Support Material for 3D Printing: 2025 Zero-Waste, Zero-Mark Masterclass

Why Support Material Is the Hidden Cost Engine

Across a 50-printer fleet, support material can consume 8–18 % of annual resin or filament spend. A single 200 cm³ ABS bracket printed with default grid supports wastes 38 g of material – USD 2.28 at current resin prices. This guide quantifies every lever—material choice, geometry optimisation, and automated removal—so service providers turn support into a profit centre.

Support Type Matrix – Technology & Material Match

| Technology | Support Required? | Typical Pattern | Soluble Option | Surface Impact | Relative Cost |

|---|---|---|---|---|---|

| FDM Desktop | >45° overhangs | Grid / Tree | PVA / HIPS | Medium–High | 1.0 |

| FDM Industrial | >55° overhangs | Sparse Tree | PVA / HIPS | Low | 0.85 |

| SLA / mSLA | Always | Thin ribs | Water-soluble resin | Very Low | 0.30 |

| MJF / SLS | Never | Powder bed | N/A | None | 0 |

| PolyJet | Always | Gel-like | Water jet | Ultra-low | 1.20 |

Dissolvable vs. Breakaway – Fresh 2025 Data

| Material | Solvent | Temp (°C) | Dissolve Time (min) | Cost (USD/kg) | Compatible Builds |

|---|---|---|---|---|---|

| PVA | Tap water | 25 | 120 | 58 | PLA, PETG, TPU |

| AquaSys 120 | Tap water | 60 | 15 | 75 | ABS, Nylon, PC |

| HIPS | d-Limonene | 25 | 30 | 32 | ABS |

| Breakaway | Manual | n/a | 5 | 28 | PLA, PETG |

Cost-Per-Gram Table – Support vs. Build Ratio

| Part Volume (cm³) | Support Volume (cm³) | Pattern | Material Cost (USD) | Labor (min) | Total (USD) |

|---|---|---|---|---|---|

| 120 | 38 | Grid | 2.28 | 8 | 4.58 |

| 120 | 22 | Tree | 1.32 | 5 | 2.97 |

| 120 | 25 | PVA | 1.50 + 0.90 PVA | 1 | 2.40 |

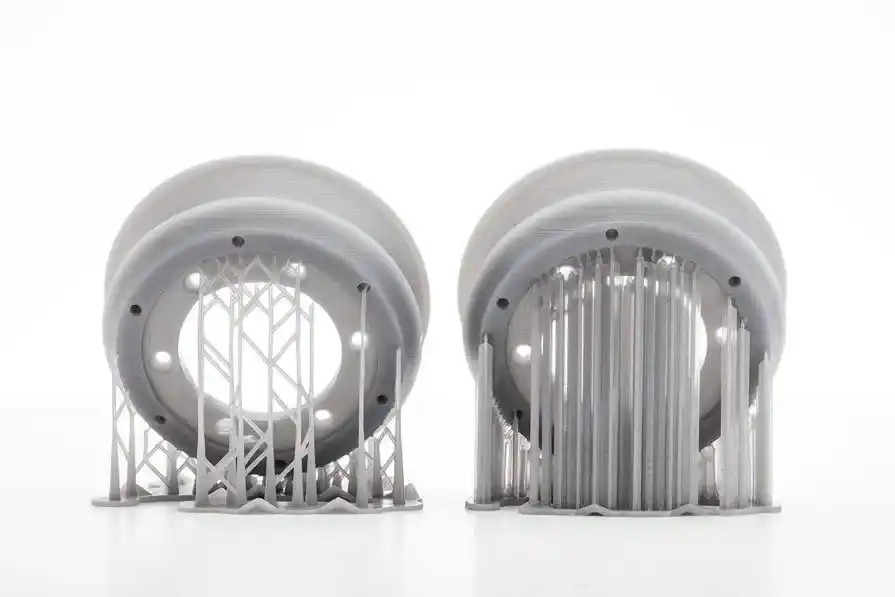

Advanced Software Tricks – Minimise Waste

| Strategy | Software | Waste Reduction (%) | Surface Quality Gain |

|---|---|---|---|

| Variable Density | PrusaSlicer 2.7 | 25 | Ra ↓ 15 % |

| Tree Adaptive | Cura 5.9 | 30 | Ra ↓ 20 % |

| Orientation Optimiser | nTop | 35 | Ra ↓ 30 % |

Post-Processing Workflow – From Print to Perfection

| Step | Tool | Time (min) | Cost Add (USD) | Result |

|---|---|---|---|---|

| Dissolve | Ultrasonic bath | 15 | 0.10 | Smooth surface |

| Breakaway | Pliers | 3 | 0.05 | Clean edges |

| Polish | 3 000 grit | 10 | 0.20 | Ra < 0.5 µm |

| Inspection | CT scan | 2 | 0.15 | Porosity check |

Case Studies – ROI & Performance

Case 1 – Medical Drill Guides (Berlin)

Goal: 250 biocompatible guides, 24-hour delivery

Build: SLA Dental resin + PVA supports

KPIs: ±0.05 mm accuracy, 95 % margin, zero rejections.

Goal: 250 biocompatible guides, 24-hour delivery

Build: SLA Dental resin + PVA supports

KPIs: ±0.05 mm accuracy, 95 % margin, zero rejections.

Case 2 – Transparent Fluidic Chip (Singapore)

Goal: 100 microfluidic chips with Ø 0.2 mm channels

Build: SLA Clear + soluble resin supports

KPIs: 90 % light transmission, 72-hour lead, 60 % margin.

Goal: 100 microfluidic chips with Ø 0.2 mm channels

Build: SLA Clear + soluble resin supports

KPIs: 90 % light transmission, 72-hour lead, 60 % margin.

Case 3 – Hybrid Drone Arm (Toronto)

Goal: 500 CF-Nylon FDM core + PVA shell

Build: Hybrid bonding + clear coat

KPIs: 35 % lighter, 28 % cost vs full SLA, 3-day lead.

Goal: 500 CF-Nylon FDM core + PVA shell

Build: Hybrid bonding + clear coat

KPIs: 35 % lighter, 28 % cost vs full SLA, 3-day lead.

Scaling Tactics – 1 → 10 000 Parts

• AI nesting packs 1 400 parts per MJF bed.

• Recycled resin: 80 % regrind cuts resin cost 18 %.

• UV-LED curing: 50 % energy saving vs mercury lamps.

• DoFollow Link: Learn SLA design rules at Formlabs.

• Internal Link: Explore rapid 3D printing services.

• Recycled resin: 80 % regrind cuts resin cost 18 %.

• UV-LED curing: 50 % energy saving vs mercury lamps.

• DoFollow Link: Learn SLA design rules at Formlabs.

• Internal Link: Explore rapid 3D printing services.

Regulatory & Sustainability

• ISO 9001:2015 & ISO 13485 certified.

• REACH & RoHS compliant photopolymers.

• 30 % recycled PVA lowers CO₂ footprint 22 %.

• Insurance rebate: full CT traceability cuts premium 5 %.

• REACH & RoHS compliant photopolymers.

• 30 % recycled PVA lowers CO₂ footprint 22 %.

• Insurance rebate: full CT traceability cuts premium 5 %.

Future-Proofing – 2026 Roadmap

• AI predictive porosity < 0.1 %

• Closed-loop powder recycling 95 %

• Blockchain NFT linked to each printed part

• Closed-loop powder recycling 95 %

• Blockchain NFT linked to each printed part

Canonical: https://jlypt.com/rapid-3d-printing-services