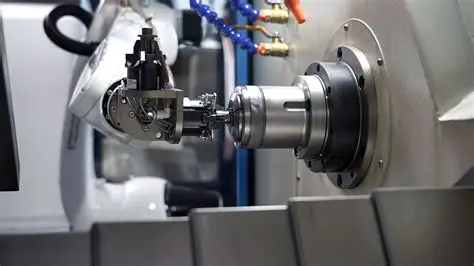

Introduction: The Unseen Mechanical Intelligence in Modern Robotics

The contemporary narrative surrounding CNC Robotics often centers on robotic systems performing machining operations—an application of undoubted importance. However, a more fundamental and equally critical synergy exists: the indispensable role of Computer Numerical Control (CNC) machining in manufacturing the robots themselves. The performance, reliability, and precision of any robotic system, from a collaborative arm on a factory floor to a surgical manipulator in an operating theater, are ultimately and irrevocably defined by the quality of its mechanical components. At JLYPT, we operate within this foundational layer of automation, specializing in the precision manufacture of robotic components, where the convergence of advanced metallurgy, multi-axis machining strategies, and metrological rigor creates the physical backbone of intelligent motion.

The distinction between a robot that functions and one that excels is measured in microns and milliseconds. It is determined by the runout tolerance of a harmonic drive component, the surface finish of a linear guide rail, and the residual stress profile within a robot arm link. These are not assembly parameters but characteristics forged during the manufacturing process. CNC machining provides the unique capability to translate theoretical designs—often optimized through Finite Element Analysis (FEA) and computational dynamics—into physical reality with the repeatability and accuracy that robotic kinematics demand. This process is the silent enabler, transforming lines of code and conceptual force diagrams into durable, high-performance hardware capable of millions of precise cycles.

This technical exploration delves into the core principles that define the CNC Robotics manufacturing paradigm. We will examine the material science behind components that must resist fatigue while minimizing inertia, the advanced 5-axis and micromachining techniques that produce complex, integrated geometries, and the critical importance of post-process treatments and validation in ensuring long-term reliability. Through detailed analysis of kinematic chains, dynamic loading, and real-world application case studies, this guide demonstrates why a deep partnership with a precision machining specialist is not merely a supply chain decision, but a strategic engineering collaboration essential for realizing the full potential of next-generation robotic systems. Discover how our focused expertise at JLYPT Precision Robotic Parts Manufacturing bridges the gap between digital design and physical excellence in automation.

The Mechanical DNA of a Robot: Core Components and Their Machining Imperatives

A robotic system is a symphony of interconnected mechanical systems, each with distinct and demanding manufacturing requirements. Understanding these components is key to specifying their manufacture.

1. Structural Links and Arm Segments:

These elements form the kinematic chain, transmitting forces and motions. Their primary requirements are high stiffness-to-weight ratio and controlled dynamic response.

-

Key Tolerances: Straightness (≤0.02mm/100mm), parallelism of mounting faces, true position of joint interfaces.

-

Manufacturing Challenge: Preventing deflection during machining of long, thin-walled sections. High-Speed Machining (HSM) strategies with constant tool engagement and specialized tool holders are used to minimize cutting forces and vibration.

-

Material Evolution: While 7075-T6 aluminum remains standard, there is growing use of continuous carbon fiber-reinforced polymer composites with CNC-machined titanium end fittings. This hybrid approach offers exceptional stiffness and damping.

2. Joint Housings and Actuator Integration Points:

These are the nexus points of motion, containing bearings, seals, and often gear reducers like harmonic drives or cycloidal drives. They demand absolute precision.

-

Key Tolerances: Bore diameter (H6/H7), concentricity (≤0.008mm), perpendicularity of bearing seats, surface finish (Ra ≤ 0.4 µm).

-

Manufacturing Challenge: Achieving perfect bore geometry and relationship between multiple bores in a single housing. Single-Setup 5-Axis Machining is critical here to machine all critical features without re-fixturing, eliminating stack-up error.

-

Thermal Management: These housings must dissipate heat from motors and gears. CNC machining allows for the integration of conformal cooling channels near heat sources, a feature impossible with casting or welding.

3. Precision Transmission Components (Gears, Flexsplines, Output Flanges):

These components convert motor torque into controlled motion, often at high reduction ratios. They are subject to extreme cyclic stresses.

-

Key Tolerances: Tooth profile (AGMA Class 10+), pitch accuracy, surface integrity, microgeometry.

-

Manufacturing Challenge: Machining hardened steels or specialized alloys like maraging steel after heat treatment. This often requires hard turning with Cubic Boron Nitride (CBN) inserts or precision grinding.

-

Special Case – Harmonic Drive Flexspline: This thin-walled, cup-shaped component undergoes elastic deformation. It requires ultra-fine surface finishes and a stress-free microstructure, often necessitating single-point diamond turning or specialized grinding after solution annealing.

4. End-Effector and Tool Changer Mechanisms:

These interface directly with the work environment. Requirements include low mass, high stiffness, and often, complex internal pathways for utilities (air, vacuum, electrical, data).

-

Key Tolerances: Repeatability of coupling interface (≤0.005mm), sealing surface flatness, utility port alignment.

-

Manufacturing Challenge: Creating a monolithic body that integrates mechanical coupling, utility pass-throughs, and mounting features in a compact envelope. Multi-Axis Mill-Turn Centers are ideal, combining turning for concentric features with milling for flats and ports.

Table 1: Robotic Component Taxonomy: Requirements & CNC Solutions

| Component Family | Primary Function | Critical Material Properties | Key CNC Machining Capabilities | Post-Process Treatment |

|---|---|---|---|---|

| Structural Links | Create kinematic chain; transmit load. | High specific stiffness, good damping, fatigue resistance. | 5-axis contouring for topology-optimized shapes; Thin-wall HSM; Stress-relieving passes. | Anodizing (Type II/III) for corrosion/wear; Powder coating for durability. |

| Joint Housings | House bearings & drives; provide alignment. | High strength, good thermal conductivity, dimensional stability. | Single-setup 5-axis machining; Precision boring; Integrated channel machining. | Hardcoat anodizing of bearing seats; Electroless nickel plating for corrosion. |

| Transmission Elements | Convert & transmit torque with precision. | Ultra-high strength, wear resistance, controlled elasticity. | Hard turning & grinding; Gear hobbing/skiving; Micro-finishing. | Superfinishing (Ra < 0.1µm); Diamond-like carbon (DLC) coating. |

| End-Effector Bases | Interface with tools/ environment; route utilities. | High stiffness, low mass, sometimes ESD-safe. | Mill-turn processing; Deep-hole drilling; Micro-machining for ports. | Media blasting for grip; PVD coating for wear surfaces. |

| Sensor Mounts & Brackets | Precisely locate vision, force, position sensors. | Dimensional stability (low CTE), vibration damping. | Micro-machining; High-tolerance milling; Kinematic coupling features. | Black anodizing for light absorption; Passivation for stainless. |

The Machining Technology Stack for Robotic Components

Producing the components outlined above requires a suite of advanced CNC technologies, each selected for its ability to meet specific technical challenges.

5-Axis Simultaneous Machining: The Cornerstone of Complexity

This technology is non-negotiable for modern robotic parts. Its advantages are transformative:

-

Geometric Freedom: Enables machining of the organic, weight-optimized shapes generated by topological optimization algorithms, which cannot be produced in 3-axis.

-

Superior Accuracy: By finishing multiple complex surfaces in one clamping, it eliminates the cumulative error introduced by moving parts between multiple setups.

-

Enhanced Surface Quality: The ability to maintain optimal tool orientation and contact with the workpiece results in better surface finish and tool life.

-

Application Example: Machining a complete robot wrist unit from a solid forging, creating bearing seats, motor mounts, and cable passages in a single, uninterrupted operation.

Ultra-Precision Micromachining:

For the miniaturization trend in electronics assembly and medical robotics, features demand micron-level accuracy.

-

Equipment: Machines with nanometric resolution, high-frequency spindles (up to 160,000 RPM), and advanced temperature control.

-

Tools: Diamond-coated or solid carbide micro-end mills as small as 0.02mm in diameter.

-

Application Example: Manufacturing the jaws for a micro-gripper or the fluidic channels in a bio-dispensing end-effector.

Multi-Tasking Mill-Turn Centers:

These hybrid machines combine the capabilities of a lathe and a machining center, ideal for complex, cylindrical parts.

-

Process: A part is turned (creating concentric features), then milled, drilled, and tapped—all without leaving the chuck. A second spindle allows complete machining of both ends.

-

Benefit: Dramatically reduces cycle times and improves concentricity between turned and milled features.

-

Application Example: Producing a harmonic drive wave generator with ground bearing surfaces, splined ID, and mounting bolt pattern in one cycle.

Additive Manufacturing (AM) Hybrid Solutions:

While not purely subtractive, CNC machining is critical in hybrid AM processes.

-

Process: A near-net-shape part is created via Metal Additive Manufacturing (e.g., DMLS). It is then fixture on a CNC machine for precision finishing of all critical functional surfaces, threads, and interfaces.

-

Benefit: Achieves complex internal geometries (lattices, conformal cooling) with the surface quality and dimensional accuracy of CNC machining.

-

Application Example: A lightweight, coolant-channel-filled robot arm link printed in titanium and finish-machined at bearing interfaces.

Material Science in Action: Selecting Substrates for Performance

The choice of material is a first-principles decision that dictates manufacturing strategy and final performance.

Advanced Aluminum Alloys:

-

7075-T6: The benchmark for high-stress components. Its high copper and zinc content provide precipitation hardening. Machining Note: It is less ductile than 6061; chip evacuation and sharp tools are critical to avoid built-up edge.

-

6082-T6: A European grade similar to 6061 but with better strength and excellent corrosion resistance. Often specified for marine or outdoor robotics.

-

Aluminum Metal Matrix Composites (MMCs): Aluminum reinforced with silicon carbide (SiC) particles. Offers higher stiffness and wear resistance but is highly abrasive, requiring Polycrystalline Diamond (PCD) tooling.

High-Performance Steels:

-

Managing Steel (e.g., 18Ni-300): Can be machined in a soft, solution-annealed state and then age-hardened to over 50 HRC with minimal distortion. Ideal for high-stress, high-wear transmission components.

-

Case-Hardening Steels (e.g., 8620, 9310): Used for gears. The core remains tough while the case provides a hard, wear-resistant surface after carburizing or nitriding.

Titanium and Specialty Alloys:

-

Ti-6Al-4V (Grade 5): The workhorse titanium alloy. Machining Challenge: Poor thermal conductivity leads to heat concentration at the cutting edge. Requires low cutting speeds, high feed rates, sharp tools, and ample coolant.

-

Invar (Fe-36Ni): An ultra-low expansion alloy used for metrology frames in ultra-precision robots. Difficult to machine due to work hardening and low thermal conductivity.

Table 2: Robotic Component Material Selection & Machining Guide

| Material | Typical Robotic Application | Key Advantages | Machining Challenges | Recommended Tooling |

|---|---|---|---|---|

| 7075-T6 Aluminum | Arm links, housings, mounting plates. | Excellent strength-to-weight, good machinability. | Can be gummy; stress corrosion cracking risk if not stress-relieved. | Sharp, polished carbide end mills with high helix angle. |

| Maraging Steel (18Ni-300) | High-strength gears, flexsplines, critical shafts. | Can be machined soft, then age-hardened with ~0% distortion. | Abrasive when hardened; requires post-hardening grinding. | Carbide for soft state; CBN or ceramic for hardened state. |

| Ti-6Al-4V Titanium | Aerospace/medical robot links, surgical tooling. | Excellent specific strength, biocompatibility, corrosion resistance. | Poor thermal conductivity, high chemical reactivity (galling). | Sharp carbide with specialized coatings (TiAlN), low speeds, high pressure coolant. |

| PEEK (Polyetheretherketone) | Insulating bushings, lightweight gears, cleanroom parts. | High strength polymer, chemical/thermal resistance, self-lubricating. | Low thermal conductivity can lead to melting; poor chip formation. | Sharp, polished carbide or diamond-coated tools. High rpm, low feed. |

| Invar 36 | Metrology frames, reference structures in precision robots. | Extremely low coefficient of thermal expansion (CTE). | Work-hardens rapidly, stringy chips, low thermal conductivity. | Sharp, positive-rake carbide tools. Consistent feed to avoid work hardening. |

Quality Assurance: The Metrological Backbone of Reliability

In CNC Robotics, quality is not inspected in; it is built in and meticulously verified.

In-Process Metrology:

-

Machine-Integrated Probing: A touch-trigger probe automatically measures key features after critical operations, allowing for tool wear compensation and adaptive control before a part is completed.

-

Laser Tool Setting: Measures tool length and diameter automatically, eliminating manual setup error and detecting broken tools.

Post-Process Validation:

-

Coordinate Measuring Machine (CMM): For comprehensive 3D geometric verification. Modern CMMs with scanning probes can compare the entire part surface to the CAD model, generating a detailed color map of deviations.

-

Surface Metrology: Using profilometers to measure surface roughness (Ra, Rz) and waviness, critical for bearing performance and seal integrity.

-

Non-Destructive Testing (NDT): Fluorescent Penetrant Inspection (FPI) or X-ray Computed Tomography (CT Scanning) to detect internal voids or cracks in safety-critical components like cast housings or additive-manufactured parts.

Case Studies: Precision in Practice

Case Study 1: High-Speed Delta Robot Central Wrist Assembly

-

Challenge: A manufacturer of packaging robots needed a new central wrist assembly to increase speed from 150 to 220 picks per minute. The existing design, a fabricated weldment, lacked the stiffness and dynamic balance for the higher speed.

-

JLYPT Solution: We redesigned the assembly as a monolithic 7075-T6 part to be machined on a 5-axis mill.

-

Design: Used modal analysis to shape the structure, pushing its first natural frequency above 500 Hz to avoid resonance with motor harmonics.

-

Machining: Employed single-setup 5-axis machining to ensure the three arm attachment points were perfectly coplanar and angularly positioned within 15 arc-seconds.

-

Finishing: The part was hardcoat anodized for wear resistance. After assembly with bearings, the complete wrist underwent dynamic balancing.

-

-

Result: The new wrist reduced vibration by over 70% at the target speed, enabling the robot to reliably achieve 220 picks/min with improved positional accuracy. The monolithic design also eliminated periodic maintenance to re-tighten fasteners.

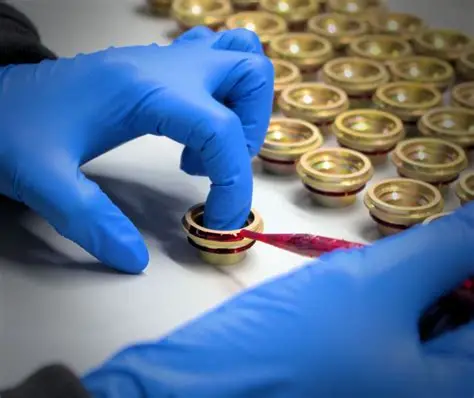

Case Study 2: Surgical Robot Instrument Driver Gearbox

-

Challenge: A medical robot company required a miniature, sealed gearbox for a sterile instrument driver. The housing needed to be biocompatible (ISO 10993), contain four stainless steel spur gear stages, and provide absolute sealing against fluid ingress.

-

JLYPT Solution: We machined the main housing from Ti-6Al-4V ELI (Grade 23).

-

Precision: All gear bearing bores were held to H6 tolerance with a positional tolerance of 0.008mm to ensure perfect gear mesh alignment and minimal backlash.

-

Sealing: Incorporated a sophisticated double O-ring groove system with machined sealing surfaces of Ra 0.8 µm.

-

Cleanliness: All parts underwent a rigorous multi-stage ultrasonic cleaning and passivation process to meet medical cleanliness standards.

-

-

Result: The gearbox achieved a leakage rate of less than 1×10⁻⁶ mbar·L/s in helium leak testing, ensuring sterility barrier integrity. The precise gear alignment resulted in smooth operation with less than 0.1° of backlash, crucial for the surgeon’s tactile feedback.

Case Study 3: Collaborative Robot (Cobot) Force-Torque Sensor Housing

-

Challenge: For a new collaborative robot, a sensor manufacturer needed an ultra-rigid yet lightweight housing for a 6-axis force-torque sensor. The housing had to precisely locate strain gauges while minimally affecting the sensor’s compliance.

-

JLYPT Solution: We produced the housing from 7075-T6 aluminum using a multi-step machining process.

-

Rigidity: The design used a closed-box structure with internal ribs, machined via trochoidal milling to achieve high stiffness with thin walls.

-

Accuracy: The top and bottom mounting surfaces were machined to be parallel within 0.005mm and feature precisely located dowel pin holes for sensor and robot interface alignment.

-

Thermal Management: Incorporated mounting holes for temperature sensors to allow for software-based thermal drift compensation.

-

-

Result: The housing added negligible compliance to the sensor system, allowing it to maintain its rated accuracy of 0.1% full scale. Its high stiffness prevented false strain readings from housing deflection, ensuring the cobot could perform sensitive contact tasks reliably.

The Future Trajectory: Smart Manufacturing and Advanced Materials

The future of CNC Robotics manufacturing is converging with digitalization and new material science.

Digital Thread and Smart Factories: The integration of IoT sensors on machine tools will enable real-time monitoring of cutting forces, vibration, and thermal conditions. This data stream will feed into digital twins of the machining process, allowing for predictive adjustments to optimize tool life and part quality for every single component.

Advanced Composite Integration: The use of continuous fiber 3D printing combined with CNC-machined metal interfaces will become more prevalent. This will allow for the creation of robot structures that are not only lightweight but have tunable directional stiffness and built-in vibration damping properties.

On-Machine Metrology and Closed-Loop Correction: The line between machining and measurement will continue to blur. In-process laser scanning will immediately after finishing passes, with the CNC controller automatically generating and executing a corrective toolpath if deviations are detected, ensuring first-part-correct manufacturing even for complex, low-volume components.

Conclusion: Precision as the Pathway to Robotic Potential

The journey of a robot from a digital model to a physical entity capable of precise, reliable work is fundamentally a journey of precision manufacturing. CNC machining is the essential technology that makes this journey possible, providing the control, flexibility, and accuracy needed to produce the sophisticated components that form a robot’s mechanical core. The relationship between robotic performance and component quality is direct and unforgiving; one cannot exceed the limits of the other.

At JLYPT, we view our role as more than part suppliers. We are engineering partners who provide the manufacturing intelligence—the understanding of materials, processes, and tolerances—necessary to transform ambitious robotic designs into dependable, high-performance systems. We bridge the critical gap between the digital design environment and the physical world where robots operate.

Are you developing robotic systems where mechanical excellence defines operational success? Partner with a manufacturer who speaks the language of precision and understands the demands of automation. Contact our engineering team to discuss how our CNC Robotics manufacturing expertise can provide the foundation for your next innovation. From prototype to production, we deliver the precision that enables progress. Begin the conversation at JLYPT Precision Robotic Parts Manufacturing.