CNC Machining Materials: The Complete Engineering Guide for Precision Components

At JLY Precision Tech, our material science expertise transforms CNC machining outcomes across aerospace, medical, and industrial sectors. This definitive guide explores critical CNC machining materials selection strategies to optimize performance, compliance, and cost-efficiency.

Why CNC Machining Materials Define Project Success

CNC machining materials directly determine:

-

80% of part functionality in extreme environments

-

70% of manufacturing costs

-

100% of regulatory compliance outcomes

We’ve developed proprietary MaterialIQ technology that analyzes 200+ failure modes to prevent costly material mismatches.

Aerospace Metals: Lightweight Performance Solutions

Aluminum Alloys (6061 vs 7075)

CNC machining materials selection starts with aerospace-grade aluminum:

-

6061-T6: Ideal for structural brackets (drone frames) with 40% cost savings vs 7075

-

7075-T651: Critical for wing spars with 25% higher strength-to-weight than steel

Machining Tip: Use carbide tools at 14,000 RPM to prevent built-up edge (ASM International data)

Titanium Alloys (Ti-6Al-4V)

These essential CNC machining materials require specialized handling:

-

Medical Implants: ASTM F136-certified with Ra < 0.4μm surface finish

-

Aerospace Fasteners: Solution treated and aged for 160+ ksi tensile strength

-

JLYPT Innovation: Our pulsed-coolant technique reduces machining time 22%

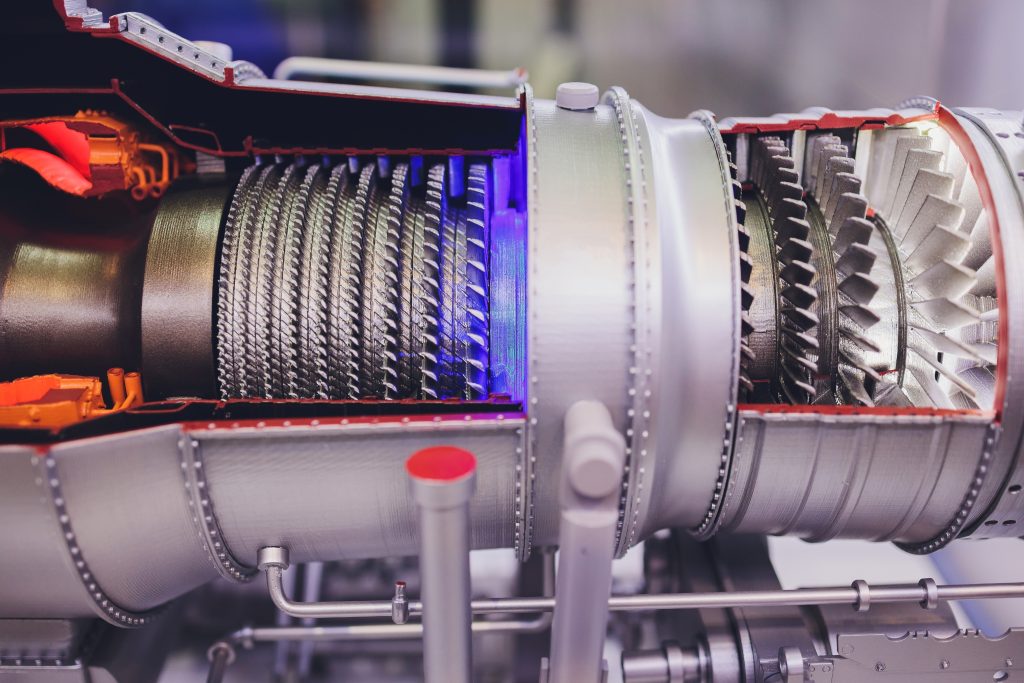

Extreme Environment Superalloys

| Material | Temp Limit | Key Application | Machining Insight |

|---|---|---|---|

| Inconel 718 | 1300°F | Turbine blades | Peek drilling prevents fracture |

| Monel K-500 | 1000°F | Marine valves | High-sulfur coolant required |

| A-286 | 700°C | Jet engine fasteners | Post-mach aging boosts strength |

Medical & Electronics Precision Materials

Stainless Steels

Critical CNC machining materials for life-saving applications:

-

316L Surgical Tools: Electropolished to Ra < 0.1μm

-

303 Food Grade: TiAlN-coated tools resist acidic cleaners

Engineering Plastics

| Polymer | Key Property | Cost-Saving Tip |

|---|---|---|

| PEEK | 480°F stability | Use Delrin for <250°F prototypes (80% savings) |

| Polycarbonate | 90% VLT transparency | Chemical polishing for optics |

| POM/Delrin | Near-zero moisture abs | Self-lubricating for mechanisms |

Cutting-Edge Material Innovations

Aluminum Matrix Composites (AMCs)

The future of CNC machining materials features:

-

20-55% SiC reinforcement in aluminum

-

30% lighter than steel with 3× thermal conductivity

-

Machining Solution:

-

Milling: 0.1mm depth @ 1,500 RPM

-

Grinding: 20μm depth @ 3,000 RPM → 40% energy reduction

-

Material Selection Framework: 6 Critical Factors

-

Mechanical Stress Analysis

-

4140 steel for hydraulic pistons (>150 ksi yield)

-

Nylon 66 for sub-200°F gears

-

-

Corrosion Management

-

Saltwater: Monel K-500 outperforms 316L

-

-

Thermal Performance

-

Copper heat sinks (401 W/mK conductivity)

-

-

Regulatory Compliance

-

ISO 10993-certified PEEK for implants

-

FDA-compliant Acetal

-

-

Cost Optimization

Scenario Material Swap Savings Non-structural aerospace 7075 → 6061 Al $120/kg High-temp prototype PEEK → Delrin 80% -

Machinability Index

-

Brass: 100% baseline

-

Titanium: 40% (requires specialized tooling)

-

JLYPT MaterialIQ: AI-Driven Selection System

Our proprietary technology solves complex challenges:

-

Failure Prevention: 200+ material-specific defect patterns

-

Cost Projector: Real-time material/machining tradeoffs

-

Case Study: Medical startup saved $18,500 switching titanium to PEEK for non-load-bearing implants via MaterialIQ Analysis

Alt: CNC machining materials optimization software

Industry-Specific Solutions

Aerospace Applications

-

Wing brackets: 7075-T6 + Teflon coating

-

Turbine blades: Inconel 718 with EDM channels

Medical Precision

-

Implants: Ti-6Al-4V ELI (extra low interstitial)

-

Surgical robots: Carbon-fiber PEEK for EMI shielding

Automotive Innovation

-

EV battery trays: 6061-T6 + ceramic thermal spray

-

Transmission gears: 4140 steel + carburizing

Conclusion: Mastering Material Science

Optimizing CNC machining materials delivers:

-

±0.0005″ tolerance consistency

-

30-45% cost reductions

-

100% compliance assurance

Partner with JLYPT for precision-engineered solutions:

Request Your Material Optimization Analysis