8 Essential Manufacturing Techniques for Precision Gear for Robotics Applications

Introduction: The Critical Role of Precision in Robotic Systems

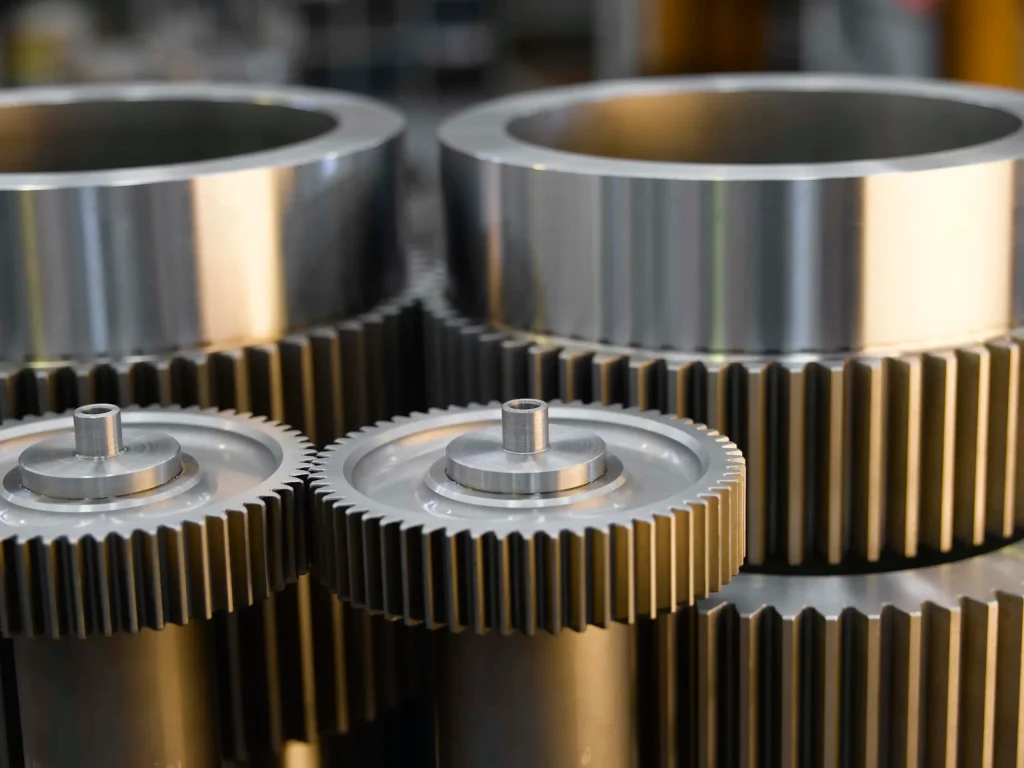

In the rapidly evolving world of industrial automation, the demand for exceptional accuracy and reliability has never been more pronounced. At the core of every high-performance robotic system lies a component that dictates its operational excellence: precision gear for robotics. These meticulously engineered components serve as the fundamental building blocks of motion control, directly influencing positioning accuracy, torque transmission, operational smoothness, and overall system reliability. The quality and precision of these gears often determine the difference between adequate performance and exceptional functionality in demanding automated environments.

As specialists in advanced CNC machining solutions, JLYPT has developed comprehensive expertise in manufacturing high-performance precision gear for robotics applications. This detailed technical examination explores eight critical manufacturing methodologies that transform raw materials into precision components capable of meeting the exacting requirements of modern robotic systems, while investigating the sophisticated engineering principles that ensure optimal performance in the most challenging operational scenarios.

1. Fundamental Requirements for Robotic Precision Gearing

1.1 Accuracy Classifications and Tolerance Standards

The manufacturing of precision gear for robotics demands adherence to internationally recognized accuracy standards that define performance expectations and quality requirements. Understanding these classifications is fundamental to specifying appropriate gear quality for different robotic applications.

AGMA Quality Classes:

-

AGMA 8-10: Commercial quality suitable for general industrial applications

-

AGMA 11-12: Precision quality for industrial robotics and automation

-

AGMA 13-15: High-precision quality for surgical robots and aerospace applications

-

AGMA 16-18: Ultra-precision quality for semiconductor manufacturing and metrology

ISO Accuracy Grades:

-

ISO 5-6: Standard precision for general machinery

-

ISO 3-4: High precision for industrial robotics

-

ISO 1-2: Ultra-precision for medical and optical positioning systems

For precision gear for robotics applications, typical requirements fall within AGMA 11-14 or ISO 3-4 classifications, with specialized applications demanding even tighter tolerances.

1.2 Critical Performance Parameters

The performance of precision gear for robotics is quantified through several key parameters that must be carefully controlled during manufacturing:

Positional Accuracy Metrics:

-

Backlash: Typically maintained below 5 arc-minutes for standard applications and under 1 arc-minute for high-precision applications

-

Torsional Stiffness: Ranging from 1-10 Nm/arc-minute depending on gear size and application requirements

-

Transmission Error: Maintained below 30 arc-seconds for smooth operation in precision positioning systems

Durability Requirements:

-

Surface Durability: Pitting resistance exceeding 10^7 cycles at rated load

-

Bending Strength: Safety factors of 2.0 or higher against tooth breakage

-

Wear Resistance: Maintained dimensional accuracy through specified service intervals

2. Advanced Material Selection Strategies

2.1 Material Properties and Application Matching

The selection of appropriate materials represents the foundation of manufacturing high-performance precision gear for robotics. Different robotic applications demand specific material characteristics to ensure optimal performance under varying operational conditions.

Comprehensive Material Selection Guide:

| Material Specification | Typical Applications | Tensile Strength (MPa) | Fatigue Limit (MPa) | Thermal Treatment |

|---|---|---|---|---|

| 16MnCr5 (Case Carburized) | High-load industrial robots | 1000-1200 | 500-600 | Carburizing & Hardening |

| 42CrMo4 (Through-Hardened) | General robotics applications | 900-1100 | 450-550 | Quench & Temper |

| 18CrNi8 (Deep Case) | Heavy-duty robotic systems | 1200-1400 | 600-700 | Carburizing & Tempering |

| Stainless 17-4PH | Medical & food robotics | 1000-1300 | 500-600 | Precipitation H900 |

| Aluminum 7075-T6 | Collaborative robots | 450-550 | 200-250 | T6 Heat Treatment |

| Ti-6Al-4V | Aerospace robotics | 900-1100 | 500-600 | Solution Treatment & Aging |

2.2 Advanced Alloy Development

Contemporary precision gear for robotics increasingly utilizes specialized alloys engineered for specific performance characteristics:

High-Performance Steel Alloys:

-

Vacuum Arc Remelted (VAR) Steel: Ultra-clean steel with minimal inclusions for enhanced fatigue performance

-

Electroslag Remelted (ESR) Steel: Superior homogeneity and improved mechanical properties

-

Nitriding Steels: Alloys specifically formulated for nitriding processes (e.g., 31CrMoV9)

Emerging Material Technologies:

-

Metal Matrix Composites: Aluminum and titanium composites with ceramic reinforcements

-

Nanostructured Alloys: Materials with controlled grain structures for enhanced strength

-

Self-Lubricating Composites: Materials with embedded solid lubricants for maintenance-free operation

3. CNC Machining Methodologies for Precision Gears

3.1 Advanced Gear Cutting Technologies

The manufacturing of precision gear for robotics requires sophisticated machining approaches that combine traditional gear manufacturing principles with modern CNC technology.

Multi-Axis CNC Gear Hobbing:

-

Simultaneous 5-Axis Control: Synchronized movement of hob and workpiece maintains optimal cutting geometry

-

Variable Hob Geometry: Specialized hob designs optimized for specific materials and gear geometries

-

Adaptive Cutting Parameters: Real-time adjustment of speed, feed, and depth of cut based on material conditions

-

Integrated Deburring: On-machine deburring eliminates secondary operations

Precision Gear Shaping:

-

CNC Profile Shaping: Computer-controlled cutting tools generate complex gear profiles

-

Internal Gear Manufacturing: Efficient production of internal gear geometries

-

Interrupted Cut Capability: Ability to machine gears with keyways and other features

Gear Grinding Technologies:

-

Continuous Generating Grinding: High-precision worm-shaped grinding wheels create perfect gear geometry

-

Profile Grinding: Precisely dressed grinding wheels replicate optimized tooth profiles

-

Creep Feed Grinding: High-depth, low-feed grinding for efficient material removal in hardened gears

3.2 Machining Parameters and Optimization

Optimal Cutting Parameters for Precision Gear for Robotics:

| Manufacturing Process | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Gear Hobbing (Soft) | 150-250 | 0.1-0.3 | 0.5-2.0 | 0.8-1.6 |

| Gear Shaping | 80-150 | 0.05-0.15 | 0.3-1.5 | 1.0-2.0 |

| Gear Grinding (Hard) | 25-35 | 0.5-2.0 | 0.02-0.1 | 0.2-0.4 |

| Honing | 30-60 | 0.1-0.5 | 0.005-0.02 | 0.1-0.2 |

| Superfinishing | 50-100 | 0.05-0.2 | 0.002-0.01 | 0.05-0.1 |

4. Heat Treatment and Surface Engineering

4.1 Precision Thermal Processing

The thermal processing of precision gear for robotics components requires exceptional control to achieve desired mechanical properties while minimizing distortion.

Carburizing Processes:

-

Atmosphere Control: Carbon potential maintained within ±0.03% for consistent case properties

-

Temperature Uniformity: Furnace temperature variation limited to ±5°C throughout the load

-

High-Pressure Gas Quenching: Uniform cooling with minimal distortion

-

Deep Cryogenic Treatment: -196°C processing converts residual austenite and enhances dimensional stability

Nitriding Technologies:

-

Plasma Nitriding: Precise control of case depth and compound layer thickness

-

Gas Nitriding: Consistent case properties for high-volume production

-

Low-Temperature Processes: Minimal distortion for precision components

4.2 Advanced Surface Engineering

Coating Technologies:

-

Physical Vapor Deposition (PVD): TiN, TiCN, and TiAlN coatings for enhanced wear resistance

-

Chemical Vapor Deposition (CVD): Diamond-like carbon coatings for reduced friction

-

Thermal Spray Coatings: Tungsten carbide coatings for extreme wear applications

Surface Integrity Optimization:

-

Compressive Residual Stresses: Shot peening and laser peening introduce beneficial surface stresses

-

Surface Texturing: Micro-dimples and patterns for improved lubrication retention

-

Superfinishing Processes: Mirror-like surfaces for reduced friction and wear

5. Quality Assurance and Metrology Systems

5.1 Comprehensive Inspection Protocols

The verification of precision gear for robotics components employs advanced measurement technologies and rigorous inspection protocols.

Gear Measurement Center Capabilities:

-

3D Tooth Geometry Analysis: Complete evaluation of profile, lead, and pitch characteristics

-

Surface Topography Measurement: Quantitative analysis of surface texture and finish

-

Automated Data Collection: Statistical process control with real-time data analysis

-

Temperature-Controlled Environment: Measurement accuracy maintained through environmental control

Coordinate Measuring Machine Applications:

-

Gear Blank Verification: Pre-machining validation of critical dimensions

-

Feature Relationship Analysis: Positional accuracy of mounting features

-

Assembly Validation: Verification of component relationships in assembled systems

5.2 Performance Validation Testing

Functional Testing Protocols:

-

Efficiency Testing: Input-output power measurement across operating range

-

Noise and Vibration Analysis: Quantitative assessment of acoustic performance

-

Durability Testing: Accelerated life testing under controlled conditions

-

Environmental Testing: Performance validation across temperature and humidity ranges

Advanced Metrology Techniques:

-

White Light Interferometry: Non-contact surface topography measurement

-

X-ray Diffraction: Residual stress measurement in surface layers

-

Scanning Electron Microscopy: Microstructural analysis of material conditions

6. Design Optimization Strategies

6.1 Micro-Geometry Modifications

Strategic modifications to gear tooth geometry optimize the performance of precision gear for robotics components:

Profile Modifications:

-

Tip and Root Relief: Controlled material removal prevents interference and reduces stress concentration

-

Profile Crowning: Compensates for misalignment and bending under load

-

Pressure Angle Optimization: Custom pressure angles for specific loading conditions

Lead Modifications:

-

Lead Crowning: Barrel-shaped tooth profile accommodates misalignments

-

End Relief: Tapered tooth ends compensate for bending under load

-

Bias Modification: Asymmetric corrections for specific loading patterns

6.2 Advanced Engineering Analysis

Modern design of precision gear for robotics incorporates sophisticated analysis tools:

Finite Element Analysis:

-

Tooth Contact Analysis: Simulation of contact patterns under load

-

Stress Distribution Mapping: Identification of stress concentrations

-

Thermal Analysis: Prediction of operating temperatures and thermal expansion

-

Dynamic Analysis: Vibration and natural frequency calculation

Performance Simulation:

-

Efficiency Modeling: Prediction of power losses across operating range

-

Durability Forecasting: Service life estimation based on application conditions

-

Noise Prediction: Acoustic performance simulation during design phase

7. Application Case Studies

Case Study 1: High-Speed Delta Robot for Packaging

Challenge: A packaging automation company required high-speed gearing for delta robots operating at 300 cycles per minute with positioning accuracy of ±0.1mm. The existing gear systems experienced premature wear and excessive backlash after 2,000 hours.

JLYPT Solution: We developed custom precision gear for robotics using 16MnCr5 steel with case carburizing to 60 HRC surface hardness. The manufacturing process incorporated multi-axis CNC hobbing followed by precision grinding to achieve AGMA 13 accuracy. Strategic profile modifications optimized tooth contact under high acceleration conditions.

Results:

-

Achieved positioning accuracy of ±0.08mm at operating speeds

-

Extended service life to 12,000 hours between maintenance

-

Reduced backlash to less than 1 arc-minute throughout service life

-

Increased operational speed to 350 cycles per minute

Case Study 2: Surgical Robotic System

Challenge: A medical device manufacturer needed ultra-precision gearing for surgical robot joints with zero detectable backlash and smooth operation at very low speeds. The application demanded compatibility with sterilization protocols and exceptional reliability.

JLYPT Solution: Our engineering team designed precision gear for robotics components using stainless 17-4PH with precipitation hardening to H900 condition. The manufacturing process emphasized geometric accuracy with tooth-to-tooth pitch errors maintained below 2 microns. Special surface treatments ensured biocompatibility and corrosion resistance.

Results:

-

Achieved positional accuracy of ±10 arc-seconds

-

Maintained zero backlash through 5,000 sterilization cycles

-

Met all medical device regulatory requirements

-

Enabled smoother motion control for precise surgical manipulations

Case Study 3: Automotive Welding Robot

Challenge: An automotive manufacturer required heavy-duty gearing for spot welding robots handling payloads of 150kg with frequent start-stop cycles and high shock loads. The existing systems experienced tooth breakage and excessive wear.

JLYPT Solution: We implemented robust precision gear for robotics using 18CrNi8 steel with deep case carburizing to 62 HRC. The design incorporated increased face width and optimized pressure angles for higher impact resistance. Precision grinding after heat treatment maintained geometric accuracy while achieving compressive residual stresses.

Results:

-

Achieved shock load capacity of 500% rated torque

-

Maintained performance through 15,000 hours of continuous operation

-

Reduced maintenance downtime by 65%

-

Improved positioning repeatability for consistent weld quality

8. Future Trends and Innovations

8.1 Emerging Manufacturing Technologies

The evolution of precision gear for robotics manufacturing continues with several promising technological directions:

Additive Manufacturing Integration:

-

Hybrid Manufacturing: Combining laser powder bed fusion with precision machining

-

Conformal Cooling Channels: Internal cooling passages for thermal management

-

Customized Lattice Structures: Weight-optimized designs with maintained stiffness

Digital Manufacturing Advances:

-

Artificial Intelligence Optimization: Machine learning algorithms for process optimization

-

Digital Twin Technology: Virtual manufacturing and performance simulation

-

Industrial Internet of Things: Real-time monitoring and adaptive control

8.2 Advanced Material Development

Next-Generation Materials:

-

Nanostructured Alloys: Materials with controlled grain structures for enhanced performance

-

Functionally Graded Materials: Gradual transition of material properties within components

-

Smart Materials: Components with embedded sensing and adaptive capabilities

Sustainable Manufacturing:

-

Green Manufacturing Processes: Reduced environmental impact through optimized processes

-

Recyclable Material Systems: Closed-loop material usage and recycling

-

Energy-Efficient Manufacturing: Reduced energy consumption through process optimization

Conclusion: The Path to Robotic Excellence Through Precision Gearing

Precision gear for robotics represents the culmination of advanced manufacturing technologies, materials science, and engineering excellence. The eight manufacturing techniques explored—advanced material selection, precision CNC machining, optimized heat treatment, surface engineering, comprehensive quality assurance, design optimization, application-specific engineering, and future innovation—demonstrate the sophisticated approach required to produce components that meet the exacting demands of modern robotic systems.

As robotic technology continues to advance, the requirements for precision gear for robotics will become increasingly demanding, driving further innovation in manufacturing technologies and material science. The integration of digital technologies, advanced analytics, and sustainable manufacturing practices will ensure that precision gearing remains at the forefront of robotic innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every precision gear for robotics component we produce meets the highest standards of accuracy, reliability, and performance. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of performance and capability in their robotic systems.

For engineering teams seeking to enhance their robotic systems through superior gearing solutions, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.