Engineering Excellence: The Strategic Value of a Prototype to Production Manufacturing Partner

The journey from initial concept to market-ready product represents one of the most complex and critical phases in product development, where effective transition between prototyping and production often determines commercial success. In today’s competitive manufacturing landscape, the traditional approach of engaging separate vendors for prototyping and production creates significant technical discontinuities, knowledge fragmentation, and costly transitions that compromise both timeline and quality objectives. At JLYPT CNC Machining, we have redefined this paradigm by establishing ourselves as a comprehensive prototype to production manufacturing partner that seamlessly bridges the gap between innovation and commercialization through integrated technologies, processes, and expertise.

This extensive technical analysis explores the sophisticated engineering frameworks, operational methodologies, and strategic advantages of engaging a unified prototype to production manufacturing partner. We examine how the integration of advanced manufacturing technologies, quality systems, and supply chain management creates a streamlined pathway from initial concept to scaled production, eliminating traditional barriers and accelerating time-to-market while optimizing costs and maintaining uncompromising quality standards.

The Manufacturing Continuum: From Concept to Commercialization

The transition from prototype to production represents a critical juncture where design intentions confront manufacturing realities. According to comprehensive industry analysis, products developed with an integrated prototype to production manufacturing partner achieve market launch 40-60% faster than those utilizing disparate suppliers. This dramatic acceleration stems from several fundamental technical and operational advantages inherent in the unified approach.

Knowledge Continuity and Technical Integration

Working with a unified prototype to production manufacturing partner ensures continuous knowledge transfer and technical integration throughout the product development lifecycle:

-

Manufacturing Feedback Integration: Early-stage design input regarding production constraints, material selection, and cost optimization informs prototype development, creating designs that balance innovation with manufacturing efficiency

-

Iterative Design Refinement: Performance improvements and manufacturing optimizations identified during prototyping phases are seamlessly incorporated into production-ready designs without information loss or reinterpretation

-

Process Validation: Manufacturing methodologies validated during prototyping provide certainty for production scaling, eliminating costly process changes during later development stages

-

Supply Chain Integration: Material selections and secondary processes proven during prototyping remain available and qualified for production scaling, ensuring consistency and reliability

Economic Optimization Across Development Phases

The financial benefits of engaging a prototype to production manufacturing partner extend significantly beyond simple per-part pricing considerations:

-

Tooling Strategy Optimization: Strategic investment in production-oriented tooling during prototyping phases reduces capital expenditure when scaling to production volumes

-

Process Efficiency Development: Manufacturing processes refined during prototyping are optimized for production, minimizing changeover costs and validation cycles

-

Risk Mitigation: Production feasibility is demonstrated throughout development, eliminating expensive late-stage design changes and tooling modifications

-

Total Cost Management: Comprehensive cost analysis from prototype through production enables accurate forecasting and strategic budget allocation

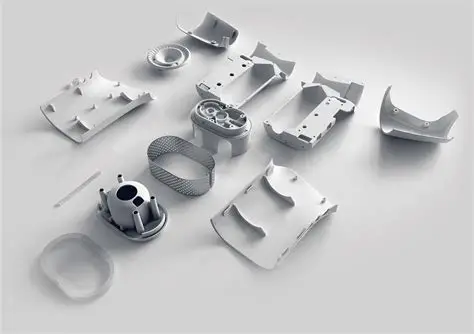

Advanced Manufacturing Capabilities for Integrated Production

The effectiveness of a prototype to production manufacturing partner hinges on sophisticated manufacturing capabilities that span the entire development continuum:

Multi-Axis CNC Machining Platforms

Our advanced CNC infrastructure supports both prototyping agility and production efficiency with varying levels of automation and optimization:

-

5-Axis Simultaneous Machining: Complex 3D contouring with continuous toolpath optimization for prototyping and low-volume production of intricate components with compound surfaces

-

High-Speed Machining Centers: Advanced spindle technology exceeding 30,000 RPM with optimized toolpaths for superior surface finishes and reduced cycle times across volume ranges

-

Mill-Turn Integration: Combined milling and turning operations for complex rotational parts with off-axis features in single setups, ideal for medium-volume production

-

Automated Production Systems: Integrated pallet changers, robotic part handling, and automated tool changing that enable continuous operation for production volumes

Additive and Subtractive Manufacturing Integration

Strategic combination of manufacturing technologies optimizes different phases of development:

-

Rapid Prototyping: Utilization of SLS, SLA, and FDM technologies for conceptual models, form-fit verification, and initial functional testing

-

Bridge Manufacturing: Application of additive technologies for small-volume production while production tooling is being developed and validated

-

Hybrid Manufacturing: Integration of 3D printing with CNC machining for complex geometries with critical precision features requiring both design freedom and accuracy

-

Production Tooling: Utilization of additive technologies for jigs, fixtures, and custom workholding that optimize production processes and reduce setup times

Technical Specifications for Prototype to Production Transition

The table below outlines the technical progression from prototype to production across key manufacturing parameters:

| Manufacturing Parameter | Prototyping Phase | Bridge Production | Full Scale Production |

|---|---|---|---|

| Volume Range | 1-50 units | 50-5,000 units | 5,000-100,000+ units |

| Primary Technologies | 3+2 & 5-axis CNC, Additive Manufacturing | 3+2 & 5-axis CNC with partial automation | Dedicated CNC cells with full automation |

| Tolerance Standards | ±0.005 inches (±0.13 mm) | ±0.002 inches (±0.05 mm) | ±0.001 inches (±0.025 mm) with SPC |

| Surface Finish Requirements | Ra 0.8 μm (32 μin) | Ra 0.4 μm (16 μin) | Ra 0.2 μm (8 μin) with consistency control |

| Material Certification | Mill certificates | Full traceability with mechanical testing | Certified material with complete lot traceability |

| Quality Documentation | First article inspection (FAI) | FAI with statistical process control | Comprehensive FAI, CPK studies, full documentation |

| Lead Time Focus | Speed and flexibility | Balanced speed and process control | Process optimization and cost efficiency |

Quality Systems for Integrated Manufacturing

Maintaining consistent quality across the prototype to production continuum requires sophisticated quality systems that scale with volume and complexity:

-

First Article Inspection (FAI): Comprehensive dimensional validation using coordinate measuring machines with comparison to CAD data at prototype phase with expanding scope through production

-

Statistical Process Control (SPC): Implementation of control charts and capability analysis for critical characteristics during bridge production with expansion to full production monitoring

-

Advanced Metrology Integration: Strategic application of CMM, optical scanning, and surface metrology throughout development with increasing frequency and rigor

-

Documentation Systems: Evolving quality documentation from basic inspection reports to comprehensive quality plans with full traceability and change management

Comprehensive Case Studies: Prototype to Production Success

Case Study 1: Aerospace Component Development

-

Challenge: An aerospace developer required rapid iteration of a complex structural bracket design and subsequent transition to production of 2,500 units annually. The component demanded exceptional strength-to-weight ratio, precise dimensional stability, and compliance with aerospace certification requirements.

-

Prototype Phase: We manufactured 18 iterative prototypes using 5-axis CNC machining from 7075-T651 aluminum, implementing high-speed machining strategies to achieve required surface finishes while compressing development timeline. Four complete design iterations were executed within a three-week timeframe.

-

Production Transition: The finalized design transitioned to dedicated CNC machining cells with automated workholding and tool management systems. Comprehensive process optimization reduced cycle time by 38% while maintaining all critical tolerances within ±0.001 inches.

-

Results: The production system achieved 99.8% first-pass yield with all components meeting aerospace certification requirements. The integrated approach reduced time-to-market by 65% compared to the customer’s previous development projects using separate prototyping and production vendors.

Case Study 2: Medical Device Manufacturing

-

Challenge: A medical device startup required development of a surgical instrument with stringent regulatory requirements, followed by production scaling to 75,000 units annually. The design demanded biocompatible materials, precise ergonomic features, and comprehensive validation for regulatory submission.

-

Prototype Phase: We produced the surgical instrument from medical-grade stainless steel with electropolished surfaces, incorporating precision micro-machining for intricate features. The process included six design iterations within five weeks, with complete documentation supporting regulatory submission.

-

Production Transition: The design transitioned to multi-axis CNC turning centers with live tooling for high-volume production. Automated inspection systems provided 100% verification of critical features. The manufacturing process underwent comprehensive validation and documentation for regulatory compliance.

-

Results: The production system achieved 99.95% quality acceptance with all instruments meeting regulatory requirements. The seamless transition identified manufacturing optimizations that reduced production costs by 28% while maintaining all design specifications and quality standards.

Case Study 3: Industrial Automation System

-

Challenge: An industrial automation provider needed to develop a precision motion control component and scale production to 150,000 units annually. The component required specialized materials, precise geometric tolerances, and exceptional durability under continuous operation in demanding environments.

-

Prototype Phase: We implemented a comprehensive prototyping approach using 17-4PH stainless steel with solution treatment and aging to achieve required mechanical properties. The process incorporated multi-axis machining with adaptive toolpaths to optimize the design for high-volume production.

-

Production Transition: The component transitioned to dedicated CNC machining cells with integrated automation for high-volume production. Strategic process optimization reduced cycle time by 42% while maintaining all critical tolerances within ±0.0005 inches through advanced tooling and fixturing strategies.

-

Results: The production system achieved 99.9% first-pass yield with demonstrated reliability exceeding 75,000 hours mean time between failures. The integrated approach reduced total development and production setup time by 50% compared to industry benchmarks, delivering significant competitive advantage.

Strategic Implementation Framework

Maximizing the benefits of a prototype to production manufacturing partner requires strategic implementation throughout the product development lifecycle:

Design for Manufacturing Integration

Strategic design approaches that facilitate seamless transition from prototype to production:

-

Feature Standardization: Implementation of standard feature sizes, tooling-compatible geometries, and production-friendly tolerances during prototyping phases

-

Material Selection Strategy: Choosing materials with appropriate availability, machinability, and cost characteristics for production scaling without performance compromise

-

Process-Aware Design: Creating geometries compatible with high-volume production methods while maintaining design intent and functional requirements

-

Design Validation: Comprehensive testing of production-intent designs during prototyping to identify and resolve manufacturing challenges before production commitment

Production Planning and Scaling Strategy

Strategic approaches to managing the transition from prototype to production:

-

Capacity Planning: Strategic alignment of production capacity with projected demand, accounting for equipment lead times and tooling development

-

Supply Chain Development: Identification and qualification of material suppliers and secondary processors during prototyping phases to ensure production readiness

-

Quality System Implementation: Evolution of quality controls from prototype verification to production process control with statistical methods and comprehensive documentation

-

Cost Management: Comprehensive cost analysis and optimization throughout development to ensure production viability and profitability targets

The Future of Integrated Manufacturing

The field of integrated prototype to production manufacturing continues to evolve with emerging technologies and methodologies:

-

Digital Thread Implementation: Seamless data flow from design through manufacturing and quality verification enabling unprecedented visibility and control across the entire product lifecycle

-

AI-Driven Optimization: Implementation of machine learning algorithms for predictive process planning, toolpath optimization, and maintenance scheduling based on historical data and real-time monitoring

-

Additive-Subtractive Hybrid: Integration of 3D printing with CNC machining for enhanced geometric freedom and further compression of manufacturing timelines while maintaining precision

-

Advanced Materials: Development and implementation of new alloys and engineered materials with enhanced properties for specific performance requirements and manufacturing efficiency

-

Sustainable Manufacturing: Implementation of energy-efficient processes, material recycling, and waste reduction strategies throughout the product lifecycle without compromising quality or performance

Conclusion: Strategic Partnership for Manufacturing Excellence

The journey from concept to commercial product represents a critical business process where effective integration of prototyping and production significantly impacts time-to-market, development costs, and ultimate commercial success. The capabilities offered by an advanced prototype to production manufacturing partner provide companies across industries with the manufacturing integration needed to navigate dynamic markets, accelerate innovation, and maintain competitive advantage in an increasingly challenging global landscape.

At JLYPT CNC Machining, our comprehensive approach as a prototype to production manufacturing partner combines state-of-the-art equipment, deep technical expertise, and optimized workflows to deliver exceptional components throughout the product lifecycle. Whether supporting initial concept validation, engineering testing, or full-scale production, our capabilities and commitment to excellence ensure that our customers can move with confidence and efficiency from concept to commercial reality.

Ready to streamline your product development with an integrated manufacturing partner? Contact JLYPT CNC Machining today to discover how our expertise as a prototype to production manufacturing partner can help you achieve your development and production goals with unprecedented speed, quality, and technical excellence. Visit our CNC Machining Services page to learn more about our comprehensive capabilities and request your instant quote.