High-Temperature Ceramic Coating for Engine Parts in CNC Machining

Introduction

In the automotive and aerospace industries, engine parts are subjected to extreme temperatures and harsh environments. To ensure optimal performance and longevity, these parts require robust and durable coatings that can withstand such conditions. High-temperature ceramic coatings are an ideal solution, offering exceptional thermal insulation, corrosion resistance, and wear protection. As a leading CNC machining service provider in China, Jlypt specializes in integrating high-temperature ceramic coatings for engine parts within the CNC machining process. This article explores the benefits, processes, and applications of high-temperature ceramic coatings for engine parts in the CNC machining domain.

Benefits of High-Temperature Ceramic Coatings for Engine Parts

1. Thermal Insulation

High-temperature ceramic coatings provide excellent thermal insulation, reducing heat transfer to critical components and protecting them from thermal stress and degradation.

2. Corrosion Resistance

These coatings offer superior corrosion resistance, shielding engine parts from corrosive agents present in fuels, lubricants, and exhaust gases.

3. Wear Protection

Ceramic coatings enhance the wear resistance of engine parts, prolonging their lifespan and reducing maintenance costs.

4. Lightweight and Strong

Ceramic materials are lightweight yet strong, contributing to improved fuel efficiency and overall engine performance.

Jlypt’s High-Temperature Ceramic Coating Services for Engine Parts

Services Offered

- Precision Application: Using advanced techniques to ensure uniform and defect-free coating application.

- Custom Coatings: Tailoring coating formulations to meet specific engine part requirements.

- Batch Processing: Efficient processing of multiple engine parts simultaneously.

- Quality Assurance: Rigorous testing and inspection to ensure coating integrity and performance.

Detailed Table of Services

| Service Type | Application | Characteristics | Example Image |

|---|---|---|---|

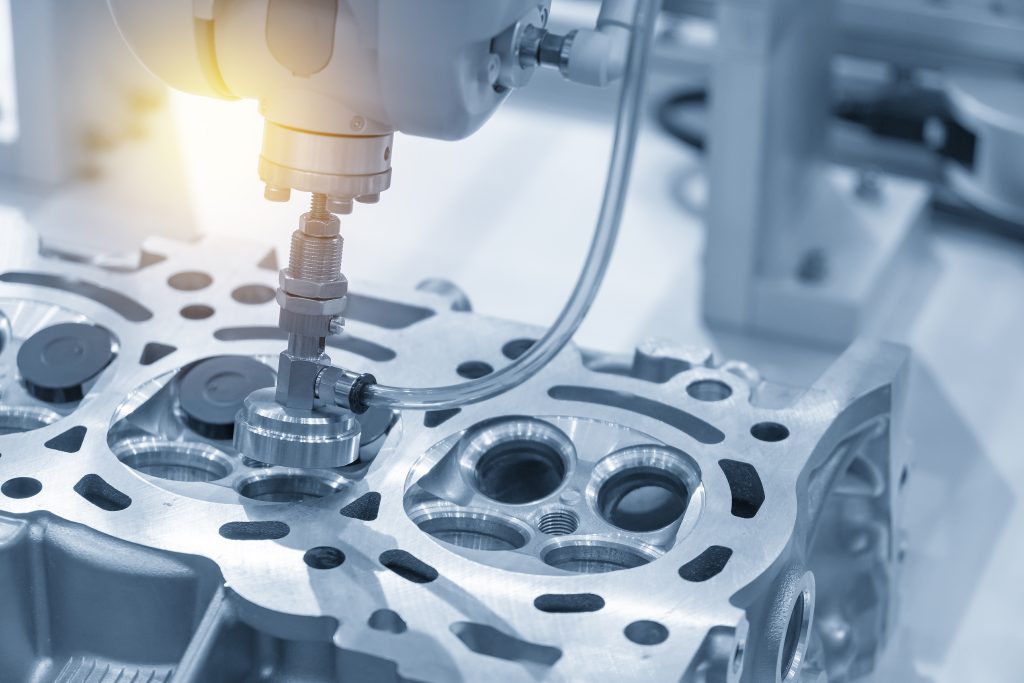

| Precision Application | Cylinder heads, piston crowns, valves | Uniform coating thickness; defect-free surface |  |

| Custom Coatings | Turbochargers, exhaust manifolds, gaskets | Tailored to specific material and operating conditions |  |

| Batch Processing | High-volume production of engine parts | Cost-effective; time-efficient |  |

| Quality Assurance | All coated engine parts | Rigorous testing; compliance with industry standards and customer specifications |  |

Case Studies

Case Study 1: Cylinder Heads and Piston Crowns

A performance automotive parts manufacturer approached Jlypt for high-temperature ceramic coating services for their cylinder heads and piston crowns. The manufacturer required a coating that could withstand extreme temperatures and reduce heat transfer, improving engine efficiency and reducing wear. Jlypt’s precision application technique ensured a uniform and defect-free coating, significantly enhancing the thermal insulation and wear resistance of the cylinder heads and piston crowns.

Case Study 2: Turbochargers and Exhaust Manifolds

An aerospace engine manufacturer sought Jlypt’s expertise for custom high-temperature ceramic coatings for their turbochargers and exhaust manifolds. These components needed to withstand temperatures exceeding 1000°C while maintaining corrosion resistance and mechanical strength. Jlypt developed a tailored coating formulation that met these demanding requirements, significantly extending the lifespan of the turbochargers and exhaust manifolds.

Case Study 3: Gaskets and Seals

A leading automotive OEM partnered with Jlypt for batch processing of high-temperature ceramic coatings on their gaskets and seals. The gaskets and seals were critical for sealing high-pressure and high-temperature fluids within the engine. Jlypt’s batch processing capabilities allowed for efficient and cost-effective coating application, ensuring consistent coating quality across all gaskets and seals. The coated gaskets and seals exhibited improved corrosion resistance and sealing performance, contributing to enhanced engine reliability.

Conclusion

High-temperature ceramic coatings are a vital component in ensuring the optimal performance and longevity of engine parts in automotive and aerospace applications. At Jlypt, we offer a wide range of high-temperature ceramic coating services specifically designed for engine parts within the CNC machining domain. Our expertise, combined with state-of-the-art equipment and skilled technicians, ensures that every engine part leaves our facility with a coating that meets or exceeds industry standards.

For more information or to request a quote, please visit our website at https://www.jlypt.com/anodizing-near-me-surface-finishing-services/ or contact us at [email protected]. We look forward to partnering with you on your next engine part coating project!