8 Advanced Manufacturing Techniques for High-Performance Robot Rotary Union Systems

Introduction: Enabling Continuous Motion in Robotic Systems

The robot rotary union represents a critical component in modern industrial automation, serving as the essential interface that enables the transmission of fluids, gases, electrical signals, and data between stationary and rotating parts of robotic systems. These sophisticated rotary feedthrough devices have become increasingly vital as industrial robots evolve to handle more complex tasks requiring multiple media transmissions during continuous rotation. The robot rotary union technology allows robots to perform uninterrupted 360-degree operations while maintaining reliable connections for hydraulic power, pneumatic control, coolant delivery, electrical signals, and data communications. As manufacturing processes become more automated and demanding, the precision and reliability of robot rotary union systems directly impact overall system performance, maintenance requirements, and operational efficiency.

At JLYPT, our expertise in precision CNC machining has positioned us as leaders in manufacturing high-performance components for robot rotary union applications. This comprehensive technical analysis examines eight essential manufacturing techniques that enable the production of reliable rotary union systems, while exploring the engineering principles that ensure optimal performance across diverse industrial applications and challenging operating conditions.

1. Fundamental Principles of Robot Rotary Union Technology

1.1 Multi-Passage Rotary Interface Architecture

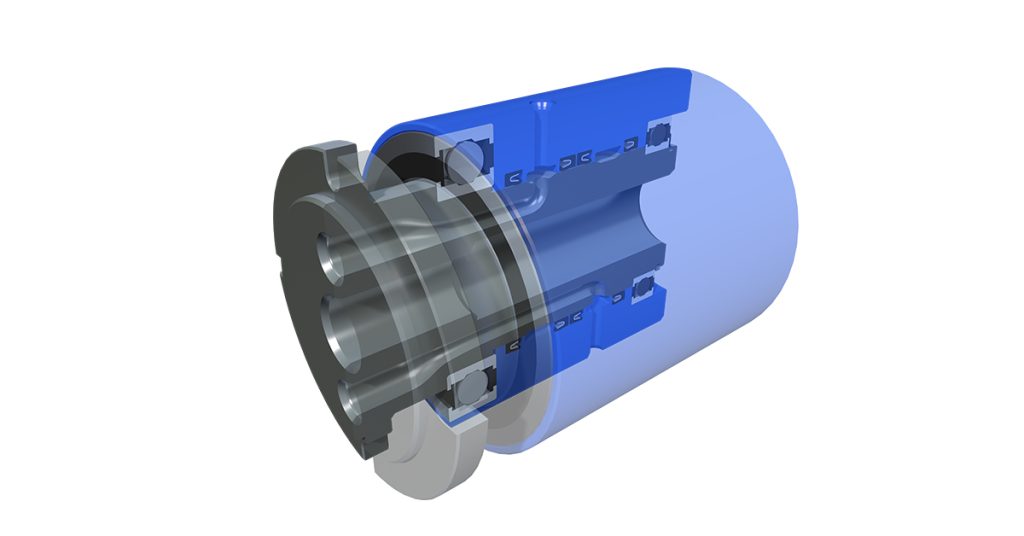

The robot rotary union operates on sophisticated principles that enable simultaneous transmission of multiple media types while maintaining seal integrity and rotational performance. Understanding this complex architecture is fundamental to appreciating the manufacturing requirements and performance capabilities.

Key Rotary Union Components:

-

Rotating Housing: Precision-machined rotating assembly with media passages

-

Stationary Body: Fixed component with inlet/outlet connections and mounting features

-

Sealing Systems: Multiple sealing arrangements for different media types and pressures

-

Bearing Assemblies: High-precision bearing systems for smooth rotation and load support

-

Passage Networks: Complex internal channels for media separation and flow optimization

Performance Comparison Table:

| Performance Metric | Standard Rotary Union | High-Performance Robot Rotary Union | Improvement Factor |

|---|---|---|---|

| Maximum Speed | 100-500 RPM | 500-3000 RPM | 3-6x higher |

| Pressure Rating | 100-300 bar | 300-700 bar | 2-3x increase |

| Passage Capacity | 1-3 passages | 4-12 passages | 3-4x more |

| Leakage Rate | 0.1-1.0 ml/min | 0.001-0.01 ml/min | 10-100x better |

| Service Life | 5-10 million cycles | 20-50 million cycles | 3-5x longer |

1.2 Performance Classification and Applications

Robot Rotary Union Performance Categories:

| Union Class | Passage Types | Maximum Speed (RPM) | Pressure Rating (bar) | Temperature Range (°C) |

|---|---|---|---|---|

| Standard Duty | 2-4 passages | 500-1000 | 200-350 | -20 to +120 |

| High Performance | 4-8 passages | 1000-2000 | 350-500 | -30 to +150 |

| Multi-Passage | 8-12 passages | 500-1500 | 250-400 | -20 to +120 |

| High Temperature | 2-6 passages | 300-800 | 150-300 | -50 to +250 |

| Corrosion Resistant | 2-6 passages | 400-1200 | 200-400 | -20 to +200 |

2. Advanced Material Selection and Engineering

2.1 Comprehensive Material Strategy

The performance of robot rotary union components depends on advanced material selection where corrosion resistance, wear properties, and mechanical strength are carefully balanced for specific media and operating conditions.

Material Selection Matrix for Rotary Union Components:

| Material Specification | Component Application | Corrosion Resistance | Wear Resistance | Mechanical Strength |

|---|---|---|---|---|

| Stainless Steel 316 | Standard housings, bodies | Excellent | Good | 515 MPa |

| Stainless Steel 17-4PH | High-strength components | Very Good | Very Good | 1310 MPa |

| Titanium Grade 5 | Aerospace, weight-critical | Exceptional | Good | 900 MPa |

| Aluminum 7075-T6 | Lightweight applications | Good | Fair | 572 MPa |

| PEEK Polymer | Sealing components | Excellent | Excellent | 100 MPa |

| Ceramic | High-wear surfaces | Exceptional | Exceptional | 400 MPa |

| Bronze C932 | Bearing surfaces | Very Good | Excellent | 310 MPa |

2.2 Specialized Material Processing

Advanced Surface Treatments:

-

Plasma Nitriding: Surface hardness to 72 HRC with minimal distortion

-

Hard Chrome Plating: Wear-resistant coating with thickness 0.02-0.05mm

-

Electroless Nickel: Uniform corrosion protection with controlled thickness

-

PVD Coatings: Titanium nitride and diamond-like carbon for extreme wear resistance

-

Anodizing: Aluminum surface hardening to 60-70 Rockwell C equivalent

Precision Heat Treatment:

-

Solution Annealing: Stress relief and homogenization of stainless steels

-

Precipitation Hardening: Optimal strength development in 17-4PH stainless

-

Stress Relieving: Dimensional stability for precision components

-

Cryogenic Treatment: Enhanced dimensional stability and wear resistance

3. Precision CNC Machining Methodologies

3.1 Multi-Axis Machining for Complex Passage Networks

The manufacturing of robot rotary union components requires advanced CNC machining capabilities to achieve the complex internal geometries and tight tolerances necessary for optimal performance.

5-Axis Simultaneous Machining Applications:

-

Complex Internal Passages: Single-setup machining of intricate media channels

-

Integrated Mounting Features: Precision machining of flange and connection interfaces

-

Micro-Machining: Production of small precision features and sealing surfaces

-

Multi-Material Components: Machining of assemblies with dissimilar materials

Critical Machining Parameters for Rotary Union Components:

| Manufacturing Process | Material Type | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tolerance (mm) |

|---|---|---|---|---|---|

| Precision Turning | Stainless 316 | 120-180 | 0.03-0.10 | 0.2-0.8 | ±0.005 |

| Deep Hole Drilling | Steel Alloys | 60-100 | 0.01-0.03 | 10-30xD | ±0.010 |

| Micro-Milling | Various | 200-400 | 0.005-0.020 | 0.05-0.20 | ±0.002 |

| Fine Boring | Stainless 17-4 | 80-120 | 0.02-0.06 | 0.1-0.3 | ±0.003 |

| Thread Milling | All Materials | 40-80 | 0.02-0.08 | 0.5-2.0 | ±0.005 |

3.2 Specialized Manufacturing Processes

Complex Passage Manufacturing:

-

Cross-Drilling Operations: Precision intersection of multiple passageways

-

Port Machining: Optimized flow channels with controlled surface finish

-

Deburring Processes: Complete removal of internal burrs and sharp edges

-

Surface Finishing: Controlled surface texture for optimal fluid dynamics

Sealing Surface Manufacturing:

-

Profile Grinding: Precision grinding of complex sealing geometries

-

Superfinishing: Final surface refinement to Ra 0.1-0.2μm

-

Lapping Processes: Achieving flatness within 0.0005mm per 25mm

-

Geometry Verification: Comprehensive measurement of critical sealing surfaces

4. Sealing Technology and Surface Engineering

4.1 Advanced Sealing Systems

The heart of any robot rotary union lies in its sealing technology, which must maintain integrity under varying pressures, temperatures, and rotational speeds.

Sealing Technology Comparison:

| Seal Type | Pressure Range | Temperature Range | Speed Limit | Media Compatibility |

|---|---|---|---|---|

| Mechanical Face Seals | 0-700 bar | -50°C to +250°C | 3000 RPM | Wide range |

| Lip Seals | 0-50 bar | -40°C to +120°C | 1500 RPM | Limited compatibility |

| O-Ring Seals | 0-700 bar | -50°C to +200°C | 500 RPM | Wide range |

| Labyrinth Seals | Low pressure | -50°C to +400°C | 5000 RPM | All media |

| Hydrodynamic Seals | 0-350 bar | -20°C to +150°C | 4000 RPM | Clean fluids |

4.2 Surface Engineering for Sealing Applications

Critical Surface Parameters:

-

Surface Finish: Ra 0.1-0.4μm for optimal seal performance

-

Flatness: 0.0005mm per 25mm for face seal applications

-

Hardness: 58-65 HRC for wear-resistant sealing surfaces

-

Surface Texture: Controlled pattern for lubricant retention and heat dissipation

5. Bearing System Integration and Alignment

5.1 Precision Bearing Technology

The bearing system in a robot rotary union must provide smooth rotation, precise alignment, and long service life under combined loads.

Bearing Selection and Performance:

| Bearing Type | Speed Capacity | Load Capacity | Stiffness | Life Expectancy |

|---|---|---|---|---|

| Deep Groove Ball | High | Medium | Medium | 20,000 hours |

| Angular Contact | Very High | High | High | 30,000 hours |

| Cylindrical Roller | Medium | Very High | Very High | 25,000 hours |

| Tapered Roller | Medium | High | High | 22,000 hours |

| Ceramic Hybrid | Very High | Medium | High | 40,000 hours |

5.2 Alignment and Mounting Precision

Critical Alignment Parameters:

-

Runout Tolerance: 0.005mm maximum for precision applications

-

Parallelism: 0.008mm per 100mm for mounting surfaces

-

Concentricity: 0.006mm maximum between bearing seats

-

Squareness: 0.010mm per 100mm for critical interfaces

6. Multi-Passage Design and Manufacturing

6.1 Complex Passage Network Engineering

The robot rotary union often requires multiple independent passages for different media types, demanding sophisticated design and manufacturing approaches.

Passage Design Considerations:

-

Flow Optimization: Computational fluid dynamics for efficient flow paths

-

Pressure Management: Strategic reinforcement for high-pressure passages

-

Cross-Contamination Prevention: Adequate separation between different media

-

Thermal Management: Heat transfer considerations for temperature-sensitive media

Manufacturing Challenges and Solutions:

-

Deep Hole Drilling: Precision drilling with aspect ratios up to 30:1

-

Intersection Management: Controlled machining of passage intersections

-

Surface Finish Control: Consistent surface texture throughout passage networks

-

Cleaning and Deburring: Complete removal of manufacturing residues

6.2 Passage Configuration Options

Standard Passage Arrangements:

| Configuration | Passage Count | Typical Applications | Complexity Level |

|---|---|---|---|

| Concentric | 2-3 passages | Basic utility transfer | Low |

| Radial Array | 4-6 passages | Multiple media transfer | Medium |

| Matrix Pattern | 7-12 passages | Complex automation systems | High |

| Hybrid Layout | 4-8 passages | Mixed media applications | Medium-High |

7. Quality Assurance and Testing Protocols

7.1 Comprehensive Metrology Systems

The verification of robot rotary union components employs advanced measurement technologies and rigorous inspection protocols.

Dimensional Metrology Capabilities:

-

Coordinate Measuring Machines: Volumetric accuracy 1.5 + L/400 μm with temperature compensation

-

Optical Scanning Systems: High-resolution 3D scanning for complex internal geometries

-

Surface Roughness Measurement: Ra measurement capability to 0.01μm resolution

-

Roundness Measurement: Accuracy to 0.1μm with advanced analysis capabilities

Performance Testing Protocols:

-

Pressure Testing: Hydrostatic and pneumatic testing to 150% of rated pressure

-

Leakage Testing: Mass spectrometer testing for helium leakage rates below 1×10⁻⁹ mbar·l/s

-

Rotational Testing: Dynamic testing under load at various speeds and temperatures

-

Endurance Testing: Accelerated life testing with continuous rotation and media transfer

7.2 Environmental and Reliability Testing

Durability Validation Protocols:

-

Thermal Cycling: -55°C to +150°C temperature extremes testing

-

Vibration Endurance: Random vibration to 15Grms per MIL-STD-810

-

Corrosion Testing: Salt spray testing per ASTM B117 for 500 hours

-

Media Compatibility: Testing with various fluids and gases per application requirements

8. Application Case Studies

Case Study 1: Automotive Welding Robot

Challenge: An automotive manufacturer required robot rotary union systems for spot welding robots with 6 passages for water cooling, hydraulic pressure, and electrical signals. Existing systems experienced seal failures and limited service life.

JLYPT Solution: We developed custom robot rotary union systems featuring advanced mechanical face seals and optimized passage geometry. The manufacturing process incorporated precision grinding of sealing surfaces and comprehensive testing under actual operating conditions.

Results:

-

Achieved service life of 15 million cycles between maintenance

-

Reduced leakage rates to less than 0.001 ml/min per passage

-

Enabled continuous 360-degree rotation at 180 RPM

-

Reduced maintenance downtime by 70%

Case Study 2: Semiconductor Processing Equipment

Challenge: A semiconductor equipment manufacturer needed ultra-clean robot rotary union for wafer handling robots with minimal particle generation and compatibility with high-purity gases.

JLYPT Solution: Our team developed specialized robot rotary union systems using electropolished stainless steel and ceramic sealing surfaces. All components underwent rigorous cleaning and packaging procedures for cleanroom compatibility.

Results:

-

Achieved particle generation rates below Class 1 requirements

-

Maintained gas purity with helium leakage rates <1×10⁻⁹ mbar·l/s

-

Enabled 24/7 operation with maintenance intervals exceeding 12 months

-

Met all SEMI standards for semiconductor equipment

Case Study 3: Aerospace Testing System

Challenge: An aerospace manufacturer required robot rotary union for testing equipment with extreme temperature operation (-55°C to +200°C) and high-pressure hydraulic transmission.

JLYPT Solution: We implemented specialized robot rotary union systems using high-temperature materials and advanced seal designs. Precision manufacturing ensured reliable performance under extreme environmental conditions.

Results:

-

Operated reliably across full temperature range

-

Maintained seal integrity at 500 bar hydraulic pressure

-

Achieved rotational speeds up to 500 RPM under full load

-

Met all aerospace qualification and certification requirements

Future Development Trends

Emerging Technologies and Innovations

The continued evolution of robot rotary union technology is driving advancements across multiple technical domains.

Advanced Material Applications:

-

Nanostructured Coatings: Enhanced surface properties for extreme wear resistance

-

Self-Lubricating Composites: Maintenance-free operation for extended periods

-

Shape Memory Alloys: Adaptive sealing technologies for varying conditions

-

Carbon Nanotube Composites: Revolutionary strength-to-weight characteristics

Smart Integration Technologies:

-

Embedded Sensors: Real-time monitoring of pressure, temperature, and wear

-

IoT Connectivity: Cloud-based monitoring and predictive maintenance

-

Digital Twin Integration: Virtual modeling for performance optimization

-

AI-Driven Optimization: Machine learning for predictive maintenance and performance tuning

Conclusion: Engineering Excellence in Rotary Interface Technology

Robot rotary union technology represents the pinnacle of precision engineering in modern industrial automation. The eight manufacturing techniques explored—advanced material engineering, precision CNC machining, sealing technology, bearing integration, multi-passage design, quality assurance, application-specific optimization, and future innovation—demonstrate the comprehensive approach required to produce components that meet the exacting demands of contemporary robotic applications.

As robotic technology continues to advance, the requirements for robot rotary union systems will become increasingly demanding, driving further innovation in manufacturing technologies and material science. The integration of smart technologies, advanced analytics, and sustainable manufacturing practices will ensure that rotary union technology remains at the forefront of industrial automation innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every robot rotary union component we produce meets the highest standards of performance, reliability, and precision. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of capability and performance in their automated systems.

For engineering teams seeking to enhance their robotic systems through superior rotary union solutions, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.