Rapid Prototyping Services in China: Revolutionizing Product Development with Precision CNC Machining

In the heart of global manufacturing, Chinese rapid prototyping services are setting new standards for speed, precision, and innovation in product development cycles.

Rapid prototyping services in China have evolved from simple model-making to sophisticated manufacturing solutions that accelerate product development across industries. As specialized providers of CNC machining services in China, we understand the critical role that high-speed, high-precision prototyping plays in today’s competitive market landscape. The integration of advanced manufacturing technologies with decades of engineering expertise has positioned China as a global leader in delivering exceptional prototyping solutions that bridge the gap between concept and production.

The rapid prototyping market in China continues to demonstrate remarkable growth, driven by increasing demand from automotive, aerospace, consumer electronics, and medical device industries. With the global online rapid prototyping service market projected to reach $1.15 billion by 2030 , Chinese manufacturers are leveraging their technological capabilities and manufacturing infrastructure to capture significant market share through quality, efficiency, and cost-effectiveness.

The Evolution of Rapid Prototyping in China’s Manufacturing Ecosystem

China’s journey in rapid prototyping began in the late 1980s with the adoption of basic additive manufacturing technologies, but has since expanded to encompass a comprehensive range of advanced processes including CNC machining, injection molding, and vacuum casting . This evolution has transformed China from a manufacturing follower to an innovation leader in rapid prototyping technologies and applications.

Current Market Landscape

The Chinese rapid prototyping market has matured significantly, with capabilities now matching and often exceeding global standards:

-

Technical Capabilities: Chinese service providers offer comprehensive solutions including multi-axis CNC machining, high-speed milling, and precision surface finishing

-

Material Selection: Extensive inventory of engineering-grade materials from domestic and international suppliers

-

Quality Standards: Implementation of international quality management systems and certification standards

-

Digital Integration: Advanced digital workflows from design to production with rigorous quality control

According to market research, CNC machining holds a significant position in China’s rapid prototyping landscape, accounting for a substantial share of the online rapid prototyping service market . This prominence reflects the technique’s versatility, precision, and compatibility with production-grade materials.

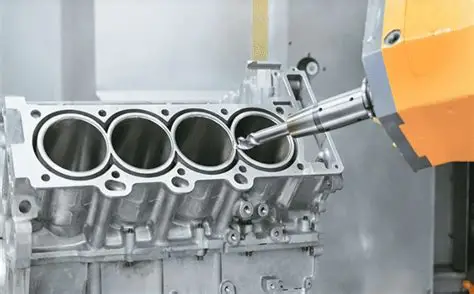

Advanced CNC Technologies in Chinese Rapid Prototyping Services

Chinese rapid prototyping providers have invested heavily in advanced CNC technologies that deliver exceptional precision, surface quality, and dimensional accuracy for prototype components.

Multi-Axis Machining Capabilities

Modern Chinese prototyping facilities feature sophisticated multi-axis CNC systems that enable complex geometry machining in single setups:

Table 1: CNC Machining Capabilities in Chinese Rapid Prototyping Services

| Machining Technology | Common Applications | Tolerance Capability | Surface Finish (Ra) | Relative Speed |

|---|---|---|---|---|

| 3-Axis Milling | Simple geometries, 2.5D features, flat surfaces | ±0.025mm to ±0.125mm | 1.6-3.2 μm | Fast for simple geometries |

| 5-Axis Simultaneous Milling | Complex contours, organic shapes, undrafted surfaces | ±0.01mm to ±0.05mm | 0.4-1.6 μm | Medium for complex parts |

| High-Speed Machining | Detailed textures, fine features, thin walls | ±0.005mm to ±0.025mm | 0.2-0.8 μm | Fast with specialized tooling |

| Mill-Turn Centers | Complex rotational parts with off-center features | ±0.005mm to ±0.02mm | 0.4-1.6 μm | Fast for complex rotational parts |

5-axis simultaneous machining has been particularly transformative for complex prototype components, reducing setup requirements and improving accuracy through continuous tool positioning. This capability enables Chinese manufacturers to produce prototypes with production-intent geometry and surface characteristics.

Material Selection for CNC Rapid Prototyping

Chinese rapid prototyping services offer extensive material options that closely match production specifications:

Table 2: Common Materials for CNC Rapid Prototyping in China

| Material Category | Specific Grades | Prototyping Applications | Advantages | Machining Considerations |

|---|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6 | Aerospace, automotive, consumer products | Excellent machinability, favorable strength-to-weight ratio | Fast machining, readily available |

| Stainless Steels | 304, 316, 17-4PH | Medical devices, food processing, marine | Good corrosion resistance, durability | Moderate machining speeds, work hardening |

| Engineering Plastics | ABS, Nylon, PC, PEEK | Consumer products, electrical insulation, bearings | Fast machining, chemical resistance, various colors | Low thermal conductivity, flexible during machining |

| Titanium Alloys | Grade 5 (6Al-4V) | Aerospace, medical implants, chemical | Excellent strength-to-weight, biocompatibility | Slow machining, specialized tooling required |

| Pre-Hardened Steels | P20, 718 | Mold making, high-wear applications | Good machinability, durability | Moderate speeds, tool wear management |

The availability of diverse materials enables Chinese prototyping services to create functional prototypes that accurately represent final production parts in terms of mechanical properties, performance characteristics, and aesthetic qualities.

Technical Advantages of China’s Rapid Prototyping Services

Several key factors differentiate Chinese rapid prototyping providers in the global marketplace, particularly when it comes to CNC machining capabilities.

Precision Engineering Capabilities

Chinese rapid prototyping services have established remarkable precision standards:

-

High-Accuracy Machining: Capable of maintaining tolerances within ±0.01mm for critical features

-

Advanced Metrology: Implementation of CMM, optical scanning, and laser measurement systems for comprehensive quality verification

-

Surface Finish Options: Range from as-machined to polished, textured, or coated surfaces based on application requirements

-

Micro-Machining: Capabilities for manufacturing small features with sizes down to 0.1mm using specialized equipment

These precision capabilities ensure that prototypes accurately represent production intent and provide reliable data for design validation and testing.

Speed and Flexibility

The operational efficiency of Chinese rapid prototyping providers delivers significant time-to-market advantages:

-

Rapid Response: Quick turnaround times with many providers offering 24-72 hour delivery for initial prototypes

-

Adaptive Manufacturing: Flexible production schedules that accommodate design changes and iterations

-

Scalable Capacity: Ability to handle projects ranging from single prototypes to small-batch production

-

Digital Workflows: Streamlined processes from file submission to production with automated DFM feedback

The growing small-batch prototyping market, projected to reach $728 million globally by 2031 , aligns perfectly with China’s manufacturing strengths in flexible, responsive production.

Quality Assurance in Chinese Rapid Prototyping

Reputable Chinese rapid prototyping services implement comprehensive quality management systems that ensure consistent results and reliable performance.

Certification and Standards Compliance

Leading Chinese prototyping providers maintain certifications including:

-

ISO 9001: Quality management systems

-

AS9100: Aerospace quality standards

-

ISO 13485: Medical device manufacturing standards

-

IATF 16949: Automotive quality management standards

These certifications provide assurance that prototyping processes meet international quality requirements and industry-specific standards.

Inspection and Verification Processes

Multi-stage inspection protocols ensure component quality throughout the manufacturing process:

-

First Article Inspection: Comprehensive measurement of initial parts using CMM and advanced metrology equipment

-

In-Process Verification: On-machine probing and intermediate checks during machining operations

-

Final Inspection: Comprehensive verification of all critical dimensions and features before shipment

-

Documentation: Detailed inspection reports with actual measurement data for customer review

Applications Across Industries: Chinese Rapid Prototyping in Action

Chinese rapid prototyping services support diverse industry sectors with specialized requirements and applications.

Automotive Industry

The automotive sector represents one of the largest consumers of rapid prototyping services in China:

-

Concept Models: Full-scale models for design evaluation and consumer research

-

Functional Testing: Engine components, intake systems, and structural elements tested under real-world conditions

-

Pre-Production Validation: Components manufactured using production-intent processes and materials

Consumer Electronics

The fast-paced consumer electronics industry relies on Chinese rapid prototyping for accelerated development cycles:

-

Enclosure Prototyping: Housing components with precise fitment and aesthetic requirements

-

Thermal Management: Heat sinks and cooling systems optimized through iterative prototyping

-

Connector Interfaces: Precision features for connectors, buttons, and user interface elements

Medical Devices

The medical device industry benefits from China’s precision machining capabilities and regulatory experience:

-

Surgical Instruments: Ergonomic handles and functional mechanisms for evaluation and testing

-

Implant Prototypes: Biocompatible materials machined to precise anatomical specifications

-

Device Housings: Enclosures with medical-grade surface finishes and regulatory compliance

Real-World Case Studies: Rapid Prototyping Excellence in China

Case Study 1: Aerospace Component Development

A European aerospace manufacturer needed to develop a complex structural bracket for satellite systems with accelerated timeline requirements.

Challenge: Produce five functional prototypes of a topology-optimized bracket from 7075 aluminum with ±0.05mm positional tolerances on mounting features within a 10-day timeframe to support critical design review.

Technical Solution: The Chinese prototyping provider implemented a dedicated 5-axis machining strategy:

-

High-Speed Machining: Optimized toolpaths utilizing dynamic milling strategies for reduced cycle times

-

Digital Simulation: Manufacturing process simulation to verify toolpaths before machining

-

In-Process Verification: On-machine probing to verify critical features without separate inspection

-

Material Certification: Certified 7075-T6 aluminum with full material traceability

Results: The components were delivered within 8 days, enabling the customer to proceed with design review two days ahead of schedule. The prototypes achieved all dimensional requirements and passed functional testing, validating the design before proceeding to production tooling.

Case Study 2: Medical Device Ergonomics Validation

A surgical instrument company required ergonomic validation prototypes of a new laparoscopic tool system for surgeon evaluation and regulatory submission.

Challenge: Create 15 fully functional device prototypes matching production intent materials and tolerances within a 7-day timeline for critical surgical team evaluation.

Technical Solution: The project employed strategic manufacturing approaches:

-

Multi-Material Machining: Combination of stainless steel for internal mechanisms and medical-grade plastics for housings

-

Parallel Processing: Multiple machines operating simultaneously to compress overall lead time

-

Surface Enhancement: Medical-grade surface finishes matching production requirements

-

Quality Documentation: Comprehensive inspection records supporting regulatory submission

Results: The prototypes enabled identification of two critical ergonomic issues that significantly improved device usability. The 7-day delivery allowed the company to maintain its FDA submission schedule while implementing design improvements based on surgeon feedback.

Case Study 3: Automotive Lighting System Development

An automotive lighting manufacturer needed functional prototypes of a new LED headlamp assembly for thermal management testing and regulatory certification.

Challenge: Produce complete lighting assemblies with optical-quality lenses, complex cooling channels, and precise mounting features within 10 days to support critical certification testing.

Technical Solution: The implementation combined multiple advanced processes:

-

Multi-Axis Machining: Complex organic shapes for lens and reflector elements

-

Crystal-Clear Machining: Optical-grade surface finishes on lighting surfaces

-

Thermal Management Features: Precise cooling channels matching production design

-

Material Simulation: Engineering plastics with thermal properties matching production materials

Results: The prototypes successfully completed thermal cycle testing, providing data that validated the cooling system design. The 10-day turnaround enabled the manufacturer to submit for regulatory certification three weeks earlier than planned, accelerating market entry.

The Future of Rapid Prototyping in China

Emerging trends and technologies continue to shape the evolution of rapid prototyping services in China.

Technology Integration

The future of rapid prototyping in China involves increased integration of complementary technologies:

-

Hybrid Manufacturing: Combining additive and subtractive processes for optimal results

-

Digital Twin Implementation: Virtual prototypes that mirror physical components throughout development

-

AI-Driven Optimization: Automated design improvement and manufacturing parameter selection

-

Advanced Materials: Development and implementation of proprietary material formulations

Market Expansion

Chinese rapid prototyping services continue to expand their capabilities and market reach:

-

Specialized Applications: Focus on industry-specific requirements and regulatory standards

-

Global Supply Chain Integration: Deeper collaboration with international partners and customers

-

Sustainability Initiatives: Implementation of environmentally conscious manufacturing practices

-

Digital Platforms: Enhanced online interfaces for seamless customer experience

As noted in market analysis, the continued growth of the rapid prototyping market in China reflects the country’s evolving capabilities and the increasing importance of speed-to-market in product development .

Implementing Successful Rapid Prototyping Partnerships with Chinese Providers

Establishing effective collaborations with Chinese rapid prototyping services requires strategic approaches to communication, project management, and quality assurance.

Partnership Selection Criteria

When evaluating Chinese rapid prototyping providers, consider these essential capabilities:

-

Technical Equipment Portfolio: Modern CNC machinery with multi-axis capabilities and appropriate sizing

-

Material Expertise: Experience with relevant materials and applications

-

Quality Systems: Documented quality management with efficient inspection methodologies

-

Communication Practices: Responsive communication with regular progress updates

-

Project Management: Formal tracking systems with clear milestone definitions

Design for Manufacturing Optimization

Preparing designs for successful rapid prototyping outcomes:

-

Design for Machinability: Incorporating appropriate draft angles, corner radii, and feature accessibility

-

Tolerance Rationalization: Applying tight tolerances only where functionally necessary

-

Material Selection: Choosing materials with favorable machining characteristics and availability

-

Design Documentation: Providing comprehensive specifications to prevent misinterpretation

Conclusion

Rapid prototyping services in China have matured into sophisticated manufacturing solutions that deliver exceptional value through technical capability, operational efficiency, and cost-effectiveness. The integration of advanced CNC machining technologies with extensive manufacturing experience positions Chinese providers as ideal partners for accelerating product development across industries from aerospace to medical devices.

The most successful prototyping implementations leverage China’s strengths in precision manufacturing while establishing clear communication channels and quality standards. By selecting appropriate partners, optimizing designs for manufacturing, and implementing comprehensive verification processes, companies can achieve remarkable reductions in development time while improving product quality and performance.

For organizations seeking to maximize their prototyping efficiency, our specialized CNC machining services in China deliver the speed, precision, and expertise required for today’s demanding development schedules. Contact our engineering team to discuss how our rapid prototyping capabilities can accelerate your next product development initiative.