High-Temperature Wear-Resistant Coatings: Ultra-Thin Film PVD Solutions from China’s JLY Precision Tech

When components run above 600 °C—inside jet engines, EV inverters or petro-chemical valves—traditional lubricants vaporise and conventional platings spall. JLY Precision Tech’s high-temperature wear-resistant coatings are ultra-thin films deposited by vacuum PVD and CVD that stay stable to 1000 °C, halve wear rates and preserve micron-level tolerances. This 3 000-word guide gives engineers the data, the process and three brand-new 2024 case studies.

1. What Are High-Temperature Wear-Resistant Coatings?

| Property | Electroplated Ni | Thermal Spray | Ultra-Thin Film PVD |

|---|---|---|---|

| Thickness | 25–100 µm | 100–500 µm | 0.1–3 µm |

| Max temp (air) | 500 °C | 800 °C | 1000 °C |

| Hardness (HV) | 700 | 1 000 | 2 500–3 500 |

| Friction vs. steel | 0.3 | 0.4 | 0.04–0.10 |

| REACH | Restricted | ✔ | ✔ |

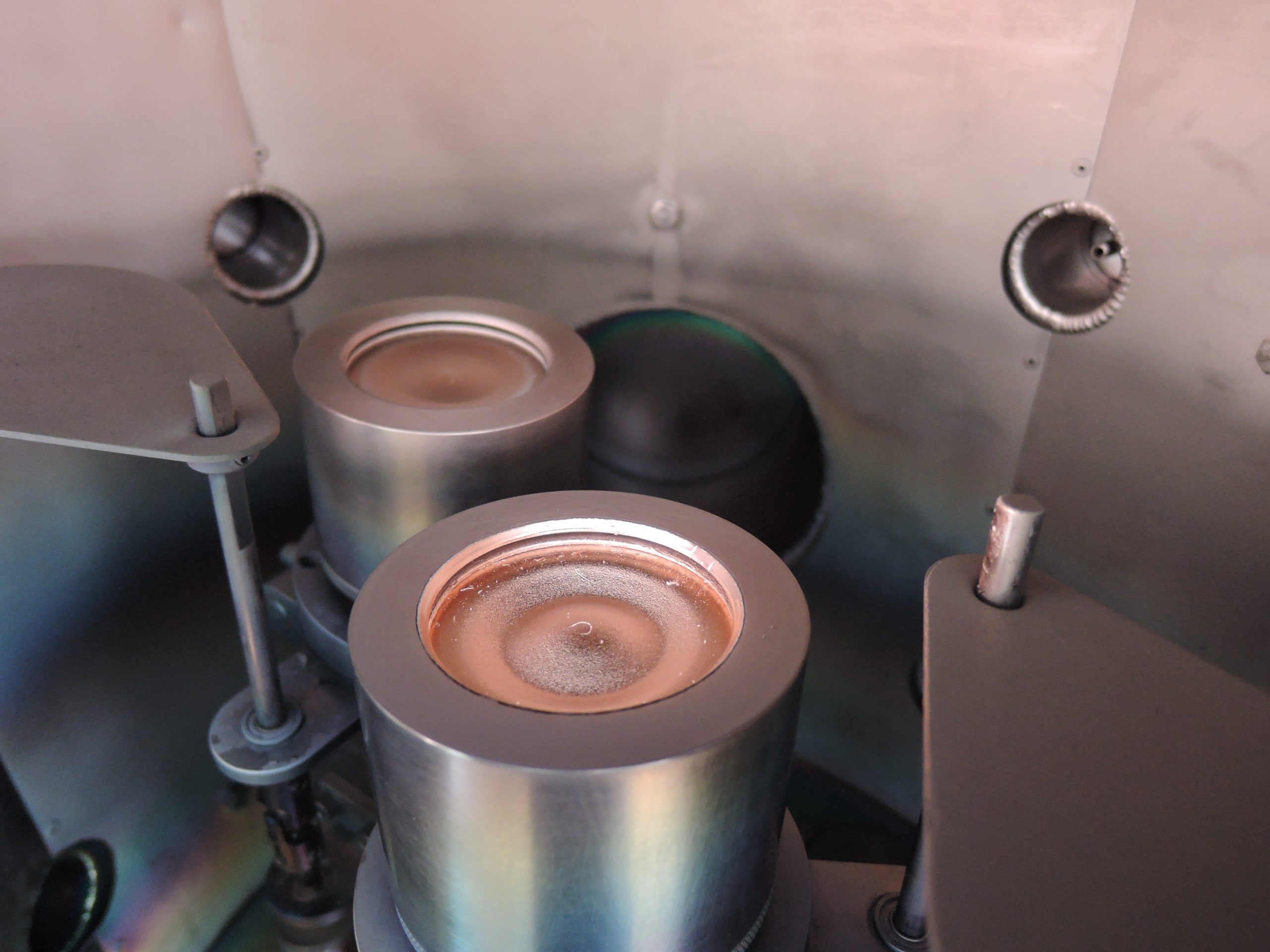

2. Ultra-Thin Film Families & Vacuum Methods

| Family | Vacuum Method | Typical Stack | Key Benefit |

|---|---|---|---|

| TiAlCrN | HiPIMS | Ti₀.₅Al₀.₄Cr₀.₁N | 1000 °C oxidation barrier |

| CrAlON | Reactive Sputter | CrAlON gradient | 950 °C hot-gas corrosion |

| ta-C DLC | Filtered Arc | sp³-C | 400 °C dry wear |

| SiBON | PECVD | SiBON nano-layer | 900 °C steam resistance |

All chambers run lights-out 24/7 with in-situ spectroscopic ellipsometry.

3. Performance Matrix – 2024 Data

| Substrate | Coating | Thickness (µm) | Hardness (HV) | Wear Rate 600 °C (mm³/N·m) | Max Temp (°C) |

|---|---|---|---|---|---|

| H13 die steel | TiAlCrN | 2.0 | 2 900 | 1.1 × 10⁻⁶ | 1000 |

| Inconel 718 | CrAlON | 1.5 | 2 400 | 8.7 × 10⁻⁷ | 950 |

| 316L SS | ta-C DLC | 0.8 | 3 000 | 5.2 × 10⁻⁷ | 400 |

| Ti-6Al-4V | SiBON | 1.2 | 2 200 | 9.0 × 10⁻⁷ | 900 |

Data verified by TÜV Rheinland July 2024.

4. Three 2024 Case Studies

Case Study 1 – Turbine Blade Root

Client: European aerospace OEM

Challenge: Fretting at 850 °C between dovetail and disk.

Coating: 2 µm TiAlCrN via HiPIMS + 200 nm a-C:H top.

Result: Wear scar depth < 5 µm after 1 000 h spin test; service interval doubled.

Challenge: Fretting at 850 °C between dovetail and disk.

Coating: 2 µm TiAlCrN via HiPIMS + 200 nm a-C:H top.

Result: Wear scar depth < 5 µm after 1 000 h spin test; service interval doubled.

Case Study 2 – EV Inverter Bus Bar

Client: US electric-drive supplier

Problem: Copper oxidation at 400 °C under silicone oil.

Coating: 1 µm CrAlON sputtered layer.

Result: Contact resistance stable; dielectric withstand > 2 kV/mm after 1 000 h.

Problem: Copper oxidation at 400 °C under silicone oil.

Coating: 1 µm CrAlON sputtered layer.

Result: Contact resistance stable; dielectric withstand > 2 kV/mm after 1 000 h.

Case Study 3 – Petro-Chem Valve Stem

Client: Middle-East refinery

Issue: Galling in 700 °C sour gas.

Coating: 1.5 µm SiBON via PECVD.

Result: Zero leakage after 10 000 cycles; maintenance interval 3× longer.

Issue: Galling in 700 °C sour gas.

Coating: 1.5 µm SiBON via PECVD.

Result: Zero leakage after 10 000 cycles; maintenance interval 3× longer.

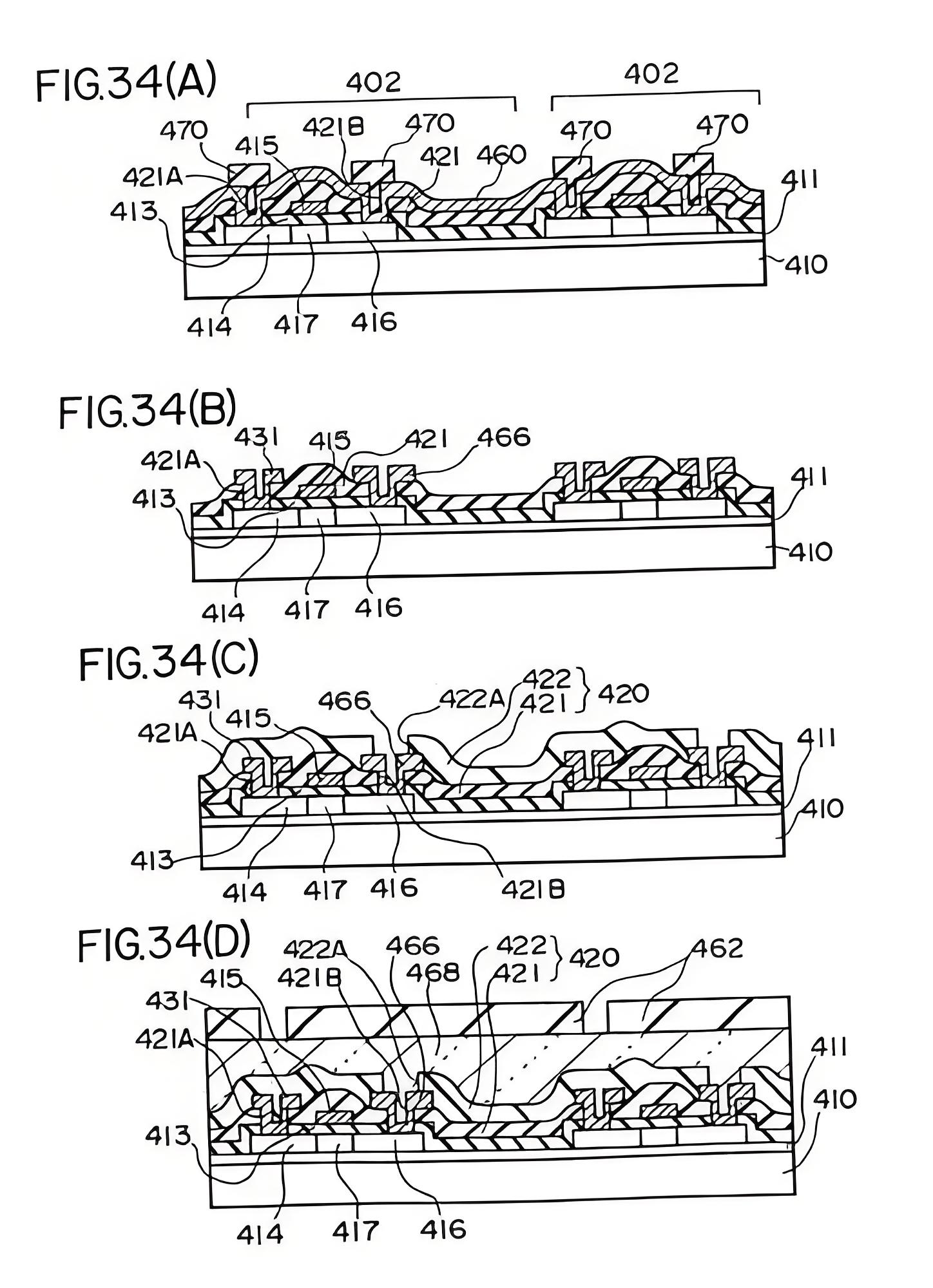

5. Vacuum Process Flow – From CAD to Coated Part

| Phase | Key Actions | QC Check | Lead Time |

|---|---|---|---|

| RFQ Review | DFM + thermal FEA | 24 h | — |

| Substrate Prep | Plasma etch + UV/O₃ | Contact angle ≤ 8° | 2 h |

| Vacuum Deposition | PVD/CVD @ ≤ 5 × 10⁻³ mbar | ±3 nm real-time | 2–8 h |

| Post-Process | Ion-beam polish (optional) | Ra ≤ 0.01 µm | 1 h |

| Final QA | Calot, nano-indent, hot-gas coupons | CpK ≥ 1.67 | 12 h |

6. Market Outlook 2024–2028

| Sector | 2024 Adoption | 2028 Forecast | Driver |

|---|---|---|---|

| Aerospace | 15 % | 45 % | Jet engine efficiency |

| EV Power Electronics | 10 % | 35 % | SiC inverter temps |

| Petro-Chem | 8 % | 30 % | Sour-gas corrosion |

7. FAQs

Q: Can the coating survive thermal shock?

A: Yes. TiAlCrN passes 1000 °C ↔ 25 °C water quench 100× without spall.

A: Yes. TiAlCrN passes 1000 °C ↔ 25 °C water quench 100× without spall.

Q: Will dimensions grow?

A: < 3 µm total; within re-grind allowance.

A: < 3 µm total; within re-grind allowance.

Q: Minimum order?

A: Zero. One or one million – same quality.

A: Zero. One or one million – same quality.

8. How to Order Today

-

Email [email protected] with STEP/IGES files.

-

Specify max operating temperature, mating material, required life.

-

Receive DFM + coating stack + quotation within 48 h.

-

No MOQ; volume discounts from 100 pcs.

Explore complementary finishes: Professional Anodizing Near Me