Prototype Machining with Fast Turnaround: Accelerating Product Development with Precision

Introduction to Rapid Prototype Machining

Prototype machining with fast turnaround represents a critical competitive advantage in today’s rapidly evolving manufacturing landscape. This specialized service enables engineers and product developers to transform digital designs into functional physical prototypes within remarkably short timeframes, often ranging from 24 hours to 5 business days. The accelerating pace of product development across industries—from automotive and aerospace to medical devices and consumer electronics—has made rapid prototyping services not just convenient but essential for maintaining competitive advantage.

The global market for rapid prototyping continues to expand significantly, driven by increasing demands for shorter product development cycles, reduced time-to-market, and accelerated innovation processes. Companies that leverage advanced prototype machining services can iterate designs more frequently, validate concepts more thoroughly, and make informed decisions faster than competitors relying on traditional manufacturing timelines.

The Critical Importance of Speed in Prototype Development

Why Fast Turnaround Matters in Prototyping

Speed in prototype development delivers measurable business benefits that extend far beyond simple convenience:

Table: Impact of Rapid Prototyping on Product Development Metrics

| Development Metric | Traditional Timeline | With Rapid Turnaround | Improvement | Business Impact |

|---|---|---|---|---|

| Design Iteration Cycles | 2-3 weeks per iteration | 2-3 days per iteration | 85% reduction | More design validation, better final product |

| Time-to-Market | 6-12 months | 3-6 months | 50% reduction | First-mover advantage, increased market share |

| Development Costs | High (multiple tooling setups) | Reduced (minimal setup) | 30-60% savings | Better ROI, more projects within budget |

| Design Flaws Identified | Late-stage (costly fixes) | Early-stage (inexpensive fixes) | 10x cost savings | Higher quality, fewer production issues |

| Stakeholder Engagement | Limited (long wait times) | Continuous (quick updates) | Improved alignment | Better decisions, increased satisfaction |

The Evolution from Traditional to Rapid Machining

Traditional machining approaches often required weeks or even months to produce functional prototypes due to extensive setup times, manual programming, and sequential processing. The advent of advanced CNC technologies, digital workflows, and specialized rapid machining services has compressed these timelines dramatically while maintaining—and often improving—precision and quality.

Technical Foundations of Fast-Turnaround Prototype Machining

Advanced CNC Equipment for Rapid Prototyping

Modern rapid prototyping facilities utilize specialized equipment configured for speed and flexibility:

-

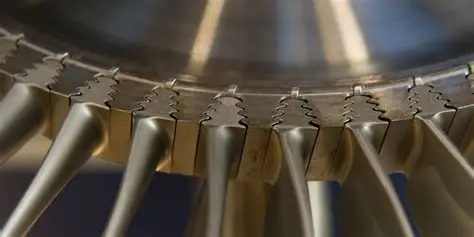

5-Axis Simultaneous Machining Centers: Enable complex geometries in single setups, reducing handling and alignment time

-

High-Speed Machining (HSM) Capabilities: Spindle speeds up to 30,000 RPM for faster material removal while maintaining precision

-

Mill-Turn Centers: Combine milling and turning operations in single setups, reducing processing time

-

Automated Material Handling: Robotic part loading/unloading for continuous operation

-

Pallet Pool Systems: Allow continuous machining while new setups are prepared externally

Digital Workflow Integration

Streamlined digital processes form the backbone of rapid turnaround services:

Table: Digital Workflow Components for Rapid Prototyping

| Workflow Stage | Traditional Approach | Rapid Turnaround Approach | Time Savings |

|---|---|---|---|

| File Submission | Email, manual processing | Secure online portal, automatic analysis | 90% reduction |

| Design Review | Manual DFM analysis, 24-48 hours | Automated DFM, instant feedback | 95% reduction |

| Quoting | Manual estimation, 1-3 days | Instant automated quoting | 99% reduction |

| CAM Programming | Manual programming, 4-8 hours | Template-based, automated toolpath generation | 70% reduction |

| Production Scheduling | Manual scheduling, batch processing | Real-time scheduling, priority management | 80% reduction |

Materials Selection for Rapid Prototype Machining

Material Considerations for Fast Turnaround

Material selection significantly impacts machining speed and prototype functionality:

Aluminum Alloys (6061-T6, 7075-T6):

-

Advantages: Excellent machinability, good strength-to-weight ratio, wide availability

-

Applications: Structural prototypes, enclosures, mechanical components

-

Machining Parameters: High feed rates possible, minimal tool wear

Plastics (ABS, Nylon, PEEK, Delrin):

-

Advantages: Very fast machining speeds, no coolant required, diverse properties

-

Applications: Consumer products, wear testing, electrical components

-

Machining Parameters: Ultra-high feed rates, specialized tool geometries

Stainless Steels (304, 316, 17-4 PH):

-

Advantages: Corrosion resistance, strength, professional appearance

-

Applications: Medical devices, food processing, marine applications

-

Machining Parameters: Moderate feed rates, appropriate tooling required

Titanium Alloys (Grade 2, Grade 5):

-

Advantages: High strength-to-weight ratio, biocompatibility

-

Applications: Aerospace, medical implants, high-performance components

-

Machining Parameters: Lower feed rates, specialized tooling, high-pressure coolant

Material Selection Guidelines for Rapid Turnaround

Table: Material Selection Guide for Rapid Prototyping

| Material | Machinability Rating | Typical Surface Finish (Ra) | Suitable Prototype Types | Special Considerations |

|---|---|---|---|---|

| Aluminum 6061 | Excellent | 0.4-0.8 μm | Functional, structural, appearance | Anodizing available for corrosion protection |

| ABS Plastic | Excellent | 0.8-1.6 μm | Form/fit testing, consumer products | Limited temperature resistance |

| Stainless 304 | Good | 0.4-0.8 μm | Food/medical, corrosion-resistant parts | Work hardening requires appropriate parameters |

| Titanium Grade 5 | Fair | 0.4-0.8 μm | Aerospace, medical, high-strength applications | Specialized tooling required, slower machining |

| PEEK | Good | 0.8-1.6 μm | High-temperature, chemical-resistant parts | Requires sharp tools, specific parameters |

Technical Strategies for Achieving Fast Turnaround

Design for Manufacturability (DFM) Optimization

Implementing DFM principles specifically for rapid prototyping:

-

Standardized Features: Use standard hole sizes, thread types, and fillet radii to minimize special tool requirements

-

Minimized Setups: Design parts for machining in minimal orientations, ideally single-setup processing

-

Tooling Considerations: Design with standard cutter sizes and reach limitations in mind

-

Material Selection: Choose materials that balance performance requirements with machinability

-

Tolerance Rationalization: Specify tight tolerances only where functionally required

Advanced Machining Techniques for Speed

Specialized machining strategies enable faster material removal while maintaining precision:

-

High-Efficiency Milling (HEM): Optimized tool paths and parameters for maximum material removal rates

-

Trochoidal Milling: Constant engagement tool paths allowing higher feed rates without tool overload

-

Adaptive Clearing: Intelligent tool paths that maintain optimal chip load and tool engagement

-

Peck Drilling Optimization: Reduced cycle times for deep hole drilling operations

Digital Integration and Automation

Automated systems streamline the entire prototyping process:

-

Instant Quoting Engines: AI-powered systems that analyze CAD files and provide immediate quotations

-

Automated CAM Programming: Template-based programming that reduces manual programming time

-

Machine Monitoring Systems: Real-time tracking of machining progress and early issue detection

-

Digital Quality Control: Automated inspection planning and execution

Quality Assurance in Rapid Prototype Machining

Maintaining Precision Under Time Constraints

Fast turnaround cannot compromise quality—implementing efficient QA processes is essential:

In-Process Verification:

-

Probe Systems: On-machine measurement for critical features

-

Tool Monitoring: Real-time tool wear detection and compensation

-

Process Control: Statistical monitoring of machining parameters

Post-Process Inspection:

-

CMM Verification: Rapid coordinate measurement of critical dimensions

-

Surface Finish Analysis: Quick verification of surface texture requirements

-

First Article Inspection: Streamlined but comprehensive initial part validation

Documentation and Traceability

Even with accelerated timelines, complete documentation remains crucial:

-

Material Certifications: Verified material properties and traceability

-

Inspection Reports: Key dimension verification and surface finish documentation

-

Process Records: Machining parameters, tooling used, and inspection results

-

Certification Compliance: Meeting relevant industry standards (ISO 9001, AS9100, etc.)

Applications and Case Studies

Case Study 1: Automotive Component Development

Challenge: Develop functional prototypes of a new transmission component for validation testing within 72 hours to avoid delaying critical vehicle testing schedules.

Solution: Implemented high-speed 5-axis machining of aluminum 7075-T6 with optimized tool paths and simultaneous machining of multiple parts. Used on-machine probing for critical feature verification without removing parts from the machine.

Results: Delivered 12 fully functional transmission components within 68 hours from CAD file receipt. Parts met all dimensional requirements with critical features within ±0.025mm. The rapid turnaround enabled on-schedule vehicle testing and identified a design issue that was corrected before production tooling commenced.

Case Study 2: Medical Device Prototype

Challenge: Produce a functional prototype of a new surgical instrument for surgeon evaluation and FDA submission within 5 business days using medical-grade materials.

Solution: Employed precision 4-axis milling of stainless steel 316L with micro-machining capabilities for fine features. Implemented electropolishing for superior surface finish and cleanliness meeting medical standards.

Results: Delivered 3 fully finished surgical instrument prototypes in 4 business days. The parts exceeded surface finish requirements (Ra < 0.4 μm) and passed all functional testing. The rapid turnaround enabled early surgeon feedback and accelerated the FDA submission process by 3 weeks.

Case Study 3: Consumer Electronics Enclosure

Challenge: Iterate through 5 design versions of a new smartphone accessory enclosure within 10 business days for consumer focus testing.

Solution: Utilized high-speed 3-axis machining of ABS plastic with automated tool changing and lights-out machining capabilities. Implemented design iteration management system to efficiently process sequential design updates.

Results: Produced 5 complete design iterations with 3 units each within 8 business days. Each iteration incorporated measurement feedback from previous versions. The rapid iteration capability identified optimal design features that increased focus group satisfaction by 40%.

Implementing Rapid Prototyping Services: Best Practices

Client-Side Preparation

Customers can accelerate their prototyping projects through proper preparation:

-

Complete CAD Data: Provide fully defined 3D models with critical dimensions clearly specified

-

Material Specifications: Identify preferred materials and any special requirements early

-

Clear Requirements: Define critical features, tolerances, and inspection requirements upfront

-

Communication Access: Ensure technical staff are available for quick clarification when needed

-

Planning: Schedule projects with consideration for potential iterations

Service Provider Capabilities

Selecting a rapid prototyping partner with the right capabilities is essential:

-

Equipment Portfolio: Modern CNC machines with high-speed capabilities

-

Technical Expertise: Experienced machinists and programmers who understand rapid processes

-

Quality Systems: Efficient but comprehensive quality assurance processes

-

Digital Infrastructure: Online quoting, file transfer, and order tracking systems

-

Material Inventory: On-hand stock of common prototyping materials

-

Capacity Management: Systems to prioritize and expedite rush projects

Future Trends in Rapid Prototype Machining

Technology Developments

Emerging technologies will further accelerate prototyping timelines:

-

AI-Powered Process Optimization: Machine learning algorithms that optimize machining parameters in real-time

-

Digital Twin Integration: Virtual machining simulations that predict and prevent issues before physical machining

-

Additive/Subtractive Hybrid: Combining 3D printing for rough shapes with CNC machining for precision features

-

Blockchain Documentation: Secure, instant verification of quality documentation and material traceability

Business Model Innovations

New approaches to service delivery will enhance speed and accessibility:

-

Subscription Prototyping: Regular capacity allocation for frequent users

-

Distributed Manufacturing: Geographic distribution of machining capacity to reduce shipping times

-

Instant Quoting Integration: CAD plugin-based quoting without file uploads

-

Automated Design Feedback: Real-time manufacturability analysis during design phase

Conclusion: The Strategic Value of Rapid Prototype Machining

Prototype machining with fast turnaround has evolved from a specialized service to a critical capability that fundamentally impacts product development success. The ability to quickly transform digital designs into precision physical parts enables more iterative design validation, faster technical decision-making, and accelerated time-to-market.

As manufacturing continues to advance toward ever-shorter development cycles, rapid prototyping services will play an increasingly vital role in enabling innovation across industries. Companies that effectively leverage these capabilities will enjoy significant competitive advantages through faster innovation, reduced development costs, and superior final products.

By understanding the technologies, strategies, and best practices outlined in this guide, engineers and product developers can make informed decisions about rapid prototyping for their specific applications, ensuring optimal results and maximum value from their development investments.

For specific applications or to discuss your rapid prototyping requirements, please contact our technical team for personalized assistance and process recommendations: https://www.jlypt.com/cnc-machining-services/