The Precision Link: A Guide to SCARA Robot Manufacturers for CNC Machining Automation

Introduction: The Need for Speed and Precision in Modern Manufacturing

In the high-stakes world of modern manufacturing, efficiency is measured in seconds and quality in microns. As a leader in precision CNC machining, JLYPT understands that the journey of a component—from a raw billet of aerospace-grade titanium or medical-grade stainless steel to a finished part with tolerances as tight as ±0.005mm—is a symphony of subtractive processes. However, the true potential of these exquisitely machined components is often unlocked only when they are assembled, inspected, and integrated into larger systems. This is where the domain of CNC machining converges with the realm of advanced robotics, specifically with a workhorse of automation: the SCARA robot.

Selective Compliance Articulated Robot Arm (SCARA) robots, manufactured by industry giants and specialized firms, are the unsung heroes of high-speed, high-precision post-machining operations. For manufacturers leveraging 5-axis CNC milling and 7-axis hybrid machining for complex geometries, integrating a SCARA system for downstream tasks is a logical and powerful step towards a closed-loop, lights-out manufacturing cell. This guide is designed for manufacturing engineers, automation specialists, and production managers seeking to understand the landscape of SCARA robot manufacturers. We will dissect the core technology, compare leading manufacturers, and illustrate through detailed case studies how the right SCARA robot, fed by precision CNC-machined parts, can dramatically elevate throughput, consistency, and overall equipment effectiveness (OEE).

Section 1: SCARA Robot Fundamentals – Why They are Ideal for Post-CNC Operations

Before evaluating manufacturers, it’s crucial to understand the inherent design advantages of the SCARA architecture that make it a perfect partner for CNC-machined components.

1.1 Kinematic Design for Planar Speed and Precision

Unlike their 6-axis articulated cousins, SCARA robots are built with a rigid, vertically oriented structure and two parallel rotary joints in the horizontal plane. This design grants them two superpowers:

-

Extremely High Speed and Repeatability: The simple, rigid arm structure allows for incredibly fast acceleration and deceleration in the X-Y plane. Leading SCARA robot manufacturers like Epson and Yamaha design models with cycle times under 0.3 seconds for standard moves, with repeatability often exceeding ±0.01mm. This makes them ideal for rapid pick-and-place of machined parts from a conveyor to a fixture or between process stations.

-

Inherent Vertical Rigidity: The column is designed to be very stiff in the Z-axis. When combined with a precision ball screw or belt drive for vertical motion, this provides excellent downward force for tasks like precision assembly, inserting machined pins into housings, or applying consistent force during screw driving or snap-fitting operations.

1.2 The Perfect Match for CNC Output

CNC machining produces parts with predictable, precise geometries. SCARA robots excel in structured environments that leverage this predictability:

-

Machine Tending: A SCARA robot can unload a finished part from a CNC mill or lathe and load a raw blank with unmatched speed, minimizing machine idle time. Their footprint is often smaller than a 6-axis robot, making them easier to integrate into dense shop floor layouts.

-

Post-Process Handling: After machining, parts often require secondary operations—deburring, washing, laser marking, or surface finishes like passivation or electropolishing. A SCARA robot can shuttle parts through these sequential stations with clockwork reliability.

-

Precision Assembly and Inspection: The marriage of a CNC-machined component (like an aluminum actuator housing from JLYPT) and a SCARA robot is seen in assembly cells. The robot can pick sensors, fasteners, or other sub-components and assemble them into the machined part with vision-guided accuracy, followed by automated optical inspection (AOI).

Table 1: Core Performance Metrics for SCARA Robots in Precision Manufacturing

| Performance Metric | Why It Matters for CNC-Based Cells | Typical High-Performance SCARA Range | Impact on Production |

|---|---|---|---|

| Repeatability (Positioning Accuracy) | Determines if the robot can reliably place a part into a tight-tolerance fixture or mate components within spec. | ±0.01mm to ±0.02mm | Ensures assembly quality, prevents jamming, and protects high-value machined parts from damage. |

| Cycle Time / Pick-and-Place Speed | Directly impacts throughput and the ability to keep up with CNC machine cycles or high-volume assembly lines. | 0.25 – 0.4 seconds (for standard 25mm move) | Maximizes OEE by reducing non-cut time. Enables one robot to service multiple machines. |

| Payload Capacity | Must support the weight of the heaviest part plus the end-effector (gripper, vacuum tool, screwdriver). | 3kg – 20kg+ (standard industrial models) | Defines the scope of parts the cell can handle. Critical for handling steel or multiple parts per cycle. |

| Vertical Stroke (Z-axis travel) | Determines the height difference it can bridge, e.g., from a deep parts bin to a raised conveyor. | 200mm – 600mm+ | Influences cell layout flexibility and the ability to handle parts with significant height or work with pallet stacks. |

| Controller and Integration Features | Ease of connecting to CNC machine PLCs, vision systems, and force sensors for adaptive tasks. | Ethernet/IP, Profinet, EtherCAT, built-in vision processing. | Reduces integration time and cost. Enables smart, responsive cells with error recovery. |

Section 2: The Competitive Landscape: A Comparative Analysis of Leading SCARA Robot Manufacturers

The global market for SCARA robots is dominated by a few key players, each with distinct strengths and philosophical approaches to design and control.

The Established Titans: Fanuc, Epson, and Yamaha

These SCARA robot manufacturers represent the gold standard for reliability, speed, and global support.

-

Fanuc (Japan): Synonymous with industrial robustness. Fanuc SCARAs, like the SR-3iA and SR-12iA, are known for their brute-force reliability in the harshest environments (e.g., near grinding or foundry operations). Their strength lies in seamless integration with Fanuc CNCs, allowing for unified control in a factory setting. The trade-off can be a proprietary ecosystem and a controller that prioritizes robustness over the simplest programming.

-

Epson (Japan): The perennial leader in precision and speed. Epson’s philosophy, stemming from its watchmaking heritage, focuses on ultra-high accuracy and vibration minimization. Their T-Series SCARAs are legendary for fast, delicate tasks in electronics assembly. Epson also pioneered integrated vision systems (RC+ vision), making them a top choice for vision-guided precision tasks right out of the box.

-

Yamaha (Japan): A leader in innovative mechanical design and cost-effectiveness. Yamaha offers an exceptionally wide range of SCARA models, including dual-arm and linear-track configurations. They are often praised for providing high performance at a competitive price point and for their flexibility in cell design, making them a favorite for OEMs and system integrators.

The Challengers and Specialists: Mitsubishi, Denso, and Stäubli

-

Mitsubishi Electric (Japan): Offers a strong balance of performance, precision, and user-friendly programming with their MELFA series. They excel in providing total automation solutions, with strong integration between their robots, CNCs, and PLCs.

-

Denso (Japan): Originally developed for its own demanding automotive assembly lines, Denso robots are compact, fast, and incredibly durable. They are a “manufacturer’s manufacturer” choice, known for exceptional longevity and precision in high-cycle applications.

-

Stäubli (Switzerland): Represents the pinnacle of European precision engineering. While including SCARA in its lineup, Stäubli is renowned for its unmatched accuracy and sealed models for cleanroom applications (e.g., medical device or semiconductor manufacturing). They command a premium price for premium performance in the most demanding environments.

Table 2: Comparative Analysis of Major SCARA Robot Manufacturers

| Manufacturer | Core Brand Strength | Typical Application Focus | Controller & Integration Notes | Ideal For CNC Shops That… |

|---|---|---|---|---|

| Fanuc | Industrial Ruggedness, Ecosystem Integration | High-duty cycle machine tending, heavy part handling, welding. | Fanuc CNC-style controller. Excellent with Fanuc CNCs but can be complex. | Already use Fanuc CNCs and want minimal integration friction in harsh environments. |

| Epson | Ultra-High Speed & Precision, Integrated Vision | Electronics assembly, micro-dispensing, high-speed pick-and-place of small parts. | User-friendly RC+ suite with powerful built-in vision. | Produce small, high-value parts (medical, optics, electronics) requiring flawless precision. |

| Yamaha | Design Flexibility & Cost-Performance | Diverse applications from food packaging to automotive modules; dual-arm cells. | Flexible and programmer-friendly. Wide communication protocol support. | Need versatile, cost-effective automation for a varied part mix and innovative cell layouts. |

| Mitsubishi | Balanced Performance & Ease of Use | General assembly, material handling, coordinated tasks with other Mitsubishi gear. | Intuitive programming (RT ToolBox). Integrates well with their PLCs and CNCs. | Value a smooth learning curve and have a mix of mid-volume assembly and tending tasks. |

| Denso | Compact Durability & High-Cycle Reliability | Automotive component assembly, relentless high-speed sorting, precision testing. | Compact controller. Known for exceptional uptime in demanding 24/7 cycles. | Run high-volume production with a focus on maximizing uptime and minimizing maintenance. |

| Stäubli | Supreme Accuracy & Cleanroom Specialization | Medical device assembly, semiconductor handling, sensitive laboratory automation. | High-end, precise control. Offers absolute cleanliness (ISO Class 1 capable). | Manufacture for medical, pharma, or semiconductor sectors where contamination control is critical. |

Section 3: Integration Imperatives – The CNC Machining Perspective

Selecting a SCARA robot is only half the battle. Successful integration into a workflow that starts with CNC machining requires careful engineering.

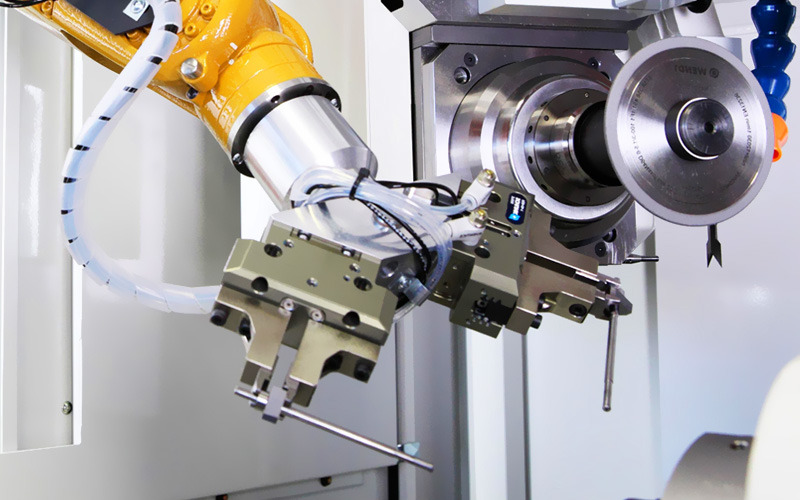

The Critical Interface: End-of-Arm Tooling (EOAT) Design

The robot’s “hand” must be as precise as the robot itself. For handling CNC-machined parts, EOAT design is paramount:

-

Gripper Selection: Mechanical grippers must locate on non-critical datum surfaces without marring finished areas (e.g., an anodized or electropolished surface). Vacuum grippers are excellent for flat, non-porous surfaces but require a perfect seal.

-

Custom Jaws and Adapters: The interface between the gripper and the part often requires custom, precision-machined soft jaws or fixtures. This is where JLYPT’s expertise becomes invaluable—producing CNC-machined aluminum or steel jaw profiles that grip the part securely and repeatably, ensuring the robot’s inherent accuracy is fully realized.

Communication and Synchronization with the CNC Cell

The robot and CNC machine must operate as one system.

-

I/O Interlocks: Basic communication involves digital I/O signals: “CNC Door Open,” “Part Ready,” “Robot Clear.” This handshake ensures safe, sequenced operation.

-

Higher-Level Integration: Advanced cells use fieldbus networks (Ethernet/IP, PROFINET) to exchange more data. The robot controller might receive a part ID from the Manufacturing Execution System (MES), select the correct program, and even feed back assembly verification data.

Section 4: Case Studies – SCARA Robots in Action with Precision Machined Parts

Case Study 1: Automotive Sensor Manufacturer – High-Speed Assembly & Testing

-

Challenge: A supplier of machined aluminum engine sensor housings needed to assemble a ceramic sensing element, a spring, and a connector, then perform a 100% electrical function test. Manual assembly was slow and testing was a bottleneck.

-

Solution: A Yamaha dual-arm SCARA robot cell was implemented. One arm, equipped with a vision-guided precision gripper, assembled the internal components into the housing (machined by JLYPT to ±0.02mm tolerances). The second arm picked the assembled unit and placed it into a custom test fixture. The test results were digitally logged against the part’s serial number, engraved by laser marking in a previous step.

-

Outcome: Assembly and test cycle time reduced by 65%. Quality data became fully traceable. The dual-arm design allowed simultaneous assembly and testing, doubling the effective throughput of a single station.

Case Study 2: Medical Device OEM – Sterile Packaging Loading

-

Challenge: After machining and cleaning, titanium orthopedic implants needed to be loaded into sterile barrier packaging trays. Manual loading in a cleanroom was a contamination risk and limited output.

-

Solution: A Stäubli cleanroom-certified SCARA robot was installed in a Class 7 cleanroom environment. The robot used a sterile, smooth-surface gripper to pick implants from a washing basket and place them into nest pockets within a polymer tray. The cell was integrated with a vision system to verify correct implant orientation and tray pocket occupancy before sealing.

-

Outcome: Contamination risk from human handling was eliminated. Throughput increased by 50% while ensuring 100% placement accuracy. The system met all FDA guidelines for aseptic processing, providing impeccable documentation for audits.

Case Study 3: Consumer Electronics – CNC Machined Enclosure Final Assembly

-

Challenge: A company producing high-end audio equipment used intricate, CNC-machined aluminum enclosures. Final assembly required placing a circuit board, aligning it with machined standoffs, and driving four miniature screws.

-

Solution: An Epson G-Series SCARA robot with integrated force sensing was deployed. The robot picked the circuit board using a vacuum cup, used vision to align it with the machined features of the enclosure, and then used a servo-electric screwdriver attachment to drive the screws. The force sensor ensured perfect torque control without stripping the threads in the delicate aluminum.

-

Outcome: This eliminated potential damage from manual misalignment or over-torquing. Assembly consistency was perfect, and the cell could run unattended, feeding completed assemblies to a laser-engraving station.

Conclusion: Building the Automated Value Chain

For precision manufacturers, the journey from raw material to shipped product is a chain of value-adding steps. SCARA robot manufacturers provide the critical technology to automate the links in that chain that follow the CNC machining process. The choice of manufacturer—be it the rugged integration of Fanuc, the blistering precision of Epson, or the flexible innovation of Yamaha—must be driven by the specific requirements of the parts being produced and the tasks being automated.

The synergy is clear: Precision CNC machining creates components of exacting geometry. Precision SCARA robotics handles and assembles those components with matching exactitude. By understanding the landscape of SCARA robot manufacturers and focusing on seamless integration—especially the design of precision EOAT and robust communication—manufacturers can build automated cells that are faster, more reliable, and of higher quality than any manual process.

This automated value chain is the future of competitive manufacturing. It protects the investment made in high-tolerance machining by ensuring every subsequent step is performed with equal care and precision.

Ready to explore how precision robotics can complete your automated manufacturing workflow? Contact JLYPT to discuss how our machined components and systems expertise can form the foundation of your next high-performance automation cell. Learn more about our capability-driven approach at JLYPT CNC Machining Services.