10 Advanced Manufacturing Techniques for High-Performance Robotic Servo Motor Systems

Introduction: Precision Engineering for Modern Robotics

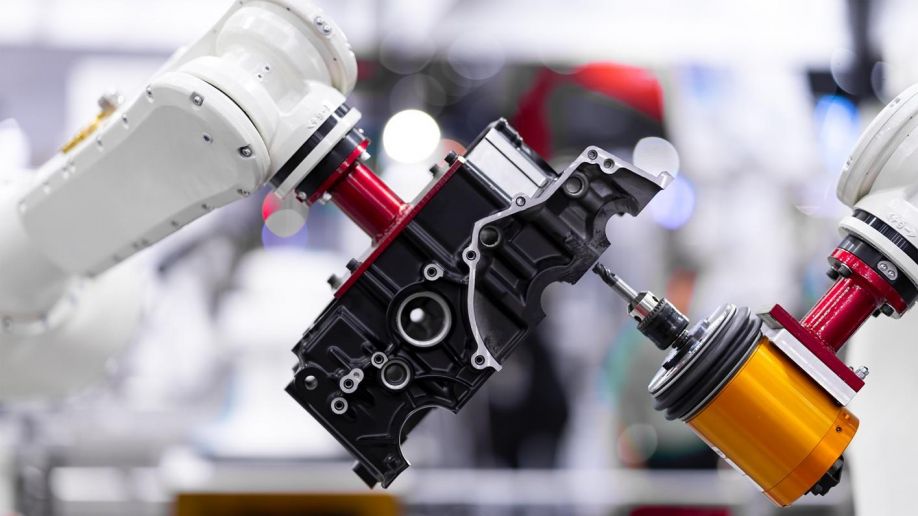

In the sophisticated landscape of industrial automation, the robotic servo motor stands as a cornerstone technology that enables the precise, dynamic motion control required by modern robotic systems. These advanced electromechanical devices combine high-torque density, exceptional positioning accuracy, and rapid response characteristics to meet the demanding requirements of contemporary automation applications. The manufacturing precision applied to robotic servo motor components directly influences system performance, reliability, and operational lifespan, making precision engineering absolutely critical for success in competitive industrial markets.

As specialized precision machining experts at JLYPT, we have developed comprehensive manufacturing methodologies for producing high-performance components for robotic servo motor applications. This detailed technical examination explores ten essential manufacturing techniques that transform engineering designs into reliable motion components, while investigating the sophisticated engineering principles that ensure optimal performance in demanding operational environments.

1. Fundamental Principles of Robotic Servo Motor Technology

1.1 Servo Motor Architecture and Classification

Understanding the complex architecture of robotic servo motor systems begins with recognizing their fundamental components and operational principles.

Key Servo Motor Components:

-

Stator Assembly: Precision-wound copper coils in laminated electrical steel cores

-

Rotor Construction: Permanent magnet arrangement on balanced rotor structure

-

Feedback Devices: High-resolution encoders and resolvers for position sensing

-

Thermal Management: Advanced cooling systems for heat dissipation

-

Structural Housing: Precision-machined enclosures for component protection

Performance Classification Table:

| Servo Motor Class | Torque Range (Nm) | Speed Range (RPM) | Positioning Accuracy | Typical Applications |

|---|---|---|---|---|

| Micro Servo | 0.01-0.5 | 1-3,000 | ±0.1° | Small robotic joints, precision instruments |

| Standard Industrial | 0.5-50 | 1-6,000 | ±0.05° | Industrial robots, CNC machinery |

| High-Performance | 50-300 | 1-8,000 | ±0.01° | Aerospace, semiconductor manufacturing |

| High-Torque | 300-2,000 | 1-3,000 | ±0.02° | Heavy automation, press systems |

| Ultra-Precision | 0.1-20 | 1-5,000 | ±0.001° | Medical robots, optical systems |

1.2 Critical Performance Parameters

The operational excellence of robotic servo motor systems is quantified through several key performance indicators that must be carefully engineered during manufacturing:

Motion Control Metrics:

-

Torque Density: 2.5-4.5 Nm/kg for standard industrial servos, up to 7.5 Nm/kg for premium models

-

Velocity Regulation: 0.01-0.1% of base speed under load variations

-

Settling Time: 10-50 milliseconds for 95% position acquisition

-

Speed-Torque Characteristics: Flat torque curve up to rated speed, constant power beyond

Durability Requirements:

-

Bearing Life: L10 rating exceeding 20,000 hours at rated load

-

Insulation Class: Class F (155°C) or higher for thermal robustness

-

Vibration Resistance: 5-15G operational capability depending on application

-

IP Rating: IP65 standard, IP67 for harsh environments

2. Advanced Material Selection Strategies

2.1 Metallic Material Engineering

The performance characteristics of robotic servo motor components are fundamentally influenced by material selection, with each application demanding specific mechanical and electromagnetic properties.

Comprehensive Material Selection Guide:

| Material Specification | Applications | Yield Strength (MPa) | Thermal Conductivity (W/m·K) | Magnetic Properties |

|---|---|---|---|---|

| Electrical Steel M19 | Stator laminations | 345 | 25 | Excellent |

| Electrical Steel M15 | Premium stator cores | 380 | 23 | Superior |

| Aluminum 6061-T6 | Motor housings, heat sinks | 275 | 167 | Non-magnetic |

| Aluminum 7075-T6 | High-strength structural | 503 | 130 | Non-magnetic |

| Stainless 17-4PH | Shafts, fasteners | 1,100 | 18 | Semi-magnetic |

| Alloy Steel 4140 | High-strength shafts | 655 | 42 | Magnetic |

| Copper C10100 | Windings, connectors | 69 | 391 | Non-magnetic |

| Neodymium Magnets | Rotor assemblies | 800 | 9 | Excellent |

2.2 Specialized Material Applications

Lamination Steel Processing:

-

Laser Cutting: Precision cutting with minimal heat-affected zone

-

Etching Processes: Chemical etching for complex geometries

-

Heat Treatment: Stress relief annealing for dimensional stability

-

Insulation Coating: C5 organic coating for interlamination resistance

Magnet Material Advancements:

-

Neodymium Iron Boron: Maximum energy product up to 52 MGOe

-

Samarium Cobalt: High-temperature operation to 350°C

-

Bonded Magnets: Complex geometries with good magnetic properties

-

High-Purity Materials: Reduced inclusions for improved performance

3. Precision CNC Machining Methodologies

3.1 Multi-Axis Machining Strategies

The manufacturing of high-performance components for robotic servo motor demands sophisticated machining approaches that combine micron-level accuracy with production efficiency.

5-Axis Simultaneous Machining:

-

Complex Housing Geometries: Ability to machine intricate cooling channels and mounting features

-

Reduced Setup Time: Complete machining in single setups minimizes cumulative error to under 0.01mm

-

Optimal Tool Engagement: Continuous tool path optimization maintains consistent cutting forces

-

Superior Surface Finish: Elimination of stair-stepping artifacts achieves Ra 0.4μm or better

Swiss-Type Turning Applications:

-

Micro-Machining Capability: Production of small precision components to ±0.002mm tolerances

-

Complex Part Features: Ability to machine multiple diameters, threads, and contours in single operation

-

Material Efficiency: Minimal material waste through optimized bar stock utilization

-

High Volume Production: Consistent quality in manufacturing large quantities

3.2 Specialized Machining Processes

High-Speed Machining Parameters for Robotic Servo Motor Components:

| Material Type | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Depth of Cut (mm) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Aluminum Housings | 800-1,200 | 0.08-0.20 | 0.5-3.0 | 0.4-0.8 |

| Steel Shafts | 120-180 | 0.04-0.12 | 0.3-1.2 | 0.6-1.2 |

| Stainless Components | 90-150 | 0.03-0.10 | 0.3-1.0 | 0.8-1.6 |

| Copper Windings | 200-400 | 0.05-0.15 | 0.4-2.0 | 0.5-1.0 |

| Electrical Steel | 60-100 | 0.02-0.08 | 0.2-0.8 | 1.0-2.0 |

4. Critical Component Manufacturing

4.1 Motor Housing and Frame Production

The manufacturing of housings for robotic servo motor requires precise control of dimensional accuracy, thermal management characteristics, and structural integrity.

Housing Manufacturing Process:

-

Precision Boring: Achieving bearing seat tolerances within ±0.003mm with surface finish Ra 0.4μm

-

Thermal Management Features: Optimized cooling fin geometry with calculated surface area for heat dissipation

-

Mounting Interface Machining: Precise flange and base machining for accurate alignment within 0.01mm

-

Sealing Surface Preparation: Specialized finishing for effective IP65/67 sealing performance

Quality Parameters for Servo Motor Housings:

-

Bore concentricity: 0.008mm maximum

-

Flatness: 0.012mm per 100mm

-

Surface finish: Ra 0.8-1.6μm for sealing surfaces

-

Thread quality: Class 4H or better for mounting features

4.2 Rotor and Shaft Manufacturing

The production of rotating components for robotic servo motor demands exceptional attention to balance, straightness, and electromagnetic performance.

Rotor Manufacturing Techniques:

-

Magnet Slot Machining: Precision slots within ±0.005mm positional accuracy

-

Dynamic Balancing: High-speed balancing to G1.0 quality grade

-

Surface Grinding: Achieving diameter tolerances within ±0.0025mm

-

Hard Turning: Precision machining of hardened materials to Ra 0.4μm

Critical Rotor Specifications:

-

Straightness: 0.008mm per 300mm maximum

-

Surface hardness: 45-60 HRC depending on application

-

Runout: 0.010mm maximum at bearing journals

-

Balance quality: G1.0 for standard applications, G0.4 for high-speed applications

5. Thermal Management Solutions

5.1 Advanced Cooling Technologies

Effective thermal management is crucial for maintaining performance and longevity in robotic servo motor systems, particularly in high-duty-cycle applications.

Cooling Method Comparison:

| Cooling Method | Heat Dissipation Capacity | Complexity | Cost Factor | Typical Applications |

|---|---|---|---|---|

| Natural Convection | 10-30 W/in² | Low | 1.0x | Small motors, low duty cycle |

| Forced Air Cooling | 30-80 W/in² | Medium | 1.5-2.0x | General industrial servos |

| Liquid Cooling | 80-300 W/in² | High | 3.0-5.0x | High-performance applications |

| Conduction Cooling | 50-120 W/in² | Medium | 2.0-3.0x | Compact designs, harsh environments |

| Phase Change Cooling | 150-600 W/in² | Very High | 5.0-10.0x | Extreme performance applications |

5.2 Integrated Thermal Management Features

Advanced Cooling Solutions:

-

Spiral Cooling Channels: Optimized fluid paths within motor housings for maximum heat transfer

-

Heat Pipe Integration: Passive cooling for high heat flux areas in compact designs

-

Thermal Interface Materials: Advanced compounds with 3-8 W/m·K conductivity

-

Composite Materials: Thermally conductive polymers and metal composites for lightweight solutions

6. Precision Bearing and Alignment Systems

6.1 Bearing Selection and Integration

The performance and lifespan of robotic servo motor are heavily dependent on proper bearing selection and precision installation.

Bearing Technology Comparison:

| Bearing Type | Speed Factor | Load Capacity | Stiffness | Life Expectancy |

|---|---|---|---|---|

| Deep Groove Ball | 1.0x | Medium | Medium | 20,000 hours |

| Angular Contact | 1.4x | High | High | 30,000 hours |

| Cylindrical Roller | 0.8x | Very High | Very High | 25,000 hours |

| Hybrid Ceramic | 1.6x | Medium | High | 40,000 hours |

| Magnetic Bearings | 3.0x | Low | Low | 100,000+ hours |

6.2 Alignment and Mounting Precision

Critical Alignment Parameters:

-

Shaft alignment: 0.020mm maximum offset

-

Parallelism: 0.012mm per 100mm

-

Bearing preload: Controlled within 2-5% of design specification

-

Thermal expansion accommodation: Designed for operational temperature range of -40°C to +150°C

7. Quality Assurance and Testing Protocols

7.1 Comprehensive Metrology Systems

The verification of robotic servo motor components employs advanced measurement technologies and rigorous inspection protocols.

Dimensional Metrology:

-

Coordinate Measuring Machines: Volumetric accuracy to 1.8 + L/300 μm with temperature compensation

-

Roundness Measuring Instruments: Accuracy to 0.025μm with harmonic analysis capability

-

Surface Roughness Testers: Ra measurement capability to 0.01μm with 3D topography

-

Optical Comparators: Magnification to 100x with digital measurement and documentation

Electrical Testing:

-

Hi-Pot Testing: Dielectric strength verification at 2U + 1000V for 60 seconds

-

Insulation Resistance: Megohm testing at 500V DC with minimum 100MΩ requirement

-

Winding Resistance: Four-wire measurement to 0.1% accuracy with temperature compensation

-

Surge Testing: Turn-to-turn insulation integrity verification at 2.5-3.0kV

7.2 Performance Validation

Dynamic Testing Protocols:

-

Efficiency Mapping: Input-output power measurement across operating range with 0.2% accuracy

-

Thermal Performance: Temperature rise verification under load with infrared thermography

-

Vibration Analysis: FFT analysis to identify resonant frequencies with 0.01g resolution

-

Noise Testing: Acoustic performance measurement in semi-anechoic chambers to 20dBA

Environmental Testing:

-

Thermal Cycling: -40°C to +150°C temperature range testing with 500 cycles minimum

-

Vibration Endurance: Random and sine vibration per MIL-STD-810H specifications

-

IP Rating Verification: Ingress protection testing for IP65/67/69K ratings

-

Salt Spray Testing: Corrosion resistance verification per ASTM B117 for 500 hours

8. Application Case Studies

Case Study 1: High-Speed Delta Robot for Packaging

Challenge: A packaging automation company required high-performance robotic servo motor for a new generation of delta robots operating at 500 cycles per minute with positional accuracy of ±0.05mm. The existing systems experienced thermal issues and bearing failures after 1,200 hours.

JLYPT Solution: We developed custom robotic servo motor using aluminum 7075-T6 for structural components and integrated liquid cooling channels. The manufacturing process incorporated 5-axis simultaneous machining for complex housing geometries and precision grinding for shaft components. Special attention was paid to thermal management and bearing alignment.

Results:

-

Achieved continuous operation at 550 cycles per minute

-

Maintained positional accuracy within ±0.03mm

-

Extended service life to 15,000 hours between maintenance

-

Reduced energy consumption by 22% through improved efficiency

Case Study 2: Semiconductor Wafer Handling Robot

Challenge: A semiconductor equipment manufacturer needed ultra-clean robotic servo motor for wafer handling robots with minimal particle generation and exceptional reliability in vacuum environments.

JLYPT Solution: Our engineering team designed specialized robotic servo motor using stainless steel 17-4PH with mirror-like surface finishes (Ra 0.2μm). The manufacturing process emphasized debris-free assembly techniques and specialized lubrication systems compatible with vacuum environments. All components underwent rigorous cleaning and packaging procedures.

Results:

-

Achieved particle generation rates below Class 1 cleanroom requirements

-

Maintained performance through 25,000 hours of continuous operation

-

Enabled 35% faster wafer transfer cycles through higher acceleration

-

Reduced maintenance downtime by 85% through extended service intervals

Case Study 3: Heavy-Duty Industrial Manipulator

Challenge: An automotive manufacturer required robust robotic servo motor for material handling robots with 800kg payload capacity and high shock load resistance. The existing systems experienced structural failures and bearing damage under heavy loads.

JLYPT Solution: We implemented heavy-duty robotic servo motor using alloy steel 4140 with through-hardening to 40 HRC. The design incorporated increased shaft diameters and optimized bearing arrangements for higher impact resistance. Precision machining after heat treatment maintained geometric accuracy while achieving compressive residual stresses.

Results:

-

Achieved shock load capacity of 700% rated torque

-

Maintained performance through 18,000 hours of heavy-duty operation

-

Reduced maintenance requirements by 75%

-

Improved positioning repeatability for consistent operation

9. Future Trends and Innovations

9.1 Emerging Technologies

The evolution of robotic servo motor technology continues with several promising directions:

Advanced Materials:

-

Carbon Nanotube Composites: Revolutionary strength-to-weight ratios with 5x current capacity

-

High-Temperature Superconductors: Dramatically increased power density with near-zero losses

-

Shape Memory Alloys: Adaptive performance characteristics based on operational conditions

-

Metamaterials: Customized thermal and electromagnetic properties for optimized performance

Digital Integration:

-

Embedded Fiber Optic Sensors: Real-time temperature, vibration, and load monitoring

-

IoT Connectivity: Remote monitoring and predictive maintenance capabilities with cloud analytics

-

Digital Twins: Virtual modeling and performance optimization with real-time synchronization

-

AI-Driven Control: Adaptive performance based on operational conditions and wear patterns

9.2 Manufacturing Technology Advances

The future of robotic servo motor manufacturing includes:

Additive Manufacturing:

-

Complex Cooling Channels: Optimized thermal management geometries impossible with traditional machining

-

Integrated Structures: Combined multiple components into single pieces reducing assembly time

-

Customized Designs: Application-specific optimization through generative design algorithms

-

Lightweight Structures: Topology-optimized weight reduction with maintained stiffness

Sustainable Manufacturing:

-

Energy-Efficient Processes: Reduced environmental impact through optimized machining parameters

-

Recyclable Materials: Closed-loop material usage with 95% recycling rates

-

Green Manufacturing: Environmentally conscious production methods with carbon neutrality goals

-

Lifecycle Optimization: Design for extended service life and complete recyclability

10. Industry Standards and Compliance

10.1 International Standards

Robotic servo motor manufacturing must comply with numerous international standards:

Safety and Performance Standards:

-

IEC 60034: Rotating electrical machinery standards

-

ISO 13849: Safety-related parts of control systems

-

UL 1004: Standard for rotating electrical machines

-

CE Marking: European conformity for health, safety, and environmental protection

Quality Management:

-

ISO 9001: Quality management systems certification

-

ISO 14001: Environmental management systems

-

IATF 16949: Automotive quality management system

Conclusion: Engineering Excellence in Robotic Motion Systems

Robotic servo motor technology represents the pinnacle of precision engineering in modern automation systems. The ten manufacturing techniques explored—advanced material selection, precision CNC machining, thermal management, bearing integration, quality assurance, electrical optimization, application-specific engineering, performance validation, future innovation, and standards compliance—demonstrate the comprehensive approach required to produce components that meet the exacting demands of contemporary robotic applications.

As robotic technology continues to advance, the requirements for robotic servo motor systems will become increasingly demanding, driving further innovation in manufacturing technologies and material science. The integration of digital technologies, advanced analytics, and sustainable manufacturing practices will ensure that servo motor technology remains at the forefront of industrial innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every robotic servo motor component we produce meets the highest standards of performance, reliability, and efficiency. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of capability and performance in their automated systems.

For engineering teams seeking to enhance their robotic systems through superior servo motor components, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.