The Complete Guide to CNC Machining Online: Revolutionizing Precision Manufacturing

Introduction to Online CNC Machining Services

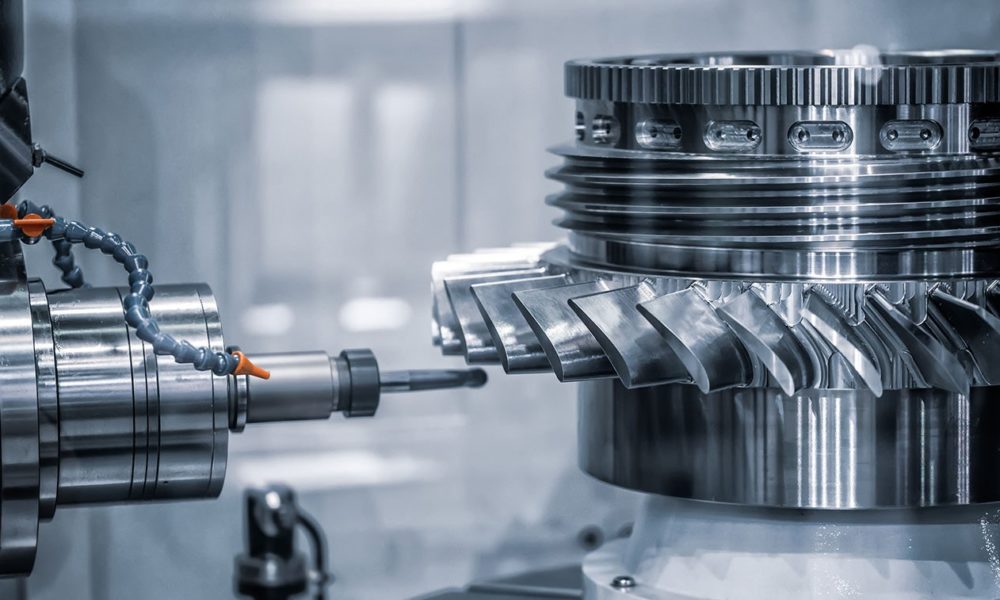

The manufacturing landscape has undergone a digital transformation in recent years, with online CNC machining services emerging as a game-changing solution for industries worldwide. These platforms have revolutionized how engineers, designers, and businesses access precision manufacturing capabilities, eliminating traditional barriers and dramatically accelerating production timelines.

Online CNC machining represents the convergence of traditional manufacturing expertise with digital technology, creating a seamless bridge between design concepts and physical parts. This integration has democratized access to industrial-grade manufacturing, enabling startups and established corporations alike to leverage advanced capabilities without significant capital investment in machinery and specialized personnel.

The global online CNC machining market has experienced substantial growth, driven by increasing demand for rapid prototyping, customized components, and distributed manufacturing capabilities. This expansion reflects a broader shift toward digital manufacturing ecosystems that prioritize efficiency, accessibility, and scalability.

How Online CNC Machining Platforms Work

The Digital Manufacturing Workflow

Online CNC machining platforms operate through a sophisticated digital infrastructure that streamlines the entire manufacturing process:

-

Digital Design Submission: Users upload 3D CAD models (typically in STEP, IGES, or STP formats) through web-based interfaces or mobile applications

-

Automated Design Analysis: AI-powered algorithms immediately analyze the design for manufacturability, identifying potential issues such as thin walls, sharp internal corners, or inadequate clearance for standard cutting tools

-

Instant Quoting Engine: The system generates real-time quotations based on material selection, quantity, required tolerances, and surface finish specifications

-

Material and Process Selection: Users choose from extensive material options and finishing processes, with immediate updates to pricing and lead times

-

Order Processing and Production: Once approved, the order is automatically routed to appropriate manufacturing facilities with compatible capabilities

-

Quality Assurance and Shipping: Completed parts undergo rigorous inspection before being shipped directly to the customer

Technological Infrastructure

Advanced online platforms employ sophisticated technologies to ensure accuracy and efficiency:

-

Cloud-Based Processing: Distributed computing resources handle complex calculations for toolpath generation and manufacturing analysis

-

AI and Machine Learning: Algorithms continuously improve quoting accuracy and manufacturability assessments based on historical data

-

Digital Twin Technology: Virtual replicas of manufacturing processes enable predictive optimization before physical production begins

-

Blockchain Integration: Some platforms utilize distributed ledger technology for supply chain transparency and quality assurance

Key Advantages of Online CNC Machining Services

Unmatched Speed and Efficiency

The digital nature of online CNC services dramatically compresses traditional manufacturing timelines:

Table: Comparison of Traditional vs. Online CNC Machining Timelines

| Process Stage | Traditional Approach | Online Platform | Time Savings |

|---|---|---|---|

| Quotation | 1-3 business days | 2-5 minutes | 99% reduction |

| DFM Feedback | 24-72 hours | Instantaneous | 100% reduction |

| Order Processing | 1-2 days | Immediate | 90% reduction |

| Production | 5-15 business days | 1-5 business days | 50-70% reduction |

| Total Lead Time | 2-3 weeks | 3-7 days | 65-80% reduction |

This dramatic reduction in lead times enables businesses to accelerate product development cycles and respond more quickly to market opportunities.

Cost Optimization and Transparency

Online platforms provide unprecedented cost transparency and optimization:

-

Real-Time Pricing: Immediate quotations based on current material costs and machine availability

-

Comparative Analysis: Ability to quickly evaluate different material and process options for cost optimization

-

No Hidden Costs: Transparent pricing models that include all aspects of production

-

Economies of Scale: Access to distributed manufacturing networks that optimize machine utilization

Global Access to Specialized Capabilities

Online platforms eliminate geographical constraints, providing access to:

-

Advanced Equipment: Multi-axis CNC systems (5-axis simultaneous machining), Swiss-type lathes, and other specialized machinery

-

Material Variety: Hundreds of material options from aerospace alloys to engineering plastics

-

Technical Expertise: Manufacturing specialists with experience across diverse industries

-

Quality Certifications: ISO 9001, AS9100, ISO 13485 compliant facilities without local availability

Technical Capabilities of Online CNC Services

Machining Processes Available Through Online Platforms

Modern online CNC services offer comprehensive manufacturing capabilities:

Table: CNC Machining Processes Available Through Online Platforms

| Process Type | Capability Description | Tolerance Range | Typical Applications |

|---|---|---|---|

| 3-Axis Milling | Basic milling operations on three linear axes | ±0.005″ (0.127mm) | Simple brackets, plates, and components |

| 5-Axis Simultaneous Milling | Complex contouring and undercut capabilities | ±0.0005″ (0.0127mm) | Aerospace components, medical implants |

| CNC Turning | Rotational parts production | ±0.0002″ (0.005mm) | Shafts, bushings, cylindrical components |

| Mill-Turn Combinations | Complete machining in single setup | ±0.0005″ (0.0127mm) | Complex rotational parts with features |

| Swiss-Type Machining | High-precision small part production | ±0.0001″ (0.0025mm) | Medical components, electronic connectors |

| Micro-Machining | Ultra-precision small feature creation | ±0.00005″ (0.00127mm) | Micro-fluidics, optical components |

Material Selection

Online platforms typically offer extensive material libraries:

Metals:

-

Aluminum Alloys: 6061-T6, 7075-T6, 5052-H32

-

Stainless Steels: 304, 316, 17-4 PH, 416

-

Tool Steels: A2, D2, O1, S7

-

Exotic Alloys: Titanium (Grade 2, 5), Inconel, Monel, Copper alloys

Plastics:

-

Engineering Grades: PEEK, Ultem, Delrin, Nylon

-

Performance Polymers: PTFE, PPS, PSU, PEI

-

Composites: G10/FR4, Carbon Fiber, Fiberglass

Surface Finishing Options

Comprehensive finishing services ensure parts meet functional and aesthetic requirements:

-

As-Machined: Standard finish directly from CNC equipment

-

Bead Blasting: Uniform matte surface texture

-

Anodizing: Type II (decorative) and Type III (hard coat)

-

Plating: Nickel, chrome, zinc, and precious metals

-

Powder Coating: Durable decorative finishes

-

Specialized Treatments: Passivation, chemical filming, laser engraving

Quality Assurance in Online CNC Machining

Digital Quality Management Systems

Reputable online CNC services implement rigorous quality control processes:

-

Automated DFM Analysis: Immediate identification of potential manufacturing issues during quotation

-

First Article Inspection: Comprehensive measurement and verification of initial production parts

-

In-Process Monitoring: Real-time tracking of critical dimensions during production

-

Final Inspection Documentation: Complete measurement reports with CMM data and surface finish analysis

Certification and Compliance

Leading providers maintain various quality certifications:

-

ISO 9001:2015: Quality management systems certification

-

AS9100D: Aerospace quality management standard

-

ISO 13485: Medical device quality management systems

-

ITAR Compliance: For defense and aerospace applications

-

NADCAP: Special processes accreditation for aerospace

Applications Across Industries

Aerospace and Defense

The aerospace sector leverages online CNC machining for:

-

Prototype Development: Rapid iteration of component designs

-

Test Fixtures: Custom tooling for validation and testing

-

Maintenance, Repair, and Overhaul (MRO): Replacement parts for legacy systems

-

Lightweight Structures: Complex geometries optimized for weight reduction

Case Study: Composite Tooling for UAV Systems

A developer of unmanned aerial vehicles utilized an online CNC platform to produce composite layup tools for wing structures. The digital process enabled:

-

60% reduction in tooling development time

-

Cost savings of 45% compared to traditional tooling methods

-

Incorporation of conformal cooling channels for improved cure cycles

-

Delivery of production-ready tools in 7 business days

Medical Device Manufacturing

The medical industry benefits from online CNC through:

-

Surgical Instrument Prototyping: Rapid iteration of ergonomic designs

-

Implant Development: Customized surgical guides and trial implants

-

Diagnostic Equipment: Enclosures and components for medical devices

-

Low-Volume Production: Patient-specific devices and instruments

Case Study: Biocompatible Instrument Development

A medical startup developing minimally invasive surgical instruments used an online platform to:

-

Prototype 15 design iterations in 4 weeks

-

Manufacture production instruments from 17-4 PH stainless steel

-

Achieve medical-grade surface finishes (Ra < 0.4 μm)

-

Maintain compliance with FDA design control requirements

Automotive and Motorsports

The automotive sector utilizes online machining for:

-

Prototype Components: Engine, transmission, and suspension parts

-

Customization Parts: Performance upgrades and custom fittings

-

Test and Validation: Components for durability and performance testing

-

Vintage Restoration: Reproduction parts for classic vehicles

Case Study: Electric Vehicle Battery Enclosure

An electric vehicle manufacturer leveraged online CNC capabilities to:

-

Produce functional prototypes of battery enclosure components

-

Test multiple design approaches with different materials

-

Optimize thermal management features through iterative testing

-

Reduce development time by 8 weeks compared to traditional methods

Selecting an Online CNC Machining Provider

Key Evaluation Criteria

When choosing an online CNC service, consider these critical factors:

-

Technical Capabilities: Ensure the provider offers the specific processes, materials, and tolerances your projects require

-

Quality Systems: Verify certifications and quality control processes match your industry requirements

-

Digital Experience: Evaluate the platform’s user interface, quoting speed, and design analysis capabilities

-

Manufacturing Network: Consider the geographic distribution of manufacturing partners for supply chain resilience

-

Customer Support: Assess the availability and expertise of technical support resources

Cost Considerations

While price is important, consider the total value proposition:

-

Hidden Costs: Evaluate if shipping, expedite fees, or minimum charges apply

-

Quality Investment: Higher initial costs may yield better results and fewer failed parts

-

Time Value: Faster turnaround may justify premium pricing for critical projects

-

Volume Pricing: Understand how pricing scales with quantity for production runs

Future Trends in Online CNC Machining

Technology Integration

The future of online CNC machining includes several emerging trends:

-

Generative Design Integration: AI-driven design optimization directly within quoting platforms

-

Additive-Subtractive Hybrid: Combining 3D printing with CNC machining in integrated workflows

-

Digital Inventory: On-demand production of certified parts without physical inventory

-

Blockchain Verification: Immutable quality records and supply chain transparency

-

AR/VR Implementation: Virtual reality factory assessments and augmented reality assembly guidance

Sustainability Initiatives

Online platforms are increasingly focusing on environmental responsibility:

-

Material Optimization: AI-driven nesting and processing to minimize waste

-

Carbon Footprint Tracking: Calculation and offsetting of manufacturing emissions

-

Recycling Programs: Closed-loop material recycling systems

-

Energy-Efficient Manufacturing: Selection of facilities based on renewable energy usage

Best Practices for Online CNC Machining Success

Design Optimization

Maximize the benefits of online CNC services through design for manufacturability:

-

Standardize Features: Use standard hole sizes, thread types, and fillet radii where possible

-

Minimize Setups: Design parts that can be machined in minimal orientations

-

Consider Tool Access: Ensure internal features are accessible to standard cutting tools

-

Material Selection: Choose materials that balance performance, machinability, and cost

-

Tolerance Rationalization: Specify tight tolerances only where functionally required

Project Management

Effective management of online manufacturing projects:

-

Prototype Iteratively: Use rapid iterations to validate designs before production

-

Document Requirements: Provide comprehensive specifications to avoid misunderstandings

-

Plan for Inspection: Include inspection requirements and methods in your order

-

Manage Logistics: Consider shipping times and customs requirements for international orders

-

Build Relationships: Develop ongoing relationships with preferred manufacturers for consistent quality

Conclusion: Embracing the Digital Manufacturing Revolution

Online CNC machining services have fundamentally transformed how businesses access precision manufacturing capabilities. By leveraging digital technologies, these platforms have democratized industrial production, making it accessible to organizations of all sizes without sacrificing quality, capability, or reliability.

The continued evolution of online manufacturing platforms will further integrate advanced technologies like artificial intelligence, machine learning, and blockchain, creating even more efficient, transparent, and accessible manufacturing ecosystems. As these platforms mature, they will increasingly serve as the foundation for a new era of distributed, responsive, and sustainable manufacturing.

For engineers, designers, and businesses seeking to maintain competitive advantage in an increasingly fast-paced global market, embracing online CNC machining is no longer optional—it’s essential. Those who effectively leverage these digital manufacturing capabilities will enjoy significant advantages in speed, cost efficiency, and innovation capacity.

By understanding the capabilities, processes, and best practices outlined in this guide, you can make informed decisions about utilizing online CNC machining services for your specific applications, ensuring optimal results while maximizing the value of your manufacturing investment.