Sealed for Success: Engineering Dust-Proof Robotic Grippers for Demanding Industrial Applications

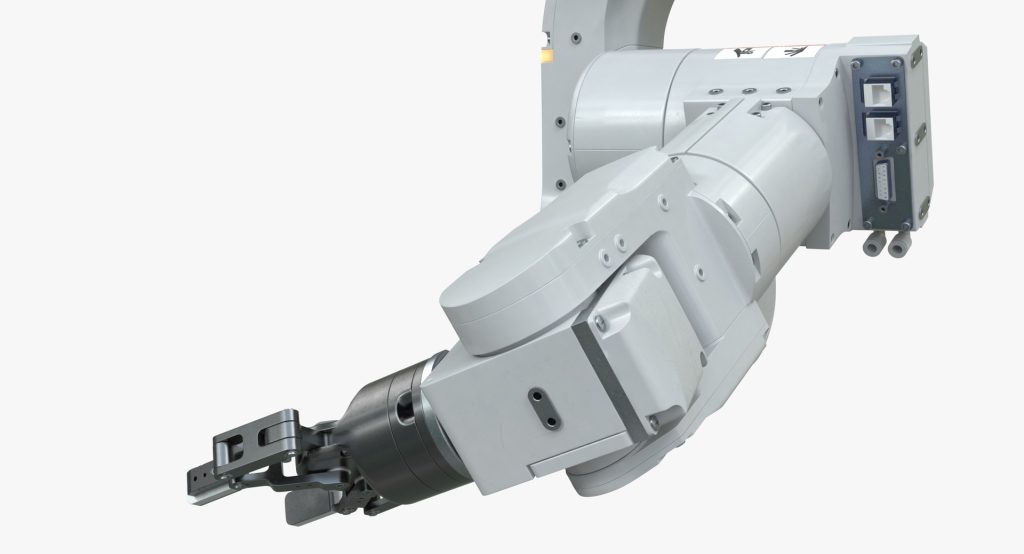

In modern industrial automation, environmental contamination represents one of the most significant challenges to robotic system reliability. Dust-proof robotic gripper technology has emerged as a critical engineering discipline, addressing the fundamental need for reliable manipulation in environments where particulate contamination threatens both equipment longevity and process integrity. At JLYPT, our specialized expertise in designing and manufacturing dust-proof robotic gripper systems combines precision mechanical engineering with advanced sealing technologies to deliver solutions that maintain operational reliability in the most challenging industrial environments.

The Contamination Challenge: Understanding Industrial Particulate Threats

Industrial environments present diverse contamination challenges that demand sophisticated dust-proof robotic gripper solutions:

Particulate Classification and Behavior

Understanding particulate characteristics is essential for effective dust-proof robotic gripper design:

-

Particle Size Distribution: Industrial particulates range from coarse abrasives (>100μm) to fine powders (<10μm), with penetration risk following Stokes’ Law for particle dynamics:

v_t = (ρ_p - ρ_f) * d^2 * g / (18 * μ)

Where v_t is terminal velocity, ρ is density, d is particle diameter, g is gravity, and μ is fluid viscosity -

Triboelectric Charging: Many industrial powders acquire electrostatic charges exceeding 5 kV, requiring specialized grounding strategies in dust-proof robotic gripper designs to prevent adhesion and discharge risks

-

Abrasive Properties: Mohs hardness scale considerations for particulate materials, from talc (1) to silicon carbide (9), dictate wear resistance requirements for exposed surfaces

Environmental Standards and Protection Ratings

Dust-proof robotic gripper systems must comply with international protection standards:

-

IP Code Requirements: IP5X and IP6X ratings for dust protection, with specific testing protocols:

-

IP5X: Limited dust ingress permitted, tested with talcum powder for 8 hours

-

IP6X: Complete dust protection, tested with vacuum differential of 20 mbar

-

-

NEMA Enclosure Standards: Type 3, 3R, 3S, 4, 4X, 5, 6, 6P, 12, 12K, and 13 classifications for industrial environments

-

ATEX/IECEx Considerations: For explosive dust atmospheres (Zones 20, 21, 22), requiring specialized dust-proof robotic gripper designs with temperature class ratings and ignition protection

Advanced Sealing System Engineering

The effectiveness of dust-proof robotic gripper systems depends on sophisticated sealing technologies:

Dynamic Seal Solutions

-

Lip Seal Configurations: Spring-energized PTFE seals maintaining contact pressure >0.3 MPa across temperature ranges -40°C to 200°C

-

Labyrinth Seal Designs: Non-contact multiple-baffle systems creating pressure drops exceeding 50 Pa per stage

-

Magnetic Fluid Seals: Ferrofluidic barriers providing zero-leakage protection for rotational interfaces in dust-proof robotic gripper systems

Static Seal Applications

-

Compression Gasket Systems: Elastomeric or metallic gaskets with compression deflection characteristics optimized for housing interfaces

-

Welded Enclosures: Hermetic sealing using laser or electron beam welding achieving leak rates <10⁻⁹ mbar·L/s

-

Adhesive Bonding: Structural adhesives with continuous bead application ensuring 100% perimeter sealing

Breather and Ventilation Systems

-

Membrane Breathers: ePTFE membranes with pore sizes 0.2-10μm allowing pressure equalization while blocking particulates

-

Desiccant Cartridges: Silica gel or molecular sieve systems maintaining internal humidity <10% RH

-

Positive Pressure Systems: Clean air purge maintaining 5-20 Pa overpressure within dust-proof robotic gripper enclosures

Material Selection for Contaminated Environments

The performance of dust-proof robotic gripper components depends on strategic material selection:

Wear-Resistant Surface Technologies

-

Hard Coat Anodizing: Type III anodizing achieving surface hardness >500 HV on aluminum components

-

Electroless Nickel Coatings: Ni-P or Ni-B coatings with hardness up to 1,200 HV and uniform deposition in complex geometries

-

Thermal Spray Coatings: WC-Co or Cr₃C₂-NiCr coatings providing exceptional abrasion resistance in dust-proof robotic gripper applications

Structural Material Optimization

-

Aluminum Alloys: 6061-T6 and 7075-T6 for optimal strength-to-weight ratio with good corrosion resistance

-

Stainless Steels: 316L or 17-4PH for enhanced corrosion resistance in humid or chemical environments

-

Engineering Polymers: PEEK, PPS, and PVDF for components requiring chemical resistance and low friction

Surface Energy Management

-

Hydrophobic Treatments: Surface modifications achieving water contact angles >120° to prevent particulate adhesion

-

Anti-static Coatings: Surface resistivities of 10⁶-10⁹ Ω/sq to prevent dust accumulation through electrostatic attraction

-

Easy-Clean Surfaces: Micro-textured or low-energy surfaces facilitating contaminant removal during maintenance cycles

Precision Manufacturing and Quality Assurance

JLYPT’s manufacturing approach ensures the reliability of dust-proof robotic gripper systems:

CNC Machining for Sealing Integrity

-

Surface Finish Optimization: Critical sealing surfaces machined to Ra 0.4-0.8μm with controlled waviness (Wt < 0.5μm)

-

Geometric Tolerance Control: Flatness < 0.01mm/100mm and perpendicularity < 0.005mm for sealing interfaces

-

Deformation Management: Stress-relief annealing and balanced machining strategies preventing distortion in thin-walled sections

Assembly and Testing Protocols

-

Cleanroom Assembly: Class ISO 7 (10,000) cleanroom conditions for critical dust-proof robotic gripper assembly

-

Leak Testing: Helium mass spectrometry testing achieving sensitivity to 5×10⁻⁹ mbar·L/s

-

Environmental Cycling: Thermal cycling from -40°C to 85°C with humidity exposure to verify seal integrity

Technical Performance Specifications

Table 1: Dust-Proof Robotic Gripper Performance Classification

| Performance Parameter | IP54 Protected | IP65 Sealed | IP67 Submersible | IP69K High-Pressure |

|---|---|---|---|---|

| Dust Protection | Limited ingress | No ingress | No ingress | No ingress |

| Water Protection | Splash resistant | Low pressure jets | Immersion to 1m | High pressure/temp |

| Operating Temp | -20°C to 60°C | -30°C to 70°C | -40°C to 80°C | -40°C to 85°C |

| Seal Life | 1-2 million cycles | 3-5 million cycles | 5-8 million cycles | 2-4 million cycles |

| Max Particle Size | >50μm excluded | >1μm excluded | All particles excluded | All particles excluded |

| Pressure Differential | N/A | N/A | 0.1 bar for 30 min | 100 bar at 80°C |

| Material Compatibility | Standard industrial | Chemical resistant | Full chemical resistant | Steam cleaning safe |

| Maintenance Interval | 500-1,000 hours | 2,000-3,000 hours | 5,000+ hours | 1,000-2,000 hours |

| Weight Penalty | 5-15% | 15-30% | 25-40% | 20-35% |

| Typical Applications | General manufacturing | Food processing | Pharmaceutical | Automotive washdown |

Actuation System Protection

The internal mechanisms of dust-proof robotic gripper systems require specialized protection:

Pneumatic System Sealing

-

Rod Seal Designs: U-cup or double-acting piston seals with extrusion gaps < 0.1mm

-

Cylinder Tube Protection: Wiper seals with multiple scraping lips and particle exclusion chambers

-

Port Protection: 5μm filtration with automatic drainage for pneumatic supplies

Electric Actuator Protection

-

Motor Encapsulation: Potting compounds with thermal conductivity > 1.0 W/m·K

-

Bearing Isolation: Contact seals or magnetic fluid barriers for rotational elements

-

Connector Sealing: IP-rated connectors with double-sealing systems

Sensor Integration

-

Vision System Protection: Optical windows with hydrophobic coatings and air purge systems

-

Force Sensor Sealing: Strain gauge protection with hermetic sealing and moisture barriers

-

Position Feedback: Encoder systems with redundant sealing at rotational interfaces

Case Study Applications

Case Study 1: Pharmaceutical Powder Handling

-

Challenge: A pharmaceutical manufacturer required robotic handling of active pharmaceutical ingredients (APIs) with particle sizes < 10μm. Standard grippers experienced contamination issues and cross-contamination risks between batches.

-

Solution: JLYPT developed a dust-proof robotic gripper system with IP65 rating and laminar airflow purge system maintaining ISO 5 cleanroom conditions at the gripping interface. The design incorporated quick-change mechanisms with positive-displacement sealing during tool changes.

-

Result: Achieved 99.97% containment efficiency for particles > 0.3μm. The system enabled 6-sigma process capability in powder handling while reducing cleaning validation time by 70%.

Case Study 2: Carbon Fiber Composite Manufacturing

-

Challenge: An aerospace composites facility needed robotic handling of carbon fiber prepreg materials, where carbon dust (particles 1-100μm) caused electrical shorts and contamination in robotic systems.

-

Solution: We engineered a dust-proof robotic gripper with conductive materials (surface resistivity 10⁴ Ω/sq) and integrated ionization systems to neutralize static charges. The design included HEPA-filtered ventilation maintaining positive pressure within all moving assemblies.

-

Result: Eliminated electrical failures from carbon dust accumulation while achieving 12,000 hours MTBF in continuous operation. The solution maintained positioning accuracy of ±0.05mm despite aggressive particulate environment.

Case Study 3: Mineral Processing Automation

-

Challenge: A mining equipment manufacturer required robotic systems for abrasive mineral handling where silica dust (Mohs 7) caused rapid wear and lubrication contamination in standard grippers.

-

Solution: JLYPT designed a heavy-duty dust-proof robotic gripper featuring tungsten carbide-coated wear surfaces and multi-stage labyrinth seals. The lubrication system incorporated centrifugal particle separation and continuous filtration.

-

Result: Achieved 8,000-hour service intervals in highly abrasive environment, representing 400% improvement over previous solutions. Wear rates measured at < 0.01mm/1,000 hours on critical sealing surfaces.

Maintenance and Serviceability Considerations

Effective dust-proof robotic gripper designs must balance protection with maintainability:

Modular Seal Replacement

-

Cartridge Seal Designs: Pre-assembled seal modules allowing replacement without complete disassembly

-

Split Seal Technology: Radial seals installable without shaft disassembly

-

Quick-Change Interfaces: Sealed connectors and couplings facilitating component replacement

Condition Monitoring Integration

-

Pressure Differential Sensors: Monitoring filter loading and seal integrity

-

Particle Count Sensors: Real-time contamination monitoring within protected volumes

-

Seal Wear Detection: Vibration analysis and acoustic emission monitoring for incipient seal failure

Cleaning and Decontamination

-

Clean-in-Place Systems: Integrated spray nozzles and drainage for automated cleaning cycles

-

UV-C Sterilization: Internal germicidal irradiation for biological contamination control

-

Dry Ice Blasting: Non-abrasive cleaning capability for sensitive components

Future Technology Development

The evolution of dust-proof robotic gripper technology continues with emerging innovations:

Advanced Material Science

-

Self-Healing Elastomers: Polymers with reversible cross-linking restoring seal integrity after minor damage

-

Superhydrophobic Surfaces: Nanostructured surfaces with contact angles >150° preventing particulate adhesion

-

Adaptive Sealing Systems: Shape-memory alloys adjusting seal preload based on temperature and pressure

Intelligent Protection Systems

-

Predictive Filter Monitoring: IoT-enabled filter condition monitoring with remaining life prediction

-

Adaptive Purge Control: Dynamic adjustment of purge flow based on environmental sensor data

-

Autonomous Cleaning: Integrated cleaning cycles triggered by contamination level detection

Modular Protection Solutions

-

Field-Upgradable Sealing: Modular protection systems allowing in-field upgrade of protection levels

-

Condition-Based Sealing: Smart seals indicating replacement timing through visual or electronic indicators

-

Multi-Environment Adaptation: Grippers automatically adjusting protection strategies based on environmental sensing

Implementation Best Practices

Successful deployment of dust-proof robotic gripper systems requires comprehensive planning:

Design Integration Guidelines

-

Cable Management: Protected cable routing with continuous sealing through movement ranges

-

Thermal Management: Heat dissipation strategies accounting for insulation effects of sealing systems

-

Service Access: Maintenance access points with resealable interfaces for service operations

Environmental Assessment

-

Contamination Analysis: Detailed analysis of particulate characteristics including size, shape, hardness, and electrostatic properties

-

Environmental Cycling: Evaluation of temperature, humidity, and pressure variations affecting seal performance

-

Chemical Compatibility: Assessment of cleaning agents and process chemicals contacting dust-proof robotic gripper surfaces

Validation and Testing

-

Accelerated Life Testing: Combined environmental and mechanical cycling simulating years of operation

-

Field Testing: Controlled exposure to actual operating conditions with detailed performance monitoring

-

Certification Compliance: Third-party testing and certification for applicable protection standards

Conclusion: Engineering Reliability in Contaminated Environments

The design and manufacturing of advanced dust-proof robotic gripper systems represent a critical engineering discipline that directly impacts automation system reliability in challenging industrial environments. These sophisticated systems combine precision mechanical design with advanced sealing technologies to deliver exceptional performance where particulate contamination threatens both equipment longevity and process integrity.

At JLYPT, our comprehensive approach to dust-proof robotic gripper manufacturing encompasses everything from initial environmental analysis and material selection through precision machining, advanced sealing integration, and rigorous validation testing. Our expertise in contamination control engineering ensures that we deliver solutions that meet the most demanding application requirements while providing exceptional value through extended service life and reduced maintenance costs.

Ready to protect your automation investment with advanced dust-proof robotic gripper technology? Contact JLYPT today to discuss your specific environmental challenges with our engineering team. Our specialists will provide comprehensive technical support and custom manufacturing solutions tailored to your contamination control requirements and operational objectives.