Precision Prototyping: Mastering Low Volume Electronic Enclosure Machining for Startups

The journey from concept to market-ready product presents unique challenges for hardware startups, particularly when it comes to electronic enclosures that must balance aesthetic appeal, functional requirements, and manufacturing feasibility. In the critical early stages, the ability to rapidly iterate designs while maintaining professional quality can determine a startup’s success. At JLYPT CNC Machining, we specialize in low volume electronic enclosure machining for startups, providing the technical expertise and manufacturing flexibility that emerging companies need to transform innovative concepts into production-ready products.

This comprehensive guide explores the technical considerations, manufacturing strategies, and collaborative approaches that define successful low volume electronic enclosure machining for startups. We examine how strategic implementation of CNC technologies, combined with design for manufacturability principles and rapid iteration capabilities, enables startups to navigate the complex journey from prototype to production with confidence and efficiency.

The Startup Manufacturing Challenge: Balancing Quality, Speed, and Cost

Startups face unique manufacturing challenges that require specialized approaches and flexible manufacturing partnerships. Successful low volume electronic enclosure machining for startups must address several critical factors simultaneously:

Technical and Operational Considerations

The manufacturing approach for startup enclosures must accommodate both immediate and long-term requirements:

-

Design Flexibility: Accommodating frequent design changes and iterations without significant cost penalties or timeline impacts

-

Scalability Planning: Implementing manufacturing strategies that support seamless transition from prototype quantities to initial production volumes

-

Budget Optimization: Maximizing value through strategic material selection, efficient machining approaches, and minimized secondary operations

-

Timeline Management: Compressing development cycles through rapid turnaround manufacturing and streamlined communication protocols

Quality and Compliance Requirements

Even at low volumes, enclosures must meet stringent quality standards:

-

Dimensional Accuracy: Maintaining tight tolerances for component integration, mounting features, and aesthetic elements

-

Material Performance: Selecting appropriate materials for structural integrity, thermal management, and environmental resistance

-

Regulatory Compliance: Addressing EMI/RFI shielding, thermal considerations, and safety requirements from the earliest prototypes

-

Surface Quality: Achieving professional finishes that enhance product perception and brand identity

Advanced Manufacturing Technologies for Startup Enclosures

Modern CNC technologies provide startups with manufacturing capabilities previously accessible only to established companies with substantial resources:

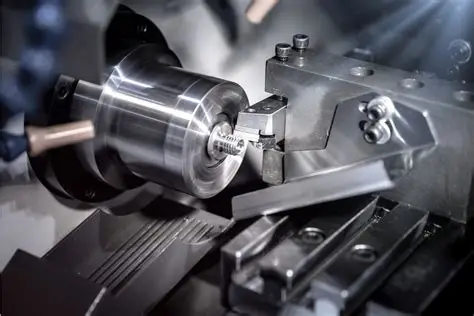

Multi-Axis CNC Machining Capabilities

Our advanced manufacturing infrastructure supports the diverse requirements of startup enclosure development:

-

3+2 Axis Machining: Efficient processing of complex geometries and multiple sides in single setups, reducing handling and accelerating turnaround times

-

High-Speed Machining: Optimized toolpaths and cutting parameters for superior surface finishes, reduced machining times, and enhanced dimensional stability

-

Adaptive Clearing Strategies: Efficient material removal while maintaining tool integrity and minimizing machining stresses on thin-walled enclosure features

-

Rest Machining Techniques: Automated detection and removal of remaining material from previous operations, ensuring complete feature definition and surface consistency

Specialized Processes for Enclosure Manufacturing

Certain enclosure features require specialized manufacturing approaches:

-

Thin-Wall Machining: Precision processing of delicate wall sections down to 0.5mm while maintaining structural integrity and dimensional stability

-

Integrated Heat Management: Strategic implementation of cooling fins, thermal pathways, and heat sink features directly within enclosure designs

-

EMI/RFI Shielding Features: Precision machining of grooves, contacts, and sealing surfaces for effective electromagnetic compatibility

-

Snap-Fit and Living Hinge Creation: Manufacturing of interlocking features and flexible elements for assembly and access requirements

Material Selection for Startup Electronic Enclosures

The choice of enclosure material significantly impacts aesthetics, functionality, manufacturability, and cost – all critical considerations in low volume electronic enclosure machining for startups:

Aluminum Alloys for Performance Applications

-

6061-T6 Aluminum: Excellent all-around properties with good machinability, strength, and anodizing response for general purpose enclosures

-

5052-H32 Aluminum: Superior corrosion resistance and formability for applications requiring additional environmental protection

-

7075-T6 Aluminum: High strength-to-weight ratio for demanding applications where structural integrity is paramount

Engineering Plastics for Specialized Requirements

-

ABS: Good impact resistance, dimensional stability, and surface finish capability for consumer-oriented products

-

Polycarbonate: Excellent impact strength and transparency options for applications requiring visibility or additional durability

-

PEEK: Superior thermal and chemical resistance for demanding environmental conditions and high-temperature applications

-

Delrin (POM): Low friction and excellent dimensional stability for moving parts and precise mechanical interfaces

Technical Design Considerations for Startup Enclosures

The table below outlines critical design factors and manufacturing considerations for successful low volume electronic enclosure machining for startups:

| Design Feature | Technical Considerations | Manufacturing Approach | Startup Benefit |

|---|---|---|---|

| Wall Thickness | Uniform distribution, transition zones, structural requirements | Adaptive toolpaths, specialized fixturing, thermal management | Reduced warpage, consistent quality, improved yield |

| Mounting Features | Boss design, thread engagement, stress distribution | Thread milling, helical interpolation, proper chip evacuation | Secure component mounting, reduced assembly issues |

| Connector Cutouts | Tolerance compliance, surface finish, orientation control | High-speed machining, specialized tooling, proper support | Reliable interface connections, professional appearance |

| Heat Management | Dissipation pathways, surface area optimization, material selection | Integrated fin machining, thermal interface surfaces | Improved reliability, extended component lifespan |

| Aesthetic Elements | Surface finish, texture consistency, brand identity | Strategic toolpath planning, post-processing optimization | Enhanced market appeal, professional product presentation |

| Assembly Features | Alignment pins, snap fits, fastener access | Precision boring, living hinge machining, proper clearance | Simplified assembly, reduced production time and cost |

For comprehensive understanding of electronic enclosure standards and design guidelines, we regularly consult resources from IPC – Association Connecting Electronics Industries to ensure compliance with industry requirements and best practices.

Comprehensive Case Studies: Startup Enclosure Success Stories

Case Study 1: IoT Sensor Platform Enclosure

-

Challenge: An IoT startup needed a weatherproof enclosure for their environmental monitoring system capable of housing sensitive electronics while withstanding outdoor conditions. The design required IP67 certification, integrated mounting features, and professional aesthetics for commercial deployment.

-

Technical Solution: We engineered a two-part enclosure from 6061 aluminum with precision-machined sealing surfaces and strategic thermal management features. The design incorporated concealed fasteners, cable gland interfaces, and optimized internal layout for component placement and service access.

-

Manufacturing Approach: The enclosure halves were machined using 3+2 axis strategies with specialized tooling for the O-ring grooves and sealing surfaces. Critical interfaces underwent high-speed finishing to achieve the required surface quality for weatherproof performance.

-

Technical Outcomes: The enclosure achieved IP67 certification on first-round prototypes and provided excellent thermal management in field testing. The professional appearance helped secure pilot deployments with commercial clients, while the design supported seamless scaling to production volumes.

-

Internal Link: Discover our comprehensive approach to enclosure manufacturing through our Precision CNC Machining Services.

Case Study 2: Medical Device Startup Enclosure System

-

Challenge: A medical technology startup required a complex enclosure system for a portable diagnostic device with stringent regulatory requirements, ergonomic considerations, and sophisticated aesthetic appeal. The design needed to accommodate multiple PCBs, display interfaces, and user controls while maintaining clinical-grade appearance and durability.

-

Technical Solution: We developed a multi-component enclosure system using medical-grade polycarbonate with aluminum reinforcement elements. The design incorporated textured grips, status indicator windows, and precisely aligned interface components with seamless transitions between materials.

-

Manufacturing Approach: Complex internal features were machined using specialized small-diameter tooling with optimized stepover distances for smooth surfaces. Critical alignment features employed precision boring and reaming operations to ensure perfect component registration.

-

Technical Outcomes: The enclosure system exceeded usability testing requirements and provided the professional appearance necessary for clinical environments. The precision manufacturing supported regulatory submissions with comprehensive documentation, accelerating the path to market approval.

Case Study 3: Robotics Startup Controller Enclosure

-

Challenge: A robotics startup needed a durable enclosure for their motion controller capable of withstanding industrial environments while providing adequate cooling for high-power components. The design required extensive connector interfaces, status indicators, and robust mounting provisions for machine integration.

-

Technical Solution: We designed a heavy-duty enclosure from 5052 aluminum with integrated heat sinking and strategic ventilation patterns. The solution included EMI shielding features, industrial-grade connectors, and protective elements for vulnerable components.

-

Manufacturing Approach: The enclosure employed adaptive clearing strategies for efficient material removal while maintaining structural integrity. Heat dissipation features were machined using specialized toolpaths to maximize surface area and thermal performance.

-

Technical Outcomes: The enclosure provided exceptional thermal management in validation testing, maintaining component temperatures 15°C below requirements. The robust construction survived environmental testing exceeding industry standards, supporting successful field deployments and investor demonstrations.

Design for Manufacturability in Startup Environments

Effective low volume electronic enclosure machining for startups requires strategic application of DFM principles tailored to startup constraints:

Early-Stage Design Optimization

-

Feature Consolidation: Combining multiple components into single machined parts to reduce assembly operations and improve reliability

-

Tolerance Rationalization: Applying appropriate tolerances based on functional requirements rather than default CAD settings

-

Material Optimization: Selecting materials that balance performance, manufacturability, and cost for specific application requirements

-

Process Integration: Designing for efficient machining, finishing, and assembly within startup manufacturing workflows

Prototyping to Production Transition

-

Design Continuity: Maintaining design intent and functionality while optimizing for changing manufacturing considerations

-

Documentation Development: Creating comprehensive manufacturing documentation that supports seamless transition to production partners

-

Supply Chain Preparation: Identifying and qualifying materials and processes that scale effectively to production volumes

-

Quality System Foundation: Establishing inspection protocols and quality standards that support future manufacturing

Quality Assurance for Startup Manufacturing

Even at low volumes, comprehensive quality assurance provides critical value in low volume electronic enclosure machining for startups:

-

First Article Inspection: Comprehensive dimensional validation using coordinate measuring machines with comparison to design specifications

-

Functional Testing: Verification of assembly integrity, component fitment, and interface functionality

-

Surface Quality Assessment: Precise evaluation of surface finish, texture consistency, and aesthetic appeal

-

Documentation Package: Complete inspection reports, material certifications, and manufacturing records supporting future production

The Startup Manufacturing Partnership Advantage

Successful low volume electronic enclosure machining for startups extends beyond manufacturing to encompass broader partnership benefits:

-

Technical Guidance: Expert advice on design optimization, material selection, and manufacturing strategies based on practical experience

-

Resource Optimization: Strategic approaches to maximize limited budgets while maintaining quality and performance standards

-

Timeline Management: Proactive project coordination and rapid response capabilities supporting aggressive development schedules

-

Scalability Planning: Manufacturing approaches that support seamless transition from prototype to production volumes

Conclusion: Strategic Manufacturing Partnerships for Startup Success

The journey from concept to market-ready product represents a critical phase for hardware startups, where effective enclosure development can significantly impact funding, market entry, and ultimate success. At JLYPT CNC Machining, our specialized approach to low volume electronic enclosure machining for startups provides emerging companies with the manufacturing capabilities, technical expertise, and strategic partnership needed to navigate this challenging landscape successfully.

Our methodology recognizes that startup manufacturing requires balancing ambitious technical goals with practical constraints and aggressive timelines. Through close collaboration, technical guidance, and flexible manufacturing approaches, we help startups transform innovative concepts into professional, functional enclosures that support product validation, investor presentations, and initial market entry.

Ready to accelerate your product development with professional enclosure solutions? Contact JLYPT CNC Machining today to discover how our expertise in low volume electronic enclosure machining for startups can help you achieve your development goals with quality, efficiency, and strategic manufacturing partnership.