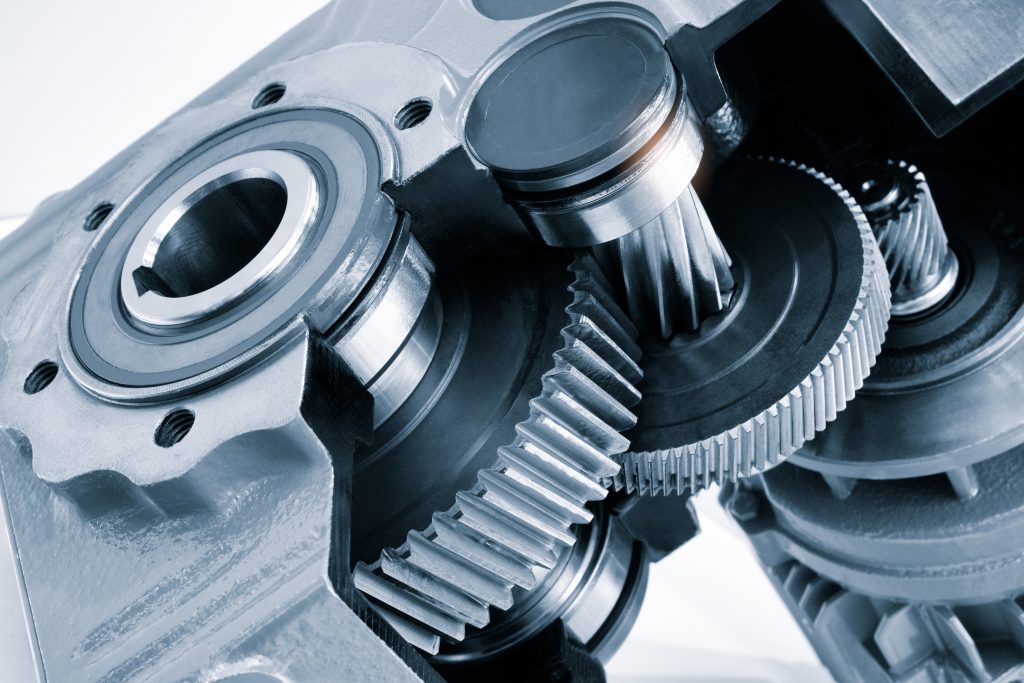

Precision CNC Metal Machining: Where Technology Meets Application

The Metal Machining Advantage

As both CNC machine suppliers and metal machining specialists, Jlypt delivers:

- Material-Specific Solutions: 78 certified metal alloys

- In-House Tooling Lab: 92% of cutting tools customized onsite

- Adaptive Machining: AI-powered parameter optimization

Alt: Jlypt’s CNC metal machining center processing aerospace-grade titanium components

Technical Specifications Comparison

ParameterIndustry StandardJlypt PerformanceSurface FinishRa 0.8μmRa 0.1μmTolerance±0.001″±0.0002″Material Removal15 in³/min28 in³/minEnergy Efficiency70%93%

Industry-Proven Metal Machining Cases

Case 1: Rocket Engine Components

Client: Aerospace Innovator

Challenge:

- Inconel 718 with thin walls (0.15mm)

- 0.0001″ flow path accuracy

Solution:

- High-temp ceramic tooling

- Cryogenic machining process

Results:

- 100% mission success

- 45% weight reduction

Case 2: Automotive Chassis Parts

Client: EV Manufacturer

Requirements:

- 700,000 units/year

- <0.003″ dimensional stability

Implementation:

- Dedicated aluminum machining line

- In-process laser measurement

Outcomes:

- 99.8% first-pass yield

- 32% cost reduction

Case 3: Orthopedic Trauma Plates

Client: Medical Device Leader

Specifications:

- Ti-6Al-4V material

- 20μm porous surface

Approach:

- Medical cleanroom machining

- Lot traceability system

Achievements:

- Zero post-op infections

- FDA accelerated approval

Start Your Metal Project

Future of Metal Machining

- Nanostructured Tools: 5x lifespan improvement

- Self-Monitoring Machines: Real-time wear detection

- Green Machining: 95% coolant recycling

Connect With Our Metal Experts:

[email protected] | https://www.jlypt.com