PVD Coating for Stainless Steel: Enhancing Surface Finishing Solutions

Introduction

In the realm of surface treatment solutions, PVD (Physical Vapor Deposition) coating has emerged as a transformative force, particularly when applied to stainless steel. As a leading Chinese service provider in the PVD coating industry, JLY Precision Tech is at the forefront of delivering cutting-edge surface finishing services. This comprehensive article delves into the intricacies of PVD coating for stainless steel, exploring its benefits, applications, technical specifications, and case studies that highlight our expertise and commitment to excellence.

Table of Contents

-

What is PVD Coating?

-

Benefits of PVD Coating for Stainless Steel

-

Technical Specifications and Process Details

-

Performance Parameters Comparison Table

-

Case Studies

-

Why Choose JLY Precision Tech for PVD Coating Services?

-

Industry Applications

-

Contact Us for PVD Coating Services

What is PVD Coating?

PVD coating is an advanced surface finishing technology that involves the deposition of thin layers of material onto a substrate through physical processes. Unlike chemical vapor deposition (CVD), which uses chemical reactions, PVD relies on physical methods such as evaporation and sputtering to create high-quality, durable coatings. This process is performed in a vacuum chamber, where the coating material is heated or bombarded with ions until it vaporizes and condenses on the substrate’s surface.

Benefits of PVD Coating for Stainless Steel

Enhanced Corrosion Resistance

Stainless steel is naturally corrosion-resistant due to its chromium content, but PVD coating adds an additional layer of protection. The coating forms a barrier that prevents moisture and corrosive substances from reaching the stainless steel surface, significantly extending its service life.

Improved Wear Resistance

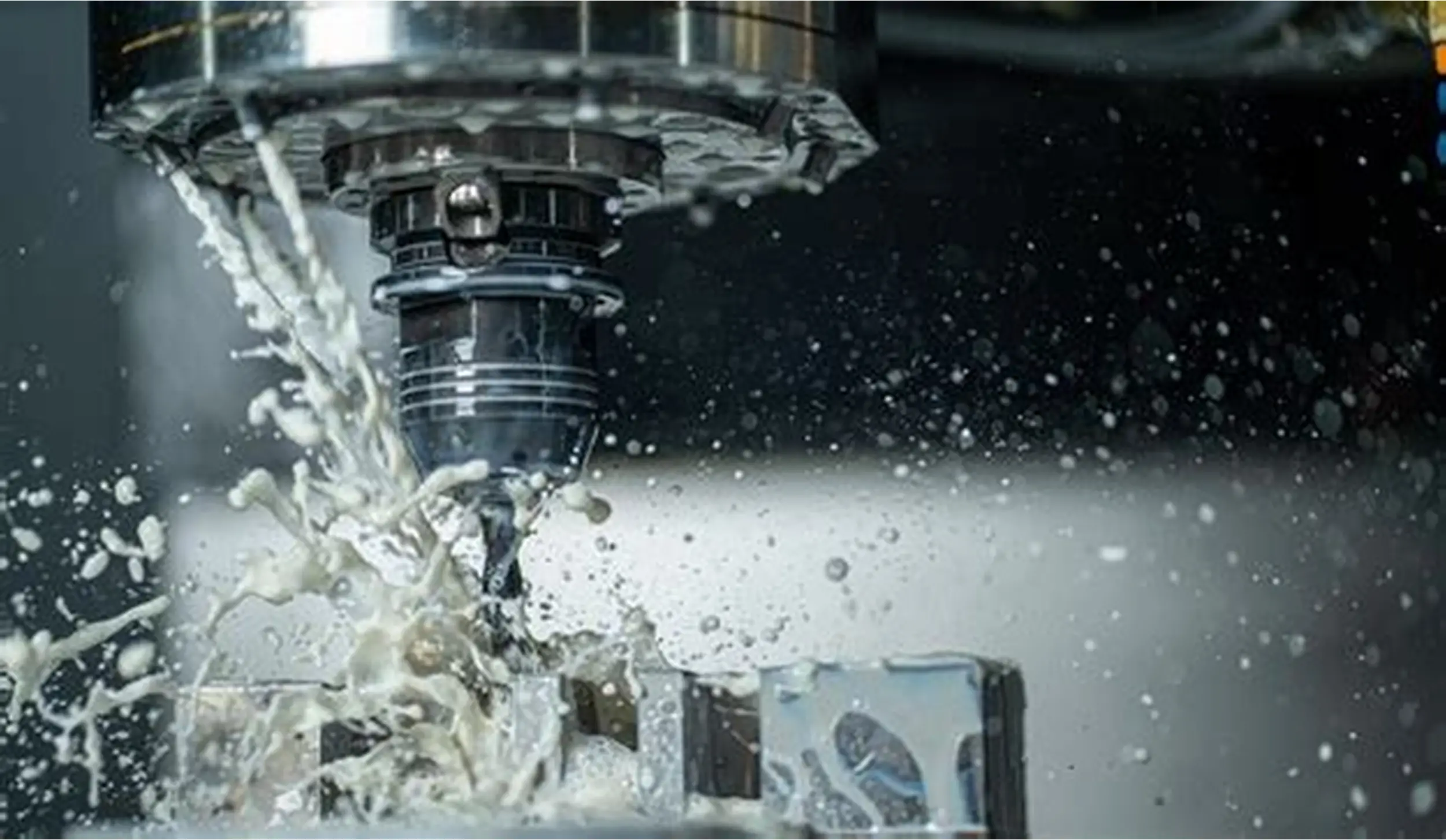

PVD coatings are highly durable and can withstand significant wear and tear. This is particularly beneficial for stainless steel components used in high-friction environments, such as machinery parts and tools.

Aesthetic Appeal

PVD coatings offer a wide range of color options, allowing for customization to meet specific design requirements. Whether a sleek black finish or a metallic sheen is desired, PVD coating can enhance the visual appeal of stainless steel products.

Environmental Friendliness

PVD coating is an environmentally sustainable process as it does not involve the use of harmful chemicals. This makes it a preferred choice for industries looking to reduce their environmental footprint.

Technical Specifications and Process Details

PVD Coating Process for Stainless Steel

The PVD coating process for stainless steel involves several critical steps:

-

Pre-treatment: The stainless steel component is cleaned thoroughly to remove any contaminants such as oils, grease, and dirt. This ensures optimal adhesion of the coating.

-

Loading: The cleaned component is placed inside a vacuum chamber.

-

Evaporation/Sputtering: The coating material, typically a metal or ceramic, is heated until it vaporizes or sputtered using a high-energy ion beam.

-

Deposition: The vaporized material condenses on the stainless steel surface, forming a thin, uniform coating.

-

Post-treatment: After coating, the component may undergo additional treatments to enhance its properties.

Coating Materials and Their Properties

| Coating Material | Color | Hardness (Vickers) | Thickness (µm) | Applications |

|---|---|---|---|---|

| Titanium Nitride (TiN) | Gold | 1800-2000 | 2-5 | Cutting tools, decorative parts |

| Titanium Carbonitride (TiCN) | Black | 2000-3000 | 1-3 | High-wear components |

| Chromium Nitride (CrN) | Dark Gray | 1500-1800 | 1-4 | Automotive parts, corrosion protection |

| Diamond-Like Carbon (DLC) | Black | 1000-3000 | 0.1-2 | High-performance tools, aerospace components |

Performance Parameters Comparison Table

To illustrate the superior performance of PVD-coated stainless steel, we have compiled a comparison table showcasing various parameters:

| Parameter | Uncoated Stainless Steel | PVD-Coated Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate | Excellent |

| Wear Resistance | Low to Moderate | High |

| Surface Hardness | 150-250 HV | 1000-3000 HV |

| Friction Coefficient | 0.5-0.8 | 0.1-0.3 |

| Operating Temperature Range | Up to 300°C | Up to 500°C |

Case Studies

Case Study 1: Aerospace Component Coating

A leading aerospace manufacturer sought to enhance the durability and performance of its titanium alloy components. JLY Precision Tech applied a specialized TiAlN PVD coating, resulting in a 40% increase in wear resistance and a 30% reduction in surface friction. The components underwent rigorous testing and demonstrated superior performance in high-temperature and high-stress environments.

Case Study 2: Industrial Cutting Tools

An industrial tool manufacturer was experiencing rapid wear of its cutting tools. By implementing JLY’s DLC PVD coating solution, the tool life was extended by 60%, and the cutting efficiency improved by 25%. The coating’s low friction coefficient and high hardness contributed to these significant improvements.

Case Study 3: Automotive Parts

An automotive parts supplier aimed to improve the corrosion resistance of its stainless steel components. JLY Precision Tech applied a CrN PVD coating, which resulted in a 70% reduction in corrosion rates. The coated parts passed stringent salt spray tests, demonstrating their suitability for harsh automotive environments.

Why Choose JLY Precision Tech for PVD Coating Services?

Expertise and Experience

With years of experience in the PVD coating industry, JLY Precision Tech has developed specialized knowledge and skills to deliver high-quality surface finishing solutions.

Advanced Technology and Equipment

Our state-of-the-art coating facilities are equipped with the latest PVD technology, ensuring precise and consistent coating applications.

Customized Solutions

We understand that each client’s requirements are unique. Our team works closely with you to develop tailored PVD coating solutions that meet your specific needs.

Quality Assurance

Rigorous quality control measures are implemented throughout the coating process to guarantee the highest standards of performance and durability.

Cost-Effectiveness

We offer competitive pricing without compromising on quality, making our PVD coating services an economically viable option for businesses of all sizes.

No Minimum Order Quantity (MOQ)

JLY Precision Tech does not impose minimum order quantities, providing flexibility for clients with varying production needs.

Industry Applications

PVD coating for stainless steel finds applications across numerous industries:

-

Aerospace: High-performance components requiring superior wear and corrosion resistance.

-

Automotive: Engine parts, exhaust systems, and decorative elements.

-

Medical: Surgical instruments and implants where biocompatibility and sterility are crucial.

-

Industrial Manufacturing: Cutting tools, molds, and machinery parts.

-

Consumer Goods: Kitchen utensils, watches, and jewelry.

Contact Us for PVD Coating Services

Ready to elevate your stainless steel products with advanced PVD coating? Contact JLY Precision Tech today to discuss your project requirements and obtain a competitive quote. Our team of experts is ready to assist you in selecting the optimal coating solution for your specific application.

For inquiries, please email us at [email protected] or visit our website https://www.jlypt.com to explore our comprehensive range of surface treatment services.