Power Transmission Revolution: Advanced High Torque Planetary Gearbox Technology for Heavy-Duty Robotic Systems

In the rapidly evolving landscape of industrial automation and heavy-duty robotics, the demand for reliable, high-performance power transmission systems has never been more critical. At the heart of these advanced mechanical systems lies the High Torque Planetary Gearbox – a sophisticated power transmission solution that combines compact design with exceptional torque capacity and operational efficiency. At JLYPT, our expertise in precision CNC machining has positioned us at the forefront of manufacturing these critical components, enabling us to deliver solutions that meet the exacting demands of modern heavy-duty robotic applications across various industries.

This comprehensive technical analysis examines the engineering principles, design considerations, and manufacturing methodologies that define high-performance High Torque Planetary Gearbox systems. We will explore the complete spectrum of planetary gearbox technology, from fundamental kinematic principles to advanced manufacturing techniques, providing engineers and manufacturers with detailed insights into optimizing power transmission systems for demanding applications.

Fundamental Principles of Planetary Gear Systems

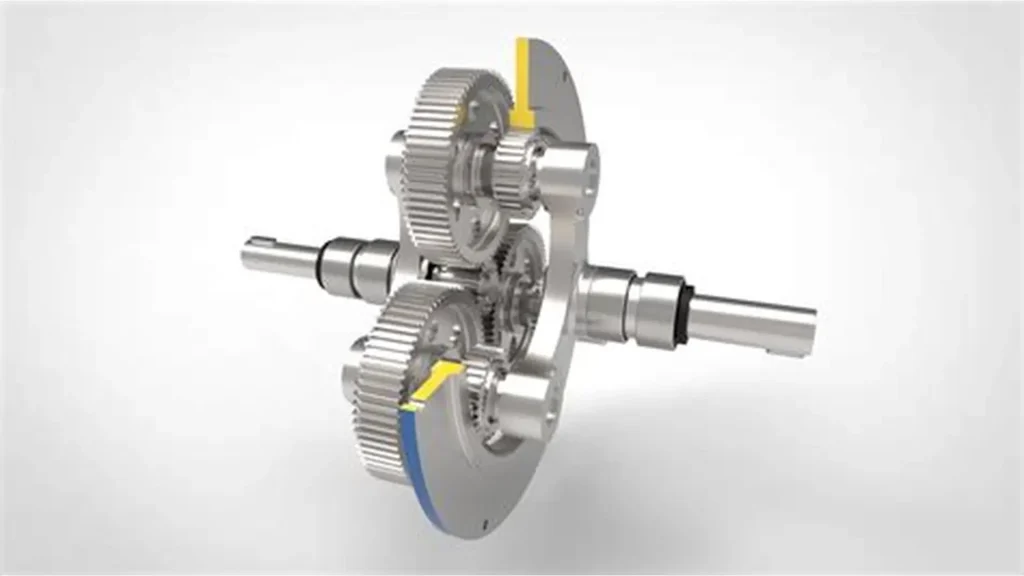

Understanding the core mechanical principles of planetary gear systems is essential for appreciating their advantages in high-torque applications. The High Torque Planetary Gearbox operates on well-established gearing principles but achieves exceptional performance through sophisticated engineering:

-

Epicyclic Gearing Kinematics: Planetary systems employ a central sun gear, multiple planet gears mounted on a carrier, and an outer ring gear. This configuration enables torque distribution across multiple gear meshes simultaneously, significantly increasing power density compared to conventional parallel-shaft arrangements.

-

Load Sharing Characteristics: The multi-planet design inherently distributes transmitted torque across several gear meshes, reducing individual tooth loads and enabling higher overall torque capacity within compact dimensions. Advanced systems typically incorporate 3 to 7 planet gears depending on torque requirements.

-

Compound Power Flow Paths: Planetary systems offer multiple configuration options including star, planetary, and solar arrangements, each providing distinct speed-torque relationships and efficiency characteristics suitable for specific application requirements.

-

Static and Dynamic Load Distribution: Sophisticated design methodologies ensure equal load sharing among planets through precision manufacturing of components and careful consideration of floating elements that compensate for manufacturing tolerances and operational deflections.

The practical implementation of these principles in High Torque Planetary Gearbox systems requires meticulous attention to geometric accuracy, material properties, and thermal management to achieve optimal performance and service life.

Advanced Design Engineering for Heavy-Duty Applications

The engineering of High Torque Planetary Gearbox systems for heavy-duty robotic applications involves multiple critical design considerations:

1. Tooth Profile Optimization

-

Advanced Involute Modifications: Modern gear designs incorporate profile shifting, tip relief, and lead crowning to optimize load distribution, reduce stress concentrations, and minimize noise generation under heavy loading conditions.

-

Contact Ratio Maximization: Design strategies focus on achieving high transverse and overlap contact ratios to ensure smooth power transmission and reduced individual tooth loading through multiple tooth engagement.

-

Surface Durability Enhancements: Advanced tooth flank modifications and surface treatments improve pitting resistance and wear characteristics, extending service life in high-cycle applications.

2. Bearing System Configuration

-

Multi-Bearing Support Arrangements: Heavy-duty applications employ complex bearing configurations including combined axial-radial bearings and preloaded angular contact bearings to manage high moment loads and thrust forces.

-

Bearing Life Optimization: Sophisticated calculation methods account for dynamic loading conditions, lubrication regimes, and environmental factors to achieve required L10 life specifications exceeding 20,000 hours.

-

Thermal Expansion Compensation: Bearing arrangements incorporate clearance adjustments and material selection to accommodate differential thermal expansion between components during operation.

3. Housing and Structural Design

-

Stiffness Optimization: Finite element analysis (FEA) techniques optimize housing geometry to maximize torsional and bending stiffness while minimizing weight and material usage.

-

Thermal Management Integration: Advanced designs incorporate cooling channels, heat dissipation fins, and thermal barrier technologies to manage heat generation from mechanical losses.

-

Sealing System Engineering: Multi-stage sealing arrangements employing labyrinth seals, lip seals, and magnetic fluid seals ensure contaminant exclusion and lubricant retention in harsh operating environments.

Manufacturing Excellence through Precision CNC Machining

The performance of High Torque Planetary Gearbox systems is fundamentally dependent on manufacturing precision and quality. At JLYPT, our CNC machining capabilities enable us to achieve the exacting tolerances required for high-performance gear systems:

Gear Manufacturing Processes:

-

Precision Gear Hobbing: Multi-axis CNC hobbing machines produce gear teeth with profile accuracy better than DIN 6 standards, ensuring optimal mesh characteristics and load distribution.

-

Profile Grinding Operations: Post-hardening grinding processes achieve surface finishes of Ra 0.4 μm or better, eliminating heat treatment distortions and ensuring precise tooth geometry.

-

Hard Finishing Technologies: Advanced processes including honing, skiving, and superfinishing further enhance surface characteristics and geometric accuracy for maximum durability and efficiency.

Component Machining Capabilities:

-

Multi-Axis Machining Centers: 5-axis CNC machining enables complete component processing in single setups, ensuring critical geometric relationships and minimizing cumulative tolerance stack-ups.

-

High-Speed Machining Strategies: Optimized tool paths and cutting parameters maintain dimensional stability while machining complex geometries in hardened materials up to 60 HRC.

-

Metrology and Quality Assurance: In-process monitoring and final inspection using coordinate measuring machines (CMM) and gear analyzers verify compliance with specifications exceeding AGMA 2000 standards.

Technical Comparison: Planetary Gearbox Performance Specifications

The following table provides a detailed technical comparison of planetary gearbox systems across different performance categories and application requirements.

Table 1: Comprehensive Planetary Gearbox Specification Matrix

| Technical Parameter | Standard Duty | High Torque | Ultra Precision | Extreme Environment |

|---|---|---|---|---|

| Torque Capacity | 100-500 Nm | 500-5000 Nm | 50-1000 Nm | 200-3000 Nm |

| Peak Torque Rating | 2.0x rated | 3.0-4.0x rated | 2.5x rated | 2.8x rated |

| Transmission Efficiency | 94-96% | 92-95% | 96-98% | 90-93% |

| Backlash | 5-10 arc-min | 3-8 arc-min | 1-3 arc-min | 4-7 arc-min |

| Torsional Stiffness | 5-20 Nm/arc-min | 20-100 Nm/arc-min | 10-50 Nm/arc-min | 15-80 Nm/arc-min |

| Noise Level | 65-75 dB | 68-78 dB | 60-68 dB | 70-80 dB |

| Operating Temperature | -20°C to 90°C | -20°C to 100°C | -10°C to 80°C | -40°C to 120°C |

| IP Protection Rating | IP54 | IP65 | IP54 | IP67 |

| Service Life | 10,000 hours | 20,000 hours | 15,000 hours | 25,000 hours |

| Weight/Power Ratio | 0.8-1.2 kg/kW | 1.2-2.0 kg/kW | 1.0-1.5 kg/kW | 1.5-2.5 kg/kW |

| Maximum Radial Load | 0.2-0.5x torque | 0.3-0.7x torque | 0.15-0.4x torque | 0.4-0.8x torque |

Material Science and Heat Treatment Technologies

The performance and durability of High Torque Planetary Gearbox components are fundamentally dependent on material selection and thermal processing:

Advanced Material Applications:

-

Case-Hardened Steel Alloys: Materials including 20MnCr5, 18CrNiMo7-6, and SAE 8620 provide exceptional surface hardness (58-62 HRC) with tough, ductile cores resistant to impact loading.

-

Through-Hardened Steels: Alloys such as 42CrMo4 and 34CrNiMo6 offer consistent material properties throughout the component cross-section, suitable for applications requiring high core strength.

-

Specialty Alloys and Treatments: Nitriding, carburizing, and induction hardening processes create tailored material properties optimized for specific loading conditions and environmental factors.

Heat Treatment Methodologies:

-

Atmosphere-Controlled Carburizing: Precision carbon diffusion processes create optimal case depth profiles matching specific tooth loading requirements, typically 0.8-1.2 mm for medium modules.

-

Low-Distortion Hardening Techniques: High-pressure gas quenching and marquenching processes minimize geometric distortion during hardening, reducing subsequent machining requirements.

-

Stabilization Treatments: Multiple tempering cycles and cryogenic processing ensure dimensional stability and residual stress relief for long-term precision maintenance.

Strategic Advantages in Heavy-Duty Robotic Applications

The implementation of High Torque Planetary Gearbox systems in heavy-duty robotic applications delivers significant operational advantages:

-

Exceptional Power Density: Planetary configurations achieve torque-to-weight ratios 30-50% higher than equivalent parallel shaft arrangements, enabling more compact robot joint designs with reduced moving masses and improved dynamic performance.

-

High Overload Capacity: The distributed load sharing among multiple planet gears provides inherent resistance to shock loads and temporary overload conditions common in heavy-duty material handling and processing applications.

-

Precision Motion Control: Low backlash designs and high torsional stiffness enable precise position control essential for applications requiring accurate path following and repeatable positioning.

-

Multi-Axis Configuration Flexibility: Compact coaxial designs facilitate integration into complex robotic joint arrangements with multiple degrees of freedom while maintaining optimal weight distribution and envelope efficiency.

Case Studies: High Torque Planetary Gearbox Applications

Case Study 1: Automotive Robotic Welding System

-

Challenge: An automotive manufacturer required robotic welding cells capable of handling heavy welding fixtures (85 kg) with precise path following at speeds up to 2 m/s. Existing systems suffered from excessive backlash and limited service life under continuous production.

-

Solution: JLYPT designed and manufactured a custom High Torque Planetary Gearbox with optimized tooth profiles for shock load resistance and specialized bearing arrangements for high moment loads. The design incorporated a backlash of less than 3 arc-min and torsional stiffness exceeding 50 Nm/arc-min.

-

Result: Achieved 40% improvement in positioning accuracy (±0.1 mm) and extended service life to 25,000 hours between overhaul. The solution reduced maintenance downtime by 60% and improved weld quality consistency across three-shift operation.

Case Study 2: Aerospace Composite Material Handling

-

Challenge: A aerospace composites manufacturer needed robotic automation for handling large carbon fiber panels (4m × 6m) weighing up to 350 kg. The application required smooth motion at low speeds with zero cogging and high positional stability.

-

Solution: We developed a ultra-precision High Torque Planetary Gearbox with modified helix angles and specialized surface finishing to minimize torque ripple. The design incorporated ceramic hybrid bearings and advanced sealing systems to prevent contamination in the cleanroom environment.

-

Result: Eliminated visible cogging effects at speeds as low as 0.01 m/s while maintaining positional stability of ±0.05 mm during extended holds. The solution enabled automated handling of delicate composite materials without surface damage or fiber distortion.

Case Study 3: Heavy-Payload Material Handling Robot

-

Challenge: A logistics automation provider required关节 actuators for heavy-payload robots (1500 kg capacity) with high dynamic performance for rapid acceleration and deceleration cycles. Standard gearboxes failed prematurely due to shock loads during rapid direction changes.

-

Solution: JLYPT engineered a robust High Torque Planetary Gearbox with enhanced surface treatments and proprietary heat treatment processes to withstand peak loads up to 4 times nominal torque. The design incorporated torque monitoring and overload protection systems.

-

Result: Achieved 500% improvement in mean time between failures (MTBF) under aggressive duty cycles. The solution supported acceleration rates of 3 m/s² with payloads up to 1500 kg, enabling 35% faster cycle times in palletizing applications.

Future Development Trajectories in Planetary Gearbox Technology

The continuing evolution of High Torque Planetary Gearbox technology focuses on several key innovation vectors:

-

Integrated Smart Monitoring Systems: Incorporation of embedded sensors for temperature, vibration, and torque monitoring with wireless data transmission for predictive maintenance and condition-based monitoring.

-

Advanced Material Applications: Implementation of composite materials, ceramic components, and surface engineering technologies to further increase power density and operational reliability.

-

Additive Manufacturing Integration: Utilization of metal additive manufacturing for complex internal cooling channels and optimized lightweight structures impossible to produce with conventional manufacturing methods.

-

Digital Twin Technology: Development of virtual gearbox models that mirror physical performance characteristics, enabling performance optimization and failure prediction through operational data analysis.

Implementation Best Practices and Technical Considerations

Successful deployment of High Torque Planetary Gearbox systems requires adherence to established engineering principles:

System Integration Guidelines:

-

Alignment and Mounting: Precision machining of mounting interfaces and proper alignment procedures to prevent parasitic loads that reduce bearing life and gear mesh accuracy.

-

Lubrication System Design: Selection of appropriate lubricants and delivery systems matched to operational speed, temperature, and environmental conditions.

-

Thermal Management Planning: Adequate heat dissipation provisions and thermal growth accommodation to maintain optimal operating clearances and lubrication performance.

Operational Maintenance Protocols:

-

Condition Monitoring Implementation: Vibration analysis, oil analysis, and thermal monitoring systems to detect incipient failures and schedule maintenance during planned downtime.

-

Preventive Maintenance Scheduling: Established maintenance intervals based on actual operating conditions rather than fixed time periods to optimize component life and reliability.

-

Spare Parts Strategy: Critical component inventory planning based on failure mode analysis and lead time considerations to minimize production interruptions.

Conclusion: Engineering Excellence in Power Transmission

The development and implementation of advanced High Torque Planetary Gearbox systems represent a critical enabling technology for modern heavy-duty robotic applications. These sophisticated power transmission components combine high power density, exceptional reliability, and precision motion control capabilities that are essential for demanding industrial automation applications.

At JLYPT, our comprehensive approach to High Torque Planetary Gearbox manufacturing encompasses everything from material selection and heat treatment to precision machining and quality assurance. Our engineering expertise and advanced manufacturing capabilities ensure that we deliver solutions that meet the most demanding application requirements while providing exceptional value through extended service life and reduced maintenance requirements.

Ready to enhance your robotic systems with advanced high torque planetary gearbox technology? Contact JLYPT today to discuss your specific application requirements with our engineering team. Our specialists will provide comprehensive technical support and manufacturing solutions tailored to your performance and reliability objectives.