The Strategic Fork in the Road: Cobots vs. Traditional Robots in Modern CNC Machining

Introduction: The New Automation Dilemma for Precision Manufacturers

The decision to automate a CNC machining process is a pivotal moment for any manufacturer. It’s a commitment to higher efficiency, improved consistency, and enhanced competitiveness. However, today’s engineering manager faces a more complex choice than ever before: which type of automation is right for the shop floor? The long-dominant paradigm of caged, high-speed traditional industrial robots is now challenged by the agile, user-friendly approach of collaborative robots (cobots). This isn’t merely a choice between two machines; it’s a strategic decision between two fundamentally different philosophies of automation that impacts safety protocols, workflow flexibility, capital expenditure, and workforce dynamics.

For a precision CNC machining service provider like JLYPT, this distinction is critical. We not only utilize this technology but also manufacture the high-tolerance components that enable both systems to function reliably. Understanding the nuanced comparison of cobots vs traditional robots is essential for our clients to invest wisely and build a future-proof manufacturing operation. This comprehensive guide will dissect the technical, operational, and economic differences between these two robotic classes, providing a clear framework to determine the optimal path for your specific CNC machining applications.

Chapter 1: Fundamental Definitions and Design Philosophies

1.1 Traditional Industrial Robots: The Powerhouses of Automation

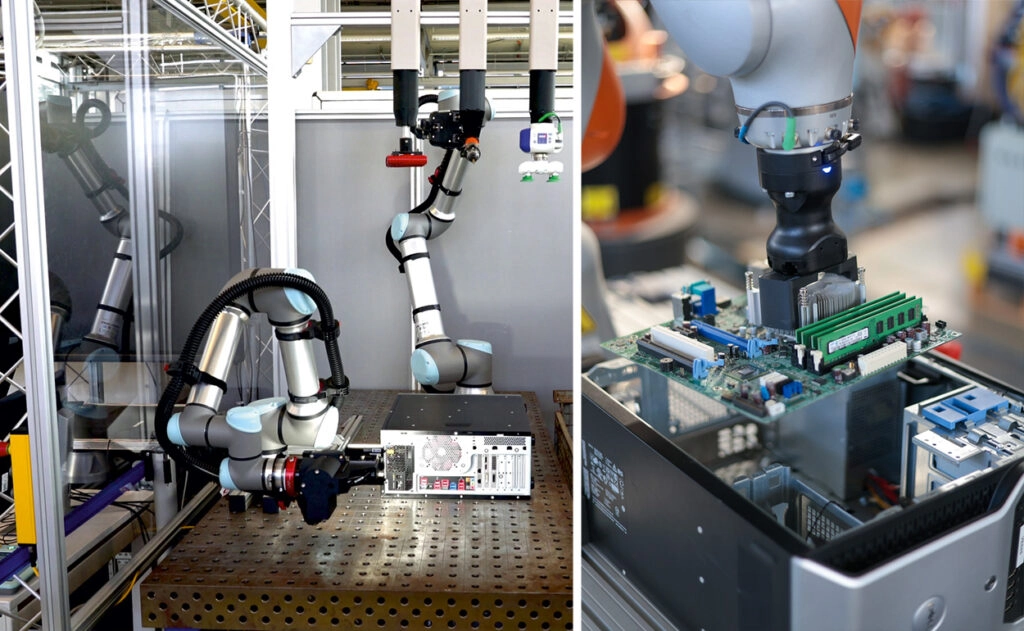

Traditional robots (e.g., articulated 6-axis arms from Fanuc, ABB, KUKA) are engineered for maximum performance in isolated, predictable environments. Their primary design goals are speed, precision, payload capacity, and repeatability over endless cycles. They operate within a pre-defined, safeguarded work envelope—typically behind physical fencing, light curtains, or laser scanners—with no human access during operation. Their programming often requires specialized knowledge of proprietary languages and offline simulation software. In a CNC context, they excel in high-volume, low-mix scenarios, such as tending multiple machines on a rail or palletizing thousands of identical parts.

1.2 Collaborative Robots (Cobots): The Agile Partners

Cobots (from pioneers like Universal Robots, Techman Robot, and the collaborative models from Fanuc and ABB) are built on a different premise: safe interaction and easy integration. Their core design incorporates inherent safety features like force-limited joints, rounded edges, and collision detection algorithms, allowing them to work alongside human operators without extensive fixed guarding. They are famously easy to program, often via intuitive hand-guiding or graphical tablet interfaces, empowering machinists and technicians to deploy and re-task them. Their value shines in high-mix, low-volume (HMLV) environments, complex assembly, and tasks requiring human-robot teamwork.

Chapter 2: A Detailed Comparative Analysis

The choice between a cobot and a traditional robot hinges on a matrix of technical and operational factors. The following table provides a foundational comparison.

Table 1: Core Technical & Operational Comparison: Cobots vs. Traditional Robots

| Parameter | Traditional Industrial Robots | Collaborative Robots (Cobots) | Implication for CNC Machining |

|---|---|---|---|

| Primary Design Goal | Maximized throughput, precision, and uptime in a controlled cell. | Safe, flexible collaboration and easy deployment alongside people. | Dictates the fundamental role: dedicated workhorse vs. flexible assistant. |

| Safety Standard & Setup | ISO 10218-1/2. Requires a risk assessment and comprehensive safeguarding (fencing, interlocks) to separate humans from the high-speed, high-force hazard. | ISO/TS 15066. Designed for inherent safety (power/force limiting). Can operate with minimal or no guarding after a collaborative risk assessment. | Cobots enable faster, lower-cost integration into existing workflows without major floor reconfiguration. |

| Programming & Deployment | Complex, often requiring specialized robotics engineers and offline programming (OLP) software. Changes are time-intensive. | Simplified, typically using hand-guiding, drag-and-drop interfaces, or simple script coding. Operators can be trained quickly. | Cobots offer rapid ROI for small batches and frequent changeovers. Traditional robots require more upfront engineering for long-term, fixed processes. |

| Payload & Reach | High (10kg to 1000kg+). Large reach (often >2m). Ideal for heavy parts like engine blocks or large fixtures. | Low to Medium (typically 3kg to 20kg). Smaller reach. Suited for small to medium-sized machined components, tools, and instruments. | Limits application scope. A cobot cannot handle a large titanium billet, while a traditional robot is overkill for inserting small pins. |

| Speed & Cycle Time | Very High. Optimized for the fastest possible cycle times to maximize throughput. | Moderate, Safety-Limited. Speed is inherently restricted by collision force monitoring to ensure human safety. | Traditional robots are superior for high-volume part production where seconds per cycle are critical. |

| Accuracy & Repeatability | Extremely High (e.g., ±0.02mm). Built for precision tasks like arc welding or precise dispensing. | Good (e.g., ±0.03mm to ±0.1mm). Sufficient for many pick-and-place, machine tending, and assembly tasks common in job shops. | For ultra-high-precision placement beyond standard machining tolerances, a traditional robot may be necessary. |

| Integration Flexibility | Low. Once installed in a caged cell, repurposing is a major project. | Very High. Often mobile (on wheeled bases), easily moved between machines or tasks—ideal for a job shop’s changing needs. | Cobots act as a shared resource, automating a lathe in the morning and a deburring station in the afternoon. |

| Typical Cell Cost | High (Robot + expensive safeguarding + extensive engineering + integration). | Lower (Robot + minimal safeguarding + simpler, faster integration). | Lower upfront cost and faster deployment make cobots accessible to small and medium-sized enterprises (SMEs). |

Chapter 3: The CNC Machining Applications Lens

The “best” choice is entirely application-dependent. Here’s how each technology fits into common CNC workflows.

3.1 Machine Tending: The Core Application

-

Traditional Robot Cell: A heavy-duty robot on a linear rail tending 3-4 CNC machines in a high-volume production line. It runs 24/7 with blazing speed, handling heavy steel forgings or large aluminum castings with unwavering precision. The cell is a dedicated, locked-down island of automation.

-

Cobot Cell: A single cobot on a mobile cart deployed to tend a 3-axis vertical machining center (VMC) during lights-out shifts. It handles a family of smaller, lighter aluminum brackets. By day, the same cobot is moved to assist with final assembly or packaging. It is a flexible tool that augments existing operations.

3.2 Post-Process Operations: Finishing, Inspection, and Assembly

-

Traditional Robot: Performing consistent, high-quality plasma coating on turbine blades or repetitive spot welding on fabricated assemblies. The process demands high repeatability and operates in a hazardous environment best isolated from people.

-

Cobot: A machinist hand-guides a cobot to teach a complex deburring path on a one-off prototype. The cobot then replicates the path perfectly for the remaining parts in the batch. Another cobot, equipped with a vision camera, performs final quality inspection of machined features, working next to a quality technician.

3.3 The Critical Role of Precision Tooling

Regardless of the robot type, its effectiveness is gated by the End-of-Arm Tooling (EOAT). A cobot’s payload advantage is lost with a poorly designed, heavy gripper. The fixture that presents the part to the robot must be rock-solid to avoid vibration. This is where JLYPT’s expertise is pivotal. We design and machine:

-

Lightweight, stiff gripper jaws from aluminum to maximize a cobot’s usable payload.

-

Precision mounting plates and tool changers that ensure repeatable tool positioning.

-

Custom workholding fixtures that interface perfectly with both the robot and the CNC machine, ensuring part location accuracy is maintained throughout the automated cycle.

Chapter 4: The Decision Framework: How to Choose for Your Shop

Selecting between a cobot and a traditional robot is a strategic process. Answering these key questions will guide you to the correct solution.

Step 1: Analyze Your Production Profile

-

Volume & Mix: Is your production High-Volume/Low-Mix or High-Mix/Low-Volume?

-

Part Characteristics: What is the weight, size, and material of your typical workpiece?

-

Process Stability: Is the task and part design fixed for years, or does it change weekly?

Step 2: Evaluate Technical & Spatial Constraints

-

Floor Space: Do you have room for a large, permanently caged cell, or do you need a solution that shares existing floor space?

-

Cycle Time Requirement: Is shaving seconds off the cycle critical to your business case, or is achieving any unmanned production a win?

-

In-House Skills: Do you have robotics engineers, or will your CNC programmers and machinists need to set up and maintain the system?

Step 3: Calculate Total Cost of Ownership (TCO) & Strategic Value

Look beyond the robot’s sticker price.

-

Traditional Robot TCO: High robot cost + very high integration/safeguarding cost + specialized programmer cost.

-

Cobot TCO: Moderate robot cost + low integration cost + existing operator training cost.

-

Strategic Value: Does the solution provide flexibility to adapt to future work? Does it empower your team or create a new dependency?

Table 2: Decision Matrix for CNC Machining Automation

| Your Primary Driver | Recommended Solution | Rationale |

|---|---|---|

| Maximizing throughput on a dedicated, high-volume part line. | Traditional Industrial Robot | Unmatched speed and durability for 24/7 operation justify the high upfront cell cost. |

| Automating high-mix, low-volume production with frequent changeovers. | Collaborative Robot (Cobot) | Low redeployment time and easy programming make automation of small batches economical. |

| Achieving lights-out machining on existing machines with minimal floor disruption. | Collaborative Robot (Cobot) on mobile base | Can be deployed at the end of a day shift and easily integrated without rebuilding the shop floor. |

| Handling very heavy (>20kg) raw materials or large finished parts. | Traditional Industrial Robot | Cobots lack the necessary payload and reach for heavy-duty material handling. |

| Seeking a first automation step with limited capital and in-house robotics expertise. | Collaborative Robot (Cobot) | Lower risk, faster ROI, and a gentler learning curve for the workforce. |

| Performing a hazardous process (e.g., extensive grinding, toxic material handling). | Traditional Industrial Robot in sealed cell | Complete isolation of the hazard is paramount and best achieved with a fully guarded traditional system. |

Chapter 5: Real-World Case Studies

Case Study 1: Aerospace Job Shop – Cobot for Flexible Inspection & Re-work

-

Challenge: A shop machining complex aluminum aerospace fittings needed to perform a 100% visual and probe inspection on hundreds of low-volume part numbers. Manual inspection was a bottleneck, and dedicating a CMM was inefficient.

-

Solution: They deployed a Universal Robots UR10 cobot on a mobile cart, equipped with a dual EOAT: a touch probe and a high-resolution camera. Machinists would hand-guide the cobot to teach inspection points for a new part in minutes. The cobot would then autonomously inspect subsequent parts, logging data directly to the job traveler.

-

Outcome: Inspection throughput increased by 300%. The same cobot was also used to guide a small spindle for localized re-work when the probe detected an out-of-tolerance feature, closing the quality loop instantly.

Case Study 2: Automotive Supplier – Traditional Robots for High-Speed Machining Cell

-

Challenge: A Tier 1 supplier needed to produce millions of transmission valve bodies annually. The process involved machining on both sides, requiring unloading, flipping, and reloading into a second CNC machine with extreme speed.

-

Solution: A fully integrated cell using two Fanuc M-20iB traditional robots on linear tracks was installed. They operated within a fully guarded, safety-rated cell. The robots used custom, heavy-duty grippers to handle the raw castings and finished parts at cycle times impossible for a human or cobot.

-

Outcome: The cell achieved >95% uptime, running three shifts. It eliminated several manual stations, reduced labor costs, and provided the consistent, high-volume output required by the automotive OEM.

Case Study 3: Medical Device Manufacturer – Hybrid Collaboration for Assembly

-

Challenge: Assembling a surgical device required the delicate placement of a CNC-machined titanium component into a plastic housing, followed by the application of adhesive—a task requiring dexterity and consistency.

-

Solution: A Techman Robot TM cobot was stationed at an assembly workstation. A human operator would perform the initial complex alignment. The cobot, using integrated vision, would then take over to hold the part perfectly steady and apply a precise bead of adhesive from a dispensing tool on its other arm.

-

Outcome: This human-robot collaboration combined human judgment for complex tasks with robotic steadiness and consistency for repetitive sub-tasks. Yield improved, ergonomic strain on the operator was reduced, and the process was fully documented by the cobot’s controller.

Conclusion: Complementary Forces, Not Competitors

The debate of cobots vs traditional robots is not about finding a universal winner. It is about matching the right tool to the specific job, economic model, and strategic vision of a manufacturing business. They are complementary technologies that address different segments of the automation spectrum.

Traditional industrial robots remain the undisputed champions of raw power, speed, and precision in structured, high-volume environments. Collaborative robots have democratized automation, bringing its benefits to applications where flexibility, ease of use, and human partnership are paramount.

For the forward-thinking machine shop, the most powerful strategy may involve both. A shop might use traditional robots in a dedicated “lights-out” cell for its highest-volume product lines, while deploying a fleet of mobile cobots to handle everything else—from machine tending and inspection to packaging and kitting. This hybrid approach builds a resilient, adaptable, and highly competitive manufacturing operation ready for the challenges of Industry 4.0 and beyond.

Ready to navigate your automation journey? The first step is a clear analysis of your needs. Contact JLYPT today to discuss how our expertise in precision component manufacturing for both cobot and traditional robot systems can help you build a reliable, high-performance automated future.

Internal Link: Discover how precision-machined components form the critical link in any robotic system at JLYPT CNC Machining Services.