Advanced Strategies for Machining Hardened Tool Steel: A Comprehensive CNC Guide

Introduction: Mastering the Art of Hardened Tool Steel Machining

Hardened tool steel represents one of the most challenging materials in precision CNC machining, combining exceptional hardness, wear resistance, and thermal stability that push conventional machining technologies to their limits. With hardness levels typically ranging from 45-68 HRC, these materials require specialized tooling strategies, precise parameter optimization, and advanced machining techniques to achieve dimensional accuracy and surface integrity.

The evolution of hardened steel machining has revolutionized manufacturing across industries, enabling production of longer-lasting tools, higher-performance components, and reduced maintenance cycles. As industries increasingly demand superior wear resistance and durability, the ability to effectively machine hardened tool steels has become a critical competitive advantage for precision manufacturing providers seeking to deliver exceptional value to their clients.

Understanding Hardened Tool Steel Properties and Material Characteristics

Material Classification and Key Properties

Tool steels encompass a range of alloy steels specifically formulated to provide high hardness, abrasion resistance, and ability to hold a cutting edge. The hardening process, typically involving heat treatment to specific temperature ranges followed by quenching, transforms the material’s microstructure to achieve these properties:

Table 1: Common Hardened Tool Steel Grades and Machining Characteristics

| Steel Grade | Typical Hardness (HRC) | Primary Alloying Elements | Key Applications | Machining Challenges |

|---|---|---|---|---|

| D2 | 58-62 | Cr, Mo, V | Blanking dies, forming rolls, molds | High abrasiveness, tool wear |

| A2 | 57-61 | Cr, Mo | Gauges, punches, die inserts | Moderate machinability, consistent wear |

| O1 | 58-62 | Mn, Cr, W | Cutting tools, knives, shearing blades | Good machinability for hardened steel |

| H13 | 48-52 | Cr, Mo, V | Die casting dies, extrusion dies | Thermal fatigue resistance |

| M2 | 62-64 | W, Mo, Cr, V | High-speed cutting tools | Extreme hardness, abrasiveness |

| S7 | 56-58 | Cr, Mo, Si | Shock-resistant tools, punches | Impact resistance, ductility |

The high hardness characteristics of these materials, particularly grades like M2 that reach 64 HRC, necessitate machining approaches fundamentally different from those used for conventional steels . The hardened microstructure, while providing exceptional wear resistance, creates significant challenges for traditional cutting tools and processes.

Primary Machining Challenges

Several material characteristics present significant obstacles in hardened tool steel machining:

-

Rapid Tool Wear: The extreme hardness and abrasiveness of carbide particles in tool steels accelerate cutting edge deterioration, particularly with conventional tooling

-

High Cutting Forces: The material’s resistance to deformation requires substantial cutting forces, demanding rigid machine tools and workholding systems

-

Thermal Management: Poor thermal conductivity causes heat concentration at the cutting zone, potentially altering material properties or damaging the workpiece

-

Surface Integrity Control: Achieving required surface finishes while maintaining compressive residual stresses demands precise parameter control

-

Dimensional Accuracy: Springback effects and thermal expansion complicate the maintenance of tight tolerances

Advanced Tooling Strategies for Hardened Tool Steels

Cutting Tool Material Selection

Proper tool selection is critical for successful hardened steel machining. Conventional high-speed steel tools are inadequate for these applications, necessitating advanced tool materials:

Table 2: Tooling Recommendations for Hardened Tool Steel Machining

| Tool Material | Hardness (HV) | Thermal Stability | Optimal Applications | Limitations |

|---|---|---|---|---|

| PCBN (Polycrystalline Cubic Boron Nitride) | 3,000-4,000 | >1,000°C | Finishing operations (45-68 HRC) | Cost, brittleness in interrupted cuts |

| Ceramic | 1,800-2,200 | >1,200°C | High-speed continuous machining | Poor thermal shock resistance |

| CBN (Cubic Boron Nitride) | 3,000-4,500 | >1,000°C | Hard turning (50-65 HRC) | Edge preparation critical |

| Coated Carbide | 1,600-2,000 | 800-900°C | Roughing, semi-finishing | Limited to <55 HRC |

| Advanced TiAlN-coated Carbide | 2,000-2,400 | 900-950°C | Interrupted cuts, complex geometries | Progressive wear patterns |

Research indicates that PCBN tools demonstrate exceptional performance in hardened steel machining applications, particularly in finishing operations where they can maintain dimensional accuracy and surface quality significantly better than alternative tool materials . The extreme hardness and thermal conductivity of CBN minimizes abrasive wear while effectively dissipating heat from the cutting zone.

Tool Geometry Optimization

Specific geometric considerations significantly impact tool performance and workpiece quality in hardened steel machining:

-

Rake Angles: Negative rake angles (5°-7°) typically provide better edge strength in hardened materials, though they increase cutting forces

-

Cutting Edge Preparation: Honed edges (0.02-0.05mm) or T-land preparations enhance edge strength and reduce micro-chipping susceptibility

-

Clearance Angles: Adequate clearance (5°-7°) prevents rubbing against the workpiece, minimizing heat generation and potential rehardening

-

Chipbreaker Geometry: Specialized chipbreaker designs facilitate controlled chip formation and evacuation in continuous machining operations

Optimized Machining Parameters for Hardened Tool Steels

Precision Machining Parameters

Establishing optimal cutting parameters requires balancing material removal rates with surface finish requirements and tool life considerations:

-

Cutting Speeds: 80-250 m/min for PCBN tools, 150-350 m/min for ceramics, depending on material hardness and operation type

-

Feed Rates: 0.05-0.15 mm/rev for turning, 0.05-0.10 mm/tooth for milling operations

-

Depth of Cut: 0.1-0.5mm for finishing, 0.5-2.0mm for roughing operations in semi-hardened states

-

Coolant Strategy: Typically dry machining or minimal quantity lubrication (MQL) to avoid thermal shock

Experimental investigations have demonstrated that surface roughness decreases linearly with increasing cutting speed in hard turning applications . However, this relationship must be balanced against potential trade-offs in tool life, particularly at extreme parameters.

Adaptive Machining Strategies

Advanced machining approaches address hardened steel’s specific challenges through strategic parameter adjustments:

-

Trochoidal Milling: Reduced tool engagement per revolution manages cutting forces and heat generation in hard materials

-

High-Speed Machining: Elevated cutting speeds transfer heat to chips rather than workpiece, potentially improving surface integrity

-

Progressive Roughing: Multiple passes with increasing precision approach final dimensions while managing residual stresses

-

Vibration Damping Techniques: Variable helix/pitch tools and dynamic stability monitoring mitigate chatter in hard machining

Specialized Techniques for Hardened Steel Components

Thermal Management Strategies

Controlling machining temperatures is crucial since excessive heat can alter the hardened microstructure or induce undesirable tensile stresses:

-

Cryogenic Machining: Liquid nitrogen application provides extreme cooling without contaminating the cutting zone

-

Through-Tool Coolant: Precise delivery directly to the cutting edge, particularly effective in drilling and deep cavity operations

-

Air Cooling Systems: Directed compressed air effectively removes chips and provides moderate cooling in dry machining scenarios

-

Cutting Parameter Optimization: Strategic speed and feed selection to control thermal generation at the source

Surface Integrity Enhancement

Beyond dimensional accuracy, hardened steel components often require specific surface characteristics:

-

Finish Machining Strategies: Light final passes (0.05-0.10mm) to achieve required surface roughness while inducing beneficial compressive stresses

-

Residual Stress Management: Parameter selection to control the balance between compressive and tensile stresses in the surface layer

-

Microstructural Preservation: Avoiding thermal alterations or rehardening phenomena that compromise component performance

-

Post-Machining Treatments: Subsequent processes like polishing or superfinishing to enhance surface characteristics further

Quality Assurance for Hardened Steel Components

Surface Integrity Verification

Maintaining surface integrity is critical for hardened steel components, particularly in fatigue-sensitive applications:

-

Surface Roughness Measurement: Profilometry confirming Ra values meet specifications, typically <0.8μm for precision components

-

Residual Stress Analysis: X-ray diffraction techniques verifying compressive surface stresses that enhance fatigue life

-

Microhardness Testing: Ensuring absence of thermal alterations or softening in the surface layer

-

White Layer Detection: Identifying potential rehardened layers that could compromise component performance

Dimensional Validation Techniques

Advanced metrology ensures compliance with stringent tolerances required for tooling and precision components:

-

CMM Inspection: Volumetric accuracy up to 0.0003mm for complex geometric features common in mold and die applications

-

Optical Scanning: Non-contact measurement of contoured surfaces and free-form geometries

-

Specialized Fixturing: Simulation of operating conditions for functional validation of tooling components

-

Statistical Process Control: Real-time monitoring of critical dimensions throughout production runs

Industry Applications: Case Studies in Hardened Steel Machining Excellence

Case Study 1: Precision Blanking Die Components

Challenge: An automotive components manufacturer needed D2 tool steel blanking dies with exceptional edge retention and dimensional stability. The components required hardness of 60-62 HRC with critical clearances maintained within 0.005mm across the cutting profile.

Solution: Our team implemented a multi-stage machining approach incorporating:

-

Rough machining in annealed condition followed by heat treatment to final hardness

-

Precision finishing with PCBN tooling using trochoidal milling strategies

-

Custom fixturing to support thin sections during finishing operations

-

In-process temperature monitoring to prevent thermal alterations

Results: The dies achieved all dimensional requirements with edge radii <0.005mm and surface roughness of 0.4μm. The components demonstrated 40% longer service life compared to previous suppliers’ components, with reduced maintenance requirements .

Case Study 2: High-Performance Injection Mold

Challenge: A medical device company needed H13 steel injection molds for high-volume production of precision components. The molds required hardness of 48-50 HRC with complex cooling channels and textured surfaces.

Solution: We developed a specialized machining process featuring:

-

High-speed machining strategies with advanced coated carbide tools

-

Optimized tool paths for complex contoured surfaces

-

Precision drilling of cooling channels using through-tool coolant delivery

-

Surface texturing through controlled EDM and machining techniques

Results: The molds achieved exceptional surface quality with consistent texture replication across the molding surface. The optimized cooling channel design reduced cycle times by 25% while maintaining dimensional stability through extended production runs .

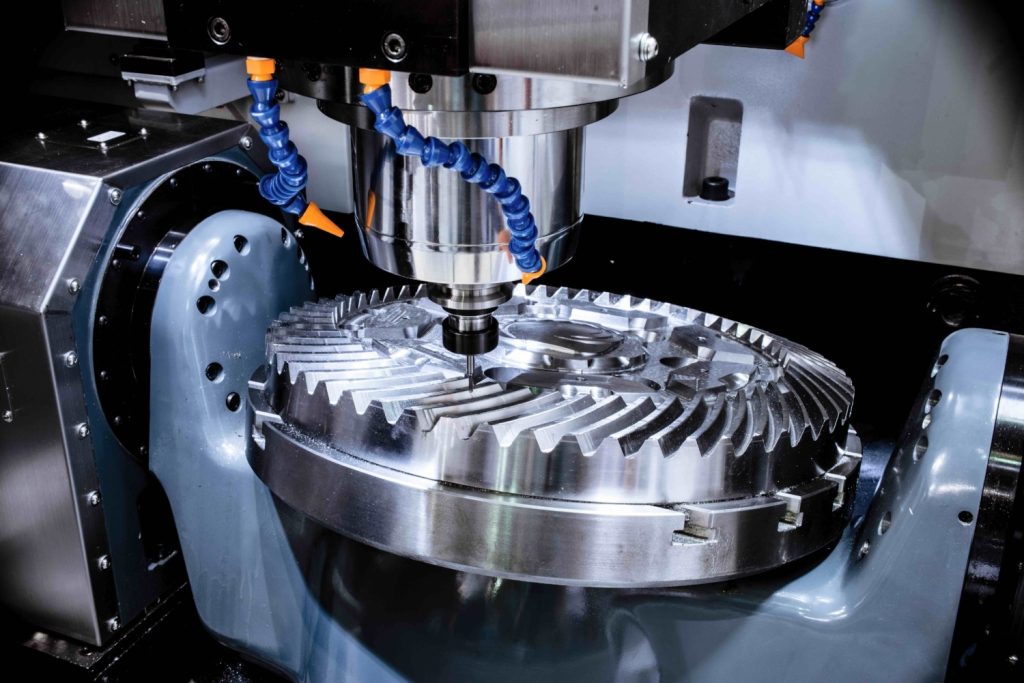

Case Study 3: Aerospace Gear Cutting Tools

Challenge: An aerospace manufacturer needed M2 high-speed steel cutting tools for gear manufacturing applications. The tools required hardness of 63-64 HRC with precise tooth profiles and critical edge preparation.

Solution: Our comprehensive approach included:

-

Progressive machining from soft to hardened state with intermediate heat treatments

-

Final profile machining with CBN tooling using customized edge geometry

-

Sophisticated sharpening techniques to achieve required cutting edge characteristics

-

100% inspection of critical features with optical comparators and CMM verification

Results: The cutting tools achieved superior edge retention and profile accuracy, resulting in extended tool life and consistent gear quality. The solution provided a 30% improvement in tool life compared to previous suppliers, significantly reducing production costs for the aerospace manufacturer .

Technical Comparison: Hard Machining vs. Traditional Approaches

Hard Machining vs. EDM for Mold Applications

While electrical discharge machining has traditionally been used for hardened steels, precision hard machining offers significant advantages:

-

Surface Integrity: Hard machining typically produces superior surface finishes without the recast layer associated with EDM

-

Geometric Flexibility: Complex 3D contours are more efficiently produced through 5-axis machining

-

Production Efficiency: Significantly faster material removal rates reduce lead times for mold production

-

Environmental Considerations: Eliminates dielectric fluids required for EDM processes

Hard Turning vs. Grinding for Bearing Applications

For precision bearing components, hard turning with PCBN tools offers compelling advantages over traditional grinding:

-

Flexibility: Quick changeover between components compared to dedicated grinding wheels

-

Surface Compression: Often produces beneficial compressive stresses versus potentially tensile stresses from grinding

-

Dry Machining: Eliminates coolant management issues associated with grinding operations

-

Integrated Manufacturing: Complex geometries can be completed in single setups versus multiple grinding operations

Future Trends in Hardened Steel Machining Technology

Advanced Manufacturing Technologies

Emerging technologies are transforming hardened steel machining capabilities:

-

AI-Driven Optimization: Machine learning algorithms that dynamically adjust parameters based on real-time sensor data to optimize tool life and surface quality

-

Hybrid Manufacturing: Combining additive manufacturing for near-net-shape preforms with precision hard machining for final dimensions

-

Digital Twin Technology: Virtual modeling of the machining process to predict outcomes and optimize parameters before physical cutting

-

Sustainable Machining Practices: Reducing energy consumption and environmental impact while maintaining quality standards

Tooling and Equipment Developments

Ongoing research continues to expand the capabilities of hardened steel machining:

-

Advanced Tool Materials: Nanostructured coatings and substrate materials with enhanced thermal and mechanical properties

-

Smart Tooling Systems: Embedded sensors for real-time monitoring of cutting forces and temperature

-

Adaptive Control Systems: Closed-loop systems that automatically compensate for tool wear and thermal effects

-

High-Speed Spindle Technology: Increased power and torque at higher rotational speeds for improved efficiency

Conclusion: Excellence in Hardened Tool Steel Machining Services

Hardened tool steel machining represents the pinnacle of precision manufacturing, demanding specialized expertise, advanced equipment, and rigorous process controls. The exceptional properties of these materials—outstanding wear resistance, high hardness, and thermal stability—make them indispensable for demanding applications across tooling, aerospace, automotive, and energy industries. However, realizing these advantages requires comprehensive understanding of the material’s machining characteristics and implementation of optimized strategies throughout the manufacturing process.

At our manufacturing facility, we’ve combined state-of-the-art CNC technology with deep materials knowledge to establish leadership in hardened steel component machining. Our comprehensive approach addresses every aspect of the manufacturing process, from initial design consultation through final inspection and delivery, with particular emphasis on surface integrity, dimensional accuracy, and documentation.

The case studies presented demonstrate our capability to solve complex manufacturing challenges while maintaining the highest quality standards across diverse applications. As technology continues to evolve toward increasingly demanding performance requirements, we remain committed to investing in advanced equipment and methodologies that enhance our hardened steel machining capabilities.

For your next high-performance component project, partner with a manufacturer that understands both the technical complexities and practical considerations of working with these exceptional materials. Contact us today to discuss how our hardened tool steel machining services can address your specific application requirements.