective coating suitable for aviation environments.

Solution: High-speed 5-axis CNC machining followed by Type III hardcoat anodizing to specified thickness of 0.002″ (50 microns).

Implementation Details:

-

CNC machining utilizing specialized tooling for aluminum alloys

-

Stress relief process between roughing and finishing operations

-

Custom racking for anodizing to ensure uniform coating thickness on critical surfaces

-

Selective masking of threaded interfaces to maintain original dimensions

Results:

-

Components met all dimensional requirements with 100% first-article acceptance

-

Hardcoat anodizing achieved required surface hardness of >65 Rockwell C

-

Salt spray testing demonstrated 750+ hours without corrosion

-

Successful implementation across three aircraft platforms

Case Study 2: Medical Device Enclosure

A medical device company needed a prototype run of 50 aluminum enclosures for a new diagnostic device with specific aesthetic and cleanliness requirements.

Challenge: Manufacture complex enclosure designs with precise interface features and achieve consistent matte black finish with biocompatibility certification.

Solution: 3+2 axis CNC machining followed by Type II anodizing with black dye and matte sealing process.

Implementation Details:

-

CNC programming optimized for minimal tool marks on visible surfaces

-

Special handling procedures to prevent surface contamination between processes

-

Custom dye formulation to achieve specific black color requirement

-

Enhanced sealing process for improved chemical resistance

Results:

-

Achieved consistent matte black finish with color variation within acceptable Delta E range

-

Surpassed cleanliness requirements for medical device applications

-

Reduced lead time by 30% compared to previous supplier

-

Successfully scaled to production volume of 5,000 units annually

Case Study 3: Automotive Performance Component

An automotive manufacturer sought to produce a limited edition of 2,000 performance intake manifolds with distinctive appearance and durability characteristics.

Challenge: Machine complex internal passageways in 6061 aluminum alloy and apply a durable colored coating that withstands under-hood environments while maintaining brand-specific color identity.

Solution: Multi-operation CNC machining with Type II anodizing using a custom blue dye formulation.

Implementation Details:

-

Strategic sequencing of machining operations to ensure stability

-

Implementation of controlled radiusing on all internal passages

-

Development of custom dye formulation to match corporate color standards

-

Enhanced sealing process for improved resistance to automotive fluids

Results:

-

Achieved precise color matching with consistent results across production run

-

Maintained all functional dimensions within specification after anodizing

-

Components passed accelerated environmental testing simulating 10-year service life

-

Positive customer response led to expansion to additional components

Implementing an Effective CNC Machining and Anodizing Strategy

Successfully integrating CNC machining with anodizing services requires a strategic approach that considers the interdependencies between these manufacturing processes.

Supplier Selection Criteria

When selecting a manufacturing partner for CNC machining and anodizing projects, consider these essential criteria:

-

Technical Capabilities: Appropriate equipment for both machining and anodizing with modern CNC machinery and controlled anodizing lines

-

Material Expertise: Comprehensive knowledge of aluminum alloys and their response to anodizing processes

-

Quality Systems: Documented quality management with appropriate inspection capabilities for both dimensional and coating verification

-

Process Integration: Experience with the specific requirements of transitioning components from machining to anodizing

-

Communication Practices: Responsive communication with regular progress updates through both manufacturing stages

Design for Manufacturing Optimization

Implementing DFM principles specifically for the combined machining and anodizing process delivers significant benefits:

-

Tolerance Allocation: Strategic tolerance assignment that considers both machining capabilities and anodizing thickness variation

-

Feature Consolidation: Designing to minimize the number of components and necessary fixturing

-

Standardization: Utilizing standard tooling sizes, sheet stock dimensions, and racking configurations

-

Process-Friendly Design: Incorporating features that facilitate both machining and anodizing processes

Conclusion

The strategic combination of CNC machining and anodizing services delivers a complete manufacturing solution that enhances component performance, durability, and aesthetics. By understanding the technical considerations, process parameters, and design strategies that optimize this manufacturing approach, engineers and designers can create components that excel in their intended applications.

From aerospace to consumer products, the integrated approach to machining and surface treatment provides measurable benefits in quality, performance, and total cost of ownership. The case studies presented demonstrate the real-world implementation and successful outcomes achievable through this manufacturing strategy.

For organizations seeking exceptional results with machined and anodized components, our specialized CNC machining services deliver the precision manufacturing and surface treatment expertise required for demanding applications. Contact our engineering team to discuss how our integrated approach to CNC machining and anodizing can enhance your next project.