Part Finishing and Coating Services: Enhancing CNC Machined Components for Superior Performance

In precision manufacturing, the final surface treatment often determines whether a component merely meets specifications or exceeds expectations for performance, durability, and aesthetics.

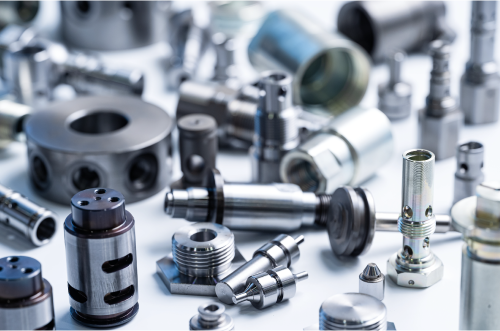

Part finishing and coating services represent the critical final phase in the CNC manufacturing process, where precisely machined components receive their functional and aesthetic properties. As specialized providers of CNC machining services, we understand that the selection and application of appropriate surface treatments can dramatically alter a part’s performance characteristics, corrosion resistance, and service life. The transformation from raw machined part to finished component requires specialized expertise in material science, application techniques, and industry-specific requirements.

Surface finishing technologies have evolved from simple protective measures to sophisticated engineering processes that actively contribute to component performance. Modern finishing services bridge the gap between base material properties and application demands, enabling CNC-machined components to perform in environments far beyond their inherent capabilities.

The Strategic Importance of Part Finishing in CNC Manufacturing

The journey from digital design to functional part doesn’t end with the last machining pass. Part finishing services complete the manufacturing process by addressing the surface-level limitations of even the most precisely machined components. The strategic application of finishing technologies delivers measurable benefits across critical performance metrics:

-

Enhanced Corrosion Resistance: Protective coatings create barriers against chemical attack, moisture, and environmental contaminants

-

Improved Wear Resistance: Surface treatments increase hardness and reduce friction, extending component life in moving applications

-

Superior Aesthetic Quality: Finishing processes create consistent visual appeal and brand identity for consumer-facing components

-

Optimized Surface Characteristics: Specific treatments can alter electrical conductivity, light reflection, or chemical inertness

The economic impact of appropriate finishing selection extends throughout the component lifecycle. While adding a marginal cost to the manufacturing process, premium finishing can reduce warranty claims, decrease replacement frequency, and minimize downtime in critical applications.

Why Finishing Selection Matters in CNC Manufacturing

CNC machining achieves exceptional dimensional accuracy and geometric complexity, but the as-machined surface often requires enhancement for real-world performance:

-

Material Limitations: Base materials rarely possess ideal surface properties for their application environment

-

Microscopic Imperfections: Machining leaves micro-scale peaks and valleys that can initiate crack propagation or corrosion sites

-

Tribological Considerations: Unfinished surfaces often exhibit suboptimal friction characteristics that accelerate wear

-

Environmental Compatibility: Many applications require material surfaces different from the structural core

The finishing selection process must balance technical requirements, economic constraints, and regulatory considerations to deliver optimal value across the component lifecycle.

Critical Finishing and Coating Technologies for CNC Machined Parts

Modern finishing technologies span a broad spectrum of processes, from traditional electrochemical treatments to advanced vapor deposition methods. The table below details the primary finishing technologies deployed for CNC-machined components.

Table 1: Critical Finishing Technologies for CNC Machined Components

| Process Category | Specific Technologies | Key Application Methods | Materials Compatible | Performance Characteristics |

|---|---|---|---|---|

| Electrochemical Treatments | Anodizing (Type I, II, III), Hardcoat Anodizing, Electropolishing | Immersion, Electrical Current | Aluminum, Titanium, Magnesium | Excellent corrosion resistance, electrical insulation, dye absorption |

| Conversion Coatings | Chemical Film (Chromate/Phosphate), Passivation, Alodine | Spray, Immersion | Aluminum, Steel, Stainless Steel, Zinc | Enhanced paint adhesion, corrosion protection, electrical conductivity |

| Plating Technologies | Electroplating, Electroless Nickel, Zinc Plating, Chrome Plating | Electrochemical Deposition | Steel, Copper, Aluminum, Brass | Wear resistance, corrosion protection, aesthetic appeal |

| Paint & Polymer Coatings | Powder Coating, Liquid Painting, E-coating | Spray, Electrostatic, Curing | Metals, Some Plastics | Superior color matching, texture options, environmental protection |

| Advanced Vapor Deposition | PVD (Physical Vapor Deposition), CVD (Chemical Vapor Deposition) | Vacuum Chamber Deposition | Metals, Ceramics, Plastics | Extreme hardness, temperature resistance, decorative finishes |

| Mechanical Finishes | Sandblasting, Vibratory Finishing, Brushing, Polishing | Abrasive Media, Manual/Automated | All Machinable Materials | Improved appearance, stress relief, preparation for other coatings |

Advanced Electrochemical Finishing Processes

Anodizing represents one of the most versatile and widely-applied finishing processes for aluminum components. This electrochemical process converts the aluminum surface into a durable, corrosion-resistant aluminum oxide layer that is integral to the metal rather than merely sitting on top of it. The anodizing process involves:

-

Cleaning: Removal of contaminants to ensure uniform coating formation

-

Etching: Controlled dissolution of surface aluminum to create a matte finish

-

Anodizing: Immersion in acid electrolyte bath with electrical current application

-

Coloring: Optional infusion of dyes or metallic salts for aesthetic enhancement

-

Sealing: Hydrothermal treatment to lock in color and maximize corrosion resistance

Type II anodizing produces coatings ranging from 1.8-25.2μm thickness for decorative applications with moderate corrosion protection, while Type III (hardcoat) anodizing creates coatings from 25.4-101.6μm thickness for extreme wear resistance applications . The resulting surface demonstrates exceptional hardness, measuring 60-70 Rockwell C on the scale.

Electropolishing serves as both a finishing process and preparatory treatment for stainless steel components. This electrochemical process selectively removes surface material at the microscopic level, resulting in a smooth, polished appearance with enhanced corrosion resistance. The process proves particularly valuable for complex geometries that challenge mechanical polishing methods, reaching internal surfaces and tiny crevices inaccessible to traditional methods.

Material-Specific Finishing Considerations for CNC Components

The selection of appropriate finishing processes must account for base material characteristics, as compatibility varies significantly across material families.

*Table 2: Material-Specific Finishing Recommendations*

| Material Family | Recommended Finishes | Technical Considerations | Industry Applications | Limitations |

|---|---|---|---|---|

| Aluminum Alloys | Anodizing, Chemical Film, Powder Coating, Electropolishing | Thickness adds dimension; magnesium content affects color | Aerospace, consumer electronics, automotive | Not recommended for alkaline environments |

| Stainless Steels | Passivation, Electropolishing, PVD Coating, Plating | Passivation restores corrosion resistance after machining | Medical devices, food processing, marine | Some processes affect dimensional stability |

| Titanium Alloys | Anodizing, Bead Blasting, PVD Coating | Anodizing creates interference colors for identification | Aerospace, medical implants, chemical | Limited color options with anodizing |

| Steel & Alloy Steels | Plating, Phosphating, Black Oxide, Painting | Most processes require copper nickel underlayer | Automotive, industrial machinery, tools | Poor corrosion resistance without coating |

| Copper & Alloys | Clear Coating, Plating, Chemical Patina | Naturally tarnishes; requires clear coating for preservation | Electrical, architectural, marine | Limited wear resistance without plating |

| Engineering Plastics | Painting, Plating, Vapor Deposition | Surface activation often required for adhesion | Consumer goods, automotive, electronics | Temperature limitations during curing |

Aluminum Finishing Specialization

Aluminum alloys represent the most commonly machined non-ferrous material, with finishing selection heavily dependent on application requirements:

-

Architectural Components: Anodizing with integral color provides exceptional UV resistance and aesthetic consistency

-

Aerospace Structures: Chemical film (chromate conversion) offers corrosion protection without dimensional impact

-

Consumer Products: Powder coating delivers unlimited color options with exceptional durability

-

Heat Transfer Applications: Irridite coatings provide protection while maintaining thermal conductivity

The welding and chemical polishing processes referenced in semiconductor component manufacturing demonstrate how specialized aluminum finishing ensures ultra-high vacuum integrity for critical applications.

Stainless Steel Surface Treatments

Stainless steels derive corrosion resistance from their chromium oxide surface layer, but machining operations can compromise this protective layer. Finishing processes address this limitation:

-

Passivation: Nitric or citric acid treatment removes iron contamination and restores the chromium oxide layer

-

Electropolishing: Micro-level material removal creates a pristine surface with enhanced corrosion resistance

-

PVD Coating: Thin, hard coatings provide additional wear resistance while maintaining corrosion protection

The electropolishing reference in ultra-high vacuum components highlights how surface smoothing improves performance in critical semiconductor manufacturing applications.

Technical Implementation: Optimizing Finishing Processes for CNC Components

Successful implementation of finishing technologies requires specialized approaches that address the unique characteristics of CNC-machined components.

Design for Finishing (DFF) Considerations

Component design significantly influences finishing quality and cost-effectiveness. Implementing Design for Finishing principles during the engineering phase ensures optimal results:

-

Uniform Section Thickness: Minimizes current density variations in electrochemical processes

-

Adequate Radius Specifications: Sharp edges result in thin coating coverage and premature failure

-

Proper Drainage Features: Prevents chemical entrapment in electrochemical processes

-

Accessible Surface Geometry: Ensures consistent media contact in mechanical finishing processes

-

Appropriate Masking Provisions: Allows selective application to critical areas

The relationship between CNC machining and finishing begins with understanding how machining parameters affect surface finish. Optimal surface roughness values for specific coating processes ensure maximum adhesion and performance.

Process Control and Quality Assurance

Maintaining consistency in finishing processes requires rigorous control of multiple parameters:

-

Chemical Concentration Monitoring: Regular titration ensures bath effectiveness

-

Temperature Control: Maintains process stability and repeatability

-

Time Management: Process duration directly impacts coating characteristics

-

Electrical Parameters: Current density and voltage control electrochemical processes

-

Environmental Conditions: Humidity and contamination affect outcome quality

Quality verification includes both destructive and non-destructive testing methods:

-

Coating Thickness Measurement: Eddy current, magnetic, or ultrasonic gauges

-

Adhesion Testing: Tape tests, cross-hatch adhesion, or bend tests

-

Corrosion Testing: Salt spray exposure, humidity testing, or environmental simulation

-

Appearance Verification: Color matching, gloss measurement, or visual inspection

Real-World Case Studies: Finishing Solutions in Action

Case Study 1: Semiconductor Vacuum Component Enhancement

A manufacturer of semiconductor processing equipment required aluminum vacuum chambers with exceptional internal surface characteristics for ultra-high vacuum applications.

Challenge: Achieve vacuum integrity with low outgassing characteristics while maintaining precise dimensional stability on large (φ900mm) aluminum chambers with complex internal geometries.

Finishing Solution: The project implemented a multi-stage finishing process:

-

Precision Machining: CNC milling of A6061 aluminum to achieve dimensional accuracy

-

Welding Integration: Aluminum welding of ports and fittings with full penetration

-

Leak Testing: Helium mass spectrometry to verify integrity before finishing

-

Electropolishing: Internal surface refinement to reduce surface area and adsorption potential

-

Final Verification: Second leak testing to confirm vacuum integrity after finishing

Outcome: The finished chambers achieved vacuum levels below 10⁻¹⁰ Pa, with the electropolished surface significantly reducing outgassing and contamination risk. The process yielded a 100% success rate in customer acceptance testing, with components exceeding performance specifications .

Case Study 2: Marine Component Corrosion Protection

A naval equipment supplier needed corrosion protection for bronze propeller components operating in saltwater environments with minimal maintenance requirements.

Challenge: Provide long-term corrosion protection for nickel-aluminum bronze components with complex geometries, including deep recesses and internal passages inaccessible to mechanical methods.

Finishing Solution: The project employed specialized electrochemical techniques:

-

Surface Activation: Chemical treatment to ensure uniform coating initiation

-

Electroless Nickel Application: Autocatalytic deposition for consistent coverage regardless of geometry

-

Heat Treatment: Post-plating baking to enhance coating adhesion and hardness

-

Selective Masking: Protection of critical dimensional areas from coating buildup

-

Quality Verification: Coating thickness mapping and adhesion testing

Outcome: The finished components demonstrated exceptional corrosion resistance in accelerated salt spray testing exceeding 2,000 hours without failure. The uniform coating coverage in recessed areas eliminated previous corrosion issues, extending service life by 400% while reducing maintenance requirements .

Case Study 3: Medical Device Surface Enhancement

A surgical instrument manufacturer required specialized surfaces for stainless steel laparoscopic tools combining lubricity, corrosion resistance, and biocompatibility.

Challenge: Create a durable, biocompatible surface with enhanced lubricity for repeated sterilization cycles without compromising precise dimensional tolerances on cutting edges.

Finishing Solution: A multi-technology approach addressed all requirements:

-

Precision Machining: CNC grinding of cutting edges to maintain sharpness

-

Passivation: Nitric acid treatment to restore corrosion resistance

-

PVD Coating: Thin, hard titanium nitride application for wear resistance and lubricity

-

Selective Application: Precision masking to protect cutting edges during coating

-

Sterilization Validation: Testing against autoclave and chemical sterilization methods

Outcome: The finished instruments demonstrated a 60% reduction in friction compared to untreated surfaces, with no degradation after 500 sterilization cycles. The enhanced surface characteristics improved surgeon feedback during procedures while extending instrument lifespan beyond previous generation products.

Implementing Quality Assurance in Finishing Services

The critical nature of finished components demands rigorous quality assurance protocols throughout the finishing process.

Advanced Inspection Methodologies

Modern finishing facilities employ comprehensive inspection technologies to verify coating compliance:

-

X-Ray Fluorescence: Non-destructive coating thickness measurement for quality verification

-

Scanning Electron Microscopy: High-magnification coating structure analysis for process optimization

-

Adhesion Testing: Quantitative measurement of coating-to-substrate bond strength

-

Accelerated Corrosion Testing: Salt spray, humidity, and environmental simulation for performance prediction

These inspection technologies generate comprehensive documentation packages that satisfy the traceability requirements of regulated industries and quality standards.

Certification and Compliance

Reputable providers of part finishing services maintain certifications that demonstrate their commitment to quality and compliance:

-

ISO 9001: Quality management systems

-

AS9100: Aerospace quality standards

-

ISO 13485: Medical device manufacturing standards

-

NADCAP: Special process accreditation for aerospace applications

These certifications provide assurance that finishing processes meet the rigorous standards required for critical applications in aerospace, medical, and other regulated industries.

The Future of Part Finishing and Coating Services

Finishing technology continues to evolve, with several emerging trends particularly relevant to CNC-machined components:

Environmental Compliance and Sustainability

Regulatory pressure continues to drive innovation in environmentally compliant finishing technologies:

-

Transition from Hexavalent Chromium: Trivalent chromium alternatives for conversion coatings

-

Water-Based Formulations: Replacement of solvent-borne coatings with aqueous systems

-

Waste Minimization: Advanced filtration and recovery systems for process chemicals

-

Energy Efficiency: Low-temperature processes and reduced curing requirements

These sustainable technologies maintain performance while reducing environmental impact and regulatory burden.

Advanced Coating Technologies

Emerging coating technologies offer new possibilities for component performance:

-

Nanocomposite Coatings: Incorporation of nanoparticles for enhanced properties

-

Self-Healing Coatings: Microencapsulated repair mechanisms for damage mitigation

-

Multifunctional Surfaces: Single coatings providing multiple performance characteristics

-

Digital Finishing: Precise application control through robotic and vision systems

These advanced technologies continue to expand the performance envelope for finished CNC components across industries.

Selecting a Finishing Partner for CNC Machined Components

Choosing the right finishing provider requires careful evaluation of technical capabilities, industry experience, and quality systems.

Technical Capabilities Assessment

-

Process Portfolio: Evaluate available finishing technologies against application requirements

-

Capacity Considerations: Assess equipment sizing for component dimensions and production volumes

-

Material Expertise: Verify experience with specific alloys and their finishing characteristics

-

Quality Systems: Review inspection capabilities and certification status

Industry-Specific Experience

-

Application Knowledge: Understanding of performance requirements in specific industries

-

Regulatory Familiarity: Experience with industry-specific standards and compliance requirements

-

Supply Chain Integration: Ability to coordinate with machining operations for optimal results

-

Technical Support: Engineering resources for process selection and troubleshooting

The ideal partner combines technical capability with specific industry expertise to deliver finishing solutions that enhance component performance and reliability.

Conclusion

Part finishing and coating services represent the critical transformation point where precision-machined components gain their functional capabilities and aesthetic qualities. The strategic selection and application of appropriate surface treatments elevates component performance beyond the limitations of base materials, enabling operation in demanding environments across industries from aerospace to medical devices.

The most successful manufacturing partnerships embrace finishing selection as an integral part of the design process rather than an afterthought. This integrated approach delivers measurable benefits: extended service life, reduced maintenance costs, enhanced reliability, and superior aesthetic appeal.

For organizations seeking to maximize the performance of their CNC machined components, our specialized CNC machining services combine advanced manufacturing capabilities with comprehensive finishing expertise to deliver complete manufacturing solutions. Contact our engineering team to discover how our finishing-driven approach can enhance your next CNC machining project.