The Science of Surface Enhancement: A Comprehensive Guide to PVD Coating Services for Precision Components

Introduction: The Surface Engineering Revolution in Precision Manufacturing

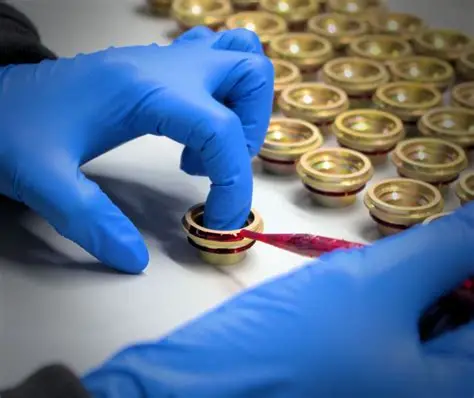

In the world of high-performance manufacturing, where component failure is measured in microns and operational lifespan in millions of cycles, the boundary between success and failure often lies not in the bulk material but at the surface. PVD Coating Services represent a transformative surface engineering discipline that fundamentally alters the interaction between precision components and their operating environments. At JLYPT, we integrate Physical Vapor Deposition (PVD) technology directly into our manufacturing workflow, creating components that don’t just meet specifications but exceed traditional performance boundaries through atomic-level surface engineering.

The distinction between coated and uncoated components manifests in quantifiable performance metrics: a 0.003mm PVD coating can increase surface hardness from 62 HRC to 85 HRC, reduce coefficient of friction by 60%, and extend tool life in machining applications by 300-800%. Unlike electroplating or thermal spray processes that add material indiscriminately, PVD coating services utilize vacuum deposition physics to create metallurgically bonded, nanoscale surface layers with precisely engineered properties. This technological approach enables manufacturers to specify surface characteristics independently from substrate properties—creating aluminum components with the wear resistance of tool steel or medical implants with both biocompatibility and antimicrobial properties.

This technical exploration examines the complete spectrum of PVD coating applications for precision manufactured components. We’ll analyze the plasma physics behind different PVD methodologies, how coating architecture affects functional performance, and what pretreatment protocols ensure optimal adhesion on CNC-machined surfaces. Whether you’re developing surgical instruments requiring both sharpness and corrosion resistance, aerospace components needing thermal barrier protection, or high-volume production tooling demanding extended service life, understanding PVD coating science represents the critical difference between adequate and exceptional component performance. Discover how our integrated approach at JLYPT PVD Coating Services transforms precision-machined components into high-performance systems through advanced surface engineering.

The Physics of Perfection: Understanding PVD Deposition Mechanisms

Physical Vapor Deposition encompasses several vacuum-based technologies that share fundamental principles but differ in their methods of generating and depositing coating material. Understanding these mechanisms is essential for selecting the optimal process for specific applications.

Vacuum Environment Fundamentals

All PVD processes operate in high-vacuum conditions (typically 10⁻³ to 10⁻⁶ Torr) that serve three critical functions:

-

Mean Free Path Extension: Reducing atmospheric particle density allows vaporized coating atoms to travel directly from source to substrate without collisions, ensuring line-of-sight deposition and precise thickness control.

-

Contamination Elimination: Removing oxygen, water vapor, and other reactive gases prevents oxide formation during deposition and ensures pure metallurgical bonding.

-

Plasma Generation: The low-pressure environment enables efficient creation and maintenance of plasma, which is essential for most modern PVD processes.

Primary PVD Technology Platforms

Cathodic Arc Deposition

This process utilizes a high-current, low-voltage arc that literally explodes micron-sized particles from the cathode (target) material. The arc creates a highly ionized plasma (70-100% ionization) with particles possessing high kinetic energy (10-100 eV).

-

Advantages: Excellent adhesion due to high particle energy; high deposition rates; efficient utilization of target material

-

Challenges: Potential for micro-droplet formation (macroparticles) that can create surface defects; requires effective filtering for optical or precision applications

-

Typical Applications: TiN, CrN coatings for cutting tools; decorative coatings with excellent adhesion

Magnetron Sputtering

In this process, argon gas ions are accelerated toward a target material in a magnetic field, physically dislodging (sputtering) atoms that then condense on the substrate. The magnetic field confines electrons near the target, increasing ionization efficiency.

-

Advantages: Extremely smooth, uniform coatings; excellent thickness control; no droplet formation; can deposit virtually any material

-

Challenges: Lower deposition rates than arc evaporation; lower ionization percentage (typically 5-10%)

-

Typical Applications: DLC coatings for medical devices; transparent conductive coatings; precision optical coatings

Electron Beam Physical Vapor Deposition (EB-PVD)

This method uses a focused electron beam to heat and vaporize source material in a crucible. The vaporized atoms then condense on substrates positioned above the source.

-

Advantages: Highest deposition rates; excellent for thick coatings (>25µm); can deposit refractory materials with very high melting points

-

Challenges: Line-of-sight deposition limits coating uniformity on complex geometries; lower adhesion strength compared to plasma-based processes

-

Typical Applications: Thermal barrier coatings for turbine blades; thick wear coatings for industrial components

Hybrid and Enhanced PVD Processes

Modern coating systems often combine technologies to leverage their respective advantages:

-

Arc-enhanced magnetron sputtering increases ionization for better adhesion

-

High Power Impulse Magnetron Sputtering (HiPIMS) generates extremely high plasma densities for exceptionally dense, well-adhered coatings

-

Plasma-enhanced EB-PVD combines the high rate of EB-PVD with plasma activation for improved coating properties

Table 1: PVD Technology Comparison for Precision Components

| Process Parameter | Cathodic Arc Deposition | Magnetron Sputtering | EB-PVD | HiPIMS |

|---|---|---|---|---|

| Ionization Percentage | 70-100% | 5-10% | <1% | 70-90% |

| Particle Energy (eV) | 10-100 | 1-10 | 0.1-1 | 50-200 |

| Deposition Rate (µm/hr) | 1-10 | 0.1-5 | 10-100 | 0.5-5 |

| Coating Density | High | Medium to High | Medium | Very High |

| Surface Roughness | May increase due to droplets | Maintains or improves | Maintains | Improves |

| Thickness Uniformity | Good | Excellent | Poor on complex parts | Good to Excellent |

| Optimal Applications | Cutting tools, wear parts | Medical devices, optics, electronics | Thermal barriers, thick coatings | High-stress applications, precision tools |

Coating Materials and Architecture: Engineering Surface Properties

The selection of coating material and its architectural design determines the functional characteristics imparted to the component surface.

Monolithic Coatings

Single-material coatings provide specific, focused properties:

-

Titanium Nitride (TiN): The original PVD workhorse coating with characteristic gold color. Provides excellent wear resistance and reduces friction. Hardness: 2300-2400 HV.

-

Chromium Nitride (CrN): Superior corrosion and oxidation resistance compared to TiN, with excellent release properties. Ideal for plastic injection molds and components exposed to corrosive environments.

-

Diamond-Like Carbon (DLC): A metastable form of amorphous carbon with significant sp³ bonding. Provides extremely low friction (µ=0.05-0.15), high hardness (2000-4000 HV), and excellent chemical inertness. Variants include hydrogenated (a-C:H) and metal-doped (Me-C:H) DLC.

-

Aluminum Titanium Nitride (AlTiN): Contains aluminum oxide formation at high temperatures, providing exceptional hot hardness and oxidation resistance up to 900°C. The aluminum content typically ranges from 50-67%.

Multilayer and Nanostructured Coatings

Advanced coating architectures significantly enhance performance:

-

Multilayer Coatings: Alternating nanoscale layers of different materials (e.g., TiN/TiAlN) disrupt crack propagation and provide multiple mechanisms for stress accommodation. Typical layer thickness: 5-50nm.

-

Gradient Coatings: Gradually changing composition from substrate to surface minimizes interfacial stress and improves adhesion.

-

Nanocomposite Coatings: Ultra-fine crystalline phases (3-10nm) embedded in an amorphous matrix, such as nc-TiN/a-Si₃N₄, can achieve hardness exceeding 40 GPa through Hall-Petch strengthening and limited dislocation movement.

Doping and Alloying for Enhanced Properties

Adding specific elements to base coating materials tailors properties:

-

Yttrium or Zirconium doping in thermal barrier coatings improves oxidation resistance and phase stability

-

Silicon addition to CrN or TiAlN forms lubricious oxides at high temperature

-

Vanadium incorporation creates self-lubricating vanadium oxide at elevated temperatures

*Table 2: PVD Coating Selection Guide for CNC-Machined Components*

| Coating Type | Composition | Hardness (HV) | Max Service Temp. | Coefficient of Friction | Key Properties | Optimal Substrates |

|---|---|---|---|---|---|---|

| TiN | Titanium Nitride | 2300-2400 | 600°C | 0.4-0.6 | General wear resistance, good adhesion, golden color | HSS, tool steels, carbide |

| TiAlN | Ti₁₋ₓAlₓN (x≈0.67) | 2800-3200 | 900°C | 0.5-0.7 | High temp hardness, oxidation resistance, thermal stability | Carbide, hot-work steels |

| CrN | Chromium Nitride | 1800-2100 | 700°C | 0.5-0.6 | Corrosion resistance, anti-galling, low adhesion | Stainless steels, molds, aluminum |

| DLC | a-C:H or ta-C | 2000-4000 | 400°C | 0.05-0.15 | Ultra-low friction, chemical inertness, dry lubrication | Tool steels, bearing steels, titanium |

| TiCN | Titanium Carbonitride | 3000-3500 | 400°C | 0.3-0.5 | High hardness, abrasion resistance, good toughness | Cutting tools, forming tools |

| ZrN | Zirconium Nitride | 2500-2800 | 550°C | 0.4-0.6 | Corrosion resistance, decorative gold color harder than TiN | Medical instruments, decorative hardware |

| AlCrN | Aluminum Chromium Nitride | 2800-3200 | 1100°C | 0.5-0.7 | Extreme oxidation resistance, high temp stability | High-speed cutting tools, die casting molds |

Pretreatment Protocols: The Foundation of Coating Adhesion

The performance of any PVD coating is fundamentally limited by its adhesion to the substrate. For CNC-machined components, specific pretreatment protocols are essential.

Surface Finish Optimization

PVD coatings typically replicate and slightly amplify the underlying surface topography:

-

Optimal Roughness Range: Ra 0.1-0.4 µm provides sufficient surface area for mechanical interlocking while allowing complete coating coverage

-

Directionality Elimination: Isotropic surface finishes (e.g., vapor honed, chemically etched) provide more uniform coating adhesion than surfaces with pronounced lay from machining

-

Defect Management: Micro-cracks, pores, or inclusions can create localized stress concentrations that compromise coating integrity

Chemical Cleaning and Degreasing

Residual contaminants prevent proper coating adhesion:

-

Alkaline cleaning to remove oils and organic compounds

-

Ultrasonic agitation in multiple solvent stages

-

Acid etching for oxide removal and surface activation

-

Deionized water rinsing with conductivity monitoring

-

Drying in controlled atmosphere to prevent recontamination

In-situ Plasma Etching

Immediately before deposition, components undergo argon plasma etching:

-

Ion Bombardment: High-energy argon ions physically sputter remaining surface contaminants

-

Surface Activation: Creates chemically reactive sites for enhanced coating bonding

-

Temperature Ramping: Gradual heating to deposition temperature prevents thermal shock

Substrate Hardness and Stress State

-

Minimum Hardness: Most PVD coatings require substrate hardness >45 HRC for optimal support against applied loads

-

Compressive Stress: Machining processes that induce beneficial compressive surface stresses (e.g., shot peening before coating) significantly improve coating performance under cyclic loading

-

Thermal Expansion Matching: Selecting coatings with CTE similar to the substrate minimizes interfacial stress during thermal cycling

Performance Validation and Quality Assurance

Comprehensive testing ensures PVD coatings meet specified performance requirements.

Adhesion Testing

-

Scratch Testing: A diamond stylus is drawn across the coated surface under increasing load until coating failure (Lc critical load). Typical requirements: Lc > 30N for most industrial applications

-

Rockwell Indentation: A hardened steel ball is pressed into the coating and adhesion is qualitatively assessed by optical examination of crack patterns around the indentation

-

Tape Testing (ASTM D3359): Cross-hatch pattern is cut through coating and adhesive tape applied and removed

Thickness and Composition Analysis

-

Calotester (Ball Cratering): Creates a spherical crater through the coating, with coating thickness calculated from crater dimensions

-

X-ray Fluorescence (XRF): Non-destructive measurement of coating thickness and elemental composition

-

Glow Discharge Optical Emission Spectroscopy (GDOES): Depth profiling of coating composition

Functional Performance Testing

-

Pin-on-Disc Wear Testing: Quantifies wear rates and coefficients of friction under controlled conditions

-

Microhardness Testing: Vickers or Knoop indentation at low loads (25-50g) to measure coating hardness without substrate influence

-

Corrosion Testing: Salt spray (ASTM B117), electrochemical impedance spectroscopy, or potentiodynamic polarization

Table 3: PVD Coating Quality Standards and Validation Methods

| Quality Parameter | Test Method | Equipment/Standard | Acceptance Criteria | Frequency |

|---|---|---|---|---|

| Coating Thickness | Calotester | CSEM Calotest | ±0.2µm of specification | First article & batch sampling |

| Adhesion Strength | Scratch Test | Revetest, ISO 20502 | Lc > 30N (industrial), Lc > 50N (cutting tools) | First article & periodic |

| Surface Hardness | Nanoindentation | Fischerscope H100, ISO 14577 | Within 10% of specification | First article |

| Wear Resistance | Pin-on-Disc | ASTM G99 | Wear coefficient < 1×10⁻⁶ mm³/N·m | First article & annual |

| Coefficient of Friction | Pin-on-Disc | ASTM G99 | µ < 0.6 (nitrides), µ < 0.2 (DLC) | First article |

| Corrosion Resistance | Salt Spray | ASTM B117 | No red rust at 24h (CrN), 48h (TiN) | First article & quarterly |

| Coating Composition | XRF | Fischer XDV-SDD | Within 5% of target stoichiometry | First article & batch |

| Surface Roughness | Profilometry | Taylor Hobson, ISO 4287 | Ra < specification + 0.05µm | First article |

Application-Specific Case Studies

Case Study 1: Aerospace Turbine Blade Thermal Barrier Coating

Challenge: A turbine component manufacturer needed to extend service life of nickel superalloy blades operating at 1100°C with thermal cycling between ambient and operating temperatures.

Solution: We implemented a multilayer EB-PVD coating system:

-

Bond Coat: 150µm MCrAlY (M=Ni,Co) coating applied via vacuum plasma spray for oxidation resistance and CTE matching

-

Thermal Barrier Coating: 300µm yttria-stabilized zirconia (YSZ) deposited via EB-PVD with engineered columnar microstructure for strain tolerance

-

Top Coat: 50µm alumina layer via magnetron sputtering for erosion resistance

Results: Coated blades demonstrated 3X lifetime improvement in thermal cycling tests, with surface temperature reduction of 150°C at constant gas temperature. The columnar YSZ structure provided exceptional thermal shock resistance compared to plasma-sprayed alternatives.

Case Study 2: Medical Orthopedic Implant Biocompatible Coating

Challenge: A medical device company required titanium hip implants with enhanced osseointegration and reduced polyethylene wear debris generation.

Solution: We developed a dual-function coating system using hybrid PVD technology:

-

Adhesion Layer: 50nm pure titanium deposited via magnetron sputtering

-

Functional Coating: 3µm titanium nitride with graded nitrogen concentration for optimal stress distribution

-

Surface Modification: Post-deposition hydroxyapatite impregnation through controlled porosity

Results: The coated implants demonstrated 40% faster bone integration in animal studies with 60% reduction in polyethylene wear compared to uncoated titanium. The coating passed ISO 10993 biocompatibility testing and showed excellent adhesion in simulated implantation tests.

Case Study 3: High-Volume Automotive Fuel Injector Component

Challenge: An automotive supplier needed to reduce friction and wear in stainless steel fuel injector components while maintaining precise dimensional tolerances (±0.002mm).

Solution: We implemented a low-temperature DLC coating process:

-

Pretreatment: Vapor honing to Ra 0.2µm followed by argon plasma etching

-

Interlayer: 100nm chromium deposited via magnetron sputtering for adhesion promotion

-

Functional Coating: 2µm hydrogenated DLC (a-C:H) deposited via plasma-enhanced CVD at <200°C

-

Post-treatment: Laser trimming of coating from critical sealing surfaces

Results: Coated components showed coefficient of friction reduction from 0.6 to 0.12, with wear life extended from 500,000 to over 5,000,000 cycles in accelerated testing. Dimensional change was limited to 0.0015mm, well within tolerance limits.

The Future of PVD Coating Technology

Intelligent Coating Systems

-

Real-time Process Control: Optical emission spectroscopy and plasma impedance monitoring for closed-loop deposition control

-

Machine Learning Optimization: AI algorithms correlating process parameters with coating performance for continuous improvement

-

Digital Twin Integration: Virtual coating process simulation predicting outcomes before physical deposition

Advanced Coating Architectures

-

Functionally Graded Coatings: Continuous variation in composition and structure for optimal property distribution

-

Self-healing Coatings: Incorporation of elements that form protective oxides at defect sites

-

Smart Coatings: Responsive surfaces that change properties with environmental conditions (temperature, pH, stress)

Sustainable PVD Processing

-

Reduced Energy Consumption: High-efficiency power supplies and improved vacuum system design

-

Target Material Optimization: Increased utilization rates through rotating magnets and improved cooling

-

Green Chemistry: Replacement of hexavalent chromium processes with PVD alternatives

-

Circular Economy Integration: Coating removal and reapplication services for high-value components

Conclusion: Surface Engineering as a Performance Multiplier

PVD Coating Services have evolved from a specialized finishing option to an essential engineering tool that fundamentally transforms component performance. The ability to independently specify surface properties apart from substrate characteristics represents a paradigm shift in manufacturing—enabling components to operate in environments far beyond their base material limitations, extending service life by orders of magnitude, and solving complex tribological challenges that were previously insurmountable.

The successful implementation of PVD technology requires more than deposition equipment; it demands integrated expertise in materials science, plasma physics, surface preparation, and performance validation. At JLYPT, we’ve built our PVD capabilities on this comprehensive understanding, viewing surface engineering not as a separate process but as an integral component of the complete manufacturing solution.

Ready to transform your components through advanced surface engineering? Contact our materials engineering team to discuss how our PVD Coating Services can solve your most challenging performance requirements. From initial coating selection through application and validation, we provide complete surface engineering solutions that enhance performance, extend lifespan, and enable new applications. Begin your surface enhancement project at JLYPT PVD Coating Services.