Reverse Engineering Services for Legacy Parts: Breathing New Life into Obsolete Components

When original designs fade into obscurity and replacement parts vanish from catalogs, reverse engineering emerges as the critical bridge between manufacturing history and operational future.

Reverse engineering services for legacy parts represent a sophisticated manufacturing discipline that transforms physical components into digital CAD models and functional replacements. As specialized providers of CNC machining services, we understand the critical importance of maintaining operational continuity for equipment that long outlives its original supply chain. This technical process of deconstructing and analyzing existing parts to extract design information has become increasingly vital across industries where equipment longevity exceeds component availability.

The challenge of legacy components affects virtually every industrial sector, from manufacturing and energy to transportation and defense. When original equipment manufacturers cease operations, discontinue product lines, or no longer support older equipment, reverse engineering becomes the only viable path to maintain operational readiness and prevent catastrophic downtime.

The Growing Imperative for Legacy Part Reverse Engineering

The need for reverse engineering services continues to accelerate as industrial equipment demonstrates remarkable longevity while supply chains face increasing disruption. The average lifespan of industrial machinery now exceeds 25 years, while product lifecycles for components continue to shorten due to technological advancement and economic pressures.

The Economics of Legacy Component Management

The financial impact of equipment downtime creates a compelling business case for reverse engineering investment. Studies across multiple industries reveal:

-

Manufacturing: Unplanned downtime costs average $50,000-$250,000 per hour in lost production

-

Energy Sector: Critical component failure can result in millions in lost revenue daily

-

Transportation: Aircraft on ground (AOG) situations cost $10,000-$150,000 per hour

-

Defense: Mission-critical system availability directly impacts national security readiness

Beyond immediate downtime costs, organizations face secondary expenses including expedited shipping, premium pricing for remaining obsolete inventory, and potential regulatory penalties for compliance failures.

Technical Challenges in Legacy Component Recreation

Reverse engineering legacy parts presents unique technical hurdles that differentiate it from conventional manufacturing:

-

Material Identification: Original specifications often unavailable, requiring composition analysis

-

Dimensional Wear Assessment: Used parts exhibit wear patterns that must be distinguished from original design intent

-

Manufacturing Process Knowledge: Historical manufacturing methods may differ from contemporary approaches

-

Tolerance Stack Analysis: Understanding cumulative dimensioning approaches from earlier engineering eras

The Reverse Engineering Process: Methodical Recreation

Successful reverse engineering follows a structured methodology that ensures accuracy, functionality, and manufacturability of recreated components.

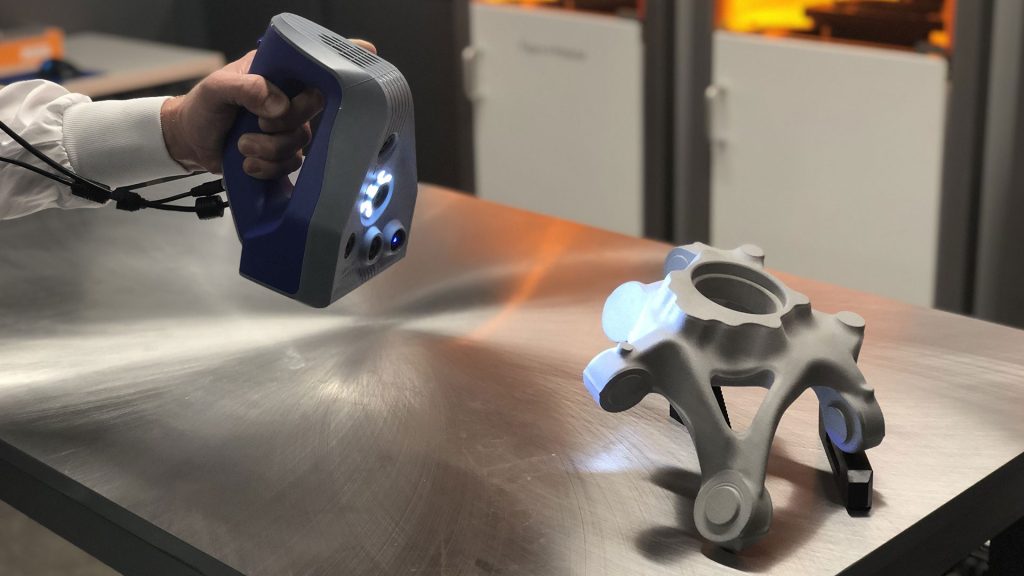

Phase 1: Digital Capture and Data Acquisition

The foundation of any reverse engineering project lies in precise dimensional capture of the existing component:

-

3D Laser Scanning: Non-contact measurement capturing millions of data points with accuracy to ±0.025mm

-

Structured Light Scanning: Projecting patterns onto surfaces to calculate complex geometries

-

Coordinate Measuring Machines (CMM): Touch-probe verification of critical features and datums

-

Computed Tomography (CT): X-ray scanning for internal features and hidden geometries

The selection of scanning technology depends on component size, complexity, material, and required accuracy. The table below outlines the optimal applications for each scanning methodology:

Table 1: 3D Scanning Technologies for Legacy Component Reverse Engineering

| Scanning Technology | Accuracy Range | Best Applications | Data Output | Limitations |

|---|---|---|---|---|

| Laser Scanning | ±0.025mm to ±0.1mm | Medium to large components, free-form surfaces | High-density point cloud | Challenging with reflective or dark surfaces |

| Structured Light | ±0.01mm to ±0.05mm | Small to medium parts, fine details | Photorealistic textured mesh | Sensitive to environmental vibrations |

| CT Scanning | ±0.02mm to ±0.1mm | Internal features, complex assemblies | Volumetric data with internal structures | Limited by material density and part size |

| CMM Probing | ±0.005mm to ±0.025mm | Critical features, geometric primitives | Discrete point measurements | Slow for complex organic shapes |

Phase 2: Point Cloud Processing and Surface Reconstruction

Raw scan data requires significant processing to become usable CAD geometry:

-

Noise Reduction: Filtering out measurement artifacts and surface imperfections

-

Point Cloud Alignment: Registering multiple scans into a unified coordinate system

-

Mesh Generation: Creating watertight polygonal models from point data

-

Surface Fitting: Converting mesh data into parametric CAD surfaces

Advanced software tools like Geomagic Design X and PolyWorks bridge the gap between scan data and engineering models, preserving design intent while accommodating manufacturing realities.

Phase 3: CAD Model Recreation and Design Intent Recovery

The transformation from scanned data to engineering model represents the most critical phase:

-

Feature Recognition: Identifying geometric primitives (planes, cylinders, cones) within scan data

-

Parametric Modeling: Rebuilding components with proper feature history and constraints

-

Design Intent Deduction: Distinguishing between original design features and subsequent modifications

-

Tolerance Analysis: Applying appropriate tolerances based on function and manufacturing capability

This phase requires experienced engineering judgment to recreate not just the component’s geometry, but its original design intelligence.

Phase 4: Manufacturing Process Selection and DFM Optimization

With validated CAD models complete, the focus shifts to manufacturing preparation:

-

Material Selection: Identifying suitable modern equivalents for obsolete materials

-

Process Planning: Selecting optimal manufacturing approaches based on quantity, complexity, and lead time

-

Design for Manufacturing (DFM): Adapting designs for contemporary production methods

-

Quality Planning: Developing inspection methodologies to verify recreated components

Advanced Technical Considerations in Legacy Part Recreation

Beyond the fundamental process, several technical considerations significantly impact the success of reverse engineering projects.

Material Analysis and Substitution

Legacy components often utilize materials no longer available or containing restricted substances:

-

Spectrographic Analysis: Identifying elemental composition through XRF or OES testing

-

Metallurgical Examination: Assessing microstructure, heat treatment, and mechanical properties

-

Modern Equivalents: Selecting contemporary materials with equivalent or superior properties

-

Regulatory Compliance: Ensuring replacement materials meet current environmental and safety standards

The table below outlines common legacy material challenges and contemporary solutions:

Table 2: Legacy Material Analysis and Modern Substitutions

| Legacy Material Challenge | Analysis Methods | Common Substitutions | Technical Considerations |

|---|---|---|---|

| Obsolete Steel Grades | Spark testing, hardness, spectroscopy | AISI/SAE modern equivalents | Machinability, heat treatment response |

| Lead-Containing Bronzes | XRF composition analysis | Lead-free bronze alloys | Bearing properties, corrosion resistance |

| Asbestos Composites | Microscopic examination, XRD | Modern composite materials | Temperature resistance, friction properties |

| Restricted Plastics | FTIR spectroscopy, DSC | RoHS-compliant engineering plastics | Chemical resistance, mechanical properties |

Geometric Dimensioning and Tolerancing (GD&T) Reconstruction

Recreating functional tolerance schemes presents one of the most challenging aspects of legacy part reverse engineering:

-

Datum Structure Analysis: Identifying reference features and their hierarchy

-

Tolerance Stack Analysis: Understanding cumulative dimensioning approaches

-

Functional Requirement Deduction: Inferring tolerance requirements from component operation

-

Contemporary Standards Application: Converting legacy tolerance approaches to modern GD&T

This process often requires disassembly and measurement of mating components to understand fit and function requirements fully.

Real-World Case Studies: Reverse Engineering in Action

Case Study 1: Aerospace Actuator Component Recreation

A commercial airline faced imminent AOG situations due to failed actuator components in legacy aircraft flight control systems.

Challenge: Reverse engineer a complex hydraulic actuator housing manufactured in the 1980s with no surviving documentation, internal passageways, and critical sealing surfaces.

Technical Approach:

-

CT Scanning: Penetrated the aluminum housing to map internal hydraulic passages

-

Multi-Technology Scanning: Combined laser scanning for external features with structured light for sealing surfaces

-

Material Analysis: Conducted spectrographic analysis to identify aluminum alloy composition

-

Functional Testing: Measured mating components to determine critical interface dimensions

Engineering Solution:

-

Recreated CAD model with parametric feature history for future modifications

-

Identified modern aluminum 7075-T6 as suitable replacement material

-

Optimized internal passages using CFD analysis to improve performance

-

Implemented modern sealing technology while maintaining interface compatibility

Results: The reverse engineered components exceeded original performance specifications while reducing manufacturing cost by 32%. The airline avoided an estimated $4.2 million in aircraft downtime and secured a reliable supply chain for future requirements.

Case Study 2: Historical Manufacturing Equipment Restoration

A specialty materials manufacturer needed to restore a 1940s-era production machine critical to their unique manufacturing process.

Challenge: Document and recreate multiple complex mechanisms with worn components, modified geometries, and no surviving engineering records.

Technical Approach:

-

Comprehensive Disassembly: Systematically documented each subassembly with photographic evidence

-

Wear Analysis: Differentiated between original dimensions and decades of service wear

-

Functionality First: Prioritized recreation of the machine’s unique processing capabilities

-

Modern Control Integration: Updated control systems while preserving mechanical functionality

Engineering Solution:

-

Created complete digital twin of the entire machine system

-

Replaced obsolete mechanical controls with CNC servo systems

-

Identified modern material substitutes for components originally made from unavailable materials

-

Implemented safety improvements while maintaining historical operation principles

Results: The restored equipment achieved 125% of original production capacity while maintaining the unique material characteristics impossible to reproduce on modern machinery. The $850,000 restoration project prevented a projected $15 million facility redesign and new equipment purchase.

Case Study 3: Nuclear Power Plant Safety Component Replacement

A nuclear facility needed immediate replacement of safety-critical valve components that had exceeded their service life and were no longer available.

Challenge: Reverse engineer radiation-exposed components with dimensional changes and material degradation while meeting nuclear quality assurance standards.

Technical Approach:

-

Radiological Safety: Implemented remote handling and decontamination procedures

-

Multi-Modal Scanning: Used laser scanning and CMM verification for maximum accuracy

-

Material Degradation Assessment: Analyzed material changes from prolonged radiation exposure

-

Regulatory Compliance: Documented every process step to nuclear quality standards

Engineering Solution:

-

Developed radiation-resistant material substitution strategy

-

Created manufacturing process that exceeded original component quality

-

Implemented enhanced inspection protocols for critical safety features

-

Established qualified manufacturing process for future replacements

Results: The reverse engineered components received nuclear regulatory approval and were installed during a planned outage. The project secured long-term component availability while improving safety margins. The facility avoided potential extended shutdown that would have cost approximately $2 million daily.

Quality Assurance in Reverse Engineered Components

The critical nature of legacy component replacement demands rigorous quality assurance throughout the reverse engineering process.

Verification and Validation Methodologies

-

First Article Inspection: Comprehensive measurement of initial production parts

-

Functional Testing: Performance verification in operational conditions or simulated environments

-

Accelerated Life Testing: Stress testing to validate durability and service life

-

Material Certification: Verification of material properties and composition

Documentation and Traceability

Complete documentation packages provide the foundation for ongoing support:

-

Reverse Engineering Report: Detailed methodology and technical decisions

-

Material Certifications: Traceable material test reports and certificates of compliance

-

Inspection Records: Dimensional verification data and functional test results

-

Manufacturing Process Records: Documentation of production methods and quality controls

Implementing Reverse Engineering: Strategic Considerations

Successfully integrating reverse engineering capabilities requires strategic planning and resource allocation.

Technology Investment

Essential technologies for comprehensive reverse engineering services:

-

High-Resolution 3D Scanners: Multiple technologies to address different component types

-

Advanced CAD/CAM Software: Capable of handling large scan datasets and complex surfaces

-

Material Analysis Equipment: Composition and property testing capabilities

-

Precision Measurement: CMMs, optical comparators, and surface measurement systems

Expertise Development

Beyond technology, successful reverse engineering demands specialized expertise:

-

Metallurgical Engineering: Material identification and substitution knowledge

-

Tribology Understanding: Wear analysis and surface interaction expertise

-

Historical Manufacturing Knowledge: Understanding of period-specific production methods

-

Regulatory Compliance: Industry-specific standards and certification requirements

The Future of Legacy Component Reverse Engineering

Emerging technologies continue to enhance reverse engineering capabilities and applications.

Digital Thread and Digital Twin Integration

-

Lifetime Component Tracking: Digital records following components throughout service life

-

Predictive Replacement: Analytics identifying components approaching end of life

-

Performance Optimization: Using operational data to improve recreated designs

-

Supply Chain Resilience: Digital inventories reducing physical stock requirements

Artificial Intelligence and Machine Learning

-

Automated Feature Recognition: AI-assisted identification of geometric features

-

Design Intent Prediction: Machine learning algorithms suggesting original design approaches

-

Manufacturing Process Selection: AI recommendations for optimal production methods

-

Quality Prediction: Anticipating potential issues before manufacturing

Conclusion

Reverse engineering services for legacy parts have evolved from emergency remediation to strategic manufacturing capability. Organizations that systematically address component obsolescence through professional reverse engineering secure significant competitive advantages through uninterrupted operations, controlled costs, and extended equipment lifecycles.

The most successful implementations recognize reverse engineering as an investment rather than an expense, delivering returns through avoided downtime, improved performance, and supply chain resilience. As manufacturing continues its digital transformation, reverse engineering capabilities will become increasingly integrated into comprehensive lifecycle management strategies.

For organizations facing legacy component challenges, our integrated CNC machining services with reverse engineering capabilities provide complete solutions from obsolete parts to functional replacements. Contact our engineering team to discuss how our reverse engineering expertise can address your legacy component requirements.