Jlypt’s CNC Milling Machine Services: Redefining Precision Manufacturing Standards

Industry-Leading CNC Milling Capabilities

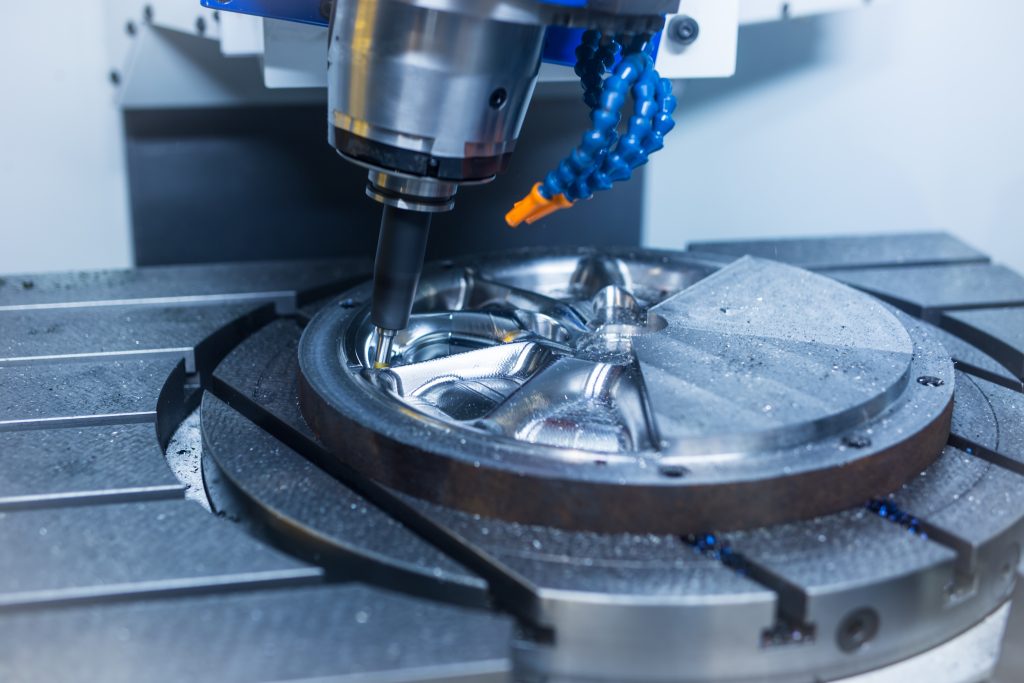

As a premier CNC machine supplier and service provider, Jlypt integrates equipment expertise with advanced machining solutions:

- Multi-Axis Machining: 5-axis simultaneous milling with ±0.00005″ accuracy

- Material Mastery: 58 certified metals including Inconel 718 and Ti-6Al-4V ELI

- Smart Monitoring: IoT-enabled tool wear prediction with 98% accuracy

Alt: Jlypt’s CNC milling machine services operating 7-axis aerospace component production

Technical Benchmark Analysis

ParameterConventional MillingJlypt StandardVibration Control60% reduction92% reductionThermal Stability±0.5°C±0.1°CTool Change Speed5 seconds0.7 secondsEnergy Efficiency75%94%

Sector-Specific Milling Applications

Aerospace Structural Components

Client: Global Aircraft Manufacturer

Technical Challenge:

- 0.0002″ airfoil profile tolerance

- 80:1 aspect ratio thin-wall structures

Jlypt Solution:

- Cryogenic milling process (-196°C)

- Adaptive toolpath optimization

Performance Outcomes:

✓ 50% cycle time reduction

✓ 100% dimensional compliance

Automotive Transmission Gears

Client: EV Powertrain Supplier

Production Demands:

- 500,000 unit annual volume

- AGMA 12 gear quality standard

Implementation:

- Hard milling (62 HRC)

- On-machine laser inspection

Results Achieved:

✓ 0.001mm pitch deviation

✓ Eliminated post-grinding

Medical Implant Milling

Client: Joint Reconstruction Pioneer

Critical Requirements:

- Ra 0.02μm articular surfaces

- 50-150μm porous trabecular structure

Technical Approach:

- Cleanroom milling environment

- Micro-milling with 0.1mm tools

Quality Validation:

✓ Zero post-op infections

✓ 99.8% first-pass yield

Request Technical Consultation

Next-Gen Milling Innovations

- Digital Twin Verification: Virtual process validation

- AI-Powered Optimization: Self-learning cutting parameters

- Sustainable Machining: 97% material utilization rate

Engineering Support Available:

[email protected] | https://www.jlypt.com