The Complete Guide to Low Volume CNC Production Runs: From Prototype to Mid-Volume Manufacturing

Executive Summary

Low volume CNC production runs represent a sophisticated manufacturing approach that bridges the gap between prototype development and full-scale production, typically ranging from 50-500 units per batch. This manufacturing strategy combines the precision and flexibility of computer numerical control (CNC) machining with the economic efficiency required for smaller production quantities. The growing demand for customized components, rapid product iteration, and supply chain resilience has made low volume production an essential capability across industries including aerospace, medical devices, automotive, and consumer electronics. This comprehensive guide explores the technical considerations, economic factors, and strategic advantages of low volume CNC production, providing engineering professionals and manufacturing decision-makers with the insights needed to optimize their production strategies for small to medium batch sizes.

1 Introduction to Low Volume CNC Production

Low volume CNC production refers to the manufacture of components in quantities typically ranging from 50 to 500 units using computer numerical control machining processes. This approach occupies the critical middle ground between rapid prototyping (1-50 units) and mass production (1000+ units), offering manufacturers the ability to validate designs in real-world conditions, test market acceptance, and maintain operational flexibility without committing to the high costs and long lead times associated with traditional mass production tooling.

The fundamental advantage of low volume CNC production lies in its manufacturing flexibility. Unlike injection molding or die casting that require expensive tooling and setup, CNC machining can produce high-quality parts directly from digital designs with minimal setup time. This capability is particularly valuable in today’s manufacturing landscape, where product lifecycles are shortening, customization demands are increasing, and market uncertainty requires production agility.

Modern manufacturing facilities equipped with advanced CNC equipment, automated material handling, and digital quality control systems can produce low volume batches with efficiencies previously only achievable in mass production. The integration of CAD/CAM systems allows for seamless transition from design to production, while process optimization techniques ensure consistent quality across production runs regardless of batch size.

2 Technical Advantages of Low Volume CNC Production

CNC machining offers numerous technical advantages for low volume production that make it superior to other manufacturing methods for batch sizes in the 50-500 unit range.

Material Versatility: CNC machines can process an extensive range of engineering-grade materials including aluminum alloys, stainless steels, titanium, brass, copper, and various engineering plastics. This versatility allows manufacturers to use production-intent materials even for small batches, ensuring that functional testing yields accurate results that will scale to full production.

Precision and Repeatability: Modern CNC systems provide exceptional dimensional control with tolerances reaching ±0.005mm and repeatability of 0.0025mm across production runs. This precision ensures that every part in a low volume batch meets identical specifications, which is crucial for components that must interface with existing systems or require interchangeability.

Rapid Iteration Capability: The digital nature of CNC programming enables quick design changes between production runs without the need for expensive tooling modifications. This allows manufacturers to implement design improvements, correct issues, or create variants based on real-world testing feedback without significant cost penalties or schedule impacts.

Surface Finish Quality: CNC machining produces excellent surface finishes directly from the machine, typically in the range of Ra 0.8-3.2μm for milled surfaces and Ra 0.4-1.6μm for turned surfaces. This reduces or eliminates the need for secondary finishing operations, streamlining the production process for low volume batches.

Scalability: Low volume CNC production provides a natural pathway to scale manufacturing as demand increases. The same digital files and machining processes can be used for both prototype validation and production runs, ensuring consistency and simplifying the qualification process when moving to higher volumes.

Table: Comparison of Manufacturing Methods for Different Production Volumes

| Manufacturing Method | Optimal Quantity Range | Tolerance Capability | Lead Time | Tooling Cost | Material Options |

|---|---|---|---|---|---|

| CNC Machining | 1-500+ units | ±0.005mm | 3-7 days | Low | Extensive |

| 3D Printing | 1-100 units | ±0.100mm | 1-3 days | None | Limited |

| Injection Molding | 1,000+ units | ±0.050mm | 4-8 weeks | High | Thermoplastics |

| Casting | 500+ units | ±0.125mm | 3-6 weeks | Medium | Metals |

| Sheet Metal Fabrication | 50-1000 units | ±0.100mm | 5-10 days | Low | Metals |

3 Economic Considerations for Low Volume Production

The economics of low volume CNC production differ significantly from both prototyping and mass manufacturing, requiring unique strategic considerations.

Tooling Cost Avoidance: The most significant economic advantage of CNC machining for low volumes is the elimination of expensive tooling. Injection molds, die casting dies, and other production tooling can cost tens of thousands of dollars and require weeks to produce. For quantities under 500 units, this tooling cost often exceeds the total part cost when manufactured via CNC machining.

Inventory Cost Reduction: Low volume production enables just-in-time manufacturing strategies that minimize inventory carrying costs. Rather than maintaining large stocks of finished goods, manufacturers can produce smaller batches aligned with actual demand, reducing capital tied up in inventory and warehouse space requirements.

Risk Mitigation: By limiting initial production runs to smaller quantities, manufacturers can test market acceptance before committing to large-scale production. If design issues emerge or market demand fails to materialize, the financial exposure is limited to the relatively small low volume batch rather than thousands of units of obsolete inventory.

Total Cost Analysis: When evaluating manufacturing options for low volumes, it’s essential to consider total cost rather than just per-unit part cost. Factors including tooling amortization, quality control, inventory carrying costs, and obsolescence risk must be included in the analysis. In many cases, CNC machining provides the lowest total cost for quantities up to 500 units despite a higher per-part cost compared to mass production methods.

Opportunity Cost: The ability to bring products to market faster through low volume CNC production can provide significant first-mover advantages and revenue generation that offsets potentially higher manufacturing costs. For innovative products in fast-moving markets, time to market often outweighs pure manufacturing cost considerations.

4 Applications and Case Studies

Low volume CNC production serves critical functions across diverse industries where flexibility, quality, and time-to-market are prioritized over lowest possible per-unit cost.

Case Study 1: Aerospace Component Manufacturing

An aerospace startup developing unmanned aerial vehicles required flight-critical components for their initial production batch of 50 units. The parts included structural brackets, motor mounts, and payload interface components machined from 7075 aluminum with tight tolerances and rigorous documentation requirements.

Challenge: Produce 50 sets of flight-critical components with complete traceability, material certification, and first-article inspection documentation within four weeks to meet investor demo deadlines. All parts required anodizing and needed to maintain dimensional stability through the coating process.

Solution: JL YPT utilized 3-axis and 5-axis CNC machining centers with automated tool changers and high-pressure coolant to machine the components from certified 7075 aluminum stock. Each batch was tracked through production with unique identifiers, and statistical process control methods ensured consistent quality across all 50 units. A specialized racking system maintained proper orientation during anodizing to prevent distortion.

Results: All 50 units were delivered within the 4-week timeframe with complete documentation packages. The components demonstrated consistent performance during flight testing, and the startup secured additional funding based on their demonstrated manufacturing capability. The digital manufacturing process enabled seamless scaling to higher volumes as demand increased.

Case Study 2: Medical Device Component Production

A medical device company needed surgical instrument components for clinical trials of a new minimally invasive surgical system. The production quantity of 100 units required medical-grade stainless steel (17-4 PH), electropolished surfaces for cleanliness, and validation documentation for regulatory submission.

Challenge: Manufacture 100 sets of intricate surgical instrument components with strict biocompatibility requirements, Ra 0.4μm surface finish on all patient-contacting surfaces, and complete material traceability for FDA submission. The components included precise articulation features that required five-axis machining capability.

Solution: Swiss-style CNC lathes with live tooling produced the complex miniature components, maintaining tolerances of ±0.0127mm on critical features. The machining process was followed by electropolishing to achieve the required surface finish and enhance corrosion resistance. Each component lot received full material certification and process validation documentation.

Results: The surgical instruments performed excellently during clinical trials, with no device-related adverse events. The comprehensive documentation supported successful regulatory submission, and the manufacturing process validated during low volume production served as the foundation for scale-up to commercial volumes.

Case Study 3: Automotive Innovation Development

An automotive technology company developed an advanced driver assistance system (ADAS) requiring custom enclosures and mounting components for field testing. The low volume production run of 200 units needed to withstand automotive environmental conditions while providing precise sensor alignment.

Challenge: Produce 200 sets of sensor mounting brackets and electronic enclosures from 6061 aluminum with environmental sealing features, EMI/RFI shielding considerations, and vibration resistance for vehicle integration. Parts required chemical film coating for corrosion protection and needed to maintain dimensional stability across temperature extremes.

Solution: CNC milling centers with fourth-axis capability produced the complex geometries with integrated mounting features. The process included specific toolpath strategies to minimize residual stress and ensure stability after coating. A specialized chromate conversion coating provided corrosion protection while maintaining electrical connectivity for grounding purposes.

Results: The field testing units performed reliably across diverse climate conditions, validating the design before commitment to high-volume production. The low volume approach identified several design improvements that were incorporated before tooling for injection molded versions, avoiding expensive mold modifications.

5 Quality Assurance in Low Volume Production

Maintaining consistent quality across low volume production runs requires specialized approaches that differ from both prototype and mass production quality systems.

First Article Inspection: Comprehensive dimensional verification of initial production units ensures that all features conform to design specifications before proceeding with the full production run. This process typically involves complete geometric dimensioning and tolerancing (GD&T) verification using coordinate measuring machines (CMM) and specialized metrology equipment.

Statistical Process Control: Despite smaller batch sizes, SPC methodologies can be applied to low volume production to monitor process stability and detect trends that might indicate developing issues. Modified sampling plans based on c=0 zero acceptance principles provide rigorous quality assurance even for small batches.

Documentation and Traceability: Complete documentation packages including material certifications, process parameters, and inspection results provide traceability for each production run. This documentation is particularly valuable for regulated industries and for troubleshooting if issues emerge later in the product lifecycle.

Process Validation: For critical components, process validation protocols establish that the manufacturing process consistently produces parts meeting all specifications. Though traditionally associated with high-volume production, modified validation approaches can be applied to low volume processes to provide confidence in part quality.

Supplier Quality Management: Close collaboration with manufacturing partners ensures that quality standards are maintained throughout the production process. Regular process audits, quality reviews, and corrective action processes create a framework for continuous improvement even for low volume production.

Table: Quality Assurance Methods for Low Volume CNC Production

| Quality Method | Application in Low Volume Production | Implementation Approach | Documentation Requirements |

|---|---|---|---|

| First Article Inspection | Comprehensive verification of initial production units | Full dimensional inspection using CMM | Detailed inspection report with actual measurements |

| Material Certification | Verification of material properties and composition | Mill certificates with traceability to heat/lot numbers | Material certs included with shipment |

| Statistical Process Control | Monitoring process stability across small batches | Modified sampling plans based on risk assessment | Control charts and capability studies |

| Process Validation | Establishing consistent production of conforming parts | Reduced documentation approach focused on critical parameters | Validation protocol and report |

| Final Inspection | Verification of completed production run | 100% inspection of critical features, sampling of others | Certificate of Conformance provided |

6 Manufacturing Technologies for Low Volume Production

Several advanced manufacturing technologies have been developed specifically to enhance the efficiency and capabilities of low volume CNC production.

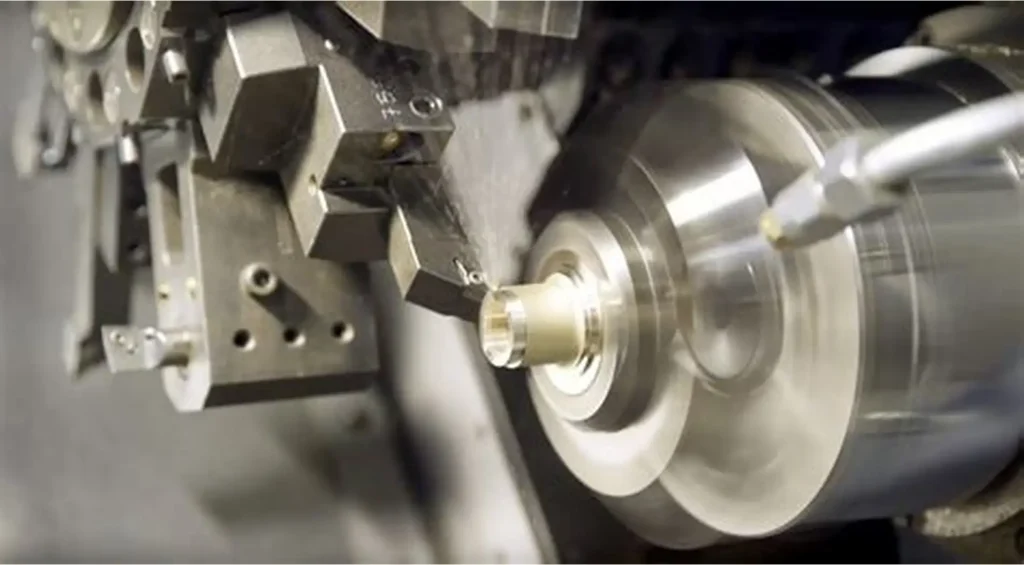

Multi-Axis Machining: 5-axis CNC machining centers enable complete machining of complex parts in a single setup, reducing handling and improving accuracy. The simultaneous movement of multiple axes allows for intricate geometries that would be difficult or impossible to produce with conventional 3-axis machines.

Automated Material Handling: Robotic part loading, pallet changers, and bar feeders enable extended unmanned operation of CNC equipment, improving utilization rates and making small batch production more economical. These systems can be configured for flexible operation, allowing quick changeovers between different parts.

Advanced Tooling Systems: Quick-change toolholders, high-performance cutting tools, and tool management systems reduce setup times and improve machining efficiency. Modern tooling solutions can significantly reduce non-cutting time, which represents a higher proportion of total processing time in low volume production.

In-Process Monitoring: Tool condition monitoring, vibration analysis, and adaptive control systems maintain process quality and prevent defects during unmanned operation. These systems are particularly valuable for low volume production where operator attention may be divided across multiple jobs.

Digital Manufacturing Integration: CAD/CAM systems with post-processor optimization streamline the transition from design to production. Manufacturing execution systems (MES) provide real-time visibility into production status, while digital twins simulate machining processes to optimize parameters before physical production begins.

7 Design Optimization for Low Volume CNC Production

Designing parts specifically for low volume CNC manufacturing can significantly improve efficiency, reduce costs, and enhance quality.

Design for Manufacturability: Understanding CNC machining constraints allows designers to create parts that can be produced efficiently. Uniform wall thicknesses, standardized feature sizes, and accessible geometries reduce machining time and improve tool life.

Feature Consolidation: Combining multiple components into single machined parts eliminates assembly operations and reduces total part count. This approach is particularly valuable in low volume production where the economic advantages of assembly labor reduction outweigh the potentially higher machining cost.

Material Selection: Choosing appropriate materials based on functional requirements, machinability, and cost optimizes the production process. Standard material sizes and grades should be selected to minimize waste and reduce lead times for material procurement.

Tolerance Optimization: Specifying tolerances based on actual functional requirements rather than defaulting to tight values reduces machining time and cost. Understanding which features require precision and which can have looser tolerances is key to efficient low volume production.

Surface Finish Specification: Defining surface finish requirements based on functional needs rather than arbitrary standards optimizes the manufacturing process. Different applications require different surface characteristics, and specifying the appropriate finish reduces unnecessary machining or secondary operations.

8 Strategic Advantages of Low Volume CNC Production

Beyond the immediate technical and economic benefits, low volume CNC production offers several strategic advantages that can significantly impact business performance.

Supply Chain Resilience: The ability to produce components in smaller batches closer to end markets reduces dependence on extended global supply chains. This resilience has become increasingly valuable in the face of disruptions and uncertainties in traditional manufacturing models.

Customization Capability: Low volume production enables mass customization strategies that allow products to be tailored to specific customer requirements or market segments without the cost penalties traditionally associated with custom manufacturing.

Sustainability Benefits: Smaller production batches aligned with actual demand reduce waste from obsolete inventory and unsold products. The digital nature of CNC manufacturing also enables more efficient material usage through nesting optimization and reduced scrap rates.

Innovation Acceleration: The ability to quickly transition from design to production accelerates the innovation cycle, allowing companies to iterate designs based on real-world feedback and bring improved products to market faster.

Risk Management: Limiting initial production quantities reduces financial exposure if designs require modification or market demand is lower than anticipated. This risk management capability is particularly valuable for new product introductions in uncertain markets.

9 Future Trends in Low Volume Manufacturing

The field of low volume CNC production continues to evolve with several emerging trends shaping its future development.

Digital Manufacturing Integration: The convergence of CAD/CAM systems, production planning, and quality management into integrated digital environments streamlines the entire production process from design to delivery.

Additive and Subtractive Hybridization: The combination of additive manufacturing for complex features and CNC machining for precision surfaces creates new possibilities for part geometries and production efficiency.

Artificial Intelligence and Machine Learning: AI-powered optimization of machining parameters, predictive maintenance, and quality prediction enhance the efficiency and reliability of low volume production processes.

Distributed Manufacturing Networks: Geographically distributed manufacturing facilities with coordinated production capabilities enable companies to produce components closer to end markets while maintaining consistent quality standards.

Sustainable Manufacturing Practices: Energy-efficient equipment, recycling of machining coolants and chips, and optimized material usage reduce the environmental impact of low volume production while often lowering costs.

10 Conclusion: Leveraging Low Volume Production for Competitive Advantage

Low volume CNC production runs represent a sophisticated manufacturing strategy that provides businesses with unprecedented flexibility, responsiveness, and efficiency for production quantities in the 50-500 unit range. By leveraging advanced CNC technologies, digital manufacturing methodologies, and strategic quality management approaches, manufacturers can overcome the traditional economic constraints of small batch production while maintaining the design freedom and rapid iteration capabilities typically associated with prototyping.

The continuing evolution of CNC machining technologies, digital manufacturing systems, and supply chain models is further enhancing the viability and advantages of low volume production approaches. Companies that master the intricacies of low volume manufacturing position themselves to respond more effectively to market opportunities, customize products for specific customer segments, and manage the risks associated with new product introduction.

At JL YPT, we combine state-of-the-art CNC machining capabilities with extensive experience in low volume production across diverse industries. Our facilities include advanced machining centers, comprehensive quality assurance equipment, and digital manufacturing systems that ensure your low volume production runs meet the highest standards of quality, precision, and efficiency.

Ready to discuss your low volume CNC production needs? Contact JL YPT today to leverage our expertise for your next manufacturing project.