Precision Engineered: Mastering Custom Fixtures and Gauges Manufacturing for Assembly Excellence

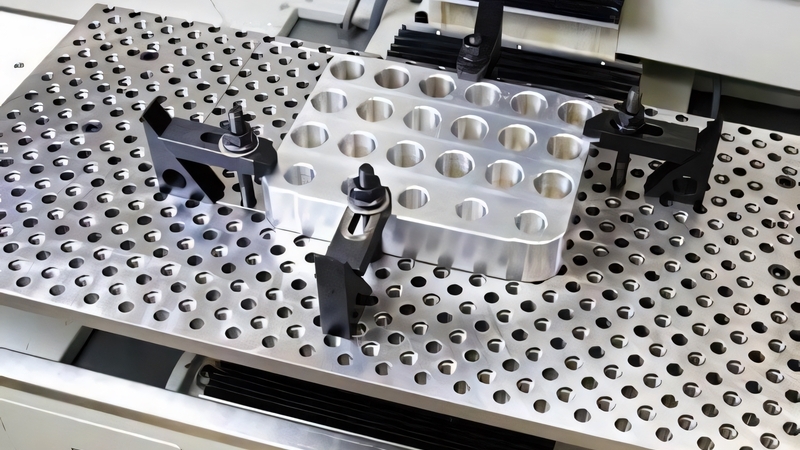

In modern manufacturing, the critical role of custom fixtures and gauges manufacturing for assembly is often the defining factor between mediocre quality and exceptional precision. These specialized tools form the backbone of efficient production lines, ensuring dimensional accuracy, interchangeability of components, and consistent quality across manufacturing operations. At JLYPT CNC Machining, we have established ourselves as industry leaders in custom fixtures and gauges manufacturing for assembly, combining advanced engineering methodologies with state-of-the-art manufacturing technologies to deliver solutions that transform assembly processes and elevate quality standards.

This comprehensive technical analysis explores the sophisticated engineering principles, advanced manufacturing technologies, and strategic implementation frameworks that define world-class custom fixtures and gauges manufacturing for assembly. We will examine how the integration of precision CNC machining, rigorous metrology, and strategic design creates assembly tools that not only ensure product quality but significantly enhance manufacturing efficiency and productivity.

The Fundamental Role of Custom Fixtures and Gauges in Modern Assembly

The implementation of specialized tooling represents a critical component in modern manufacturing ecosystems, with custom fixtures and gauges manufacturing for assembly providing foundational support for quality and efficiency:

Strategic Importance in Quality Assurance

Precision fixtures and gauges serve as the first line of defense against dimensional variations and quality deviations in manufacturing processes:

-

Dimensional Verification: Custom gauges provide rapid, reliable verification of critical part features, ensuring components meet specified tolerances before advancing to assembly operations

-

Process Standardization: Assembly fixtures establish and maintain consistent positioning and alignment throughout manufacturing processes, eliminating human error and variability

-

Interchangeability Assurance: Properly designed fixtures and gauges guarantee that components from different production batches maintain compatibility and functional interchangeability

-

Quality Documentation: Precision tooling generates objective quality data, supporting statistical process control initiatives and continuous improvement programs

Impact on Manufacturing Efficiency and Productivity

Beyond quality assurance, strategically implemented tooling delivers substantial operational advantages:

-

Cycle Time Reduction: Optimized fixtures streamline assembly processes, minimizing component handling and adjustment requirements

-

Labor Optimization: Simplified gauge operations and ergonomic fixture designs reduce operator dependency and training requirements

-

Scrap Reduction: Early detection of non-conforming components prevents value-added processing of defective parts

-

Line Flexibility: Quickly changeable fixtures and comprehensive gauge systems enable rapid production changeovers and mixed-model assembly

Advanced Engineering Principles in Fixture and Gauge Design

The development of effective assembly tooling requires rigorous application of engineering principles and manufacturing expertise:

Geometric Dimensioning and Tolerancing (GD&T) Implementation

Proper application of GD&T principles forms the foundation of precision tooling design:

-

Datums Establishment: Strategic selection and representation of datum features based on part function and assembly interfaces

-

Tolerance Stack-Up Analysis: Comprehensive analysis of dimensional relationships and cumulative variation effects throughout assembly sequences

-

Maximum Material Condition (MMC) Principles: Application of MMC concepts to functional gauge design, ensuring assembly compatibility under worst-case conditions

-

Feature Control Frameworks: Implementation of position, orientation, and form controls based on component functionality and manufacturing capabilities

Structural and Functional Design Considerations

Successful fixture and gauge design balances multiple engineering requirements:

-

Structural Rigidity: Optimization of fixture stiffness to resist deflection under clamping and processing forces while minimizing weight

-

Kinematic Principles: Application of deterministic locating schemes to constrain parts without over-constraint

-

Wear Management: Strategic material selection and surface treatment at critical contact points to maintain accuracy throughout tool life

-

Ergonomic Integration: Consideration of operator interaction, including weight reduction, handling features, and accessibility

Advanced Manufacturing Technologies for Precision Tooling

The demanding requirements of precision fixtures and gauges necessitate specialized manufacturing approaches and equipment:

Multi-Axis CNC Machining Capabilities

Modern CNC technologies provide the foundation for precision tooling manufacturing:

-

5-Axis Simultaneous Machining: Complex contouring and uninterrupted machining of sophisticated fixture bodies and gauge elements with continuous toolpath optimization

-

High-Speed Machining Strategies: Optimized toolpaths and cutting parameters for superior surface finishes, reduced machining times, and enhanced dimensional stability

-

Precision Micro-Machining Expertise: Advanced manufacturing of small features, locating pins, and gauge elements with tolerances to ±0.0005 inches

-

Adaptive Machining Techniques: Dynamic adjustment of machining parameters based on real-time conditions for consistent results in varied materials

Specialized Processes for Tooling Applications

Certain tooling components require specialized manufacturing approaches:

-

Deep-Hole Drilling: Precision drilling for fixture bushings and gauge reference features with exceptional straightness and surface finish

-

Jig Grinding Expertise: Ultra-precision machining of gauge features and locating elements with tolerances within microns

-

Coordinate Measuring Machine (CMM) Programming: Direct machining of inspection fixtures based on CMM data and reverse engineering requirements

Material Selection for Fixture and Gauge Applications

The performance and longevity of assembly tooling are directly influenced by appropriate material selection:

Metallic Materials for Structural Components

-

Tool Steels (D2, A2, O1): High wear resistance and dimensional stability for gauge elements and critical fixture components

-

Aluminum Alloys (6061, 7075): Excellent strength-to-weight ratio for fixture bodies and structural elements with good machinability

-

Stainless Steels (304, 17-4PH): Corrosion resistance and good mechanical properties for gauges used in challenging environments

-

Precipitation-Hardening Alloys: Stable thermal characteristics and consistent performance in temperature-variable manufacturing environments

Non-Metallic and Composite Materials

-

Industrial Plastics (UHMW-PE, Delrin): Excellent wear characteristics and damage resistance for part-contacting elements

-

Composite Materials: Custom-tuned thermal properties and vibration damping for metrology frames and precision applications

-

Ceramic Components: Exceptional wear resistance and dimensional stability for high-volume gauge applications

Technical Specifications for Assembly Tooling Applications

The table below details technical considerations for various fixture and gauge applications across manufacturing sectors:

| Application Type | Critical Technical Requirements | Material Selection | Manufacturing Approach |

|---|---|---|---|

| Assembly Fixtures | Deterministic locating, structural rigidity, wear resistance | 6061 Aluminum, 4140 Steel, UHMW-PE | 5-axis machining of complex contours, precision boring, stress-relieving cycles |

| Functional Test Gauges | Measurement precision, surface finish, geometric accuracy | Tool Steel, Stainless Steel, Ceramic | Jig grinding, precision milling, specialized heat treatment, calibration |

| CMM Inspection Fixtures | Metrological traceability, thermal stability, accuracy | Aluminum, Composites, Ceramic | CNC machining with CMM validation, temperature-controlled processing |

| Welding & Joining Fixtures | Thermal stability, accessibility, durability | 4140 Steel, Copper alloys, Ceramic coatings | Stress-relieved machining, thermal management features, protective treatments |

| Go/No-Go Gauges | Wear resistance, dimensional stability, handling safety | Tool Steel, Carbide, Ceramic | Precision grinding, superfinishing, wear-resistant coatings |

| Modular Fixture Systems | Interchangeability, repeatability, setup efficiency | 4140 Steel, Stainless Steel, Bronze | Precision boring, grinding, standardized interface machining |

For comprehensive understanding of gauge design standards and technical specifications, we regularly consult resources from ASME Digital Collection to ensure compliance with industry standards and technical requirements.

Comprehensive Case Studies: Fixture and Gauge Manufacturing Solutions

Case Study 1: Automotive Body-in-White (BIW) Assembly Fixture System

-

Challenge: An automotive manufacturer required a comprehensive fixture system for body assembly with exceptional repeatability and the ability to accommodate multiple vehicle variants. The system needed to maintain critical dimensional relationships within ±0.1mm across the entire assembly process.

-

Technical Solution: We designed and manufactured a modular fixture system using 7075 aluminum structural components with hardened steel locating elements. The implementation included kinematic coupling principles for precise module positioning and quick-change capabilities for variant changeovers.

-

Manufacturing Approach: Critical fixture components were machined using 5-axis CNC strategies with in-process verification. Locating pins and bushing interfaces underwent jig grinding to achieve required tolerances and surface finishes. The complete system was assembled and validated in our temperature-controlled metrology lab.

-

Technical Outcomes: The fixture system achieved repeatability of 0.05mm across all locating points, exceeding specification requirements. Changeover time between vehicle variants was reduced from 45 minutes to under 5 minutes. The implementation contributed to a 40% reduction in dimensional variation in the body assembly process.

-

Internal Link: Discover our comprehensive approach to assembly solutions through our Precision CNC Machining Services.

Case Study 2: Aerospace Composite Component Inspection Gauging

-

Challenge: An aerospace manufacturer needed comprehensive inspection gauging for complex composite structures with critical aerodynamic profiles. The gauges required exceptional dimensional stability and the ability to verify compound contours with tolerances within ±0.075mm.

-

Technical Solution: We developed a family of composite inspection fixtures using dimensionally stable aluminum alloy with ceramic wear surfaces at critical contact points. The design incorporated modular verification elements to assess various features while maintaining a common datum reference structure.

-

Manufacturing Approach: Contoured gauge surfaces were machined using 5-axis CNC with adaptive toolpaths to maintain perpendicularity to complex surfaces. Critical verification features underwent post-process grinding and lapping to achieve required tolerances. The complete system was validated using laser tracking metrology.

-

Technical Outcomes: The gauge system reduced inspection time by 65% while improving measurement consistency. The stable thermal characteristics maintained calibration through typical shop floor temperature variations. The customer realized a 92% reduction in coordinate measurement machine (CMM) validation requirements for routine inspections.

Case Study 3: Medical Device Assembly and Test Fixture Platform

-

Challenge: A medical device manufacturer required an integrated fixture system for assembly, calibration, and functional testing of a sophisticated surgical instrument. The system needed to accommodate delicate components while providing precise actuation and measurement capabilities.

-

Technical Solution: We engineered a multi-station fixture platform with precision tooling for component handling, electromechanical systems for instrument actuation, and integrated sensors for performance verification. The design incorporated quick-change tooling interfaces to accommodate instrument variants.

-

Manufacturing Approach: The fixture base was machined from stress-relieved aluminum with precision ground locating features. Actuation components were manufactured using stainless steel with specialized coatings for wear resistance and cleanliness. The complete system underwent rigorous cycle testing to validate reliability.

-

Technical Outcomes: The integrated fixture system reduced assembly time by 50% and eliminated calibration errors associated with previous manual methods. First-pass yield improved from 82% to 96% through consistent assembly processes and integrated verification. The system supported production ramp-up to 25,000 units monthly while maintaining quality standards.

Quality Assurance and Metrology for Precision Tooling

The development of precision fixtures and gauges demands comprehensive validation methodologies:

-

First Article Inspection: Comprehensive dimensional validation using coordinate measuring machines with comparison to design specifications and GD&T requirements

-

Material Certification: Verification of material properties and composition through certified mill test reports and additional testing as required

-

Surface Metrology: Precise measurement of surface finish, texture, and geometry using contact and non-contact profilometry

-

Functional Testing: Validation of tooling operation, including cycle testing, wear simulation, and ergonomic assessment

-

Documentation and Certification: Complete documentation packages including inspection reports, calibration certificates, and material traceability

The Future of Fixture and Gauge Manufacturing

The field of custom fixtures and gauges manufacturing for assembly continues to evolve with emerging technologies and methodologies:

-

Smart Tooling Integration: Implementation of sensors and data collection capabilities within fixtures and gauges for real-time process monitoring and data analytics

-

Additive Hybrid Manufacturing: Combining 3D printing with precision machining for optimized internal structures and conformal cooling channels

-

Digital Twin Implementation: Creating virtual models of tooling systems that simulate performance and predict maintenance requirements

-

Advanced Material Science: Development of new composites and engineered materials with tailored properties for specific tooling applications

-

Sustainable Manufacturing Practices: Implementing environmentally conscious manufacturing approaches without compromising technical objectives

Conclusion: Strategic Partnership for Manufacturing Excellence

The design and manufacture of precision fixtures and gauges represents a specialized domain where engineering expertise, manufacturing capability, and practical application knowledge converge. As an expert in custom fixtures and gauges manufacturing for assembly, JLYPT CNC Machining provides comprehensive solutions that extend far beyond simple part production – we deliver integrated tooling systems that transform assembly processes, ensure product quality, and enhance manufacturing efficiency.

Our technical approach recognizes that successful tooling implementation requires balancing ambitious production goals with practical manufacturing considerations and economic realities. Through deep collaboration with engineering and manufacturing teams, we transform assembly challenges into precision tooling solutions that validate design intent, optimize production processes, and establish the foundation for manufacturing excellence.

Ready to enhance your assembly operations with precision-engineered tooling solutions? Contact JLYPT CNC Machining today to discover how our expertise in custom fixtures and gauges manufacturing for assembly can optimize your production processes, ensure consistent quality, and deliver measurable operational improvements.