CNC Machining Shop: Your Partner in Precision Manufacturing Excellence

In the competitive world of manufacturing, a CNC machining shop serves as the critical link between design and reality. At JLYPT, our CNC machining shop combines cutting-edge technology, material expertise, and rigorous quality control to produce components that meet the exacting standards of industries like aerospace, medical, and automotive. This article explores how a CNC machining shop operates, its transformative applications, and why JLYPT stands out as a leader in precision manufacturing.

What is a CNC Machining Shop?

A CNC machining shop is a specialized facility equipped with computer-controlled machines that fabricate parts from raw materials like metals, plastics, and composites. These shops handle everything from prototyping to mass production, offering services such as:

-

Multi-Axis Milling/Turning: 5-axis CNC machines for complex geometries.

-

High-Speed Machining: Achieving surface finishes as smooth as Ra 0.2 µm.

-

Material Expertise: Machining titanium, Inconel, PEEK, and more.

For example, JLYPT’s CNC machining shop produces aerospace brackets from aluminum 7075-T6 with ±0.005 mm tolerances—critical for satellite stability in orbit.

Industries Transformed by CNC Machining Shops

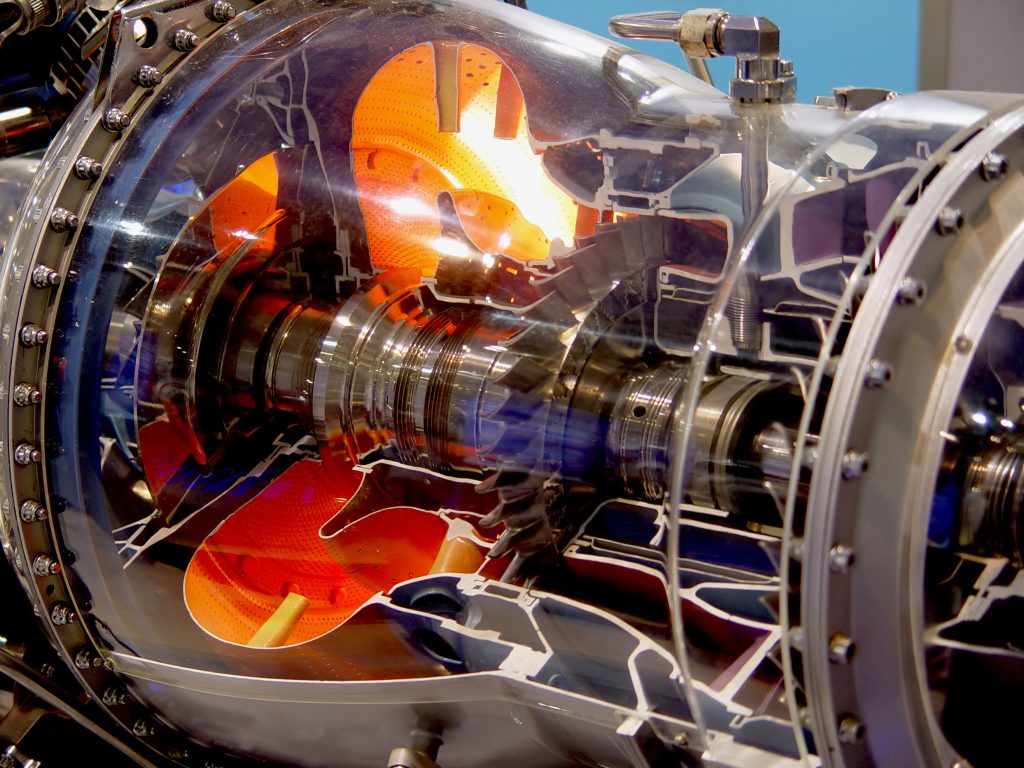

1. Aerospace: Precision Under Extreme Conditions

-

Turbine Blades: Inconel 718 components withstand 1,200°C and 15,000 RPM.

-

Satellite Housings: Magnesium alloy frames reduce weight by 30% vs. steel.

-

Case Study: A spacecraft antenna mount required titanium machining to survive -120°C to +150°C thermal cycles.

2. Medical: Life-Saving Accuracy

-

Orthopedic Implants: Ti-6Al-4V ELI hip stems polished to Ra 0.4 µm for biocompatibility.

-

Surgical Instruments: Stainless steel 316L forceps with 0.01 mm tip precision.

3. Automotive: Speed & Reliability

-

EV Battery Trays: Aluminum A380 enclosures machined to IP68 standards.

-

Transmission Gears: 8620 steel gears hardened to HRC 60, AGMA Q12 certified.

Core Capabilities of a CNC Machining Shop

1. Advanced Equipment & Technology

-

5-Axis CNC Mills: Craft impellers with internal cooling channels (0.1 mm diameter).

-

Swiss-Type Lathes: Machine Ø0.2 mm Nitinol wires for medical catheters.

-

EDM (Electrical Discharge Machining): Create intricate shapes in hardened tool steel.

2. Material Versatility

-

Metals: Titanium, stainless steel, Inconel, aluminum.

-

Plastics: PEEK, Ultem, PTFE for chemical resistance.

-

Composites: CFRP for lightweight aerospace structures.

3. Quality Assurance Protocols

-

In-Process Inspection: On-machine probes verify critical dimensions hourly.

-

CMM Validation: 3D scans ensure compliance with GD&T standards (±0.003 mm).

-

Certifications: AS9100 (aerospace), ISO 13485 (medical), IATF 16949 (automotive).

Case Study: High-Volume Automotive Component Production

Challenge: An EV manufacturer needed 50,000 aluminum motor housings (A380) with ±0.1 mm tolerances in 6 weeks.

JLYPT’s CNC Machining Shop Solution:

-

Process Optimization: High-speed 5-axis milling reduced cycle time by 25%.

-

Tooling: Diamond-coated end mills extended tool life by 40%.

-

Result: Delivered in 5 weeks, achieving 99.8% dimensional compliance.

Sustainability in a Modern CNC Machining Shop

-

Recycled Materials: 90% of metal waste reused in new billets.

-

Energy Efficiency: Solar-powered machines cut CO₂ emissions by 35%.

-

Eco-Friendly Coolants: Non-toxic, biodegradable fluids (ISO 14001 compliant).

Partnering with JLYPT: Seamless Workflow

-

Design Submission: Upload CAD files (STEP, IGES) for instant DFM feedback.

-

Material Selection: Choose from 100+ metals, plastics, and composites.

-

Production & Delivery: Track progress via JLYPT’s client portal.

The Future of CNC Machining Shops

-

AI-Driven Automation: Predictive maintenance reduces downtime by 20%.

-

Hybrid Manufacturing: Combine 3D printing and CNC finishing for complex parts.

-

Digital Twins: Simulate machining processes to preempt errors.

Conclusion: Precision, Reliability, Innovation

A CNC machining shop like JLYPT is more than a service provider—it’s a strategic partner in innovation. By leveraging advanced technology, material expertise, and sustainable practices, we deliver components that exceed expectations across aerospace, medical, and automotive industries. From rapid prototyping to high-volume production, JLYPT’s CNC machining shop ensures your projects thrive in the most demanding environments.

Ready to elevate your manufacturing? Contact JLYPT today.