Engineering Excellence: Precision Bearing Robotic Arm Components Through Advanced CNC Manufacturing

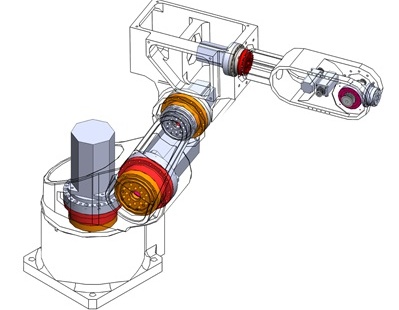

The evolution of industrial automation has created unprecedented demands for robotic systems capable of delivering exceptional accuracy, repeatability, and longevity in demanding operational environments. At the core of these advanced robotic systems, precision bearing robotic arm components serve as critical elements that enable smooth motion, precise positioning, and reliable performance under challenging conditions. At JLYPT CNC Machining, we have established ourselves as specialists in manufacturing precision bearing robotic arm components, combining sophisticated CNC technologies with deep engineering expertise to produce bearing housings, seats, and related components that meet the exacting requirements of modern industrial automation.

This comprehensive technical analysis explores the engineering principles, manufacturing methodologies, and quality assurance protocols that define world-class precision bearing robotic arm component production. We examine how strategic implementation of multi-axis CNC machining, specialized boring processes, and rigorous validation protocols enables the creation of bearing components that deliver optimal performance in demanding robotic applications across manufacturing, aerospace, medical, and research sectors.

Fundamental Principles of Precision Bearing Integration in Robotic Systems

Precision bearing robotic arm systems represent sophisticated mechanical assemblies where bearing performance directly influences overall system accuracy, stiffness, and service life. The integration of precision bearings into robotic arms requires careful consideration of multiple engineering factors that distinguish these applications from conventional bearing installations.

Kinematic and Dynamic Considerations

The performance of precision bearing robotic arm systems depends on precise mechanical relationships and dynamic characteristics:

-

Stiffness Optimization: Bearing housing design must provide sufficient structural stiffness to minimize deflection under operational loads, with typical requirements for robotic arms ranging from 50-500 N/μm depending on application and payload capacity

-

Thermal Management: Strategic design of bearing arrangements and housing geometries to manage heat generation from bearing friction, with temperature rises typically limited to 15-25°C above ambient in precision applications

-

Preload Management: Careful control of bearing preload to optimize stiffness while minimizing friction and heat generation, with preload values typically ranging from 2-20% of dynamic load capacity

-

Alignment Precision: Critical alignment of bearing bores with typical parallelism requirements of 0.005-0.015 mm and perpendicularity requirements of 0.010-0.025 mm over bearing distances

Load Capacity and Service Life Factors

The demanding duty cycles of robotic applications require meticulous consideration of load capacity and long-term reliability:

-

Dynamic Load Analysis: Calculation of equivalent dynamic loads using ISO 281 standards to ensure bearing life meets or exceeds application requirements, with typical design lives of 20,000-40,000 hours for industrial robots

-

Static Load Capacity: Evaluation of static load conditions to prevent brinelling and permanent deformation under peak loads and shock conditions

-

Fatigue Life Prediction: Advanced modeling of bearing fatigue life using Lundberg-Palmgren theory with modern modifications accounting for material cleanliness and operating conditions

-

Wear Resistance Optimization: Strategic material selection and surface treatment to minimize wear in high-cycle applications exceeding millions of motion cycles

Advanced Manufacturing Technologies for Precision Bearing Components

The production of high-accuracy precision bearing robotic arm components requires specialized manufacturing approaches and equipment capabilities:

Multi-Axis CNC Machining Capabilities

Modern CNC technologies provide the foundation for precision bearing component manufacturing:

-

5-Axis Simultaneous Machining: Complex contouring of bearing housing external geometries with continuous toolpath control while maintaining critical relationships to bearing bore axes

-

Precision Boring Operations: Specialist boring techniques utilizing single-point boring tools with micro-adjustment capabilities achieving bore diameter tolerances within ±0.0025 mm

-

High-Speed Machining: Advanced spindle technology exceeding 20,000 RPM with balanced toolholders and optimized cutting parameters for superior surface finishes in bearing bores

-

Turn-Mill Integration: Combined turning and milling operations for complex rotational components with precise bearing journals and mounting features

Specialized Bearing Seat Machining Processes

Critical bearing seating surfaces require highly specialized manufacturing approaches:

-

Multi-Stage Boring Sequences: Progressive boring operations from roughing through semi-finishing to finishing with decreasing depth of cut and increasing surface speed

-

Skiving and Roller Burnishing: Combined machining and surface enhancement processes that achieve superior surface finish and dimensional accuracy in through-holes

-

Precision Grinding Operations: Application of internal grinding for hardened bearing seats achieving roundness within 0.0005 mm and surface finishes better than Ra 0.2 μm

-

Honning and Lapping: Final finishing processes that achieve optimal surface texture and geometry for critical bearing applications

Technical Specifications for Robotic Arm Bearing Components

The table below outlines critical technical specifications for various precision bearing robotic arm applications across different robot configurations:

| Application Type | Bearing Type | Bore Tolerance | Housing Tolerance | Surface Finish | Roundness/Cylindricity |

|---|---|---|---|---|---|

| Articulated Robot Joints | Angular Contact | ISO H6 | ISO J6 | Ra 0.4 μm | 0.0015 mm |

| SCARA Robot Z-Axis | Crossed Roller | ISO H5 | ISO J5 | Ra 0.2 μm | 0.0010 mm |

| Delta Robot Arms | Four-Point Contact | ISO H6 | ISO K6 | Ra 0.8 μm | 0.0020 mm |

| Collaborative Robot Joints | Thin-Section | ISO H6 | ISO J6 | Ra 0.4 μm | 0.0015 mm |

| Gantry Robot Actuators | Tapered Roller | ISO H7 | ISO K7 | Ra 0.8 μm | 0.0025 mm |

Material Selection for Precision Bearing Components

The performance and longevity of precision bearing robotic arm systems are profoundly influenced by appropriate material selection and heat treatment:

Steel Alloys for Bearing Housings

-

AISI 4140/4140 Prehard: Excellent combination of strength, toughness, and machinability with typical hardness of 28-32 HRC for general-purpose robotic applications

-

AISI 4340/4340 Prehard: Enhanced toughness and strength for high-load applications with improved impact resistance and fatigue performance

-

AISI 8620: Good case hardenability with excellent core properties for applications requiring wear-resistant bearing seats with tough housing structures

-

AISI 1045: Cost-effective medium carbon steel with good machinability and sufficient strength for less demanding applications

Aluminum Alloys for Weight-Sensitive Applications

-

6061-T6: Excellent strength-to-weight ratio with good machinability and anodizing capability for applications where weight reduction is critical

-

7075-T6: High-strength aluminum alloy with strength approaching many steels while maintaining significant weight advantage

-

2024-T351: Good fatigue resistance and strength for dynamic applications with demanding weight constraints

Stainless Steel Alloys

-

AISI 304/316: Austenitic stainless steels for applications requiring maximum corrosion resistance with moderate strength requirements

-

AISI 416: Martensitic stainless steel offering good machinability with moderate corrosion resistance and heat treatability

-

17-4PH: Precipitation hardening stainless steel providing excellent strength and good corrosion resistance

Heat Treatment and Surface Enhancement Processes

The strategic application of heat treatment and surface enhancement processes significantly improves precision bearing robotic arm component performance:

-

Through Hardening: Uniform hardening of steel components to achieve consistent mechanical properties throughout the cross-section with typical hardness values of 30-45 HRC

-

Case Hardening: Surface hardening processes including carburizing and carbonitriding to develop hard, wear-resistant bearing seats (55-62 HRC) with tough, ductile cores

-

Nitriding: Low-temperature surface hardening process using nitrogen diffusion to develop extreme surface hardness (65-70 HRC) with minimal dimensional change and excellent fatigue performance

-

Anodizing: Electrochemical process for aluminum components that creates a hard, wear-resistant surface layer while maintaining dimensional stability

-

Surface Coatings: Application of specialized coatings including DLC (Diamond-Like Carbon), TiN, and other PVD coatings to enhance wear resistance and reduce friction

Comprehensive Case Studies: Precision Bearing Robotic Arm Applications

Case Study 1: Aerospace Robotic Manipulator Bearing Housings

-

Challenge: An aerospace manufacturer required high-precision bearing housings for a robotic manipulator used in satellite assembly. The application demanded exceptional positional accuracy (arc-second level), minimal deflection under load, and reliable operation in thermal-vacuum conditions.

-

Technical Solution: We manufactured bearing housings from AISI 4340 steel with precision boring of bearing seats to ISO H5 tolerance. The components underwent cryogenic stabilization and final precision grinding to achieve bore geometry within 0.001 mm for roundness and cylindricity.

-

Manufacturing Approach: The housing manufacturing incorporated multi-stage machining with stress relief between operations. Critical bearing seats were finished using precision boring and honing processes with continuous in-process verification. Thermal cycling validation ensured dimensional stability across the operational temperature range.

-

Results: The delivered bearing housings demonstrated positional accuracy of 1.2 arc-seconds with measured stiffness exceeding 350 N/μm. The components successfully operated in thermal-vacuum conditions from -55°C to +85°C with no measurable degradation in performance through accelerated life testing.

Case Study 2: Medical Robot Surgical Arm Bearing Components

-

Challenge: A medical device company needed miniature bearing components for a minimally invasive surgical robot. The components required biocompatible materials, exceptional dimensional stability, and the ability to withstand repeated sterilization processes including autoclaving and chemical exposure.

-

Technical Solution: We engineered the bearing housings from AISI 316L stainless steel with precision bored seats to ISO H6 tolerance. The manufacturing process incorporated specialized boring techniques to achieve superior surface finish (Ra < 0.2 μm) on all critical bearing surfaces.

-

Manufacturing Approach: The components were manufactured using 5-axis CNC machining with micro-boring processes for bearing seat finishing. Each housing underwent individual verification with coordinate measuring machines to ensure geometric requirements were met. Specialized passivation processes ensured biocompatibility and corrosion resistance.

-

Results: The medical-grade bearing housings achieved exceptional dimensional stability with thermal expansion characteristics matched to the bearing materials. The components withstood over 500 autoclave cycles without corrosion or dimensional changes, receiving regulatory approval for surgical use.

Case Study 3: Industrial Articulated Robot Joint Housings

-

Challenge: An industrial automation provider required high-stiffness bearing housings for a new generation of articulated robots with increased payload capacity and accuracy requirements. The housings needed to support 800 Nm of continuous torque while maintaining positional accuracy through 20 million duty cycles.

-

Technical Solution: We developed bearing housings from AISI 4140 prehard steel with optimized ribbing and wall sections to maximize stiffness while minimizing weight. The design incorporated precision bored bearing seats with geometric tolerances within 0.002 mm for critical features.

-

Manufacturing Approach: The housings were manufactured using advanced 5-axis CNC machining with strategic sequencing of operations to manage residual stresses. Critical bearing seats employed progressive boring operations with final honing to achieve required surface finish and geometry. Each housing underwent comprehensive inspection including CMM verification and surface texture analysis.

-

Results: The final bearing housings demonstrated stiffness exceeding 280 N/μm with tested fatigue life beyond 25 million cycles at rated load. Positional accuracy was maintained within 2.5 arc-seconds throughout accelerated life testing, enabling the customer to achieve their performance targets for the new robot series.

Quality Assurance and Metrology for Precision Bearing Components

The verification of precision bearing robotic arm component quality requires sophisticated metrology approaches and rigorous inspection protocols:

-

Geometric Dimensioning Verification: Comprehensive evaluation of bore geometry, position, orientation, and form using coordinate measuring machines with measurement uncertainty ratios better than 4:1

-

Surface Metrology: Precise measurement of surface finish, waviness, and lay pattern using contact and non-contact profilometry techniques with resolution to 0.01 μm

-

Material Verification: Confirmation of material properties including hardness, microstructure, and chemical composition using standardized testing methods

-

Dimensional Stability Assessment: Thermal cycling and stress relief validation to ensure dimensional stability under operational temperature variations and load conditions

-

Performance Validation: Functional testing under simulated load conditions to verify stiffness, deflection characteristics, and bearing fit under operational parameters

Future Trends in Robotic Arm Bearing Technology

The field of precision bearing robotic arm technology continues to evolve with emerging materials, manufacturing methods, and design approaches:

-

Additive Manufacturing Integration: Hybrid manufacturing approaches combining 3D printing of complex housing geometries with precision machining of critical bearing surfaces for optimized performance and weight reduction

-

Advanced Material Applications: Implementation of high-performance composites, engineered ceramics, and metal matrix composites with tailored properties for specific applications

-

Smart Bearing Systems: Integration of sensor technology and IoT connectivity for real-time monitoring of bearing health, load conditions, and performance metrics

-

Surface Engineering Innovations: Application of advanced coatings including graphene-enhanced composites, nanostructured coatings, and adaptive surface treatments to enhance wear resistance and reduce friction

-

Digital Twin Technology: Comprehensive virtual modeling of bearing systems that simulates performance under actual operating conditions for predictive maintenance and optimization

Conclusion: Precision Engineering for Robotic Performance

The design and manufacture of high-performance precision bearing robotic arm components represents a specialized domain where mechanical engineering, materials science, and precision manufacturing converge. Success in this demanding field requires comprehensive expertise in bearing technology, manufacturing processes, heat treatment, and quality assurance, combined with deep understanding of the unique requirements of robotic applications.

At JLYPT CNC Machining, our specialized approach to precision bearing robotic arm component manufacturing combines state-of-the-art equipment, advanced engineering capabilities, and rigorous quality systems to produce bearing housings and related components that meet the extraordinary demands of modern robotics. Whether supporting collaborative robots, industrial automation, aerospace applications, or medical devices, our capabilities and commitment to excellence ensure that our customers receive optimal solutions for their most challenging motion control requirements.

Ready to enhance your robotic systems with precision-engineered bearing components? Contact JLYPT CNC Machining today to discover how our expertise in precision bearing robotic arm manufacturing can help you achieve your performance, reliability, and efficiency goals. Visit our CNC Machining Services page to learn more about our comprehensive capabilities and request your instant quote.