Precision in Every Layer: Integrating Robotic Painting Systems with CNC Machining

The Concluding Masterstroke: Why Robotic Painting is the Logical Endpoint for Precision CNC Parts

In the world of high-value manufacturing, the journey of a component is a continuum of precision. At JLYPT, we understand this journey intimately. It begins with a digital blueprint and culminates in a block of metal being sculpted to micron-level tolerances on our advanced CNC machining centers—a process defined by absolute control, repeatability, and flawless execution. Yet, this meticulous craftsmanship can be inadvertently undermined at the final stage: the application of a protective or aesthetic coating. Traditional manual painting, with its inherent variability, introduces a point of weakness in an otherwise robust digital thread. This is where advanced robotic painting systems cease to be a mere finishing step and become the essential, concluding chapter in the saga of precision manufacturing. For components where performance, durability, and appearance are non-negotiable—from aerospace actuators to medical implants and luxury automotive parts—integrating a robotic painting system is the strategic imperative that protects your investment and elevates your product’s value.

The synergy between CNC machining and robotic painting is profound and logical. A robot, much like a CNC mill, is a deterministic machine. It follows a digital program with unwavering consistency. When the precise, complex geometries produced by CNC machining meet the programmed precision of a robotic painting system, the result is a perfectly finished part where coating thickness, coverage, and quality are as guaranteed as the dimensional accuracy of its underlying features. This article, from the perspective of a precision machining service provider, will explore the architecture, integration, and transformative benefits of deploying robotic painting systems for CNC-machined components.

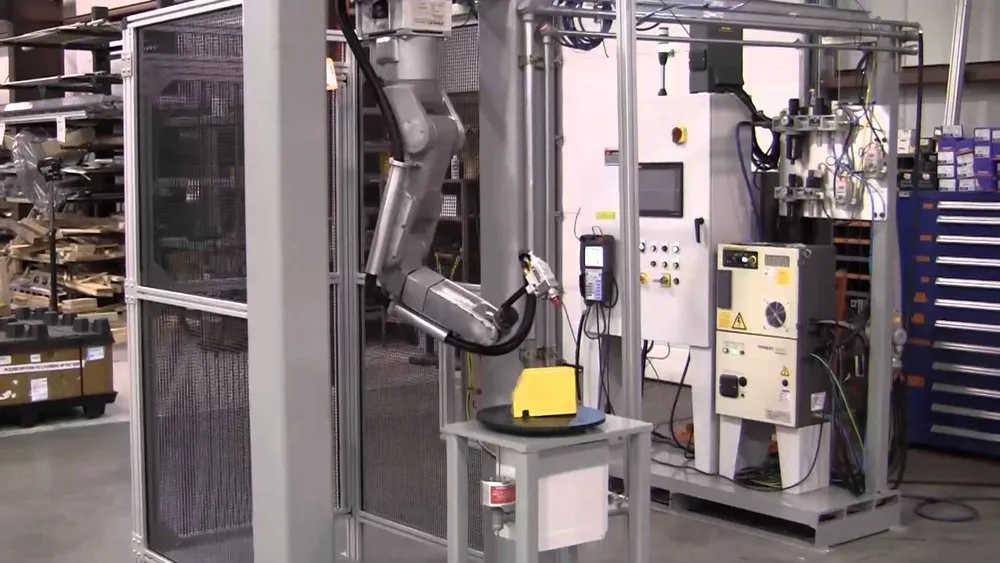

The Anatomy of a Modern Robotic Painting Cell: Beyond the Spray Gun

A state-of-the-art robotic painting system is far more than a robot arm holding a spray gun. It is an integrated ecosystem of hardware and software engineered for closed-loop control, mirroring the precision philosophy of CNC machining.

1. The Motion Platform: Articulated, Cartesian, and Collaborative Robots

The choice of robot dictates the system’s capability envelope. For the complex, multi-curved surfaces typical of many CNC-machined parts, 6- and 7-axis articulated robots offer unmatched dexterity, allowing the spray gun to maintain a consistent standoff distance and perpendicular angle to intricate contours. For larger panels or enclosures, gantry (Cartesian) systems provide exceptional stability over a vast work area. The emerging trend is toward greater flexibility. Mobile robotic bases or intelligent, multi-robot cells are being designed to maximize coverage and adaptability. Furthermore, the integration of technologies like large language models (LLMs) is beginning to allow for natural language command of these systems, lowering the barrier to programming complex tasks.

2. The Application & Control Core: Precision in Delivery

This is the “spindle” of the painting cell. Modern applicators are highly engineered systems:

-

High-Transfer Efficiency Technologies: Techniques like High Volume Low Pressure (HVLP) and air-assisted airless spraying are standard, but the forefront lies in electrostatic rotary bell atomizers. These create a fine, uniform mist while using electrostatic attraction to wrap paint onto the part, dramatically reducing overspray and material waste. Advanced systems can achieve coating material utilization rates of over 85%, a significant leap from the 60% common in manual operations.

-

Integrated Process Control: Leading systems feature unified controllers that synchronize robot trajectory with paint parameters—fluid flow, atomizing air pressure, bell speed, and electrostatic voltage—in real-time. This ensures a perfectly consistent film build, regardless of the robot’s acceleration or deceleration along its path.

3. The Sensory and Cognitive Layer: Vision, AI, and Adaptive Pathing

This is where intelligent automation diverges from simple automation. Modern systems incorporate:

-

3D Machine Vision: Offline programming (OLP) using the component’s CAD model is a start. However, advanced cells use 3D vision scanners to capture the actual workpiece, creating a point cloud that accounts for fixturing variances or inherent material deviations. This real-world data ensures the spray path is perfectly adapted to the physical part, not just its theoretical model.

-

AI-Powered Path Planning & Optimization: AI algorithms analyze the 3D model of a part to automatically generate the most efficient, complete spray trajectory. They can account for complex shadows, recesses, and edges that are challenging even for experienced programmers. This technology is pivotal for adaptive painting, where the system can handle part-to-part variations without manual reprogramming.

-

In-Line Quality Assurance: The most advanced cells integrate AI vision inspection systems that monitor the wet film in real-time, detecting defects like sags, dry spray, or insufficient coverage as small as 0.1mm. This data can feed back into the control system for immediate correction or be logged for each part, creating a complete digital quality record.

4. The Critical Support System: Environment, Safety, and Integration

A precision cell cannot operate in a vacuum. Key peripherals include:

-

Climate-Controlled Spray Booth: Consistent temperature and humidity are vital for coating chemistry and dry times. Down-draft or cross-draft ventilation ensures a clean environment and captures overspray.

-

Advanced Filtration and VOC Abatement: To meet stringent environmental regulations, systems integrate thermal oxidizers or other technology to destroy over 98% of Volatile Organic Compounds (VOCs).

-

Safety by Design: In hazardous environments, all equipment must be explosion-proof (EX-rated). The entire cell is safeguarded with interlocks, light curtains, and comprehensive risk assessments per ISO 10218 safety standards.

Table 1: Robotic Painting System Archetypes for CNC Machined Components

| System Type | Key Characteristics | Typical Reach / Work Envelope | Best Suited for CNC Part Profiles | Integration & Flexibility |

|---|---|---|---|---|

| Articulated 6/7-Axis Robot | High dexterity, complex programming, floor- or wall-mounted. | Large (e.g., 2.2m+ radius) | Complex geometries: turbine blades, engine blocks, sculptural forms, housings with deep recesses. | High. Requires extensive safety fencing and sophisticated path planning. Ideal for high-mix, complex parts. |

| Gantry (Cartesian) Robot | Superior stability, high speed, linear X-Y-Z axes. | Very Large (customizable travel) | Large flat or gently contoured panels, machine enclosures, cabinet doors, aerospace skins. | Moderate to High. Requires a rigid overhead gantry structure. Excellent for large-part throughput. |

| Mobile Painting Robot | Robot arm mounted on an AGV; highly flexible. | Defined by arm reach + AGV travel. | Very large, low-volume fabrications (e.g., custom machinery frames) or for servicing multiple workstations. | Very High. Involves mobile safety protocols, dynamic calibration, and navigation software. |

| Collaborative Robot (Cobot) Cell | Designed for safe interaction, easier programming, often enclosed. | Small to Medium (<1.5m) | Low-volume, high-value parts (prototypes, medical devices), secondary touch-up operations, or R&D environments. | Low to Moderate. Faster to deploy, easier to re-task. Perfect for bridging automation and manual processes. |

The Strategic Integration: Where CNC Machining and Robotic Painting Converge

The handoff from machining to painting is a critical interface. A seamless integration leverages the strengths of both disciplines.

Digital Thread Continuity: The CAD/CAM model used to program the CNC machine is the foundational dataset for the painting robot’s offline programming (OLP). Modern software can import this model to simulate paint coverage, calculate material usage, and generate optimized spray paths before any physical part exists. This closes the digital loop from design to finished product.

Precision Fixturing and Masking: The accuracy of CNC machining is directly leveraged to produce the precision fixturing and masking tools that hold and protect parts during painting. Critical datum surfaces, threaded holes, bearing journals, and sealing faces must be perfectly masked. CNC-machined masks and fixtures ensure a perfect fit, preventing paint ingress and eliminating costly post-paint rework or tapping—a service where JLYPT’s core expertise directly adds value.

Surface Finish (Ra, Rz) as a Foundation: The surface profile left by the final CNC machining operation has a direct impact on coating adhesion and finish quality. A properly specified and consistently achieved surface roughness provides an ideal mechanical key for the coating. Robotic painting ensures this optimal substrate is treated with consistent, controllable film layers, maximizing the coating’s performance and lifespan.

Quantifying the Value: ROI Beyond Labor Savings

While displacing manual labor is a clear benefit, the ROI of a robotic painting system for precision parts is multi-faceted and compelling.

Table 2: ROI Analysis Framework for a Robotic Painting Cell in Precision Manufacturing

| Cost/Benefit Category | Traditional Manual Spray | Robotic Painting System | Impact on Business & Product |

|---|---|---|---|

| Coating Consistency & Quality | Variable. Subject to technician skill, fatigue, and environmental factors. | Exceptional. Programmed parameters are executed identically on every part, every shift. | Eliminates cosmetic rejects and performance failures related to coating. Ensures compliance with stringent industry specs (e.g., MIL, automotive OEM). |

| Material Utilization & Waste | Typically 40-60% transfer efficiency. High overspray and waste. | 75-90%+ transfer efficiency with advanced applicators. Minimal overspray. | Direct 25-40% reduction in paint/coating material costs. Lowers hazardous waste disposal costs and environmental footprint. |

| Production Throughput & Scheduling | Pace varies. Requires breaks, and skilled labor is scarce. | Consistent, predictable cycle time. Enables 24/7 lights-out operation after programming. | Increases capacity and makes lead times predictable. Frees skilled personnel for higher-value tasks. |

| First-Pass Yield & Rework | Higher likelihood of runs, sags, dry spray, and inconsistencies requiring rework. | Near-perfect first-pass yield. In-line AI inspection catches defects in real-time. | Dramatically reduces costly, time-consuming stripping and re-spray operations. Protects the value-added machining already completed. |

| Digital Traceability & Compliance | Paper-based records or limited data. Difficult to trace failures. | Every part’s spray parameters, environmental conditions, and inspection results are digitally logged. | Provides immutable quality records for aerospace, medical, and automotive customers. Supports ISO and industry-specific certifications. |

Case Studies: Robotic Painting in Action Across Industries

Case Study 1: Aerospace Turbine Component Manufacturer

-

Challenge: A manufacturer of precision-machined nickel-alloy turbine blades needed to apply a proprietary thermal barrier coating (TBC). Manual spraying resulted in thickness variations exceeding ±3 mils, impacting performance and fuel efficiency. The process was also labor-intensive and exposed workers to hazardous materials.

-

Solution: Integration of a fully enclosed, climate-controlled robotic painting cell featuring a 7-axis articulated robot with an electrostatic bell applicator. A laser line scanner captured each blade’s unique geometry post-machining, and the path was auto-adjusted for optimal standoff distance. An in-line coating thickness gauge provided closed-loop feedback.

-

Outcome: Coating thickness variation was reduced to ±0.5 mils, significantly enhancing engine performance. Material usage dropped by 35%, and the hazardous manual operation was eliminated. The cell provided full traceability for each serialized blade, meeting rigorous aerospace quality mandates.

Case Study 2: Medical Device OEM – Implantable Components

-

Challenge: A company machining titanium spinal implants needed to apply a biocompatible, color-coded PVD (Physical Vapor Deposition) coating primer via spray. Manual application led to occasional contamination, inconsistent color saturation, and challenges in masking critical bone-in-growth surfaces.

-

Solution: A cleanroom-compliant collaborative robot (cobot) cell was deployed. The cobot, equipped with a micro-dispensing valve, was programmed offline using the implant’s CAD model. CNC-machined, autoclavable masking fixtures perfectly protected specific zones. The small, sealed cell operated within a Class 8 cleanroom environment.

-

Outcome: The process achieved zero contamination-related rejects. Color consistency was perfect across batches, simplifying surgical kit assembly. The flexibility of the cobot allowed quick changeover between different implant families, supporting high-mix, low-volume production.

Case Study 3: Industrial Machinery Builder – Custom Enclosures & Guards

-

Challenge: A manufacturer of high-end CNC machining centers and lathes produced large, welded sheet metal enclosures and chip guards. Each unit was semi-custom. Powder coating was outsourced, leading to long lead times, transport damage, and difficulty controlling quality.

-

Solution: Investment in an in-house gantry robot powder coating line. The system included an automated pre-treatment wash, dry-off oven, robotic powder application booth with quick-color-change technology, and curing oven. The robot path was programmed for the standard enclosure but could be quickly modified for custom sizes.

-

Outcome: Lead time for finished guards was reduced from 3 weeks to 2 days. In-house control eliminated transport damage and improved quality consistency. The ability to do small batches in-house provided a significant competitive advantage in offering customized machine appearances.

Conclusion: Protecting Your Precision with Equal Precision

For manufacturers like our clients at JLYPT, where excellence is machined into every component, the final finish should not be an afterthought. Advanced robotic painting systems represent the necessary evolution of the precision manufacturing ethos into the finishing domain. They transform coating from a variable, skill-dependent craft into a controlled, data-driven science.

The integration of these systems protects the significant value already embedded in a CNC-machined part by ensuring its surface is treated with the same level of accuracy, repeatability, and care. The return on investment is clear and multifaceted, spanning superior quality, material savings, throughput gains, and enhanced compliance.

As technology advances with AI, adaptive robotics, and smarter integration, the synergy between subtractive machining and additive coating will only grow stronger. For businesses seeking to command a premium in their markets, mastering this final, critical step is not just an option—it is the definitive signature of a world-class manufacturer.

Ready to explore how a precision finishing strategy can complete the value of your CNC-machined components? Contact JLYPT today to discuss how we can help you bridge the gap between machining excellence and flawless surface performance.