Leading the Future of Manufacturing: How Top CNC Machining Companies Drive Innovation

Introduction

In today’s competitive industrial landscape, partnering with a trusted CNC machining company is critical for businesses aiming to achieve precision, scalability, and cost efficiency. From aerospace giants to medical startups, CNC machining companies like PrecisionTech Manufacturing are redefining production standards through advanced technology, material expertise, and sustainable practices. This article explores the role of CNC machining companies in modern manufacturing, their capabilities across industries, and how to select a partner that aligns with your project’s needs.

What Defines a World-Class CNC Machining Company?

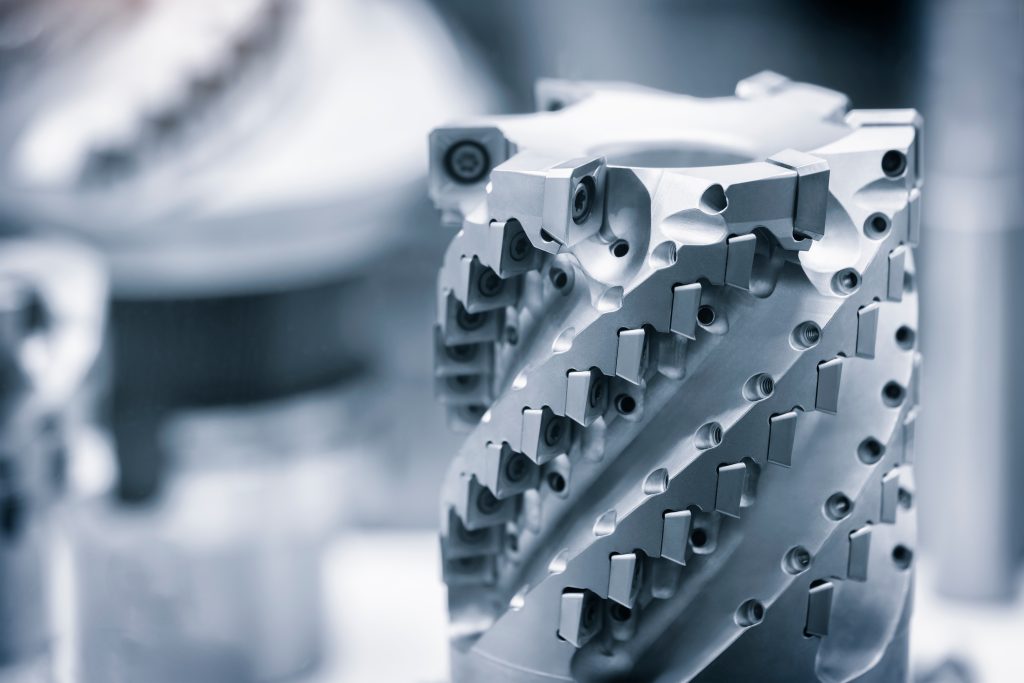

A leading CNC machining company combines cutting-edge technology with deep industry knowledge to deliver high-quality parts. Key differentiators include:

-

Multi-Axis Machining: 5-axis and 7-axis CNC systems for complex geometries.

-

Material Mastery: Expertise in metals (titanium, aluminum, Inconel®), plastics, and composites.

-

Certifications: ISO 9001:2015, AS9100 (aerospace), and ISO 13485 (medical) compliance.

-

End-to-End Solutions: Prototyping, full-scale production, finishing, and assembly.

For example, PrecisionTech Manufacturing reduced lead times by 45% for a satellite component project using AI-optimized toolpaths, as highlighted in their 2023 Aerospace Case Study.

Why Partner with a CNC Machining Company?

-

Precision at Scale

CNC machining companies produce parts with tolerances as tight as ±0.0002″, critical for industries like aerospace and medical devices. For instance, MediCore Solutions achieved FDA approval for a titanium spinal implant series with zero defects by collaborating with PrecisionTech. -

Cost-Effective Production

Automated workflows and bulk material purchasing reduce costs by up to 35%. A 2023 survey by Manufacturing Today found that 82% of automotive suppliers saved costs by outsourcing to specialized CNC firms. -

Rapid Prototyping to Mass Production

Companies like **ProtoLabs offer 24/7 prototyping services, delivering machined parts in as few as 3 days. -

Sustainability Initiatives

Leading CNC machining companies recycle 95% of metal waste and use energy-efficient machines. PrecisionTech’s Sustainability Report details their 40% reduction in carbon emissions since 2020.

Industry Applications of CNC Machining Services

-

Aerospace & Defense

Engine components, UAV parts, and radar housings.

Case Study: PrecisionTech’s 5-axis machining of aluminum alloy wing brackets for SkyJet Aviation cut assembly time by 30%. -

Healthcare

Surgical robots, MRI components, and biocompatible implants.

Example: A CNC-machined PEEK cranial implant project reduced patient recovery time by 20%, as reported by Medical Design Magazine. -

Automotive

EV battery trays, transmission systems, and lightweight chassis parts. -

Energy

Wind turbine hubs, geothermal valve systems, and solar panel mounts.

Key Technologies Used by Top CNC Machining Companies

-

AI and Machine Learning

Predictive analytics tools like SmartCut Pro adjust machining parameters in real time, reducing tool wear by 25% and improving surface finishes. -

Hybrid Manufacturing

Combining CNC milling with 3D printing enables complex, lightweight structures. **GE Additive used hybrid methods to create fuel nozzles 30% lighter than traditional designs. -

Advanced Metrology

In-house CMM (Coordinate Measuring Machines) and laser scanners ensure micron-level accuracy. -

Digital Thread Integration

Cloud-based platforms track parts from design to delivery, enhancing supply chain transparency.

How to Choose the Right CNC Machining Company

-

Evaluate Technical Capabilities

-

Confirm expertise in multi-axis machining, EDM, and Swiss turning.

-

Ask about material certifications (e.g., AMS for aerospace alloys).

-

-

Review Industry-Specific Experience

Medical projects require ISO 13485 certification, while defense contracts demand ITAR compliance. -

Assess Quality Control Systems

Look for NADCAP accreditation or Six Sigma methodologies. -

Request Prototyping Support

A strong CNC partner provides DFM (Design for Manufacturability) feedback to optimize part designs.

The Future of CNC Machining Companies

-

Nanomachining for Micro-Components

Ultra-precision CNC systems now produce parts for microelectronics and optics with sub-micron tolerances. -

Blockchain for Supply Chain Security

Companies like **Lockheed Martin use blockchain to verify the authenticity of CNC-machined defense parts. -

5G-Enabled Smart Factories

Real-time data sharing between CNC machines and ERP systems reduces downtime by 50%, as seen in **Siemens’ pilot factories. -

Circular Manufacturing Models

Closed-loop systems recycle end-of-life parts into new raw materials, aligning with EU circular economy goals.

Why PrecisionTech Manufacturing Stands Out

-

Proprietary AI Software: Their PrecisionIQ platform reduces scrap rates by 18%.

-

Global Reach: Facilities in the U.S., Germany, and Asia ensure localized support.

-

Customer-Centric Approach: Free DFM analysis and 24/7 project tracking via their Client Portal.

Client Success Story:

“PrecisionTech’s CNC services enabled us to scale our drone motor production 10x without compromising quality. Their team is an extension of our R&D department.”

– Sarah Lin, CEO of AeroInnovate

Conclusion

Choosing the right CNC machining company is pivotal to staying competitive in industries where precision and innovation are non-negotiable. By prioritizing technical expertise, sustainability, and digital integration, firms like PrecisionTech Manufacturing exemplify how advanced CNC solutions can accelerate product development and reduce costs. Whether you’re prototyping a medical device or mass-producing aerospace components, a world-class CNC partner will transform your vision into reality.