CNC Milling and Turning of ULTEM for Prototyping: Advanced Thermoplastic Manufacturing Solutions

The evolution of prototyping technologies has positioned ULTEM (polyetherimide) as a premier material for demanding prototype applications across aerospace, medical, and industrial sectors. CNC milling and turning of ULTEM for prototyping represents a sophisticated manufacturing approach that combines the exceptional material properties of this high-performance thermoplastic with precision subtractive manufacturing processes. At JLYPT CNC Machining, we specialize in CNC milling and turning of ULTEM for prototyping applications that require exceptional thermal stability, mechanical strength, and dimensional accuracy.

Understanding ULTEM Material Properties for Prototyping Applications

ULTEM’s unique combination of properties makes it ideal for functional prototypes that must perform under challenging conditions. The successful implementation of CNC milling and turning of ULTEM for prototyping requires deep understanding of this advanced thermoplastic’s characteristics.

Material Characteristics and Advantages

Thermal Properties

-

High glass transition temperature of 217°C (423°F) enabling operation in elevated temperature environments

-

Heat deflection temperature of 200°C (392°F) at 1.82 MPa per ASTM D648

-

UL 94 V-0 flammability rating without additives for safety-critical applications

-

Low coefficient of thermal expansion providing dimensional stability across temperature ranges

Mechanical and Chemical Properties

-

Tensile strength of 15,000 psi (103 MPa) at room temperature

-

Flexural modulus of 480,000 psi (3,300 MPa) for structural applications

-

Excellent chemical resistance to hydrocarbons, acids, and alcohol-based fluids

-

Inherent transparency allowing for visual inspection of internal features in prototypes

ULTEM Grades for Prototyping Applications

Standard ULTEM 1000

-

Unfilled resin providing maximum toughness and impact resistance

-

Excellent electrical properties with dielectric strength of 830 V/mil

-

FDA compliance for food contact and medical applications

-

Natural amber color for visual prototype evaluation

Reinforced ULTEM Grades

-

ULTEM 2300 with 30% glass fiber reinforcement for enhanced stiffness

-

ULTEM 4000 with 40% glass fiber for maximum mechanical properties

-

Carbon fiber reinforced versions for specialized applications requiring conductivity

-

PEI blends with optimized properties for specific prototyping requirements

Table: ULTEM Material Properties Comparison for CNC Milling and Turning of ULTEM for Prototyping

| Property | ULTEM 1000 | ULTEM 2300 (30% GF) | Testing Standard |

|---|---|---|---|

| Tensile Strength (psi) | 15,200 | 21,000 | ASTM D638 |

| Flexural Modulus (psi) | 480,000 | 1,100,000 | ASTM D790 |

| Heat Deflection Temp (°F) | 392 | 410 | ASTM D648 |

| IZOD Impact (ft-lb/in) | 1.0 | 1.6 | ASTM D256 |

| Coefficient of Thermal Expansion (in/in/°F) | 3.1×10⁻⁵ | 1.5×10⁻⁵ | ASTM D696 |

Advanced CNC Machining Strategies for ULTEM Prototypes

The successful implementation of CNC milling and turning of ULTEM for prototyping requires specialized machining strategies that account for the material’s unique characteristics and prototype requirements.

CNC Milling Techniques for ULTEM

Tooling Selection and Optimization

-

Carbide end mills with polished flutes to prevent material adhesion

-

2-flute and 3-flute designs for optimal chip evacuation in thermoplastic materials

-

Sharp cutting edges with positive rake angles for clean material separation

-

Specialized coatings including diamond-like carbon for extended tool life

Milling Parameter Optimization

-

High cutting speeds ranging from 600-1200 SFM for efficient material removal

-

Moderate feed rates of 0.002-0.006 inches per tooth to prevent overheating

-

Conservative depth of cut strategies to minimize stress and deformation

-

Climb milling preference for improved surface finish and dimensional accuracy

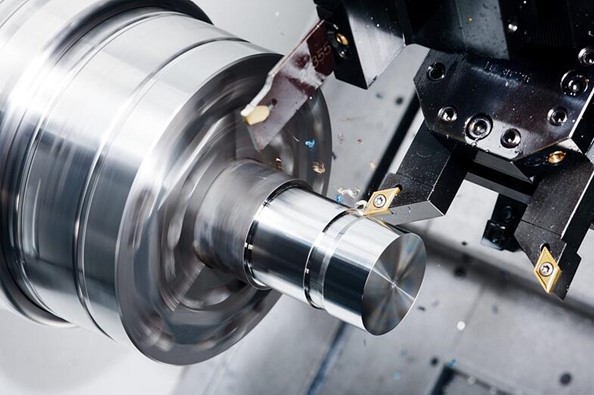

CNC Turning Approaches for ULTEM Components

Lathe Tooling Selection

-

Sharp, polished carbide inserts with positive rake geometry

-

Specialized chipbreaker designs for effective chip control in thermoplastics

-

Low-friction coatings to prevent material buildup on cutting edges

-

Custom tool geometries for complex ULTEM prototype features

Turning Parameter Strategies

-

Surface speeds of 500-800 SFM for optimal surface finish

-

Fine feed rates of 0.002-0.005 inches per revolution

-

Light depths of cut to prevent part deflection and ensure dimensional stability

-

Strategic tool path planning to minimize heat accumulation in the workpiece

Technical Considerations for CNC Milling and Turning of ULTEM for Prototyping

Successful CNC milling and turning of ULTEM for prototyping requires addressing several material-specific challenges through advanced machining techniques.

Thermal Management Strategies

Heat Generation Control

-

Consistent chip load maintenance to prevent localized overheating

-

Compressed air cooling to dissipate heat without introducing moisture

-

Strategic tool path planning to distribute cutting forces and minimize heat concentration

-

In-process temperature monitoring using infrared technology for critical features

Workholding Considerations

-

Low clamping pressure to prevent deformation of ULTEM components

-

Custom fixture design for complex prototype geometries

-

Non-marring jaw materials to protect surface finish

-

Strategic support placement to minimize vibration and deflection

Dimensional Accuracy and Surface Finish

Precision Machining Approaches

-

Multi-stage machining processes with intermediate stress relief steps

-

Spring pass implementation for final dimensional accuracy

-

Thermal stabilization periods between machining operations

-

In-process measurement to compensate for any material movement

Surface Quality Optimization

-

Progressive stepdown reduction for improved surface finish in finishing operations

-

Specialized tool path strategies including trochoidal milling for thin features

-

Polishing and deburring techniques specific to ULTEM materials

-

Surface treatment options including vapor polishing for optical clarity

Table: Machining Parameters for CNC Milling and Turning of ULTEM for Prototyping

| Operation Type | Speed (SFM) | Feed (IPT) | DoC (inches) | Tool Material | Cooling Method |

|---|---|---|---|---|---|

| Rough Milling | 600-800 | 0.004-0.008 | 0.1-0.3 | Uncoated Carbide | Compressed Air |

| Finish Milling | 800-1200 | 0.002-0.004 | 0.01-0.05 | Polished Carbide | Compressed Air |

| Contour Milling | 700-900 | 0.003-0.006 | 0.05-0.15 | DLC Coated | Compressed Air |

| Rough Turning | 500-700 | 0.004-0.008 | 0.08-0.20 | Sharp Carbide | Compressed Air |

| Finish Turning | 700-900 | 0.002-0.004 | 0.005-0.020 | Polished Carbide | Compressed Air |

Quality Assurance for ULTEM Prototypes

The production of precision prototypes through CNC milling and turning of ULTEM for prototyping requires comprehensive quality control measures to ensure component performance and accuracy.

Dimensional Verification

Advanced Metrology Applications

-

Coordinate measuring machines with temperature compensation for accurate measurement

-

Optical comparators for rapid 2D feature verification

-

Laser scanning for complex contoured surfaces

-

Custom gauge development for critical prototype features

Surface Quality Assessment

-

Surface roughness measurement using both contact and non-contact methods

-

Visual inspection under controlled lighting conditions

-

Microscope examination for edge quality and feature definition

-

Cross-sectional analysis for critical internal features

Material Integrity Verification

Physical Property Validation

-

Durometer testing for material hardness verification

-

Color consistency evaluation for aesthetic prototypes

-

Wall thickness verification using ultrasonic methods

-

Density measurement to ensure material consistency

Case Studies: Successful CNC Milling and Turning of ULTEM for Prototyping

Case Study 1: Aerospace Electrical Connector Housing

Challenge: An aerospace developer required CNC milling and turning of ULTEM for prototyping of a complex electrical connector housing that needed to withstand aircraft environmental conditions including thermal cycling, vibration, and chemical exposure. The prototype required precision features with tolerances of ±0.001″ and UL 94 V-0 compliance.

CNC Milling and Turning of ULTEM for Prototyping Solution:

JLYPT implemented a comprehensive manufacturing strategy:

-

5-axis CNC milling for complex internal geometries and connector alignment features

-

Precision CNC turning for circular connector interfaces and mounting features

-

Custom workholding to prevent deformation during machining of thin-walled sections

-

Progressive machining approach with intermediate stress relief periods

-

Comprehensive inspection using CMM and custom functional gauges

Results:

-

Achieved dimensional accuracy of ±0.0008″ on all critical features

-

Maintained UL 94 V-0 compliance throughout machining process

-

Surface finish of 32 μin Ra exceeded aerospace requirements

-

Successfully validated in thermal cycling tests from -55°C to 150°C

Case Study 2: Medical Device Fluid Handling Component

Challenge: A medical equipment manufacturer needed CNC milling and turning of ULTEM for prototyping of a complex fluid handling component for a diagnostic instrument. The prototype required biocompatibility, chemical resistance to laboratory reagents, and transparency for visual flow monitoring.

CNC Milling and Turning of ULTEM for Prototyping Solution:

Our specialized approach included:

-

Micro-milling capabilities for precise fluid channels and valve features

-

Cryogenic machining techniques to maintain optical clarity in transparent sections

-

Multi-stage finishing process to achieve medical-grade surface finishes

-

Cleanroom assembly and packaging for medical prototype validation

-

Chemical resistance testing using actual laboratory reagents

Results:

-

Achieved fluid channel accuracy within 0.0005″ of design specifications

-

Maintained material transparency for visual flow monitoring

-

Surface finish of 16 μin Ra prevented fluid retention and contamination

-

Successfully passed biocompatibility testing per ISO 10993

Case Study 3: Automotive Under-Hood Sensor Enclosure

Challenge: An automotive systems supplier required CNC milling and turning of ULTEM for prototyping of an under-hood sensor enclosure that needed to withstand continuous exposure to 150°C operating temperatures, vibration, and chemical exposure to automotive fluids.

CNC Milling and Turning of ULTEM for Prototyping Solution:

JLYPT’s comprehensive manufacturing strategy incorporated:

-

High-speed machining of glass-filled ULTEM 2300 for dimensional stability

-

Integrated turning operations for connector interfaces and mounting features

-

Vibration damping toolpaths to prevent resonance in thin-walled sections

-

Thermal management during machining to prevent material degradation

-

Environmental testing simulation to validate prototype performance

Results:

-

Maintained dimensional stability within 0.001″ at 150°C operating temperature

-

Achieved required chemical resistance to all specified automotive fluids

-

Vibration performance exceeded automotive testing requirements

-

40% reduction in prototype development time through optimized machining strategy

Future Trends in CNC Milling and Turning of ULTEM for Prototyping

The application of ULTEM in prototyping continues to evolve with advancing technologies and emerging requirements across industries.

Advanced Manufacturing Technologies

Hybrid Manufacturing Approaches

-

Additive and subtractive integration for complex prototype geometries

-

In-situ reinforcement for localized property enhancement

-

Multi-material prototyping combining ULTEM with other engineering thermoplastics

-

Smart manufacturing with real-time process adjustment based on material behavior

Digital Prototyping Integration

-

Digital twin technology for virtual prototype validation before manufacturing

-

AI-driven machining parameter optimization for ULTEM-specific requirements

-

Cloud-based manufacturing platforms for distributed prototype development

-

Augmented reality for prototype evaluation and design iteration

Material Science Advancements

Next-Generation ULTEM Formulations

-

Enhanced thermal stability for higher temperature applications

-

Improved mechanical properties for structural prototype applications

-

Specialized additive packages for specific industry requirements

-

Sustainable ULTEM variants with recycled content and improved environmental profile

According to research from ASM International, advanced thermoplastics like ULTEM are increasingly replacing metals in prototyping applications due to their combination of mechanical properties, manufacturability, and cost-effectiveness.

Conclusion: Excellence in CNC Milling and Turning of ULTEM for Prototyping

The manufacturing of ULTEM prototypes through precision CNC processes represents a critical capability for organizations developing advanced products across multiple industries. Success in CNC milling and turning of ULTEM for prototyping requires not only technical expertise in machining processes but also deep understanding of material behavior, prototype requirements, and application environments.

At JLYPT CNC Machining, our commitment to advancing CNC milling and turning of ULTEM for prototyping ensures that our clients receive prototypes that accurately represent final product performance while accelerating their development timelines. The future of ULTEM prototyping will continue to evolve with material advancements, digital technologies, and manufacturing innovations driving improved capabilities and efficiencies.

For organizations seeking expert partners in CNC milling and turning of ULTEM for prototyping, JLY Precision Technology’s CNC machining services offers comprehensive solutions with demonstrated expertise in advanced thermoplastic manufacturing for prototype applications.