CNC Machining for Automotive Performance Parts: Precision Engineering for Enhanced Driving Experience

In the highly competitive world of automotive performance, every horsepower, every gram of weight reduction, and every micron of precision matters. Computer Numerical Control (CNC) machining has revolutionized how automotive performance parts are designed, prototyped, and manufactured. This advanced manufacturing process enables unprecedented levels of precision, consistency, and complexity in creating components that push the boundaries of automotive performance. From weekend track enthusiasts to professional racing teams, CNC machining has become an indispensable technology for extracting maximum performance from vehicles.

The Technical Superiority of CNC Machining in Automotive Performance

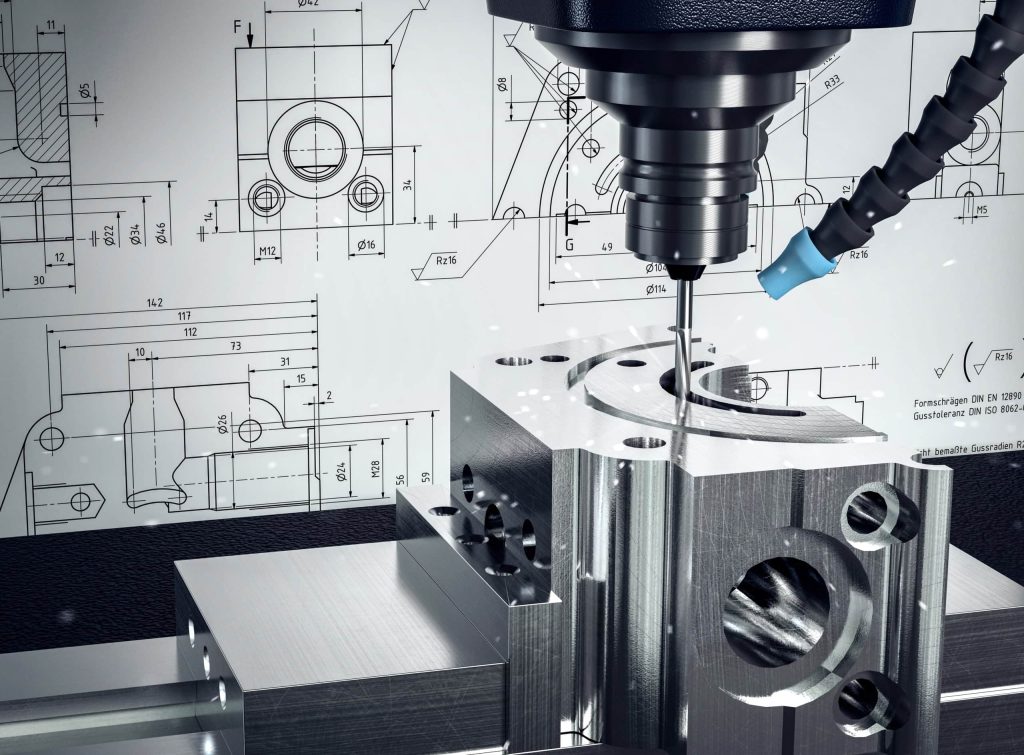

CNC machining is a subtractive manufacturing process that uses computer-controlled machine tools to remove material from a workpiece with exceptional precision. Unlike additive manufacturing or traditional manual machining, CNC offers unmatched accuracy and repeatability—critical factors in high-performance automotive applications where consistency across multiple components is paramount.

The process begins with CAD (Computer-Aided Design) models that are converted into CAM (Computer-Aided Manufacturing) programs. These programs control the movement of cutting tools with precision measured in micrometers, ensuring that each part meets exact specifications regardless of production volume.

Key Advantages of CNC Machining for Performance Applications:

-

Exceptional Precision and Tight Tolerances: CNC machines routinely achieve tolerances within ±0.001 inches (±0.025 mm) or better, ensuring perfect fitment and optimal performance characteristics.

-

Superior Material Flexibility: CNC machines can process a wide range of engineering-grade materials including aerospace aluminum alloys, titanium, stainless steels, copper alloys, and high-performance plastics—each selected for specific performance characteristics.

-

Enhanced Material Properties: Unlike casting or additive manufacturing, CNC machining preserves the intrinsic properties of materials without introducing weaknesses from heat-affected zones or porosity issues.

-

Complex Geometries: Modern 5-axis CNC systems can create intricate shapes and contours that would be impossible with conventional manufacturing methods, enabling optimized aerodynamic components and weight-reduced structures.

-

Surface Finish Excellence: CNC machining can achieve surface finishes down to Ra 0.4 μm or better, reducing friction and improving airflow in critical applications.

Critical Automotive Performance Applications of CNC Machining

1. Engine Components

The internal combustion engine represents one of the most demanding environments for automotive components, where precision directly translates to performance gains.

-

Cylinder Heads: CNC machining creates optimized intake and exhaust ports, precisely machined combustion chambers, and perfect valve seat geometry. This precision improves airflow, increases compression efficiency, and enhances cooling passage integrity.

-

Pistons and Connecting Rods: High-performance pistons are machined from billet aluminum alloys with precise ring grooves, wrist pin openings, and crown designs that maximize strength while minimizing mass.

-

Camshafts and Valvetrain Components: CNC machining creates perfect cam profiles, valve guides, and retainers that enable higher RPM limits and improved valve timing accuracy.

-

Intake Manifolds: Custom CNC-machined intake manifolds optimize airflow distribution between cylinders and can be tailored to specific power band requirements.

Table: CNC Machined Engine Components and Their Performance Benefits

| Component | Common Materials | Tolerance Requirements | Performance Benefit |

|---|---|---|---|

| Cylinder Head | Aluminum 356-T6, 6061 | ±0.0005″ | Improved airflow, higher compression |

| Performance Pistons | 4032 Aluminum, 2618 Aluminum | ±0.0004″ | Reduced mass, increased strength |

| Connecting Rods | 4340 Steel, Titanium | ±0.0003″ | Reduced rotating mass, higher RPM |

| Intake Manifold | 6061 Aluminum, Plastics | ±0.001″ | Optimized airflow, velocity stacking |

| Throttle Bodies | 6061 Aluminum, Brass | ±0.0005″ | Improved throttle response |

2. Drivetrain and Transmission Components

The transfer of power from engine to wheels requires components that can withstand tremendous forces while maintaining precise alignment and minimal power loss.

-

Gears and Sprockets: CNC gear cutting produces perfect tooth profiles with optimized engagement characteristics for reduced friction and noise.

-

Differential Components: CNC-machined limited-slip differentials provide precise lock-up characteristics for improved traction without compromising handling.

-

Drive Shafts and Axles: Lightweight CNC-machined aluminum or titanium drive shafts reduce rotational mass for improved acceleration.

-

Shift Components: Precision linkages and brackets enable crisp, accurate gear selection.

3. Suspension and Chassis Components

Handling precision begins with components that maintain exact geometries under extreme loads.

-

Control Arms and Suspension Links: CNC-machined from aluminum or titanium billet, these components reduce unsprung weight while maintaining perfect alignment geometry.

-

Spindles and Hubs: High-strength CNC-machined spindles provide precise wheel alignment and reduced mass.

-

Strut Towers and Brace Systems: CNC-machined braces increase chassis stiffness without significant weight penalty, improving handling response.

-

Adjustable Mounts: Precise camber, caster, and toe adjustment systems enable fine-tuning of handling characteristics.

4. Braking System Components

Stopping power requires precision engineering to ensure consistent performance under extreme conditions.

-

Calipers: Billet aluminum calipers are lighter and more rigid than cast units, improving brake response and reducing unsprung weight.

-

Rotors: CNC machining creates precise rotor surfaces, mounting features, and ventilation patterns for improved cooling and consistent braking.

-

Pedal Assemblies: Adjustable CNC pedal systems enable optimal positioning and improved pedal feel.

5. Aerodynamic Components

Aerodynamic efficiency becomes increasingly important at higher speeds, where downforce and drag reduction significantly impact performance.

-

Wings and Spoilers: CNC-machized aluminum wings with precise airfoil sections generate predictable downforce.

-

Diffusers: Complex diffuser designs manage airflow under the vehicle for improved stability and reduced drag.

-

Vents and Ducts: Precision air intake and outlet ducts optimize cooling airflow while reducing aerodynamic drag.

Material Selection for High-Performance Automotive Applications

The selection of appropriate materials is critical for performance components. Each application demands specific material properties that balance strength, weight, durability, and cost.

Table: Performance Automotive CNC Materials Comparison

| Material | Typical Applications | Advantages | Limitations |

|---|---|---|---|

| 6061 Aluminum | Intakes, brackets, pulleys | Excellent strength-to-weight, good machinability | Lower fatigue strength than steel |

| 7075 Aluminum | Suspension components, gears | Very high strength, good fatigue properties | Lower corrosion resistance |

| 4130/4140 Steel | Axles, gears, structural parts | High strength, excellent durability | Higher weight than aluminum |

| Titanium (6Al-4V) | Valvetrain, springs, fasteners | Exceptional strength-to-weight, corrosion resistant | Expensive, challenging to machine |

| Stainless Steel | Exhaust components, fittings | Corrosion resistance, good appearance | Heavy compared to alternatives |

| Delrin/Acetal | Bushings, spacers, guides | Low friction, self-lubricating | Temperature limitations |

| Copper Alloys | Heat exchangers, fittings | Excellent thermal conductivity | Heavy, relatively soft |

3 Detailed Case Studies: CNC Machining Enhancing Automotive Performance

Case Study 1: High-Revving Naturally Aspirated Engine Development

Challenge: A touring car racing team needed to extract maximum power from a naturally aspirated 2.0-liter engine restricted by series regulations that prohibited forced induction or significant displacement increases.

Solution: The team employed CNC machining to create optimized engine components:

-

CNC-Ported Cylinder Head: The cylinder head underwent extensive CNC porting and polishing to improve airflow characteristics. The combustion chambers were precisely machined to exact volumes for perfect compression ratio consistency across all cylinders.

-

Custom Intake Manifold: A custom velocity stack intake manifold was CNC-machined from 6061 aluminum, tuned to the specific resonance characteristics of the engine’s intended power band.

-

Lightweight Valvetrain: Titanium valves and retainers combined with CNC-machined steel springs reduced valvetrain mass, enabling reliable operation at over 9,000 RPM.

Results: The engine achieved a 17% power increase over the stock configuration while maintaining reliability throughout the racing season. The precise machining of components ensured consistent performance across all cylinders and reduced the need for extensive balancing.

Case Study 2: Precision Suspension System for Time Attack Vehicle

Challenge: A time attack team needed precise suspension geometry control for a front-wheel drive vehicle that would generate exceptional cornering grip while maintaining stability under braking.

Solution: CNC machining produced a complete custom suspension system:

-

Billet Aluminum Control Arms: CNC-machined from 7075 aluminum, these arms provided exact geometry changes for improved camber gain during cornering while reducing unsprung weight by 2.1 kg per corner.

-

Adjustable Spherical Mounts: CNC-machined aluminum mounts with stainless steel spherical bearings provided precise camber and caster adjustment with minimal compliance.

-

Chassis Reinforcement Plates: Laser-cut and CNC-machined chassis mounting points improved accuracy and rigidity of suspension component attachment.

Results: The vehicle achieved a 2.4-second improvement on a 2-minute circuit compared to the previous suspension setup, with notably improved turn-in response and mid-corner stability.

Case Study 3: Lightweight Braking System for Sports Car

Challenge: A performance shop needed to reduce unsprung weight and improve brake cooling for a track-focused sports car while maintaining OEM safety margins.

Solution: A comprehensive CNC-machined brake system was developed:

-

Billet Aluminum Calipers: 6-piston front and 4-piston rear calipers were CNC-machined from 6061 aluminum, reducing weight by 1.8 kg per corner compared to the cast iron OEM units.

-

Directionally Vented Rotors: CNC-machined rotors featured optimized ventilation patterns and mounting surfaces that improved cooling efficiency by 23%.

-

Integrated Brake Ducts: CNC-machined aluminum brake ducts provided precise airflow direction to critical areas of the braking system.

Results: The braking system showed a consistent 12% reduction in braking distances from high speed and significantly reduced brake fade during extended track sessions. The weight reduction also improved ride quality and responsiveness.

The CNC Machining Process for Performance Automotive Parts

Creating high-performance automotive components through CNC machining involves a meticulous process that ensures optimal results:

-

Design and Engineering: Using CAD software, engineers create 3D models of components, often incorporating finite element analysis (FEA) and computational fluid dynamics (CFD) to optimize designs before manufacturing.

-

Toolpath Programming: CAM software translates the 3D models into toolpaths that guide the cutting tools through the most efficient material removal sequences.

-

Material Selection and Preparation: Based on the application requirements, appropriate material is selected and prepared in the form of billets or blanks for machining.

-

Setup and Fixturing: The workpiece is securely mounted in the CNC machine using custom fixtures that ensure stability throughout the machining process while allowing access to all necessary surfaces.

-

Machining Operations: The CNC machine executes a series of operations including milling, turning, drilling, and tapping—often employing 3-axis, 4-axis, or 5-axis capabilities depending on the complexity of the part.

-

Quality Control: Completed parts undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify compliance with specifications.

-

Post-Processing: Additional treatments such as heat treatment, anodizing, plating, or polishing may be applied to enhance the properties or appearance of the components.

-

Final Assembly and Testing: Where applicable, components are assembled and tested under simulated operating conditions to ensure performance targets are met.

Future Trends in CNC Machining for Automotive Performance

The field of CNC machining continues to evolve, with several emerging trends particularly relevant to performance automotive applications:

-

Multi-Axis Machining Advancements: 5-axis machining becomes increasingly sophisticated, allowing more complex geometries to be produced in single setups, reducing alignment errors and production time.

-

High-Speed Machining Technologies: Improved spindle technologies and cutting tools enable higher machining speeds without sacrificing precision, particularly beneficial for aluminum and non-ferrous materials common in performance applications.

-

Integrated Additive and Subtractive Manufacturing: Hybrid approaches that combine 3D printing for complex features with CNC machining for precision surfaces offer new possibilities for lightweight, optimized components.

-

Smart Machining and Industry 4.0 Integration: CNC machines with integrated sensors and AI-driven optimization can automatically adjust machining parameters in real-time based on tool wear, material variations, and other factors.

-

Advanced Tooling Materials: New carbide formulations, diamond-coated tools, and ceramic cutting materials enable machining of advanced materials at higher speeds and longer tool life.

-

Sustainable Machining Practices: Reduced energy consumption, improved coolant management, and recycling of metal chips align performance manufacturing with environmental responsibility.

Selecting a CNC Machining Partner for Performance Automotive Applications

When choosing a CNC machining service provider for performance automotive components, consider these critical factors:

-

Technical Capabilities: Ensure the provider has appropriate CNC equipment (3-axis, 4-axis, 5-axis) and experience with performance automotive materials and tolerances.

-

Quality Systems: Look for ISO certification, rigorous inspection processes, and documentation practices that ensure consistent quality.

-

Engineering Expertise: The ideal partner should offer design for manufacturability (DFM) feedback and value engineering suggestions to optimize your components.

-

Prototyping and Production Flexibility: The ability to handle both prototype quantities and production runs ensures scalability as your projects evolve.

-

Industry Experience: Prior experience with performance automotive components provides valuable insight into specific requirements and potential challenges.

-

Lead Times and Responsiveness: The racing and performance industries often operate on tight timelines, so responsive service and reliable delivery are essential.

Conclusion

CNC machining has become an indispensable technology in the pursuit of automotive performance excellence. The precision, repeatability, and material flexibility offered by modern CNC systems enable performance engineers and enthusiasts to create components that push the boundaries of what’s possible in automotive design. From engine components that extract every last horsepower to suspension systems that provide razor-sharp handling, CNC machining delivers the exacting standards required in high-performance applications.

As technology continues to advance, CNC machining will play an increasingly important role in developing the next generation of performance automotive components. The integration of digital technologies, advanced materials, and innovative manufacturing approaches will further blur the lines between racing technology and production vehicle components, bringing track-proven performance enhancements to a broader range of vehicles.

For enthusiasts, racers, and manufacturers seeking to elevate automotive performance, partnering with an experienced CNC machining provider that understands the unique demands of high-performance applications is essential to achieving success on the road, track, or strip.

check the details:Precision CNC Machining Services By JLY Precision