The Anatomy of Reliability: A Manufacturing-Centric Guide to Evaluating Industrial Robots for Sale

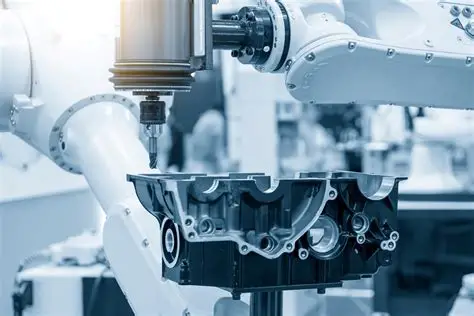

The marketplace for industrial robots for sale presents a paradox of choice: an overwhelming array of brands, models, and specifications, yet a critical scarcity of transparent information regarding the very factor that dictates long-term value—mechanical and manufacturing integrity. For engineers and operations leaders, the procurement decision extends far beyond payload, reach, and cycle time; it hinges on the often-overlooked domain of precision manufacturing, material science, and mechanical design that ensures a robot’s decade-long service life. At JLYPT, our perspective is forged at the intersection of advanced CNC machining and robotic integration. We understand that the true cost of a robot is not its purchase price, but the total cost of ownership (TCO), which is irrevocably tied to the quality of its gears, housings, shafts, and structural members. This guide provides a technical framework for evaluating industrial robots for sale, shifting the focus from marketing specifications to manufacturing excellence.

The Foundation of Performance: Structural and Mechanical Integrity

When assessing industrial robots for sale, the first principle is that performance specifications are outputs, not inputs. They are the result of underlying mechanical quality. A robot advertised with high repeatability but built with poorly machined joints will not maintain that specification under load or over time.

1. Joint Construction & Bearing Surfaces

The robot’s joints are its kinematic heart. The quality of machining on bearing seats and gear interfaces directly impacts stiffness, backlash, and longevity.

-

Bearing Seat Tolerances: High-precision grinding should achieve tolerances of IT4 or IT5 (e.g., H6/g5 fits) for critical bearing bores and shafts. Surface finishes of Ra ≤ 0.4 µm are essential for proper bearing seating and load distribution. Inspect for chatter marks or inconsistent finishes, which indicate unstable machining processes.

-

Stiffness & Harmonic Performance: The natural frequency of a robot arm is a function of its stiffness (K) and mass (m):

ω_n = √(K/m). Low stiffness, often from thin-walled or inadequately ribbed castings/machinings, leads to low natural frequencies. This causes vibration during high-acceleration moves, forcing controllers to slow down to avoid resonance, thereby reducing effective throughput. -

Material Verification: Are arm structures made from certified aluminum alloys (e.g., 6061-T6, 7075-T651) or ductile iron? Request material test certificates (MTCs). Inferior materials or improper heat treatment lead to creep, permanent deformation, and dimensional instability.

2. Gearbox & Transmission Analysis

The gearbox is the robot’s muscle. Whether harmonic drive, cycloidal, or planetary, its internal component quality is paramount.

-

Gear Tooth Geometry: For strain wave gears (harmonic drives), the flexspline’s tooth profile must be manufactured to AGMA Quality 10 or better. Sub-micron-level profile deviations from the perfect involute curve lead to uneven load sharing, accelerated wear, and increased hysteresis.

-

Heat Treatment & Case Depth: Gear teeth require precise case hardening (e.g., carburizing or nitriding) to achieve a hard, wear-resistant surface (58-62 HRC) over a tough, ductile core. Inconsistent case depth or improper tempering can cause tooth spalling or catastrophic fracture. Ask for destructive testing data from the manufacturer’s quality logs.

-

Pre-Load & Backlash: High-quality gearboxes use controlled pre-load on bearings to eliminate axial and radial play. Backlash should be measured in arc-seconds, not arc-minutes, for precision applications. Remember, backlash is not a static number; it increases with wear. Inquire about the expected backlash growth curve over the rated lifetime.

The Hidden Metric: Manufacturing Quality of Core Components

Brochures list specifications; engineering drawings define capability. When evaluating industrial robots for sale, request documentation that reveals manufacturing intent.

Table 1: Critical Component Manufacturing Benchmark

| Component | Key Manufacturing Process | Target Specification | Consequence of Deviation | Verification Method |

|---|---|---|---|---|

| Main Arm Casting/Forging | 5-Axis CNC Machining | Flatness: ≤ 0.05 mm/m, Bore concentricity: ≤ 0.01 mm TIR | Reduced stiffness, misalignment, accelerated bearing wear | Laser tracker measurement, CMM report |

| Output Flange | Precision Turning & Grinding | Face runout: ≤ 0.005 mm, Mounting thread quality: Class 4H/6g | Tool center point (TCP) instability, poor repeatability | Dial indicator test, thread gauge |

| Motor Mounting Interfaces | Boring & Facing | Perpendicularity of mount to axis: ≤ 0.01 mm | Induced binding in motor, heat generation, encoder error | Squareness gauge, alignment laser |

| Harmonic Drive Flexspline | Multi-Axis Hobbing & Heat Treat | Tooth profile error: ≤ 3 µm, Wall thickness consistency: ≤ 0.02 mm | Shortened lifespan, positional drift, torque ripple | Optical comparator, micro-CT scan (sample) |

| Cable Management Passages | Deburring & Polishing | Radiused edges, Surface finish Ra ≤ 1.6 µm | Cable abrasion, downtime, electrical failure | Visual inspection with borescope |

A Framework for Technical Due Diligence

Before committing to any industrial robots for sale, a structured evaluation process is essential. Move beyond the standard factory acceptance test (FAT).

Phase 1: Document & Design Review

-

Request Detailed Drawings: Ask for GD&T (Geometric Dimensioning and Tolerancing) drawings of key structural components. Look for proper datum structures and tolerance stacks that ensure assemblability and function.

-

Review Bill of Materials (BOM): Scrutinize the BOM for bearing brands (SKF, NSK, Nachi), seal types (SKF, Simrit), and lubricant specifications. Generic components signal cost-cutting.

-

Analyze Service Manuals: The complexity and clarity of maintenance procedures for joint rebuilds or gearbox replacement reveal the robot’s design for serviceability. Modular designs are superior.

Phase 2: Physical Inspection & Metrology

-

Static Accuracy Test: Using a laser tracker, measure the robot’s static positioning accuracy against its commanded position across its full workspace. This tests the calibration and inherent mechanical accuracy.

-

Dynamic Path Performance: Program a high-speed, contoured path (e.g., a circle). Use the laser tracker to measure path accuracy and velocity stability. Jerky execution or deviation indicates servo tuning issues or mechanical compliance.

-

Thermal Drift Test: Run the robot through a strenuous, repetitive cycle for 4-8 hours. Monitor the TCP position at a fixed command. Drift greater than 0.1 mm may indicate thermal expansion mismatches in materials or poor thermal management in motors/drives.

Case Studies: The Cost of Overlooking Manufacturing Quality

Case Study 1: The Failed Forging

-

Scenario: An automotive parts manufacturer purchased several high-payload industrial robots for sale for machine tending. Within 6 months, robots exhibited degraded repeatability (±0.5mm drift).

-

Investigation: JLYPT was engaged to diagnose the issue. Metrology revealed the main lower arm forging, a critical load-bearing component, had significant internal porosity and inconsistent wall thickness due to a flawed casting process. Under cyclical load, the arm was experiencing micro-yielding.

-

Resolution & Value: Replacing the arms with units manufactured from certified forgings and machined on 5-axis CNCs with stress-relief protocols restored accuracy. The lesson: The quality of raw stock and primary machining is non-negotiable for heavy-duty cycles.

Case Study 2: The Harmonic Drive with Hidden Flaws

-

Scenario: A electronics assembler selected industrial robots for sale based on low cost and a good warranty. After 14 months of precise assembly work, several robot wrists developed excessive backlash, ruining product.

-

Investigation: Disassembly of the harmonic drives showed premature wear on the flexspline teeth. Metallurgical analysis revealed a shallow and inconsistent case-hardened layer, below the specified 0.5mm depth.

-

Resolution & Value: The robot OEM replaced the units, but production downtime cost far exceeded the initial savings. The client’s new procurement standard includes reviewing the gearbox supplier’s heat treat process controls and certifications.

Case Study 3: The Misaligned Structure

-

Scenario: A aerospace fabricator integrated a new 7-axis robot for composite layup. It could never achieve the promised path accuracy, causing material waste.

-

Investigation: Using a laser tracker and volumetric error compensation software, our engineers mapped the robot’s error. The base structure, a large welded assembly, had significant distortion that was not corrected by stress-relieving before the final machining of mounting faces.

-

Resolution & Value: We designed and CNC machined custom compensation shims for the robot’s mounting base, effectively “re-machining” the interface in the field. This brought the robot into specification, demonstrating that final assembly machining is as critical as component machining.

The JLYPT Perspective: Precision as a Procurement Filter

Our core expertise in machining components to micron-level tolerances for the aerospace and medical industries informs our view of robotics. When we see industrial robots for sale, we see an assembly of hundreds of precision-machined parts. The manufacturers who invest in:

-

Multi-Axis Machining Centers for complex, monolithic arm structures.

-

In-Process Metrology to correct for tool wear and thermal drift during machining.

-

Certified Material Supply Chains with full traceability.

-

Advanced Surface Treatments like nitriding or fine grinding for wear surfaces.

…are the ones whose robots will deliver lower TCO through sustained accuracy, fewer failures, and longer mean time between repairs.

Conclusion: Redefining the Procurement Standard

The market for industrial robots for sale is competitive, but true value is not found in the lowest upfront cost. It is engineered into the robot through superior materials, precision manufacturing, and rigorous quality control—factors often invisible in a sales catalog. By applying a manufacturing-centric lens to your evaluation, you shift the procurement conversation from simple feature comparison to a technical audit of long-term reliability.

Demand evidence of manufacturing quality. Request inspection reports, material certs, and tolerance drawings. Invest time in advanced metrology during pre-purchase trials. This diligence transforms you from a passive buyer into an informed partner, ensuring the robot you purchase is a capital asset that appreciates in value through reliability, not a liability that depreciates through downtime.

Ready to specify robots built with uncompromising mechanical integrity? Contact JLYPT to discuss how our expertise in precision component manufacturing can inform your next robotic investment or support the maintenance of your existing fleet with OEM-quality replacement parts.