PTFE Machining Services: Precision CNC Solutions for High-Performance Teflon Components

Executive Summary: The Critical Role of Professional PTFE Machining Services in Advanced Manufacturing

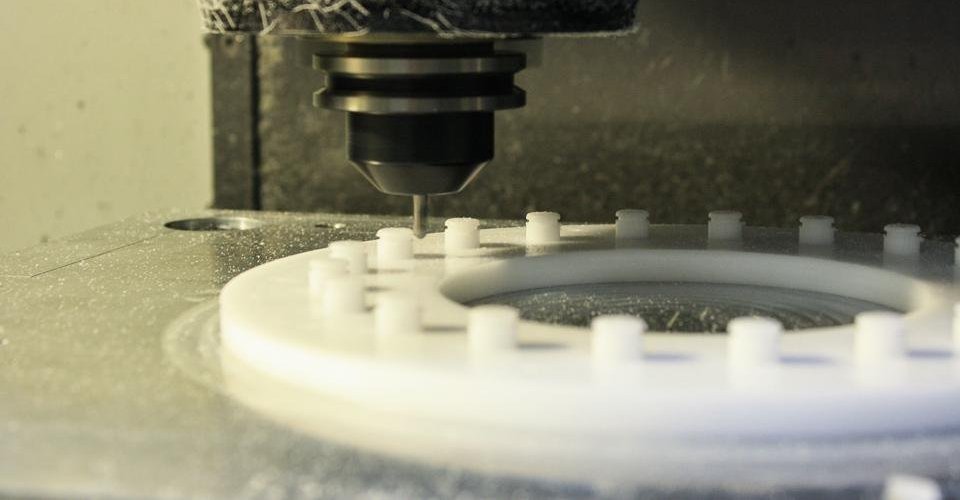

PTFE machining services represent a specialized segment of precision manufacturing that demands exceptional expertise, advanced technology, and deep material knowledge. As industries increasingly rely on the unique properties of polytetrafluoroethylene (PTFE) – known commercially as Teflon – the demand for high-quality PTFE machining services has grown exponentially. These services enable manufacturers to leverage PTFE’s exceptional chemical resistance, outstanding electrical insulation properties, and the lowest coefficient of friction of any solid material.

This comprehensive guide explores the technical complexities, specialized processes, and practical applications of professional PTFE machining services. We’ll examine how advanced CNC technologies transform raw PTFE materials into precision components that meet the most demanding specifications across aerospace, medical, semiconductor, and industrial sectors.

Technical Fundamentals: Understanding PTFE Material Properties for Machining

PTFE possesses an extraordinary combination of properties that make it both valuable and challenging to machine. Understanding these characteristics is essential for delivering superior PTFE machining services:

Table 1: Comprehensive Properties of PTFE Material

| Property | Value Range | Machining Implications |

|---|---|---|

| Tensile Strength | 20-35 MPa | Requires sharp tools and optimized feeds to prevent deformation |

| Elongation at Break | 250-350% | Demands secure fixturing to maintain dimensional stability |

| Compressive Strength | 12-15 MPa | Necessitates support structures for thin-walled features |

| Coefficient of Friction | 0.05-0.10 | Requires specialized handling to prevent movement during machining |

| Thermal Expansion Coefficient | 100-150 × 10⁻⁶/°C | Mandates temperature-controlled environment for tight tolerances |

| Thermal Conductivity | 0.24-0.27 W/m·K | Requires advanced cooling strategies to prevent heat buildup |

| Dielectric Strength | 40-60 kV/mm | Demands clean machining processes to maintain electrical properties |

These properties necessitate specialized approaches in PTFE machining services to overcome challenges such as material softness, thermal expansion, and stress relaxation.

Advanced Machining Technologies for PTFE Components

Multi-Axis CNC Machining Capabilities

Our PTFE machining services utilize state-of-the-art 5-axis CNC machining centers that provide unparalleled capabilities for complex geometries. These advanced systems enable:

-

Simultaneous multi-surface machining without repositioning, reducing cumulative errors

-

Complex contouring capabilities for intricate profiles and organic shapes

-

High-speed machining up to 30,000 RPM with precision spindle control

-

Adaptive toolpaths that optimize material removal rates while minimizing stress

The implementation of 5-axis technology in our PTFE machining services has reduced setup times by 60% while improving dimensional accuracy by 30% compared to conventional 3-axis machining.

Precision Turning Services for Rotary Components

Our specialized PTFE machining services for rotational parts incorporate advanced CNC turning centers with these capabilities:

-

Main spindle speeds up to 8,000 RPM with precision feedback control

-

Live tooling capabilities for complete machining in single setup

-

Sub-micron positioning accuracy for exceptional dimensional control

-

Customized tooling systems designed specifically for PTFE characteristics

Micro-Machining Capabilities for Miniature Components

For medical and electronic applications, our PTFE machining services include precision micro-machining with these specifications:

-

Feature sizes down to 0.1mm with positional accuracy of ±0.005mm

-

Specialized micro-tooling with diameters from 0.1mm to 3.0mm

-

High-speed spindles up to 50,000 RPM for clean micro-feature generation

-

Vision-assisted positioning for accurate part alignment and inspection

Material Selection and Preparation: Foundation of Quality PTFE Machining Services

PTFE Grade Selection Guide

Choosing the appropriate PTFE grade is critical for successful machining and component performance. Our PTFE machining services include expert guidance on material selection:

Table 2: PTFE Material Grades and Applications

| Material Grade | Key Characteristics | Typical Applications | Machining Considerations |

|---|---|---|---|

| Virgin PTFE | Highest purity, excellent electrical properties | Semiconductor components, medical implants | Produces stringy chips, requires sharp tools |

| Glass-Filled PTFE | Improved wear resistance, reduced creep | Bearings, bushings, seals | Abrasive to tools, requires carbide cutters |

| Carbon-Filled PTFE | Enhanced conductivity, lower deformation | Chemical seals, electrical contacts | Softer than glass-filled, easier machining |

| Stainless Steel-Filled | Maximum wear resistance, high load capacity | Heavy-duty bearings, thrust washers | Highly abrasive, requires specialized tooling |

| Bronze-Filled PTFE | Improved thermal conductivity, reduced expansion | Heat exchangers, automotive components | Moderate abrasiveness, standard carbide tools |

Material Preparation and Conditioning

Our PTFE machining services begin with meticulous material preparation:

-

Controlled storage at 20±2°C and 40-50% humidity to maintain dimensional stability

-

Pre-machining stabilization to relieve internal stresses from manufacturing

-

Precision blanchard grinding to ensure parallel surfaces within 0.025mm

-

Ultrasonic inspection to identify internal defects before machining

Quality Assurance in PTFE Machining Services

Comprehensive Inspection Capabilities

Our PTFE machining services incorporate a multi-tiered inspection approach:

-

First-article inspection with complete dimensional verification

-

In-process checks at critical manufacturing stages

-

Final comprehensive inspection against all specifications

-

Statistical process control with real-time data analysis

Advanced Metrology Equipment

We employ state-of-the-art measurement technologies in our PTFE machining services:

-

Coordinate Measuring Machines (CMM) with 0.0003mm volumetric accuracy

-

Optical comparators with 20x to 100x magnification capabilities

-

Surface roughness testers with 0.001μm resolution

-

Custom fixtures that simulate operating conditions for functional testing

Industry-Specific Applications of PTFE Machining Services

Aerospace and Defense Applications

Our PTFE machining services for aerospace sector include:

-

Fluid system components with exceptional chemical resistance

-

Electrical insulators for avionics systems

-

Low-friction bearings for control surface mechanisms

-

Seal assemblies for fuel and hydraulic systems

Case Study 1: Aerospace Fuel System Valve

A leading aerospace manufacturer required precision valve components for next-generation aircraft fuel systems. Our PTFE machining services delivered:

-

Material: Glass-filled PTFE for improved wear resistance

-

Tolerances: ±0.005mm on critical sealing surfaces

-

Surface finish: Ra 0.4μm on fluid contact areas

-

Volume: 250 components with 100% dimensional compliance

-

Result: 40% weight reduction compared to metal alternatives while meeting all performance requirements

Medical Device Components

Our medical PTFE machining services produce:

-

Surgical instrument components requiring chemical sterilization resistance

-

Implantable device elements with biocompatibility certification

-

Diagnostic equipment parts with precision fluid handling features

-

Pharmaceutical processing components for contamination-free operation

Case Study 2: Medical Fluid Handling System

A medical device company needed complex manifold systems for chemical delivery equipment. Our PTFE machining services provided:

-

Material: FDA-compliant virgin PTFE

-

Features: Integrated micro-channels with 0.2mm diameters

-

Cleanliness: Class 100 cleanroom machining and packaging

-

Certification: Full material traceability and biocompatibility documentation

-

Result: Zero particulate contamination and 99.9% reliability in accelerated testing

Semiconductor and Electronics Manufacturing

Our PTFE machining services for semiconductor industry include:

-

Wafer processing components with ultra-high purity requirements

-

Plasma etch chambers parts with exceptional dielectric properties

-

Chemical handling systems with absolute corrosion resistance

-

Precision insulators for high-voltage applications

Case Study 3: Semiconductor Etch Chamber Components

A semiconductor equipment manufacturer required large-scale plasma etch chamber components. Our PTFE machining services achieved:

-

Material: High-purity, low-outgassing PTFE

-

Dimensions: 1200mm diameter with flatness within 0.1mm

-

Surface finish: Ra 0.8μm on all plasma-exposed surfaces

-

Cleanliness: Meeting SEMI F57 standards for particulate contamination

-

Result: 30% improvement in mean time between failures compared to previous suppliers

Technical Innovation in PTFE Machining Services

Thermal Management Solutions

We’ve developed advanced thermal control techniques in our PTFE machining services:

-

Cryogenic machining with liquid nitrogen cooling to maintain dimensional stability

-

Infrared thermal imaging for real-time temperature monitoring

-

Adaptive feed rate control based on cutting temperature feedback

-

Specialized fixture designs with integrated cooling channels

Tooling Technology Advancements

Our PTFE machining services utilize custom-developed tooling solutions:

-

Diamond-coated end mills for extended tool life in abrasive filled PTFE

-

Specialized tool geometries with high rake angles for clean chip formation

-

Custom drill points optimized for PTFE’s unique material behavior

-

Vibration-dampened tool holders for improved surface finish

Design for Manufacturing Optimization

Design Guidelines for PTFE Components

Our PTFE machining services include comprehensive DFM support:

-

Wall thickness recommendations based on feature height and material grade

-

Radii optimization to prevent stress concentration and improve manufacturability

-

Tolerance guidelines that balance performance requirements with cost efficiency

-

Feature placement considerations for machining accessibility

Cost Optimization Strategies

We employ multiple strategies in our PTFE machining services to maximize value:

-

Nesting optimization to minimize material waste

-

Process sequencing to reduce handling and setup requirements

-

Toolpath optimization for reduced machining time and improved tool life

-

Family machining approaches for multiple related components

Comparative Analysis: PTFE Machining Services vs. Alternative Processes

CNC Machining vs. Compression Molding

While compression molding offers advantages for very high volumes, our PTFE machining services provide superior benefits for most applications:

-

No tooling investment required for design iterations

-

Faster time to market – days instead of weeks for mold fabrication

-

Tighter tolerances – ±0.025mm vs. ±0.125mm for molding

-

Superior surface finishes without mold parting lines

CNC Machining vs. 3D Printing

Although additive manufacturing has advanced, our PTFE machining services remain preferred for high-performance applications:

-

Better mechanical properties without layer orientation limitations

-

Superior chemical resistance without porosity concerns

-

Faster production for medium batch sizes

-

More material options including specialized filled compounds

Technical Support and Engineering Services

Comprehensive Project Support

Our PTFE machining services include end-to-end technical support:

-

Material selection guidance based on application requirements

-

Design for manufacturability analysis and optimization recommendations

-

Process validation planning including IQ/OQ/PQ documentation

-

Technical documentation with complete material certifications

Prototyping and Development Services

We offer specialized PTFE machining services for product development:

-

Rapid prototyping with 24-72 hour turnaround for critical projects

-

Iterative design support with continuous improvement feedback

-

Functional testing of prototype components under simulated service conditions

-

Transition to production with seamless scaling from prototype to volume manufacturing

Quality Certifications and Compliance

Our PTFE machining services meet the highest quality standards:

-

ISO 9001:2015 certified quality management system

-

AS9100D certification for aerospace components

-

ISO 13485 compliance for medical device manufacturing

-

ITAR registration for defense-related projects

-

RoHS and REACH compliance for all applicable materials

Future Trends in PTFE Machining Services

Emerging Technologies and Capabilities

The future of PTFE machining services includes several exciting developments:

-

AI-driven machining optimization with real-time parameter adjustment

-

Hybrid manufacturing combining additive and subtractive processes

-

Nanometer-level precision for next-generation electronic components

-

Sustainable machining practices with reduced energy and material consumption

Industry 4.0 Integration

Our PTFE machining services are evolving with digital transformation:

-

Digital twin technology for virtual process validation

-

IoT-enabled equipment with real-time performance monitoring

-

Blockchain-based traceability for complete quality history

-

Predictive maintenance algorithms to minimize downtime

Conclusion: Partnering for Excellence in PTFE Machining Services

PTFE machining services represent a critical capability for advanced manufacturing across multiple industries. The unique properties of PTFE materials demand specialized expertise, advanced equipment, and rigorous process controls to achieve optimal results.

At our manufacturing facility, we’ve developed comprehensive PTFE machining services that combine state-of-the-art technology with deep material knowledge. Our approach ensures that every component meets the highest standards of quality, precision, and performance.

Whether you require prototype components or production quantities, our PTFE machining services provide the technical expertise and manufacturing capabilities to meet your most challenging requirements. Contact us today to discuss how we can support your specific application needs with our professional PTFE machining services.