Precision Medical Device Component Manufacturing with CMM Inspection: Ensuring Compliance and Performance

The medical device industry operates within an environment where component precision directly correlates with patient safety and treatment efficacy. As medical technologies advance toward minimally invasive procedures and patient-specific solutions, the demand for absolutely reliable components has intensified significantly. At JLYPT Precision, we have established a comprehensive framework for medical device component manufacturing with CMM inspection that integrates advanced metrology directly into our production workflow, ensuring every component meets the rigorous standards mandated by healthcare regulations and clinical requirements.

This detailed technical examination explores the sophisticated engineering protocols, material considerations, and validation methodologies that define contemporary medical device component manufacturing with CMM inspection. We will analyze how strategic implementation of coordinate measuring technology transforms quality assurance from a final verification step to an integral manufacturing component, providing documented evidence of precision for regulatory compliance and clinical confidence.

The Critical Framework of Medical Device Manufacturing

Medical device components function under constraints that substantially exceed those of conventional precision engineering. Effective medical device component manufacturing with CMM inspection must simultaneously address multiple critical requirements:

Regulatory Compliance and Comprehensive Documentation

The medical device sector functions within a strict regulatory framework governed by standards including ISO 13485:2016 and FDA 21 CFR Part 820. These standards mandate not only final product quality but complete process control and documentation transparency. Our methodology for medical device component manufacturing with CMM inspection generates extensive data packages that deliver:

-

Complete Material Traceability: Full documentation chain from raw material certification through finished component

-

Process Validation Evidence: Documented proof demonstrating manufacturing processes consistently yield conforming parts

-

Equipment Calibration History: Regular verification records for all manufacturing and inspection equipment

-

Non-Conformance Management: Comprehensive tracking and resolution documentation for any specification deviations

Biocompatibility and Material Performance Parameters

Material selection represents a fundamental decision in medical device design, significantly influencing both manufacturing approaches and inspection requirements. Our expertise encompasses numerous medically approved materials:

-

Titanium Alloys (Ti-6Al-4V ELI): Preferred for permanent implants due to exceptional biocompatibility and mechanical properties that closely mimic human bone characteristics

-

Cobalt-Chromium Alloys (CoCrMo): Outstanding wear resistance ideal for articulating joint surfaces in orthopedic applications

-

Stainless Steels (316LV, 17-4PH): Cost-efficient solutions for surgical instruments and temporary implants requiring superior corrosion resistance

-

Medical Polymers (PEEK, UHMWPE): Increasingly utilized for radiolucent components and bearing surfaces owing to excellent mechanical and chemical properties

Each material presents distinct machining challenges that must be addressed through specialized tooling, cutting parameters, and fixturing strategies—all validated through our comprehensive medical device component manufacturing with CMM inspection protocol.

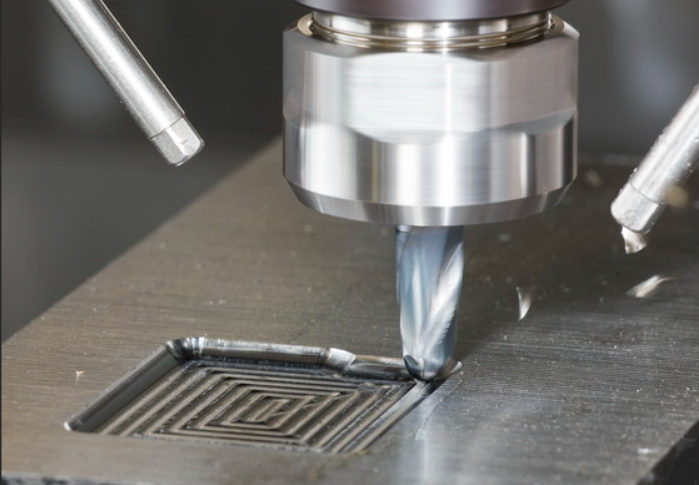

Advanced Manufacturing Technologies for Medical Applications

Different medical component geometries and material characteristics necessitate specialized manufacturing approaches. We maintain a diverse technology portfolio to align the optimal process with each component’s specific requirements.

5-Axis Simultaneous Machining for Complex Geometries

For components featuring complex contours, undercuts, and compound angles—typical in orthopedic implants and specialized surgical instruments—5-axis simultaneous machining delivers unparalleled capabilities:

-

Single-Setup Manufacturing: Complete machining from multiple orientations in one operation eliminates cumulative errors from multiple fixturing

-

Optimized Tool Access: Continuous 5-axis movement maintains ideal tool orientation relative to complex surfaces

-

Superior Surface Finishes: Consistent tool engagement produces surfaces that frequently eliminate secondary polishing operations

-

Complex Contour Machining: Direct machining of organic shapes from patient medical imaging data

CNC Swiss-Type Machining for Small, Precision Components

The evolution of Swiss-type machining has transformed production of long, slender components prevalent in medical applications:

-

Exceptional Stability: Guide bushing support immediately adjacent to cutting tools prevents deflection during machining

-

Integrated Secondary Operations: Live tooling capabilities enable complete machining of complex parts in single operations

-

Micron-Level Precision: Inherent stability maintains tolerances below ±0.0002″ on diameters and concentricities

-

Efficient Production: Continuous bar feeding optimizes machine utilization for high-volume small component production

High-Speed Micromachining for Miniature Features

Medical device miniaturization demands specialized equipment capable of machining microscopic features:

-

High-RPM Spindles: Capabilities exceeding 50,000 RPM maintain appropriate surface speeds with micro-tools

-

Advanced Micro-Tooling: Specialized end mills with unique geometries withstand extreme micromachining stresses

-

Precision Motion Systems: Ultra-fine resolution enables movements measured in millionths of an inch

-

Vibration Control: Specialized machine construction eliminates vibrations that compromise micro-feature accuracy

CMM Inspection as Manufacturing Integration

The genuine advancement in reliable medical device component manufacturing with CMM inspection resides in treating metrology as an integrated manufacturing element rather than a separate quality function.

Strategic CMM Implementation

-

First Article Inspection (FAI): Comprehensive validation of initial production parts against all design specifications

-

In-Process Verification: Strategic measurement during production enables statistical process control (SPC)

-

Tooling and Fixture Validation: Regular inspection ensures process stability and identifies maintenance requirements

-

Final Quality Certification: Detailed inspection reports provide objective evidence of specification compliance

Advanced CMM Capabilities for Medical Devices

Contemporary coordinate measuring machines offer capabilities particularly valuable for medical device applications:

-

Multi-Sensor Systems: Combined tactile probes and non-contact sensors measure diverse features without damage risk

-

High-Density Scanning: Continuous scanning captures thousands of data points per second for complete surface profiles

-

Temperature Compensation: Automatic compensation for thermal expansion effects in varying environmental conditions

-

Automated Operation: Programmable systems execute complex inspection routines with minimal operator intervention

Critical Measurement Parameters in Medical Device Manufacturing

The table below details specific geometric dimensioning and tolerancing (GD&T) parameters crucial in medical applications and how CMM technology validates each:

| GD&T Characteristic | Medical Application Example | CMM Validation Methodology | Performance Impact |

|---|---|---|---|

| True Position | Mounting holes in orthopedic reconstruction plates | Measures actual position versus theoretical exact location from CAD model | Ensures accurate screw alignment during surgical implantation for secure bone fixation |

| Flatness | Sealing surfaces in disposable surgical handpieces | Probes multiple points across surface plane calculating deviation from perfect flatness | Prevents fluid leakage and bacterial intrusion in critical sterile fields during procedures |

| Cylindricity | Implantable drug delivery pump components | Collects radial data points along cylinder length evaluating roundness and straightness | Guarantees consistent medication delivery and reliable mechanical operation |

| Surface Profile | Patient-matched cranial implants from CT data | High-density scanning of complete contoured surface compared to CAD model | Validates perfect anatomical conformity for optimal surgical outcomes and healing |

| Parallelism | Arthroscopic surgical instrument jaws | Measures angular relationships between features relative to established datums | Ensures uniform tissue compression and precise surgical cutting action |

| Concentricity | Cannulated surgical drills and guidance systems | Verifies coaxial alignment of internal and external diameters | Maintains exact surgical guidance preventing procedural deviation during operations |

For comprehensive understanding of GD&T standards, we recommend consulting the official guidelines published by the American Society of Mechanical Engineers (ASME Y14.5).

Comprehensive Case Studies: Real-World Implementation

Case Study 1: Minimally Invasive Surgical Instrument Manufacturing

-

Challenge: A surgical device company required production of complex endoscopic instruments for their advanced minimally invasive system. The components, machined from 17-4PH stainless steel, featured intricate internal articulation channels and delicate grasping mechanisms with critical tolerances under 8µm.

-

Manufacturing Solution: We implemented 5-axis micromachining strategies with specialized dynamic toolpaths to preserve precision on delicate features. Custom vacuum fixtures provided secure holding without part distortion during intricate machining operations.

-

CMM Inspection Protocol: Comprehensive CMM inspection employing micro-probe technology performed complete 3D verification of all critical features. The resulting deviation analysis confirmed that positional tolerances and geometric specifications met the 0.0003″ requirement. This data package proved indispensable during the client’s system integration and validation testing phases.

-

Internal Link: Explore our capabilities for advanced surgical components through our Precision CNC Machining Services.

Case Study 2: Orthopedic Spinal Implant with Advanced Surface Architecture

-

Challenge: An orthopedic implant manufacturer developed a titanium spinal fusion device featuring specialized surface textures for bone integration. The critical transition between precision machined surfaces and textured regions required flawless geometric transitions with specific profile requirements.

-

Manufacturing Solution: The implant was precision-machined from Ti-6Al-4V ELI using sophisticated 5-axis strategies specifically engineered to create controlled transitions between different surface geometries. Specialized tooling and machining parameters ensured burr-free interfaces.

-

CMM Inspection Protocol: Our metrology team employed a combination of tactile CMM measurements for critical datum features with white-light scanning to characterize the complex surface transitions. The comprehensive data analysis confirmed the surface profile met all specifications with no geometric discontinuities that could compromise implant performance.

-

External Resource: For detailed information on titanium material properties in medical applications, consult ASM Medical Materials Database.

Case Study 3: High-Precision Diagnostic Device Component Production

-

Challenge: A diagnostic equipment company required manufacturing of complex fluidic analysis mechanisms with micron-level channels where dimensional consistency directly influenced testing accuracy. The components demanded exceptional precision and surface finish throughout intricate internal passages.

-

Manufacturing Solution: We produced the components using advanced Swiss-type machining with integrated secondary operations. The process maintained outstanding dimensional stability while creating the complex internal features in a single manufacturing cycle.

-

CMM Inspection Protocol: Before production approval, every critical feature underwent exhaustive CMM inspection. Each fluidic channel’s geometry, sealing surface flatness, and mechanical interface locations were verified against CAD models to ensure consistent performance across the production volume. This rigorous approach to medical device component manufacturing with CMM inspection guaranteed reliable operation throughout the device lifecycle.

The Future of Medical Device Manufacturing

The field of medical device component manufacturing with CMM inspection continues to progress with several significant trends:

-

In-Line Metrology Integration: Implementation of measurement systems directly within production equipment for real-time process adjustment

-

Digital Thread Implementation: Establishing seamless data flow from design through manufacturing and inspection

-

Advanced Material Development: New bio-compatible materials presenting unique machining and inspection challenges

-

Artificial Intelligence in Metrology: AI algorithms analyzing inspection data to predict process trends and potential quality issues

Conclusion: Precision as Standard, Validation as Culture

In medical device manufacturing, where component performance directly influences patient outcomes, quality must be engineered into every aspect of the manufacturing process through disciplined protocols and rigorous validation. The integrated approach of medical device component manufacturing with CMM inspection at JLYPT Precision embodies our commitment to this philosophy—transforming subjective quality assessments into objective, data-driven certainty.

We provide our medical device partners with more than precisely machined components; we deliver documented confidence in component performance, regulatory compliance, and supply chain reliability. By implementing CMM inspection as an integral manufacturing component, we ensure that every part shipped meets the exacting standards demanded by the healthcare industry.

Ready to enhance your medical device manufacturing? Contact JLYPT Precision today to discover how our integrated approach to medical device component manufacturing with CMM inspection can improve your quality assurance, streamline regulatory compliance, and accelerate your development timeline.