Mastering PEEK Plastic CNC Machining: A Comprehensive Guide to Properties, Processing, and Performance

Introduction: Navigating the Frontier of High-Performance Polymer Machining

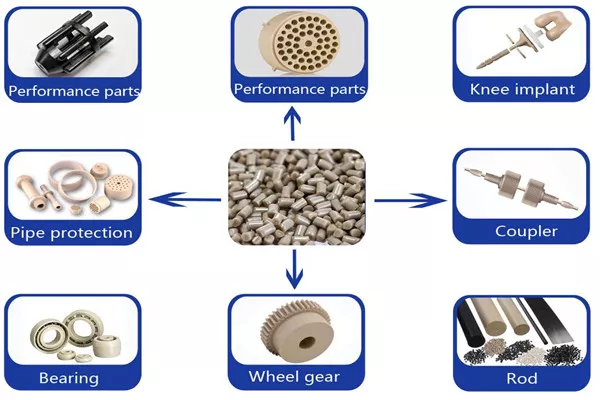

In the demanding landscape of precision manufacturing, where applications push materials to their absolute limits, PEEK plastic machining stands apart as both a formidable challenge and an extraordinary opportunity. Polyetheretherketone (PEEK), a semi-crystalline thermoplastic from the polyaryletherketone (PAEK) family, represents the pinnacle of engineered polymer performance. Its unique combination of properties—retaining significant mechanical strength at temperatures exceeding 250°C, exceptional chemical resistance, inherent flame retardancy, and excellent wear characteristics—makes it indispensable in aerospace, medical, semiconductor, and oil & gas applications. However, these same superlative properties that define PEEK’s value in service also dictate a highly specialized approach to its machining properties.

At JLYPT CNC Machining, we have cultivated expertise in transforming this premium engineering polymer from rod and plate stock into precision components where failure is not an option. The journey from a PEEK billet to a flight-worthy aerospace bushing or an implantable medical trial component requires more than standard CNC practices; it demands a deep understanding of polymer-specific rheology, thermal management, and tool interaction. Unlike metals, PEEK does not cut—it fractures in a controlled manner at the tool tip, and managing this fracture mechanics while preventing thermal degradation is the core of successful machining.

This guide delves beyond generic machining advice to explore the precise machining properties of PEEK, including unfilled, carbon-fiber reinforced (CFR), and glass-filled (GF) variants. We will examine the critical interplay between PEEK’s semi-crystalline structure, its anisotropic behavior, and optimal CNC strategies. From tool geometry and coolant controversies to achieving micron-level tolerances and superior surface finishes, this resource provides the technical foundation necessary to specify and produce PEEK components with confidence. Understanding these principles is essential for leveraging our full-spectrum capabilities at JLYPT CNC Machining Services to turn advanced polymer designs into reliable, high-performance realities.

Deciphering PEEK: Material Science Fundamentals for Machinists

To master the machining properties of PEEK plastic, one must first understand its underlying material science. PEEK is a semi-crystalline thermoplastic, meaning its molecular structure contains both ordered crystalline regions and disordered amorphous regions. The ratio between these phases—the degree of crystallinity—is not fixed; it is a function of the polymer’s thermal history during both initial manufacturing (compression molding, extrusion) and subsequent processing, including machining.

Crystallinity and Its Machining Implications

A higher degree of crystallinity (typically 30-35% in virgin PEEK) enhances key service properties: tensile strength, chemical resistance, and creep resistance. However, from a machining standpoint, increased crystallinity also increases brittleness and makes the material more prone to microfracture and chip formation rather than plastic deformation. The heat generated during machining, if uncontrolled, can alter this crystallinity. Excessive heat can anneal the part, potentially relieving stresses but also changing dimensions, or worse, cause the amorphous regions to exceed the glass transition temperature (Tg ~143°C), leading to gumming, smearing, and poor surface integrity.

Reinforcement Variants and Their Behavioral Shifts

Virgin PEEK is rarely used in high-stress applications. Engineers typically specify reinforced grades that modify its machining properties significantly:

-

Carbon-Fiber Reinforced PEEK (CFR-PEEK): Incorporating 20-30% short or continuous carbon fibers dramatically increases tensile strength, stiffness (modulus), and creep resistance. The carbon fibers also improve thermal conductivity, aiding in heat dissipation during machining. However, they are exceptionally abrasive, leading to rapid tool wear if not matched with appropriate tooling (typically polycrystalline diamond – PCD). The fibers also create an anisotropic material; strength and thermal expansion differ along vs. across the fiber orientation, which must be considered in fixturing and tolerance planning.

-

Glass-Fiber Reinforced PEEK (GF-PEEK): With 20-30% glass fiber reinforcement, this grade offers improved stiffness and dimensional stability over virgin PEEK at a lower cost than CFR-PEEK. While still abrasive, glass fibers are less so than carbon fibers. GF-PEEK machines with less pronounced anisotropy than CFR-PEEK but requires sharp, abrasion-resistant tooling.

-

Tribological Grades: These include fillers like PTFE, graphite, or carbon fibers for enhanced wear and friction properties. The addition of soft, lubricious fillers like PTFE can reduce cutting forces but may present challenges in achieving a pristine surface finish, as the fillers can smear.

The table below summarizes how these fundamental properties translate directly to machining parameters and challenges.

Table 1: PEEK Material Variants and Their Primary Machining Characteristics

| PEEK Grade | Key Structural Features | Primary Machining Advantage | Primary Machining Challenge | Optimal Tooling Recommendation |

|---|---|---|---|---|

| Virgin (Unfilled) | Semi-crystalline polymer, isotropic behavior. | Lower abrasivity, predictable chip formation, excellent surface finish potential. | Low thermal conductivity risk of heat buildup and gumming; prone to burr formation on exit edges. | Sharp, polished carbide end mills with high helix angles. |

| Carbon-Fiber Reinforced (CFR) | Carbon fibers in polymer matrix, highly anisotropic. | Superior stiffness reduces part deflection; better heat dissipation from cut zone. | Extreme abrasivity causes rapid flank and notch wear; fiber pull-out can mar surface finish. | PCD (Polycrystalline Diamond) tipped tools are mandatory for production. |

| Glass-Fiber Reinforced (GF) | Glass fibers in polymer matrix, moderately anisotropic. | Good stiffness and dimensional stability; less abrasive than CFR-PEEK. | Abrasive wear still significant; potential for fiber-end pitting on surfaces. | Micro-grain carbide or PCD-coated tools for longer runs. |

| Tribological (e.g., PEEK+PTFE) | Lubricious fillers within polymer matrix. | Reduced cutting forces and friction; excellent for final bearing surfaces. | Soft fillers can smear, complicating chip evacuation and clogging flutes; finish can be inconsistent. | Sharp carbide with polished flutes and aggressive chip evacuation geometry. |

The Machining Triad: Tooling, Parameters, and Thermal Management

Successful PEEK plastic machining requires the simultaneous optimization of three interdependent factors: tool geometry and material, cutting parameters, and thermal management strategy. Neglecting any one leads to suboptimal results, from poor surface finish and dimensional inaccuracy to outright workpiece failure.

1. Tooling Selection: Geometry is King

For PEEK, tool geometry often matters more than the substrate material. The goal is to create clean, shear-driven fractures with minimal rubbing and heat generation.

-

Tool Material: For virgin and lightly filled PEEK, micro-grain solid carbide tools provide the best balance of sharpness, edge retention, and cost. For any volume production on CFR-PEEK, PCD-tipped tools are a necessary investment despite higher upfront cost, as they offer orders-of-magnitude greater wear resistance. High-speed steel (HSS) is generally unsuitable due to rapid wear.

-

Geometry Specifications:

-

High Helix Angles (40°-45°): Facilitates efficient evacuation of the relatively bulky chips, preventing recutting and heat buildup.

-

Polished or Super-Polished Flutes: Reduces friction and adhesion of melted polymer to the tool.

-

Sharp Cutting Edges (Zero or Positive Rake): Promotes clean shearing. A honed edge, common in metal cutting, can cause rubbing and plastic deformation in PEEK.

-

Reduced Neck Length & Maximum Rigidity: PEEK machining often involves deep pockets or thin walls. Using the shortest possible tool with the largest possible diameter minimizes deflection and vibration, which are detrimental to finish and accuracy.

-

2. Cutting Parameters: Speed, Feed, and Depth of Cut

The “sweet spot” for machining PEEK involves high feed rates and moderate speeds, inverted from typical aluminum machining.

-

Cutting Speed (S): Moderate speeds of 200-600 SFM (Surface Feet per Minute) for carbide are typical. Too slow, and you risk rubbing; too fast, and you generate excessive heat. PCD tools can run faster due to their thermal stability.

-

Feed Rate (F): Aggressive chip loads are critical. A high feed per tooth (0.0015-0.004 inches per tooth) ensures the tool is cutting, not rubbing, and generates thicker chips that carry heat away more effectively. Light feeds are a primary cause of heat-related problems.

-

Depth of Cut (DOC): Prefer higher axial depths of cut and lower radial engagement (stepover). A strategy like trochoidal milling or dynamic milling, with a stepover of 5-10% of tool diameter and a full-depth axial cut, maintains a constant tool load, improves chip evacuation, and minimizes deflection for thin features.

3. Coolant and Thermal Strategy: The Critical Debate

The use of coolant in PEEK machining is a nuanced decision. While PEEK is hydrolytically stable, the primary issue is thermal shock.

-

Dry Machining: Preferred for many operations, especially with sharp tools and aggressive parameters. It avoids the risk of thermal shock, which can induce microcracks in the workpiece. It simplifies chip recovery (important for clean-room medical parts) and eliminates post-machining cleaning. Effective chip evacuation via compressed air is mandatory.

-

Compressed Air Blast: An excellent middle ground, providing cooling and superb chip evacuation without the thermal shock risk of liquid coolant.

-

Flood Coolant: Can be used, but only if applied consistently and copiously from start to finish. Intermittent cooling is worse than no cooling at all. Mist coolant is generally not recommended as it provides insufficient heat transfer.

-

Cryogenic Machining (Advanced): Using liquid nitrogen or CO2 as a coolant is an emerging technique for ultra-high-precision PEEK components, virtually eliminating thermal effects and allowing for extremely tight tolerances.

Achieving Precision: Tolerances, Surface Finishes, and Post-Processing

The end goal of understanding PEEK plastic machining properties is to produce parts that meet stringent dimensional and surface requirements.

Dimensional Stability and Tolerance Holding

PEEK has a relatively low coefficient of thermal expansion (CTE) for a plastic, but it is still 5-10 times higher than that of steel. This makes in-process heat the greatest enemy of dimensional accuracy. Strategies to hold tight tolerances (±0.025 mm or better) include:

-

Stable, Stress-Relieved Stock: Using annealed or compression-molded stock minimizes internal stresses that can be released during machining, causing warpage.

-

Balanced Machining: Removing material symmetrically to avoid creating unbalanced internal stresses.

-

Multiple Finishing Passes: A roughing pass to remove bulk material, followed by a semi-finishing pass to stabilize the part, and a final light finishing pass with a sharp tool to achieve final dimensions with minimal stress and heat.

-

Climate-Controlled Inspection: Measuring PEEK parts in a temperature-stable environment is crucial, as its CTE will cause measurable dimensional change with ambient temperature fluctuations.

Surface Finish Optimization

A well-machined PEEK surface should appear clean and slightly crystalline, not glossy or melted. Achieving a fine surface finish (Ra < 0.8 µm) requires:

-

Sharp tools with a dedicated finishing geometry.

-

High feed rates to prevent rubbing.

-

Minimal tool deflection (high rigidity).

-

Sometimes, a final pass using a vapor honing or non-abrasive tumbling process can improve aesthetics and remove microscopic burrs without degrading the surface.

Post-Machining Considerations

-

Stress Relieving: For critically toleranced parts, a post-machining thermal cycle below the Tg can relieve machining-induced stresses.

-

Cleaning: PEEK is chemically resistant, so cleaning typically involves aqueous solutions or specific solvents like isopropyl alcohol. Ultrasonic cleaning is highly effective.

-

Deburring: Mechanical deburring must be done carefully to avoid smearing or tearing the material. Thermal deburring (using a brief high-temperature exposure) is another effective method for small parts.

Industry-Specific Case Studies

Case Study 1: Neurosurgical Drill Guide (Medical Implant Trial)

-

Challenge: A medical device company needed a complex, patient-specific drill guide for spinal surgery. The guide required autoclavability (steam sterilization at 134°C), MRI compatibility (non-metallic), biocompatibility (ISO 10993), and the ability to hold a network of holes with a positional tolerance of ±0.075mm for surgical precision.

-

Material & Process Selection: Virgin PEEK was chosen for its biocompatibility, sterilizability, and strength. Machining from a solid block ensured no porosity, unlike 3D-printed guides. The risk of heat-induced distortion was the primary technical hurdle.

-

JLYPT Solution: We utilized a 5-axis CNC with a temperature-stabilized enclosure. The process involved:

-

Roughing with a 6mm PCD tool using trochoidal paths to minimize heat.

-

Semi-finishing after the part cooled to ambient temperature.

-

Final finishing of all critical bore surfaces using a dedicated, sharp carbide tool with compressed air blast only.

-

A post-machining stress-relief cycle.

The parts were vapor honed for a clean, burr-free finish. All guides passed dimensional validation on a CMM and functioned flawlessly in sterilization and surgical use.

-

Case Study 2: Aerospace Fuel System Manifold (High-Temperature, Chemical Resistance)

-

Challenge: An aerospace manufacturer required a lightweight replacement for an aluminum manifold in a jet engine fuel system. The part was exposed to jet fuel (JP-8), hydraulic fluid, and continuous temperatures of 120°C with peaks to 150°C. It required pressure ratings over 500 psi.

-

Material & Process Selection: CFR-PEEK was selected for its high strength-to-weight ratio, exceptional chemical resistance to hydrocarbons, and ability to withstand the operational temperature envelope, eliminating the corrosion issues of aluminum.

-

JLYPT Solution: Machining the complex internal passages and sealing faces of the manifold from abrasive CFR-PEEK required a specialized approach:

-

All cutting tools were PCD-tipped, with geometries optimized for composite materials.

-

High-pressure through-tool coolant was used to manage heat and evacuate the abrasive carbon-fiber dust/chips, protecting the machine tool.

-

Sealing face surfaces were finished with a single-point PCD tool on a precision lathe to achieve the required surface flatness and finish for a static seal.

-

The part was meticulously cleaned to remove all carbon dust. The final component was 60% lighter than its aluminum predecessor and passed all pressure and leak tests.

-

Case Study 3: Semiconductor Wafer Handling Arm (Ultra-Clean, Static-Dissipative)

-

Challenge: A semiconductor equipment maker needed a robotic end effector for handling 300mm silicon wafers. The arm required ultra-high purity (no particulate generation), static dissipation to prevent damaging microchips, high stiffness for positional accuracy, and resistance to occasional plasma exposure.

-

Material & Process Selection: A static-dissipative grade of PEEK, filled with specialized conductive materials, was specified. The challenge was achieving a perfectly clean, smooth surface that would not shed particles in a vacuum chamber.

-

JLYPT Solution: This project demanded a cleanroom machining environment (ISO Class 7). The process was conducted dry with HEPA-filtered extraction. Special emphasis was placed on toolpath programming to avoid any dwell marks and to ensure continuous, smooth motion. All tools were brand new and dedicated to this material. After machining, parts underwent a proprietary cleaning and surface conditioning process to seal the surface and ensure no loose fibers or particles remained. The arms met all particulate generation specs and performed reliably in the customer’s fabrication tools.

Conclusion: Partnering for High-Performance Polymer Solutions

Mastering the machining properties of PEEK plastic is not an endpoint but a continuous process of refinement that aligns deep material science with practical shop-floor execution. From selecting the correct grade and designing for manufacturability to executing with precise thermal control and expert finishing, each step influences the final component’s performance in the most demanding environments on earth—and beyond.

At JLYPT CNC Machining, we view PEEK not as a difficult material to be overcome, but as a high-value engineering solution to be precisely unlocked. Our expertise bridges the gap between the polymer scientist’s data sheet and the production of a reliable, tolerance-holding component. We provide the technical partnership necessary to navigate the complexities of PEEK, ensuring your designs benefit from its extraordinary properties without being compromised by its processing challenges.

Ready to leverage the full potential of PEEK for your critical application? Connect with our engineering team to discuss your project’s specific requirements. Visit JLYPT CNC Machining Services to explore our full material capabilities and request a detailed quotation for your next high-performance polymer component.