CNC Machining for Startups: How to Choose the Right Manufacturing Partner for Your Hardware Venture

The journey from innovative concept to market-ready product represents one of the most significant challenges hardware startups face. While brilliant ideas abound, the physical manifestation of these concepts through reliable CNC machining for startups separates successful ventures from those that never reach production. For startups navigating this complex landscape, selecting the appropriate CNC machining partner can dramatically influence time-to-market, funding milestones, and ultimately, commercial success.

The Startup Manufacturing Dilemma: Why Specialized CNC Partners Matter

Startups operate in a unique environment characterized by limited capital, compressed timelines, and frequent iterations. Traditional manufacturing approaches often prove incompatible with these constraints, creating the need for manufacturing partners who understand the distinct requirements of early-stage hardware companies seeking CNC machining for startups.

Critical Challenges Startups Face in Manufacturing:

-

Capital Constraints: Limited funding necessitates cost-effective manufacturing strategies that maximize value while maintaining quality standards in CNC machining for startups

-

Design Fluidity: Frequent product iterations require manufacturing flexibility and rapid response capabilities from CNC machining providers

-

Scale Ambiguity: Uncertainty about production volumes demands scalable solutions that accommodate both prototyping and initial production runs

-

Technical Expertise Gaps: Limited in-house manufacturing knowledge creates dependency on knowledgeable CNC machining partners who can provide design guidance

-

Timeline Pressure: Investor expectations and market windows require accelerated development cycles and compressed production timelines

What Startups Should Look for in a CNC Manufacturing Partner

Selecting the right CNC machining for startups partner requires careful evaluation across multiple dimensions. The ideal CNC machining provider for startups balances technical capability with startup-friendly business practices.

Technical Capabilities Assessment:

Equipment and Technology Stack

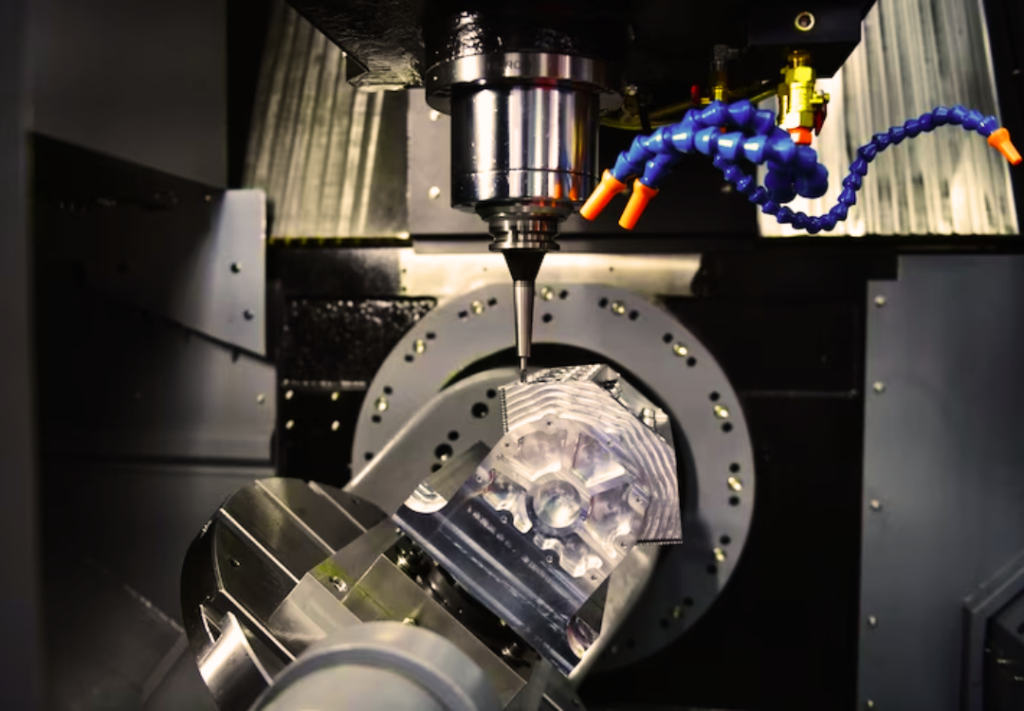

Modern CNC machining for startups facilities should feature multi-axis machining centers (3-axis, 4-axis, and 5-axis capabilities) that accommodate complex geometries without multiple setups. The presence of advanced metrology equipment like CMMs (Coordinate Measuring Machines) and optical comparators ensures consistent quality validation, while automated manufacturing systems reduce labor costs and improve repeatability.

Material Expertise and Inventory

A comprehensive material inventory encompassing both common and specialized alloys enables rapid prototyping and production. Look for CNC machining partners stocking:

-

Aluminum Series: 6061, 7075 for excellent strength-to-weight ratios

-

Stainless Steels: 303, 304, 316 for corrosion resistance

-

Engineering Plastics: PEEK, Delrin, Nylon for specialized applications

-

Exotic Alloys: Titanium, Inconel for extreme environment applications

Quality Systems and Certifications

Depending on your industry, relevant certifications for CNC machining for startups might include:

-

ISO 9001:2015 for quality management systems

-

AS9100D for aerospace applications

-

ISO 13485 for medical devices

-

ITAR compliance for defense projects

Table: CNC Manufacturing Partner Evaluation Criteria for Startups

| Evaluation Category | Critical Factors | Startup-Specific Considerations |

|---|---|---|

| Technical Capability | Multi-axis machining, Tight tolerance capability (±0.025mm), Material variety, Quality control systems | Rapid turnaround for iterations, Design for Manufacturability (DFM) feedback, Material selection guidance |

| Business Model | Minimum order quantities, Pricing transparency, Payment terms, NDA protection | Low MOQs, Flexible payment options, Startup-friendly pricing, Strong IP protection |

| Communication & Support | Responsiveness, Technical support, Project management, Progress updates | Dedicated account management, Educational resources, Willingness to guide inexperienced teams |

| Scalability | Production capacity, Lead time consistency, Secondary operations, Supply chain management | Smooth transition from prototyping to production, Ability to scale with funding rounds, Vendor management assistance |

Startup-Friendly Business Practices:

Financial Considerations

The most startup-compatible CNC machining for startups partners offer transparent pricing models with detailed cost breakdowns, flexible payment terms that accommodate cash flow constraints, and minimal tooling investments. Look for providers who offer volume-based pricing tiers that automatically reduce per-part costs as order quantities increase.

Communication and Collaboration

Effective manufacturing partnerships for CNC machining for startups feature dedicated project engineers who serve as single points of contact, regular progress updates with visual documentation, and proactive issue identification that addresses potential problems before they impact timelines. The best partners function as extended team members rather than transactional vendors.

Design for Manufacturing (DFM) Support

Perhaps the most valuable service a CNC machining partner can provide startups is comprehensive DFM analysis. This includes:

-

Manufacturability Assessment: Identifying features that may be challenging or expensive to produce

-

Cost Reduction Strategies: Recommending design modifications that reduce machining time and material waste

-

Tolerance Optimization: Advising on which dimensions require tight tolerances and where standard tolerances suffice

-

Material Selection Guidance: Recommending materials that balance performance, manufacturability, and cost

The CNC Manufacturing Process: What Startups Can Expect

Understanding the typical workflow helps startups prepare adequately and set realistic expectations for their CNC machining for startups engagements.

Phase 1: Initial Consultation and Project Scoping

The process begins with a comprehensive requirements review where the CNC machining partner seeks to understand the startup’s technical requirements, timeline constraints, budget parameters, and quality expectations. During this phase, startups should provide:

-

Detailed CAD models (preferably in STEP or IGES format)

-

Comprehensive drawings with critical dimensions and tolerances clearly specified

-

Material requirements or performance criteria for material selection

-

Surface finish specifications and any post-processing requirements

-

Quality documentation needs for inspection reports and material certifications

Phase 2: Quotation and DFM Analysis

The CNC machining for startups partner conducts detailed process planning to determine the most efficient manufacturing approach, followed by comprehensive DFM feedback highlighting potential issues and optimization opportunities. Startups receive transparent cost breakdowns separating material costs, machining time, setup charges, and any secondary operations.

Phase 3: Manufacturing and Quality Assurance

Once the startup approves the quotation, the CNC machining for startups process begins with material procurement from certified suppliers, followed by CAM programming that translates CAD models into machine instructions. The first article inspection provides comprehensive dimensional verification before full production runs, with in-process quality checks ensuring consistency throughout manufacturing.

Phase 4: Delivery and Post-Production Support

Completed parts undergo final quality certification with documented inspection reports, followed by careful packaging that ensures parts arrive undamaged. The best CNC machining for startups partners provide ongoing technical support for any assembly or production challenges that emerge.

Cost Management Strategies for Startup Budgets

Financial constraints make cost management particularly critical for startups utilizing CNC machining for startups. Implementing these strategies can significantly reduce manufacturing expenses without compromising quality.

Design Optimization Techniques:

Design Simplification

Evaluate every feature for necessity and complexity. Eliminate non-essential geometries that increase machining time without adding functional value. Consider consolidating multiple components into single machined parts to reduce assembly costs and improve reliability.

Tolerance Rationalization

Tighter tolerances exponentially increase CNC machining for startups costs. Implement a tiered tolerance approach where critical interfaces receive tight tolerances (±0.025 mm) while non-critical features use standard tolerances (±0.1 mm). This strategy can reduce costs by 30-50% without impacting functionality.

Material Selection Strategy

While performance requirements must drive material selection for CNC machining for startups, consider material cost per part rather than cost per kilogram. Sometimes a more expensive material that machines more efficiently produces lower total costs. For prototypes, consider machining equivalent materials that offer similar machining characteristics to production materials at lower cost.

Table: Cost Optimization Strategies for CNC Machined Parts

| Cost Driver | Impact on Total Cost | Optimization Strategies |

|---|---|---|

| Part Complexity | High (30-50% of total) | Reduce unnecessary features, Minimize deep pockets, Increase internal radii to standard tool sizes |

| Tolerances | Medium-High (15-30% of total) | Specify tight tolerances only where functionally required, Use geometric tolerancing rather than blanket tight tolerances |

| Material Selection | Medium (20-40% of total) | Consider machinability versus raw material cost, Use material substitutes with similar properties, Optimize blank size to reduce waste |

| Surface Finishes | Low-Medium (5-20% of total) | Specify finish requirements by surface importance, Consider mechanical finishing versus manual polishing |

| Quantity | Variable | Leverage volume pricing, Combine multiple parts on single blanks, Optimize CAM programming for batch production |

Strategic Sourcing Approaches:

Phased Manufacturing Approach

For initial funding milestones, consider CNC machining for startups for small batches of critical components for demonstration purposes rather than complete systems. This approach preserves capital while still generating the validation needed for subsequent funding rounds.

Modular Design Implementation

Design products using modular architectures that allow individual components to be manufactured in optimal quantities. This approach minimizes the financial impact of design changes and enables staged production ramp-ups aligned with market adoption.

Case Studies: Startups That Successfully Navigated CNC Manufacturing

Case Study 1: Robotics Startup Scales Production

A robotics startup developing collaborative robotic arms for manufacturing applications needed to transition from 10 prototype units to 250 production units. Their initial designs featured complex monolithic structures that required expensive 5-axis machining and specialized fixturing.

CNC Machining for Startups Solution:

Their CNC machining partner conducted a comprehensive DFM analysis that identified opportunities to modularize the arm structure into simpler components that could be produced on 3-axis machines with minimal fixturing. The redesign incorporated standardized mounting features and optimized wall thicknesses that reduced machining time by 45% while maintaining structural integrity.

Results:

-

68% reduction in per-part machining costs

-

3-week reduction in lead time for production batches

-

Improved serviceability through modular design

-

Successful production of 250 units within budget constraints

Case Study 2: Medical Device Startup Navigates Regulatory Requirements

A medical startup developing a portable diagnostic device needed to manufacture 50 units for clinical trials while maintaining compliance with FDA quality system requirements. Their design incorporated biocompatible materials and required validation documentation for regulatory submissions.

CNC Machining for Startups Solution:

The CNC machining for startups partner implemented a quality management system specifically designed for medical device manufacturing, including full material traceability, first article inspection reports, and process validation documentation. They recommended switching from machined Delrin to medical-grade PEEK for critical fluid handling components, improving chemical resistance while maintaining biocompatibility.

Results:

-

Successful FDA submission with complete manufacturing documentation

-

Zero manufacturing-related issues during clinical trials

-

Established scalable manufacturing process supporting future production

-

15% cost savings through material optimization despite upgrading to higher-performance material

Case Study 3: Consumer Electronics Startup Accelerates Market Launch

A consumer electronics startup developing a premium audio device secured retail distribution but faced aggressive timeline constraints. Their design featured precisely machined aluminum enclosures with complex internal baffling for acoustic performance.

CNC Machining for Startups Solution:

The CNC machining for startups partner implemented parallel processing workflows where different components were manufactured simultaneously across multiple machines. They developed specialized fixture systems that reduced setup time between operations and implemented aggressive machining parameters based on their material expertise with aluminum alloys, reducing machining time by 30% without compromising surface finish quality.

Results:

-

40% reduction in overall lead time versus initial projections

-

Delivery of 1,000 complete devices ahead of schedule

-

Exceptional surface quality eliminated secondary polishing operations

-

Successful retail launch meeting all timeline commitments

Building a Long-Term Manufacturing Partnership

The most successful startup-manufacturer relationships for CNC machining for startups evolve beyond transactional engagements into strategic partnerships that support growth across multiple product generations.

Partnership Development Strategies:

Regular Strategic Reviews

Establish quarterly business reviews to discuss performance metrics, upcoming requirements, and potential process improvements. These structured conversations ensure alignment and proactively address emerging needs in CNC machining for startups.

Technology Roadmap Alignment

Share your product development roadmap with CNC machining partners to ensure their capability development aligns with your future requirements. This forward-looking approach prevents manufacturing limitations from constraining future product designs.

Continuous Improvement Culture

The best CNC machining for startups partnerships feature collaborative improvement initiatives where both parties identify opportunities to enhance quality, reduce costs, or improve processes. This might include joint investment in specialized tooling or equipment that benefits both organizations.

Emerging Trends in CNC Manufacturing for Startups

The CNC machining for startups landscape continues to evolve, with several trends particularly beneficial for startup companies.

Digital Manufacturing Platforms:

Instant Quotation Systems

Online platforms that provide immediate CNC machining quotations based on uploaded CAD models enable startups to evaluate design alternatives rapidly and make informed decisions about cost-performance tradeoffs. Resources like Protolabs’ Instant Quote Platform have revolutionized accessibility for CNC machining for startups.

Manufacturing Analytics

Advanced data analytics provide unprecedented visibility into manufacturing processes, enabling startups to monitor production progress, track quality metrics, and predict potential delays before they impact timelines.

Technological Advancements:

Hybrid Manufacturing

The integration of additive and subtractive processes enables manufacturing of complex geometries that would be impossible with either technology alone. This approach particularly benefits startups developing products with integrated cooling channels, conformal surfaces, or lightweight lattice structures.

AI-Driven Optimization

Artificial intelligence applications in CNC machining for startups include predictive tool wear monitoring, adaptive machining parameters, and automated quality detection. These technologies improve consistency and reduce the expertise required to achieve high-quality results.

Conclusion: Selecting Your Manufacturing Foundation

For hardware startups, the choice of CNC machining for startups partner represents more than a vendor selection—it establishes the production foundation upon which the entire business will be built. The ideal partner combines technical expertise with startup empathy, balancing precision manufacturing with the flexibility, guidance, and support that early-stage companies require.

By thoroughly evaluating potential partners against the criteria outlined in this guide, startups can establish CNC machining for startups relationships that not only deliver quality components but actively contribute to product success. The right manufacturing partner becomes an extension of your team, providing the manufacturing expertise that allows founders to focus on their core competencies while confident that production requirements are in capable hands.

In the challenging journey from concept to customer, a superior CNC machining for startups partner provides more than just parts—they provide confidence, reliability, and partnership that can make the difference between a startup that struggles and one that thrives.