The Complete Guide to Custom CNC Machined Parts from Stainless Steels

Executive Summary

Custom CNC machined parts from stainless steels represent the pinnacle of precision manufacturing for applications demanding exceptional corrosion resistance, mechanical strength, and dimensional stability. This comprehensive guide explores the technical specifications, manufacturing processes, and applications of stainless steel components produced through computer numerical control (CNC) machining technologies. Stainless steel’s unique properties—including its chromium content for corrosion resistance, nickel content for austenitic structure stability, and various alloying elements for enhanced mechanical properties—make it an ideal material for critical components across medical devices, aerospace systems, food processing equipment, and marine applications. Through advanced machining techniques, stringent quality control measures, and specialized post-processing treatments, manufacturers can create stainless steel parts with tolerances reaching ±0.005mm and surface finishes as fine as Ra 0.2μm. This article provides engineering professionals, procurement specialists, and product designers with the essential knowledge needed to specify, manufacture, and implement custom stainless steel components that meet the most demanding application requirements.

1 Introduction to Stainless Steel CNC Machining

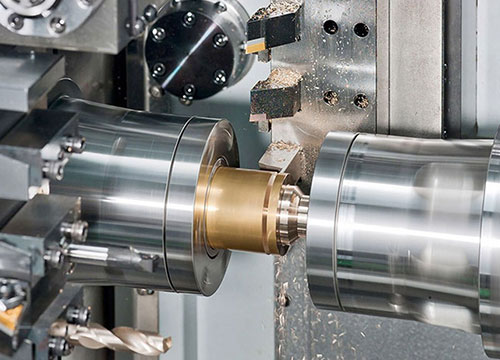

CNC machining of stainless steels involves subtractive manufacturing processes where computer-controlled equipment removes material from stainless steel stock to create precision components with specific geometries, tolerances, and surface characteristics. The term CNC stands for Computerized Numerical Control, referring to the automation of machine tools through precisely programmed commands. Stainless steel encompasses a range of iron-based alloys containing a minimum of 10.5% chromium by mass, which creates a passive layer of chromium oxide on the surface that provides exceptional corrosion resistance.

The machining of stainless steel presents unique challenges compared to other metals due to its work hardening tendency, high strength, and low thermal conductivity. These characteristics require specialized tooling, cutting parameters, and machining strategies to achieve optimal results. Advanced CNC machines equipped with high-pressure coolant systems, rigid structural components, and precision guidance systems can effectively overcome these challenges to produce components with exceptional accuracy and surface finish quality.

Stainless steel’s versatility makes it suitable for an enormous range of applications across virtually every industry sector. From medical implants requiring biocompatibility and sterilization capability to marine hardware demanding resistance to saltwater corrosion, stainless steel components manufactured through CNC processes provide the perfect combination of mechanical properties, corrosion resistance, and manufacturability.

2 Stainless Steel Grades for CNC Machining

The selection of appropriate stainless steel grade is critical for achieving the desired performance characteristics in machined components. Different grades offer varying combinations of machinability, corrosion resistance, mechanical properties, and cost effectiveness.

Austenitic Stainless Steels (300 series) contain nickel and maintain their austenitic structure at all temperatures, providing excellent corrosion resistance and formability. Stainless 303 offers enhanced machinability through sulfur addition but with slightly reduced corrosion resistance. Stainless 304 contains 18% chromium and 8% nickel, making it the most widely used stainless steel grade with good overall properties. Stainless 316 includes molybdenum for improved corrosion resistance, particularly against chlorides and acids.

Martensitic Stainless Steels (400 series) are magnetic and can be hardened through heat treatment. Stainless 416 offers the highest machinability among stainless steels but with reduced corrosion resistance compared to other grades.

Precipitation-Hardening Stainless Steels can be heat treated to achieve high strength levels while maintaining good corrosion resistance. 17-4 PH (also known as 630 stainless) can be hardened to approximately 44 HRC and offers excellent corrosion resistance and mechanical properties that can be further enhanced through heat treatment.

Table: Stainless Steel Grades for CNC Machining

| Grade | Type | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| 303 | Austenitic | 528-639 | Good | Excellent (180%) | Fasteners, fittings, shafts |

| 304 | Austenitic | 480-620 | Very Good | Good (70%) | Food processing, chemical equipment, architectural |

| 316 | Austenitic | 480-620 | Excellent | Fair (60%) | Marine applications, medical devices, pharmaceutical |

| 416 | Martensitic | 741-1400 | Fair | Excellent (200%) | Screws, gears, valves |

| 17-4 PH | Precipitation-Hardening | 896-990 | Excellent | Good (80%) | Aerospace components, nuclear applications, pump shafts |

| 15-5 PH | Precipitation-Hardening | 890-1034 | Excellent | Good (85%) | Valves, fittings, medical instruments |

3 CNC Machining Processes for Stainless Steel

CNC machining of stainless steel encompasses several specialized processes, each suited to particular geometries, tolerances, and production requirements.

CNC Milling utilizes rotary cutters to remove material from a workpiece, producing complex geometries with features such as pockets, slots, holes, and contoured surfaces. For stainless steel machining, mills employ climb milling techniques to minimize work hardening and use variable helix end mills to reduce vibration and improve surface finish. High-efficiency milling strategies with stepovers up to 15% of tool diameter and optimized tool paths enable efficient material removal while maintaining tool life.

CNC Turning processes rotate the workpiece while a single-point cutting tool removes material to create cylindrical components. Stainless steel turning requires positive rake geometry tools to reduce cutting forces and specialized chip breakers to control the stringy chips characteristic of stainless steels. The process produces parts with excellent concentricity and can achieve surface finishes to Ra 0.4μm with proper tool geometry and cutting parameters.

Multi-Axis Machining (including 5-axis simultaneous machining) enables complex geometries to be produced in a single setup, eliminating cumulative errors from multiple repositioning operations. This capability is particularly valuable for stainless steel components with compound curves, angled features, and complex contours that would be difficult or impossible to produce with conventional 3-axis machining.

Swiss-Type Machining utilizes guide bushings to provide exceptional support close to the cutting tool, enabling high-precision machining of small, complex stainless steel components with length-to-diameter ratios that would be challenging for conventional lathes. This process is ideal for medical components, electronic connectors, and precision instruments requiring tight tolerances and fine surface finishes.

4 Technical Considerations for Machining Stainless Steel

Successful machining of stainless steel requires careful attention to numerous technical factors that influence tool life, surface finish, dimensional accuracy, and overall process efficiency.

Tool Selection is critical for stainless steel machining. Carbide tools with fine-grained substrates provide the best performance for most applications, offering higher hardness and better heat resistance than high-speed steel. Coatings such as TiAlN (titanium aluminum nitride), AlCrN (aluminum chromium nitride), and DLC (diamond-like carbon) reduce friction, dissipate heat, and prolong tool life. Geometry optimization including positive rake angles, sharp cutting edges, and specialized chip breakers helps manage the high cutting forces and work hardening tendencies of stainless steels.

Cutting Parameters must be optimized for each stainless steel grade and operation. Surface speed typically ranges from 30-90 m/min for most operations, with lower speeds for harder grades and higher speeds for free-machining grades. Feed rates must be balanced to avoid excessive tool pressure while preventing dwell that can cause work hardening. Depth of cut selection considers machine power, tool rigidity, and desired material removal rates.

Coolant Application is particularly important for stainless steel due to its low thermal conductivity. High-pressure coolant (up to 1,000 psi) directed precisely at the cutting edge helps control heat generation, break chips, and extend tool life. Coolant filtration to remove fine stainless steel particles prevents recirculation of abrasive debris that can damage tools and workpieces.

Workholding solutions must provide secure clamping without distorting the workpiece or damaging finished surfaces. Hydraulic workholding offers consistent clamping force and vibration damping, while specialized jaw materials with embedded hard particles prevent slippage of hard stainless steel workpieces. Custom fixtures may be required for complex geometries to ensure proper support and accessibility for cutting tools.

5 Surface Finishes and Post-Processing

The selection and application of appropriate surface finishes and post-processing treatments enhance the performance, appearance, and functionality of CNC machined stainless steel parts.

Machined Finishes result directly from the CNC machining process and can range from rough machined surfaces (Ra 3.2-6.3μm) suitable for non-critical applications to precision machined surfaces (Ra 0.2-0.8μm) achieved through fine finishing passes with specialized tools. Surface finish quality depends on factors including tool geometry, cutting parameters, machine rigidity, and tool path strategy.

Polishing processes improve surface smoothness and appearance through progressive abrasion with increasingly fine media. Mechanical polishing can achieve mirror finishes with roughness values below Ra 0.025μm for applications requiring aesthetic appeal or easy cleaning. Electropolishing removes a thin layer of surface material through electrochemical dissolution, leveling micropeaks and improving corrosion resistance by enhancing the passive chromium oxide layer.

Passivation treatments use nitric or citric acid solutions to remove free iron particles from the surface and promote the formation of a continuous passive oxide layer. This process significantly enhances corrosion resistance without changing the part’s dimensions or appearance. Proper passivation is essential for stainless steel components that will be used in corrosive environments.

Other Surface Treatments include bead blasting for uniform matte finishes, PVD coating for enhanced wear resistance and decorative appearances, and electroplating with materials such as nickel or chromium for specific functional requirements.

Table: Surface Finishes for CNC Machined Stainless Steel Parts

| Finish Type | Process | Surface Roughness (Ra) | Characteristics | Common Applications |

|---|---|---|---|---|

| As-Machined | CNC milling/turning | 0.8-3.2μm | Tool marks visible, functional | Industrial components, non-critical parts |

| Fine Machined | Precision finishing | 0.2-0.8μm | Minimal visible tool marks | Precision mechanisms, sliding surfaces |

| Bead Blasted | Abrasive media impingement | 0.4-1.6μm | Uniform matte appearance | Medical devices, food processing equipment |

| Mechanically Polished | Progressive abrasion | 0.025-0.4μm | Reflective surface | Decorative elements, sanitary applications |

| Electropolished | Electrochemical dissolution | 0.025-0.2μm | Enhanced corrosion resistance | Pharmaceutical, chemical processing |

| Passivated | Chemical treatment | No change to roughness | Maximum corrosion resistance | Marine applications, corrosive environments |

6 Quality Control and Metrology

Quality assurance for custom CNC machined stainless steel parts involves comprehensive inspection methodologies and precise measurement techniques to verify compliance with specifications.

Dimensional Inspection utilizes various metrology equipment depending on tolerance requirements and part complexity. Coordinate Measuring Machines (CMM) with scanning capabilities provide complete geometric analysis with micron-level accuracy. Optical comparators and vision systems enable rapid non-contact measurement of 2D features, while laser scanners capture complex 3D geometries for comparison with CAD models.

Surface Finish Measurement employs contact profilometers with diamond-tipped styli to quantify surface roughness parameters (Ra, Rz, Rq) according to international standards. Non-contact optical profilers use interferometry or focus variation to measure delicate surfaces without risk of damage.

Material Verification ensures stainless steel composition meets specified requirements. X-ray fluorescence (XRF) analyzers provide non-destructive elemental analysis to verify alloy composition, while rockwell and vickers hardness testers confirm mechanical properties meet specifications.

Documentation provides traceability and verification of quality standards. Certificates of Conformance document compliance with specifications, First Article Inspection reports provide comprehensive initial part verification, and Material Test Reports certify alloy composition and properties from the mill.

7 Applications and Case Studies

Custom CNC machined stainless steel parts serve critical functions across diverse industries where corrosion resistance, strength, and precision are essential.

Case Study 1: Medical Surgical Instrument

A medical device manufacturer required a precise surgical cutting instrument from stainless 17-4PH with complex features including tapered geometries, tissue engagement features, and ergonomic handles. The component required hardening to 44 HRC after machining and needed to maintain sharp cutting edges through repeated sterilization cycles.

Solution: JL YPT utilized 5-axis simultaneous machining to produce the complex geometry in a single setup, maintaining critical relationships between features. The parts were machined in the solution annealed condition then heat treated to achieve the required hardness. Final sharpening of cutting edges and passivation completed the manufacturing process.

Results: The surgical instruments exceeded performance requirements with 30% longer cutting edge life compared to previous designs. The single-setup manufacturing approach improved feature relationship accuracy by 45% while reducing total manufacturing cost by 22% through eliminated secondary operations.

Case Study 2: Marine Propulsion Component

A marine equipment manufacturer needed a stern tube seal housing from stainless 316L for a new high-performance vessel. The large component (420mm diameter × 680mm length) required precise bore geometry for seal mounting, multiple port connections for lubrication systems, and exceptional corrosion resistance for saltwater service.

Solution: Horizontal machining centers with pallet changers enabled efficient machining of all features without repositioning. High-pressure coolant through the tools managed heat generation during extensive machining operations. In-process verification of critical dimensions ensured compliance with tight tolerances before proceeding to subsequent operations.

Results: The component achieved 0.015mm bore straightness and 0.025mm concentricity between mounting features. The manufacturing process achieved first-pass acceptance of all critical characteristics, and the component has performed without issue in service for over 12,000 hours.

Case Study 3: Food Processing Valve Body

A food processing equipment manufacturer required custom valve bodies from stainless 304 with complex internal passages, precision mounting surfaces, and sanitary finishes. The components needed to withstand daily cleaning with caustic solutions while maintaining seal integrity and operational reliability.

Solution: Multi-axis milling with boring tools created the precise internal geometries and sealing surfaces. Sequential machining operations progressed from roughing through semi-finishing to final finishing, with increasing precision and decreasing stock removal. Electropolishing after machining provided the required sanitary finish and enhanced corrosion resistance.

Results: The valve bodies achieved Ra 0.4μm surface finish on all product contact surfaces, exceeding sanitary standards. The components have demonstrated 18-month service intervals between maintenance, doubling the previous service life and significantly reducing equipment downtime.

8 Design Considerations for Stainless Steel Parts

Optimizing designs for CNC machined stainless steel components requires attention to specific considerations that improve manufacturability, enhance performance, and reduce costs.

Design for Machinability principles include minimizing deep cavities with small corner radii, avoiding extremely thin walls that may deflect during machining, and designing features that can be machined with standard tooling. Uniform wall thicknesses promote consistent machining behavior and reduce the risk of distortion.

Feature Accessibility ensures cutting tools can reach all surfaces without interference. Adequate tool clearance for standard diameter tools reduces manufacturing complexity, while strategic split lines can make complex internal features accessible without specialized tooling.

Material Selection considers the specific requirements of the application environment. Austenitic grades (304, 316) offer the best corrosion resistance, martensitic grades (410, 416) provide higher strength through heat treatment, and precipitation-hardening grades (17-4 PH, 15-5 PH) deliver an excellent combination of strength and corrosion resistance.

Tolerance Specification should reflect actual functional requirements rather than arbitrarily tight values. Commercial tolerances (±0.1mm) are suitable for non-critical features, precision tolerances (±0.025mm) accommodate most functional requirements, and high-precision tolerances (±0.005mm) are reserved for truly critical features where justified by function.

9 Conclusion: Advantages of Stainless Steel CNC Machined Parts

Custom CNC machined parts from stainless steels offer numerous advantages that make them the preferred choice for demanding applications across diverse industries.

Exceptional Corrosion Resistance provided by the passive chromium oxide layer enables components to perform reliably in hostile environments including chemical processing, marine applications, and medical sterilization. This resistance can be further enhanced through appropriate grade selection and surface treatments.

Superior Mechanical Properties including high strength, hardness, and wear resistance allow stainless steel components to withstand significant mechanical loads, abrasive environments, and repetitive use without degradation of performance or dimensions.

Hygienic Properties make certain stainless steel grades ideal for applications requiring cleanliness and sterility. The non-porous surface, ease of cleaning, and resistance to cleaning chemicals make stainless steel the material of choice for medical, pharmaceutical, and food processing applications.

Temperature Resistance allows stainless steel components to maintain their properties across a wide temperature range from cryogenic applications to elevated temperature service in excess of 800°C for some grades, far exceeding the capabilities of most engineering materials.

Aesthetic Appeal of stainless steel, particularly with polished or specialized finishes, provides a modern, professional appearance that is desirable for consumer products, architectural elements, and visible components.

Sustainability through complete recyclability at the end of service life makes stainless steel an environmentally responsible choice that supports circular economy principles.

At JL YPT, we combine advanced CNC machining capabilities with extensive materials expertise to deliver custom stainless steel components that meet your most demanding requirements. Our facilities include multi-axis machining centers, precision turning equipment, and comprehensive metrology systems that ensure every component meets specifications.

Ready to discuss your custom stainless steel machining project? Contact JL YPT today to leverage our expertise for your application requirements.