Introduction

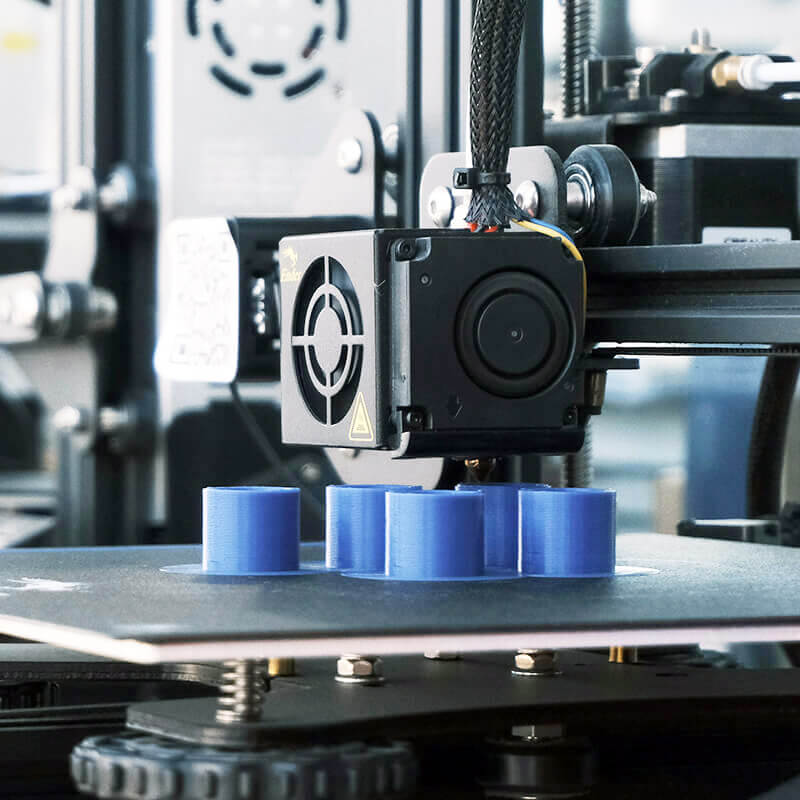

Fused Deposition Modeling (FDM) has quietly evolved from hobbyist curiosity to factory-floor workhorse. Modern gantry systems reach 400 °C, extrude carbon-filled nylons, and hold ±0.1 mm tolerances—rivaling aluminum machining on geometries that would require five-axis work. At JLYPT we operate 140 industrial FDM cells, including 8 large-format Modix BIG-120X units. This guide walks you through material science, design rules, cost drivers, and three recent case studies that saved clients over $120 k in tooling costs.

Fused Deposition Modeling (FDM) has quietly evolved from hobbyist curiosity to factory-floor workhorse. Modern gantry systems reach 400 °C, extrude carbon-filled nylons, and hold ±0.1 mm tolerances—rivaling aluminum machining on geometries that would require five-axis work. At JLYPT we operate 140 industrial FDM cells, including 8 large-format Modix BIG-120X units. This guide walks you through material science, design rules, cost drivers, and three recent case studies that saved clients over $120 k in tooling costs.

Table 1 — FDM Materials Overview (2025 Update)

| Grade | Tensile (MPa) | HDT (°C) | Impact (kJ/m²) | Key Features | Typical Uses |

|---|---|---|---|---|---|

| ABS-ESD Black | 42 | 95 | 28 | Static-dissipative | Electronics trays |

| PC-ABS FR | 60 | 110 | 45 | UL94 V-0 | Enclosures, drones |

| PETG-CF | 70 | 75 | 35 | Carbon-stiff | Structural brackets |

| Nylon 12 CF | 110 | 120 | 55 | Light-weight metal substitute | End-use arms |

| TPU 95 A | 35 | 60 | 90 | Fatigue-resistant | Shoe midsoles |

| PEEK | 100 | 250 | 85 | Autoclave sterilizable | Medical tooling |

Table 2 — Resolution vs. Build Speed vs. Cost

| Layer Height (mm) | XY Tolerance (±mm) | Speed (mm/s) | Relative Cost | Visual Finish | Best For |

|---|---|---|---|---|---|

| 0.40 | 0.20 | 120 | 1× | Ribbed | Fast draft |

| 0.25 | 0.15 | 80 | 1.3× | Visible layers | Functional test |

| 0.15 | 0.10 | 60 | 1.8× | Light texture | End-use housing |

| 0.10 | 0.08 | 40 | 2.5× | Near-injection | Display models |

| 0.05 | 0.05 | 25 | 4× | Ultra-smooth | Precision jigs |

Section 1 — Design Rules That Matter

1.1 Wall Thickness

• Standard 0.4 mm nozzle → 1.0 mm minimum wall (2 perimeters).

• Carbon-filled grades → 1.5 mm to hide fiber print-through.

• Standard 0.4 mm nozzle → 1.0 mm minimum wall (2 perimeters).

• Carbon-filled grades → 1.5 mm to hide fiber print-through.

1.2 Overhangs & Supports

• Rule of 45° still holds for ABS and PLA; PETG tolerates 55°.

• Use breakaway PLA supports for internal channels—dissolves in warm water.

• Rule of 45° still holds for ABS and PLA; PETG tolerates 55°.

• Use breakaway PLA supports for internal channels—dissolves in warm water.

1.3 Holes & Pins

• Vertical holes: design +0.2 mm Ø to compensate for polygon faceting.

• Horizontal holes: use tear-drop shape to avoid elliptical distortion.

• Vertical holes: design +0.2 mm Ø to compensate for polygon faceting.

• Horizontal holes: use tear-drop shape to avoid elliptical distortion.

1.4 Threads

• M3–M6: print undersized by 0.15 mm, chase with tap.

• For repetitive assembly, embed brass heat-set inserts at 200 °C.

• M3–M6: print undersized by 0.15 mm, chase with tap.

• For repetitive assembly, embed brass heat-set inserts at 200 °C.

Section 2 — Large-Format FDM: What Changes?

Our Modix BIG-120X offers 600 × 600 × 600 mm.

• Heated chamber 80 °C → eliminates ABS warping up to 400 mm length.

• 1.2 mm nozzle cuts print time 70 % on bulky housings.

• Downside: ±0.3 mm tolerance; compensate with machining allowance on critical faces.

• Heated chamber 80 °C → eliminates ABS warping up to 400 mm length.

• 1.2 mm nozzle cuts print time 70 % on bulky housings.

• Downside: ±0.3 mm tolerance; compensate with machining allowance on critical faces.

Table 3 — Cost Benchmark: FDM vs. Injection Molding (1,000 pcs)

| Metric | FDM (Nylon CF) | Injection Mold (PA66 GF30) |

|---|---|---|

| Tooling Cost | $0 | $18,000 |

| Part Cost | $8.50 | $1.30 |

| Lead Time | 5 days | 6 weeks |

| Design Change Cost | $0 | $2,000 |

| Break-even Volume | — | 2,500 pcs |

| Conclusion: FDM wins below 2,500 units or when design freeze is uncertain. |

Section 3 — Post-Processing & Quality Control

| Operation | Equipment | Tolerance Achieved | Typical Adder |

|---|---|---|---|

| CNC facing | Haas VF-2 | ±0.02 mm | $0.10 / cm² |

| Vapor smoothing | Stratasys Vantage | Ra 1.2 µm | $0.05 / cm² |

| Heat-staking inserts | Ultrasonic | ±0.05 mm | $0.03 / insert |

| Tapping threads | Robot arm | 6H fit | $0.08 / hole |

Every batch undergoes:

• First-article inspection with Keyence 3D scanner.

• In-process laser line sensor for layer adhesion faults.

• Final CMM report emailed to client.

• First-article inspection with Keyence 3D scanner.

• In-process laser line sensor for layer adhesion faults.

• Final CMM report emailed to client.

Section 4 — Case Studies

Case A — Automotive HVAC Duct

Client: Tier-1 EV supplier

Challenge: 380 mm long duct, 90 °C service, 200-piece pilot run.

Solution: Printed in PC-ABS FR on the BIG-120X, 0.25 mm layers. Split into two shells with tongue-and-groove joints, bonded with methylene chloride. CNC faced the flange interface to ±0.05 mm.

Result: Passed FMVSS 302 burn test; saved $38 k in aluminum tooling.

Client: Tier-1 EV supplier

Challenge: 380 mm long duct, 90 °C service, 200-piece pilot run.

Solution: Printed in PC-ABS FR on the BIG-120X, 0.25 mm layers. Split into two shells with tongue-and-groove joints, bonded with methylene chloride. CNC faced the flange interface to ±0.05 mm.

Result: Passed FMVSS 302 burn test; saved $38 k in aluminum tooling.

Case B — Wearable Medical Brace

Client: Health-tech start-up

Challenge: Custom lattice for breathability, TPU 95 A, 50 unique sizes.

Workflow:

Client: Health-tech start-up

Challenge: Custom lattice for breathability, TPU 95 A, 50 unique sizes.

Workflow:

-

Foot scan → Fusion 360 generative lattice.

-

0.20 mm layers, 100 % infill at load zones.

-

Dye-sublimated straps post-print.

Outcome: 48-hour turnaround per patient, 30 % lighter than traditional foam.

Case C — Food-Grade PETG Dispenser

Client: Beverage OEM

Challenge: Transparent hopper, 5 L volume, FDA contact.

Solution: Printed in crystal-clear PETG with 0.15 mm layers, vapor-polished interior. Threads chased to G 3/4 BSPP. Passed USP VI cytotoxicity.

Lead time: 10 days vs. 12-week injection mold.

Client: Beverage OEM

Challenge: Transparent hopper, 5 L volume, FDA contact.

Solution: Printed in crystal-clear PETG with 0.15 mm layers, vapor-polished interior. Threads chased to G 3/4 BSPP. Passed USP VI cytotoxicity.

Lead time: 10 days vs. 12-week injection mold.

Section 5 — Pricing & Lead Times

| Build Volume | Layer | ABS | PETG-CF | Nylon-CF | Rush (24 h) |

|---|---|---|---|---|---|

| < 100 cm³ | 0.15 mm | $0.06 / cm³ | $0.09 / cm³ | $0.12 / cm³ | +100 % |

| 100–1,000 cm³ | 0.20 mm | $0.05 / cm³ | $0.07 / cm³ | $0.10 / cm³ | +100 % |

| 1,000–10,000 cm³ | 0.30 mm | $0.04 / cm³ | $0.06 / cm³ | $0.08 / cm³ | +100 % |

| > 10,000 cm³ | Custom | Custom | Custom | Custom | Custom |

Prices include support removal, light sanding, and dimensional report.

Section 6 — Sustainability & Closed-Loop Grinding

• 92 % of support waste is pelletized into RePLA for non-critical jigs.

• Heated chambers run on solar thermal pre-heat, cutting kWh by 18 %.

• Take-back program shreds end-of-life parts into acoustic panels.

• Heated chambers run on solar thermal pre-heat, cutting kWh by 18 %.

• Take-back program shreds end-of-life parts into acoustic panels.

Section 7 — FAQ

Q: Can FDM achieve injection-mold surface?

A: Yes—vapor smoothing + 0.10 mm layers reach Ra 1 µm, suitable for consumer electronics.

A: Yes—vapor smoothing + 0.10 mm layers reach Ra 1 µm, suitable for consumer electronics.

Q: Maximum overhang without supports?

A: 55° for PETG, 45° for ABS. Bridging up to 50 mm at 25 mm/s.

A: 55° for PETG, 45° for ABS. Bridging up to 50 mm at 25 mm/s.

Q: Threaded brass inserts temperature?

A: 200 °C for ABS/PC, 180 °C for PLA to avoid deformation.

A: 200 °C for ABS/PC, 180 °C for PLA to avoid deformation.