The Evolution of End-Effectors: From Mechanical Clamps to Intelligent Tactile Systems in Precision CNC Machining

In the meticulously controlled environment of modern CNC machining, where spindle positioning achieves micron-level accuracy and surface finishes are measured in Ra values, a significant technological disparity has persisted. While our machining centers have evolved into marvels of digital precision, the End-Effectors responsible for handling these exquisite components often remained in the analog era of simple mechanical clamps. At JLY Precision Technology, we are closing this technological gap through the strategic implementation of Tactile Sensor Grippers—intelligent end-effectors that transform robotic systems from position-controlled automatons into force-aware, adaptive manufacturing partners.

This comprehensive technical analysis examines the fundamental shift from conventional end-effectors to sophisticated tactile sensing systems within high-precision CNC environments. We will explore the underlying technologies, operational paradigms, and tangible manufacturing benefits that these intelligent handling systems deliver.

The Critical Limitations of Conventional End-Effectors in Precision Manufacturing

Traditional robotic end-effectors—whether pneumatic two-jaw grippers, vacuum cup arrays, or magnetic chucks—operate on binary principles: engaged or disengaged. This fundamental limitation creates several critical challenges in precision component handling:

-

Surface Integrity Compromise: The concentrated point loads from rigid gripper jaws can induce micro-indentations on polished surfaces, deform thin-walled structures, or damage critical sealing surfaces. For components like optical mirrors or medical implant interfaces, such damage is irreparable and results in immediate rejection.

-

Uncompensated Process Variability: Conventional end-effectors lack the sensory capability to adapt to natural variations in raw material dimensions, thermal expansion of machined components, or the presence of residual cutting fluids, leading to inconsistent handling performance.

-

Limited Geometric Intelligence: Complex organic geometries, common in aerospace and automotive lightweighting strategies, present non-uniform gripping surfaces that rigid end-effectors cannot accommodate without expensive, custom-engineered tooling.

-

Absence of Process Verification: Standard end-effectors provide no confirmation of successful part acquisition, proper seating orientation, or the presence of manufacturing defects before component loading.

The emergence of Tactile Sensor Grippers represents a paradigm shift, introducing haptic intelligence as a fundamental process parameter in automated manufacturing.

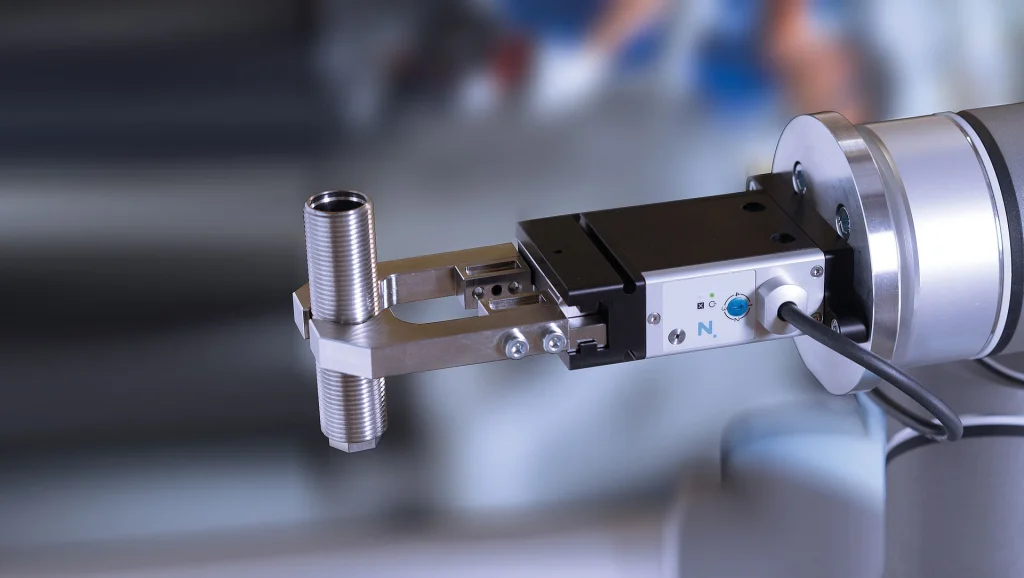

Architectural Principles of Modern Tactile Sensing End-Effectors

A Tactile Sensor Gripper constitutes an integrated system of mechanical actuation, distributed sensing technology, and real-time processing intelligence. The technological foundation comprises several critical subsystems:

-

Sensing Modality Technologies:

-

Matrix-Based Piezoresistive Arrays: Utilizing conductive elastomers or quantum tunneling composites that exhibit predictable resistance changes under applied pressure, enabling detailed force distribution mapping across the contact surface.

-

Microfluidic Tactile Sensors: Employing sealed chambers of conductive fluid with embedded electrodes to measure pressure-induced fluid displacement, offering high robustness in contaminated environments.

-

Capacitive Sensor Grids: Based on deformable dielectric layers between electrode arrays, providing exceptional sensitivity for detecting minute forces and proximity in ultra-delicate handling applications.

-

Optical Waveguide Sensing: Using light transmission through deformable elastomers with photodetectors to create high-resolution, EMI-resistant pressure distribution images.

-

-

Actuation and Compliance Mechanisms:

-

Tendon-Driven Anthropomorphic Designs: Multi-articulated fingers mimicking human kinematics, providing exceptional dexterity for complex part geometries.

-

Granular Jamming Transition Systems: Using particulate-filled membranes that transition from fluid-like to solid-state under vacuum pressure, enabling conformation to irregular shapes.

-

Pneumatic Artificial Muscles: Utilizing McKibben-type actuators that contract when pressurized, offering high power-to-weight ratios with inherent compliance.

-

-

Control System Architecture: The processing backbone executes sophisticated algorithms for:

-

Impedance Control: Regulating the dynamic relationship between applied force and positional motion to maintain stable contact under varying conditions.

-

Slip Prevention Algorithms: Detecting incipient slip through high-frequency vibration analysis and implementing predictive force compensation.

-

Tactile Signature Recognition: Identifying components and verifying proper acquisition through machine learning analysis of characteristic pressure patterns.

-

Strategic Implementation Advantages in CNC Manufacturing Environments

The integration of Tactile Sensor Grippers into robotic CNC workcells delivers transformative benefits across multiple manufacturing metrics:

-

Deterministic Surface Preservation: Through closed-loop force control maintaining precise Newton-level grip forces, these end-effectors handle polished, coated, or fragile surfaces without marring or deformation. This eliminates secondary polishing operations and protective packaging during intra-process handling.

-

Process-Integrated Metrology: The sensory capability enables in-process verification of feature presence, detection of burrs or chips in critical interfaces, and confirmation of proper part orientation before machine loading, functioning as a preliminary quality gate.

-

Dynamic Fixturing Applications: Advanced Tactile Sensor Grippers can serve as active, reconfigurable workholding devices. The robot maintains the component in optimal orientation for specific machining operations, using real-time force feedback to counteract cutting forces, thereby reducing fixture inventory and changeover time.

-

Agile Manufacturing Enablement: A single sensor-equipped end-effector can handle diverse part families without mechanical reconfiguration. The control system simply loads different force profiles and tactile verification routines, dramatically reducing changeover time in high-mix production environments.

Technical Comparison: End-Effector Technologies for Precision Applications

The following table provides a detailed technical comparison of contemporary end-effector technologies employed in manufacturing automation.

Table 1: Comparative Analysis of Robotic End-Effector Technologies

| Technical Parameter | Tactile Sensor Gripper | Standard Pneumatic Gripper | Vacuum End-Effector | Magnetic Handling System |

|---|---|---|---|---|

| Force Control Capability | Closed-Loop, Adaptive | Open-Loop, Fixed | Binary (On/Off) | Binary or Variable (Electro) |

| Surface Sensitivity | Very High (0.1-1N resolution) | Very Low | Medium (Gasket Dependent) | Low (Potential Scratching) |

| Geometric Adaptability | High (Active Conformation) | Low (Fixed Geometry) | Medium (Requires Seal Surface) | Low (Ferromagnetic Only) |

| Part Verification Capability | Yes (Tactile Signature Analysis) | Limited (Physical Contact Only) | Limited (Pressure Switch) | No |

| Slip Detection/Prevention | Yes (Real-Time Monitoring) | No | N/A | N/A |

| Cycle Time Performance | High (Optimizable) | Very High | Very High | Very High |

| Optimal Application Scope | Delicate, high-value, geometrically complex components | Robust components with parallel gripping surfaces | Large, non-porous panels and sheets | Heavy ferrous plates and structures |

| Implementation Complexity | High | Low | Low-Medium | Low-Medium |

| Total Cost of Ownership | Medium-High | Low | Low-Medium | Low-Medium |

Case Studies: Tactile Sensor End-Effectors Addressing Complex Manufacturing Challenges

Case Study 1: Ultra-Precision Handling of Hemispherical Waveguide Components

-

Challenge: We were manufacturing millimeter-wave waveguide components with internal hemispherical cavities polished to optical standards. Traditional end-effectors risked distorting the delicate throat section and leaving witness marks on critical RF surfaces, compromising signal propagation characteristics.

-

Solution: JLYPT engineered a custom Tactile Sensor Gripper with three independently controlled, compliant fingers incorporating capacitive sensor arrays. The system was calibrated to apply differential forces—higher at the robust flange section, minimal at the delicate throat—while continuously monitoring for any force anomalies indicating potential slip or excessive pressure.

-

Result: Achieved zero handling-related rejections over a production run of 450 components. The consistent, minimally invasive handling preserved the stringent surface finish requirements (Ra < 0.2μm), ensuring optimal RF performance without additional post-processing.

Case Study 2: High-Reliability Assembly of Multi-Material Medical Instruments

-

Challenge: A surgical instrument assembly required precisely joining titanium structural components with ceramic insulating elements. The brittle nature of the ceramic and the need for exact alignment created significant assembly yield challenges with conventional end-effectors.

-

Solution: We implemented a dual-arm robotic cell where one robot employed a Tactile Sensor Gripper to handle the ceramic component. The end-effector detected subtle force variations during the insertion process, enabling real-time micro-corrections to prevent binding or uneven stress distribution. The system could detect the characteristic force signature of proper seating versus potential cross-loading.

-

Result: Assembly yield improved from 78% to 99.7%, virtually eliminating ceramic fracture during assembly. The tactile feedback provided quantitative process validation for medical device regulatory compliance.

Case Study 3: Flexible Manufacturing of Composite-Cored Aerospace Brackets

-

Challenge: A project involved manufacturing mounting brackets with carbon composite cores and over-molded titanium attachment points. The variation in as-molded flash and the need to avoid crushing the composite core made automated handling problematic with standard end-effectors.

-

Solution: A Tactile Sensor Gripper with full-palm pressure mapping capability was deployed. The system could identify optimal grip points by analyzing the pressure distribution across the irregular geometry, avoiding areas with excessive flash while ensuring stable acquisition without damaging the composite substrate.

-

Result: Enabled completely automated processing of these hybrid components without dedicated fixturing. The system automatically adapted to the normal batch-to-batch variation in molding flash, maintaining a consistent throughput of 43 components per hour with zero damage incidents over 12,000 cycles.

Future Trajectory: Cognitive End-Effectors and Distributed Haptic Intelligence

The next evolutionary phase for Tactile Sensor Grippers involves the integration of edge computing and artificial intelligence to create truly cognitive end-effectors:

-

Autonomous Skill Learning: AI systems will analyze historical tactile data from successful and unsuccessful handling operations to autonomously derive optimal grip strategies for new components based solely on CAD data.

-

Predictive Maintenance Integration: By monitoring gradual changes in tactile signatures during standard operations, the system will predict end-effector wear, sensor degradation, or mechanical compliance changes before they impact production quality.

-

Distributed Haptic Networks: Multiple sensor-equipped end-effectors within a workcell will share tactile data, enabling coordinated manipulation of large or flexible components and creating a collective “haptic awareness” of the manufacturing environment.

At JLY Precision Technology, our advanced robotics laboratory is actively developing these next-generation capabilities to maintain our position at the forefront of intelligent manufacturing systems.

Conclusion: Haptic Intelligence as a Manufacturing Imperative

The integration of Tactile Sensor Grippers represents more than a technical upgrade—it signifies a fundamental reimagining of the role of end-effectors in precision manufacturing. These systems transform part handling from a positional task to a sensory-rich, adaptive process that respects and protects the value inherent in every precision-machined component.

At JLYPT, our investment in tactile sensing technology reflects our commitment to a comprehensive philosophy: every element of the manufacturing process must demonstrate the same intelligence and precision we apply to our machining operations. We engineer not just components, but the entire ecosystem required to produce them flawlessly.

Ready to transform your manufacturing automation with intelligent end-effector technology? Contact JLY Precision Technology today to discover how our Tactile Sensor Gripper integrated CNC solutions can protect your most valuable components while enhancing production flexibility and quality assurance.