Premier Aerospace Coating Services EU: Expert Surface-Finishing Solutions from China

In the aerospace industry, where precision, reliability, and performance are paramount, choosing the right coating services is crucial. While many European companies seek local solutions, partnering with a reputable surface-finishing services provider in China can offer a blend of advanced technology, expertise, and cost-effectiveness. At JLYPT, we specialize in providing aerospace coating services tailored to meet EU standards, ensuring your aerospace components are protected, enhanced, and ready for the skies.

The Importance of Aerospace Coating Services

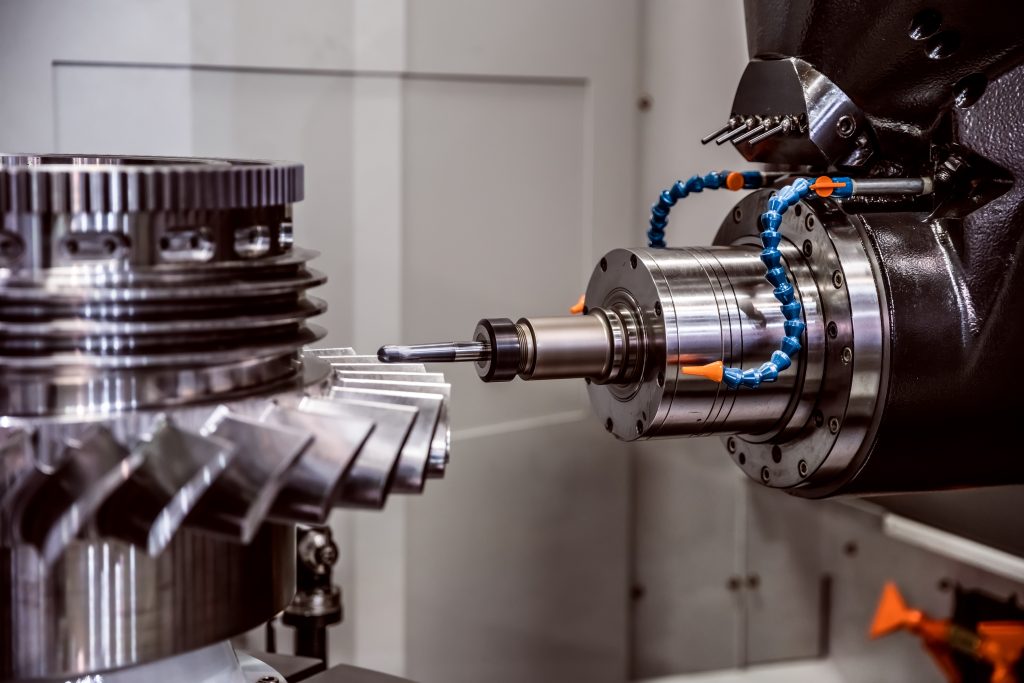

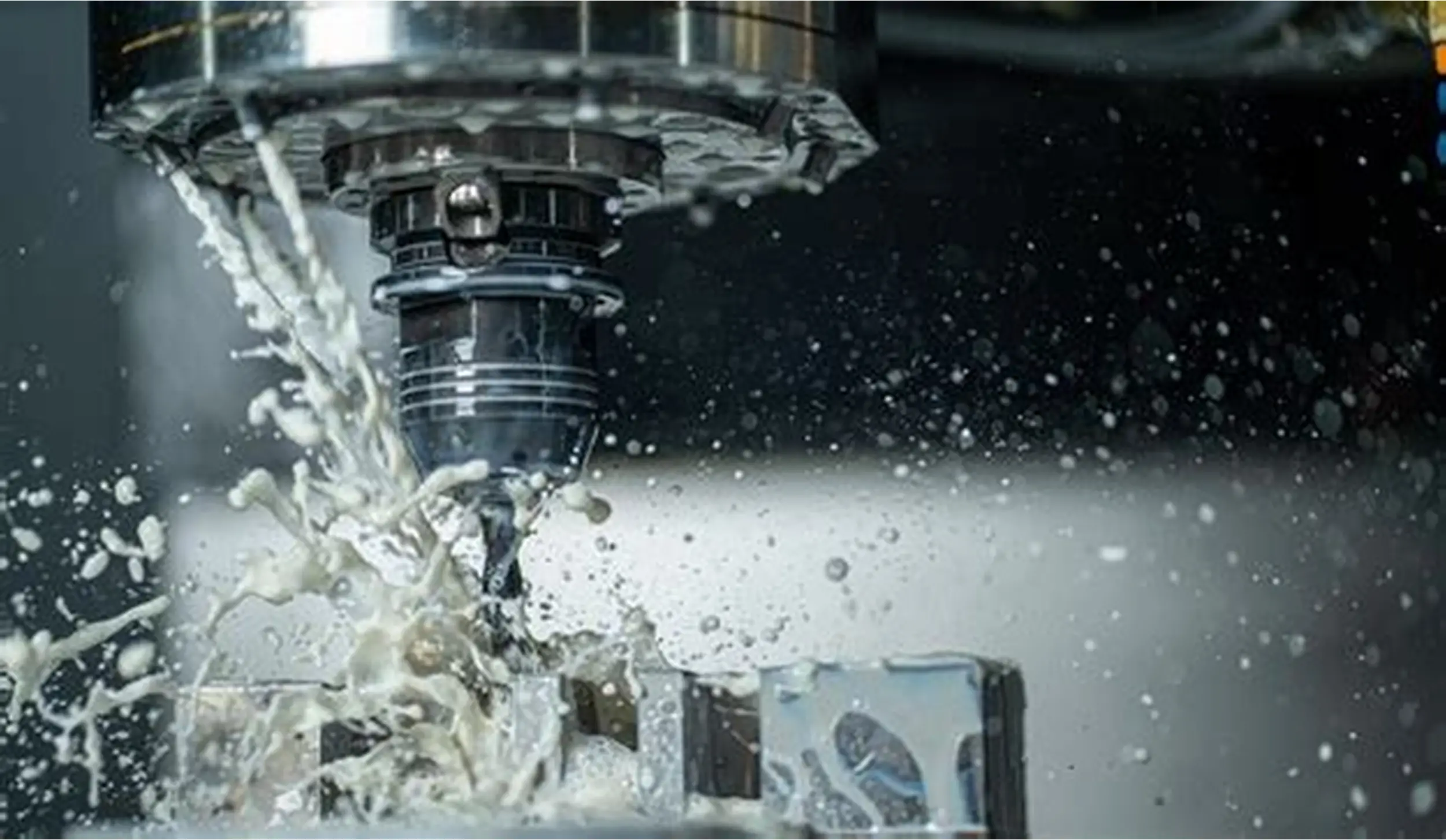

Aerospace components are subjected to extreme conditions, including high temperatures, pressures, and corrosive environments. Coatings play a vital role in protecting these components from wear and tear, corrosion, and other damage. They also enhance the aerodynamic properties, improve thermal insulation, and contribute to the overall performance and reliability of aerospace systems.

Benefits of Choosing JLYPT for Aerospace Coating Services

-

Advanced Technology and Expertise: As a leading surface-finishing services provider in China, JLYPT possesses cutting-edge coating technology and extensive expertise in applying coatings to aerospace components. Our team of engineers and technicians are well-versed in the nuances of aerospace-grade coatings, ensuring precision and reliability in every project.

-

Compliance with EU Standards: We understand the stringent regulations and standards governing aerospace components in the EU. Our coating processes are designed to comply with relevant EU directives and international standards, ensuring your aerospace components are safe and effective for use.

-

High-Performance Coatings: JLYPT offers a range of high-performance coatings tailored to meet the specific needs of the aerospace industry. From thermal barrier coatings to corrosion-resistant coatings, we have the solution to protect your components and enhance their performance.

-

Cost-Effective Solutions: Partnering with JLYPT for aerospace coating services can offer significant cost savings compared to EU-based providers. Our advanced manufacturing capabilities and economies of scale allow us to offer competitive pricing without compromising on quality.

Detailed Table of Aerospace Coating Services

| Service | Description | Benefits |

|---|---|---|

| Thermal Barrier Coatings (TBCs) | Coatings that protect aerospace components from high temperatures and thermal stresses. | Improved thermal insulation, reduced component wear, and enhanced engine efficiency. |

| Corrosion-Resistant Coatings | Coatings that provide a protective barrier against corrosion and other environmental factors. | Extended component lifespan, reduced maintenance costs, and improved system reliability. |

| Wear-Resistant Coatings | Coatings that enhance the durability and wear resistance of aerospace components. | Reduced friction and wear, improved component performance, and increased system uptime. |

| Conductive Coatings | Coatings that improve the electrical conductivity of aerospace components. | Enhanced electromagnetic shielding, improved signal transmission, and reduced interference. |

| Anti-Reflective Coatings | Coatings that reduce reflection and improve optical performance in aerospace applications. | Improved visibility, reduced glare, and enhanced sensor performance. |

Case Studies: Real-World Applications of Our Aerospace Coating Services

To illustrate the versatility and effectiveness of our aerospace coating services, here are three real-world case studies:

-

Turbine Blades: We coated turbine blades for a leading aerospace engine manufacturer with thermal barrier coatings to protect them from high temperatures and thermal stresses. The coatings significantly improved engine efficiency and reduced component wear, contributing to better overall performance.

-

Landing Gear Components: For landing gear components, we applied corrosion-resistant coatings to provide a protective barrier against moisture, salt, and other environmental factors. The coatings extended the lifespan of the components, reduced maintenance costs, and improved system reliability.

-

Optical Sensors: In aerospace applications requiring high-precision optical sensors, we developed anti-reflective coatings to reduce reflection and improve optical performance. The coatings enhanced sensor accuracy and visibility, contributing to safer and more efficient aerospace operations.

Additional Value-Added Services

In addition to our aerospace coating services, JLYPT offers a range of value-added services to support your surface-finishing needs:

-

Consultation and Design Support: Our team of experts can provide consultation and design support to help you choose the most suitable coating for your aerospace components. We work closely with you to understand your specific needs and develop a customized solution tailored to your application.

-

Quality Assurance and Testing: We adhere to strict quality assurance measures throughout the coating process to ensure consistent and reliable results. Our testing protocols include visual inspection, mechanical testing, and environmental testing to verify the performance of the coating under various conditions.

-

Regulatory Compliance: As a reputable surface-finishing services provider, we prioritize compliance with relevant regulations and standards. Our coating processes are designed to meet or exceed EU-based requirements, ensuring your aerospace components are safe and effective for use.

Conclusion: Partnering with JLYPT for Aerospace Coating Services

In conclusion, JLYPT offers top-notch aerospace coating services tailored to meet EU standards. Our advanced technology, expertise, and commitment to quality make us the ideal partner for your surface-finishing needs. With a range of coating options, value-added services, and a focus on compliance and cost-effectiveness, we can help you enhance the performance, reliability, and lifespan of your aerospace components. Contact us today to learn more about our services and how we can support your aerospace coating needs.