The Definitive Guide to Titanium Nitride (TiN) Coating Services: Engineering Surfaces for Peak Performance

Introduction: The Golden Standard in Precision Surface Engineering

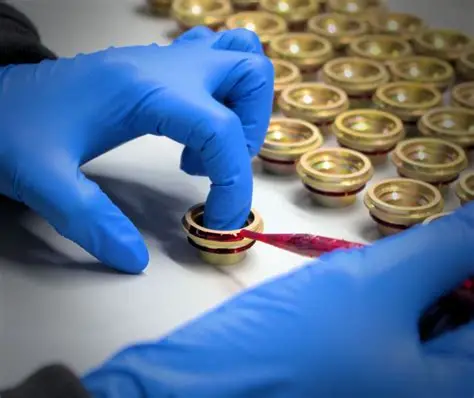

In the demanding landscape of precision manufacturing, where tool longevity, component performance, and process reliability are paramount, Titanium Nitride (TiN) coating services represent a transformative surface enhancement technology. This distinctive gold-colored ceramic coating, applied through advanced Physical Vapor Deposition (PVD) processes, has evolved from a specialty treatment into an essential manufacturing solution across industries. At JLYPT, we have perfected the integration of TiN coating services with our precision CNC machining capabilities, creating components and tools that deliver measurable performance advantages: up to 800% extended tool life, 50% reduction in friction coefficients, and significantly improved resistance to wear, corrosion, and thermal fatigue.

The characteristic auriferous appearance of TiN belies its exceptional material properties—a synergistic combination of extreme hardness (up to 2400 HV), chemical inertness, and thermal stability that is metallurgically bonded to the substrate at the atomic level. Unlike electroplated coatings or simple surface treatments, TiN coating services utilize vacuum deposition physics to create a dense, uniform layer that becomes an integral part of the component’s functional surface. This engineering approach allows manufacturers to specify surface characteristics independently from the substrate material, enabling high-speed steel tools to perform like premium carbides, or stainless steel components to withstand environments that would rapidly degrade untreated surfaces.

This comprehensive technical guide explores the complete spectrum of TiN coating applications, methodologies, and benefits. We will analyze the plasma physics behind modern PVD deposition, the microstructural characteristics that define TiN’s performance, and the precise pretreatment protocols necessary for optimal adhesion on CNC-machined components. For engineers specifying cutting tools for hardened alloys, medical instruments requiring biocompatible surfaces, or precision components operating in corrosive environments, understanding TiN coating technology represents the critical difference between adequate performance and exceptional longevity. Discover how our integrated approach at JLYPT PVD Coating Services transforms precision-machined components into high-performance systems through engineered surface enhancement.

The Material Science of Titanium Nitride: Engineering at the Atomic Scale

To appreciate the transformative impact of TiN coating services, one must first understand the fundamental material properties that make this ceramic coating uniquely valuable for demanding applications.

Crystalline Structure and Bonding Characteristics

Titanium Nitride possesses a face-centered cubic (FCC) crystal structure (NaCl-type, space group Fm3m) where titanium and nitrogen atoms occupy alternating lattice positions. This arrangement creates a combination of metallic, covalent, and ionic bonding:

-

Metallic Bonding: Between titanium atoms provides electrical conductivity (resistivity approximately 25 μΩ·cm) and thermal conductivity

-

Covalent Bonding: Between titanium and nitrogen atoms contributes exceptional hardness and chemical stability

-

Ionic Bonding: Component adds to the compound’s thermal stability and oxidation resistance

The strength of these bonds results in remarkable material properties that exceed those of the constituent elements, a phenomenon known as “compound hardening.”

Key Mechanical and Physical Properties

-

Hardness: Typically 2000-2400 HV (Vickers hardness), equivalent to approximately 80-85 HRC, significantly harder than hardened tool steels (60-65 HRC)

-

Elastic Modulus: 250-600 GPa (depending on deposition parameters and microstructure), providing excellent stiffness and load-bearing capacity

-

Coefficient of Friction: 0.4-0.6 against most materials (dry), reduced to 0.2-0.4 with lubricants, significantly lower than uncoated steel (0.6-0.8)

-

Thermal Stability: Maintains properties to approximately 600°C in air before significant oxidation begins

-

Thermal Expansion Coefficient: 9.4 × 10⁻⁶ K⁻¹, relatively close to many tool steels (11-13 × 10⁻⁶ K⁻¹), minimizing thermal stress at interfaces

-

Density: 5.22 g/cm³, creating a relatively lightweight coating that adds minimal mass to components

Chemical and Electrochemical Characteristics

-

Chemical Inertness: Exceptional resistance to most acids (except hydrofluoric and hot concentrated acids), alkalis, and organic solvents

-

Oxidation Resistance: Forms a protective titanium oxide layer at elevated temperatures, protecting the underlying coating and substrate

-

Biocompatibility: Certified for medical applications (ISO 10993), non-toxic and non-allergenic

-

Electrochemical Potential: Approximately -0.1 V vs. SCE (saturated calomel electrode), providing galvanic protection to steel substrates

Table 1: Titanium Nitride Properties vs. Common Engineering Materials

| Property | Titanium Nitride (TiN) | Hardened Tool Steel | Tungsten Carbide | Uncoated HSS |

|---|---|---|---|---|

| Hardness (HV) | 2000-2400 | 700-900 | 1400-1800 | 800-900 |

| Young’s Modulus (GPa) | 250-600 | 200-210 | 500-700 | 200-210 |

| Coefficient of Friction (dry) | 0.4-0.6 | 0.6-0.8 | 0.4-0.6 | 0.6-0.8 |

| Max Service Temp (°C) | 600 | 300-400 | 800-1000 | 300-400 |

| Thermal Conductivity (W/m·K) | 20-30 | 30-40 | 80-110 | 30-40 |

| Thermal Expansion (10⁻⁶/K) | 9.4 | 11-13 | 4.5-6.0 | 11-13 |

| Density (g/cm³) | 5.22 | 7.8-7.9 | 14-15 | 7.8-7.9 |

| Oxidation Onset (°C) | 550-600 | 400-500 | 500-600 | 400-500 |

PVD Deposition Methodologies for TiN Coatings

The performance characteristics of TiN coatings are profoundly influenced by the deposition methodology employed. Modern TiN coating services utilize several advanced PVD techniques, each with distinct advantages.

Cathodic Arc Evaporation (CAE)

This high-ionization process utilizes a high-current, low-voltage arc that travels across the surface of a titanium cathode, evaporating material through intense localized heating.

-

Process Characteristics: Plasma ionization >70%, high particle energy (10-100 eV), deposition rate 1-5 μm/hour

-

Coating Attributes: Excellent adhesion due to high particle energy, columnar microstructure with moderate density

-

Applications: Cutting tools, forming tools, components requiring maximum adhesion strength

-

Considerations: Potential for macroparticle (droplet) formation requiring filtration systems for precision applications

Magnetron Sputtering

A plasma is generated between a titanium target (cathode) and the substrates, with argon ions bombarding the target and dislodging titanium atoms through momentum transfer.

-

Process Characteristics: Lower ionization (5-10%), moderate particle energy (1-10 eV), deposition rate 0.5-3 μm/hour

-

Coating Attributes: Extremely smooth surfaces, dense microstructure, excellent thickness uniformity

-

Applications: Precision components, medical instruments, optical elements, electronics

-

Considerations: Lower deposition rates than arc evaporation, excellent for complex geometries

High Power Impulse Magnetron Sputtering (HiPIMS)

An advanced sputtering variant delivering extremely high power densities in short pulses, creating highly ionized plasma.

-

Process Characteristics: Ionization >70%, high particle energy (10-100 eV), deposition rate 0.5-2 μm/hour

-

Coating Attributes: Extremely dense, non-columnar microstructure, exceptional adhesion and smoothness

-

Applications: High-precision tools, medical implants, components requiring optimal coating density

-

Considerations: Highest equipment cost, lower deposition rates than conventional methods

Hybrid Processes

Advanced coating systems combine technologies to leverage their respective strengths:

-

Arc-enhanced sputtering: Combines high ionization of arc with smooth deposition of sputtering

-

Pulsed arc deposition: Modulates arc current to control macroparticle formation while maintaining high ionization

Table 2: TiN Deposition Technology Comparison

| Parameter | Cathodic Arc Evaporation | Magnetron Sputtering | HiPIMS | Hybrid Arc-Sputter |

|---|---|---|---|---|

| Ionization (%) | 70-90 | 5-10 | 70-90 | 40-80 |

| Particle Energy (eV) | 10-100 | 1-10 | 10-100 | 5-50 |

| Deposition Rate (μm/hr) | 1-5 | 0.5-3 | 0.5-2 | 1-4 |

| Coating Density | Moderate-High | High | Very High | High |

| Surface Roughness | May increase slightly | Maintains/improves | Improves | Maintains |

| Adhesion (Scratch Lc, N) | 40-70 | 30-50 | 50-80 | 40-70 |

| Macroparticle Issues | Possible (requires filtering) | None | None | Minimal |

| Optimal Thickness Range | 1-8 μm | 0.5-5 μm | 0.5-4 μm | 1-6 μm |

| Equipment Complexity | Moderate | Moderate | High | High |

Coating Architecture and Microstructural Engineering

Beyond simple monolithic layers, advanced TiN coating services employ sophisticated coating architectures to optimize performance for specific applications.

Monolithic TiN Layers

Single-layer TiN coatings provide excellent all-around performance for many applications:

-

Typical Thickness: 1-5 μm, optimized based on substrate hardness and application requirements

-

Microstructure: Columnar grains with preferential (111) or (200) orientation depending on deposition parameters

-

Stress State: Moderately compressive (1-3 GPa), enhancing crack resistance and fatigue life

Multilayer Architectures

Alternating TiN with other materials creates coatings with enhanced properties:

-

TiN/TiCN Multilayers: Increased toughness and wear resistance through crack deflection at interfaces

-

TiN/CrN Multilayers: Enhanced corrosion resistance with maintained hardness

-

TiN/TiAlN Multilayers: Improved high-temperature stability and oxidation resistance

-

Layer Periodicity: Typically 5-50 nm layer thickness, with optimal performance at specific periodicity-to-indentation depth ratios

Graded and Nanocomposite Structures

-

Compositionally Graded TiN: Gradual transition from titanium-rich interface to stoichiometric TiN surface minimizes interfacial stress

-

TiN-based Nanocomposites: TiN nanocrystals embedded in amorphous Si₃N₄ or BN matrices achieve hardness exceeding 30 GPa

-

Doped TiN: Addition of elements like aluminum, chromium, or yttrium tailors specific properties

Coating-Substrate Interface Engineering

The interface between coating and substrate critically determines coating performance:

-

Adhesion Layers: Thin chromium or titanium interlayers (50-200 nm) enhance bonding on difficult substrates

-

Plasma Interfacial Mixing: High-energy ion bombardment creates a graded transition zone

-

Substrate Bias Control: Negative bias voltage (50-200 V) during initial deposition enhances interface density

Substrate Preparation for Optimal TiN Performance

The efficacy of TiN coating services is fundamentally determined by substrate condition before deposition. Proper preparation ensures optimal adhesion and coating performance.

Surface Cleaning Protocols

-

Degreasing: Removal of oils, coolants, and organic contaminants through ultrasonic cleaning in alkaline solutions

-

Chemical Etching: Controlled removal of surface oxides and activation using acid solutions (HF/HNO₃ for titanium, HCl for steels)

-

Ultrasonic Rinsing: Multiple-stage deionized water rinsing with resistivity monitoring to eliminate ionic contamination

-

Drying: Forced air or vacuum drying to prevent water marks or recontamination

Surface Finishing Requirements

TiN coatings typically replicate and slightly amplify substrate surface topography:

-

Optimal Roughness: Ra 0.1-0.4 μm provides sufficient surface area for mechanical interlocking while allowing complete coating coverage

-

Directionality Elimination: Isotropic surface finishes (vapor honing, chemical polishing) provide more uniform coating adhesion than surfaces with pronounced machining lay

-

Defect Management: Removal of burrs, microcracks, and inclusions that create stress concentrations

In-situ Surface Activation

Immediately before deposition, substrates undergo surface activation:

-

Argon Plasma Etching: High-energy argon ions physically sputter remaining contaminants and create chemically active surface sites

-

Substrate Heating: Gradual heating to deposition temperature (typically 350-500°C) promotes diffusion and reduces thermal stress

-

Reverse Sputtering: Substrate bias during initial argon exposure enhances surface activation

Substrate Material Considerations

-

Tool Steels: Require proper heat treatment (hardness >50 HRC) and tempering below coating temperature

-

Carbides: Cobalt binder content affects coating adhesion; may require special etching treatments

-

Stainless Steels: Surface oxide removal critical; may benefit from nickel or chromium interlayers

-

Titanium Alloys: Require special etching to remove alpha case; benefit from graded interfaces

Table 3: Substrate Preparation Requirements for TiN Coating

| Substrate Material | Minimum Hardness | Optimal Roughness (Ra) | Pretreatment Sequence | Adhesion Promotion |

|---|---|---|---|---|

| HSS (M2, M35) | 62 HRC | 0.2-0.4 μm | 1. Ultrasonic degrease 2. Alkaline clean 3. Acid etch 4. Argon plasma etch |

None typically required |

| Tool Steel (D2, A2) | 58 HRC | 0.2-0.4 μm | 1. Vapor degrease 2. Electroclean 3. Acid activation 4. Plasma clean |

Chromium interlayer (50 nm) for highest adhesion |

| Carbide (WC-Co) | 88 HRA | 0.1-0.3 μm | 1. Ultrasonic clean 2. Chemical etch (Murakami’s reagent) 3. Acid etch 4. In-situ plasma |

None typically required |

| Stainless Steel | 30 HRC | 0.3-0.5 μm | 1. Alkaline clean 2. Electroclean 3. Passivation strip 4. Plasma activation |

Chromium or nickel interlayer (100-200 nm) |

| Titanium Alloys | 30 HRC | 0.3-0.5 μm | 1. Alkaline clean 2. HF/HNO₃ etch 3. DI rinse 4. Argon plasma |

None typically required |

| Aluminum | 60 HB | 0.4-0.6 μm | 1. Solvent clean 2. Alkaline clean 3. Deoxidize 4. Zincate treatment |

Titanium interlayer (100 nm) |

Performance Advantages of TiN Coatings

Wear Resistance and Tool Life Extension

TiN’s primary application remains cutting and forming tool enhancement:

-

Abrasive Wear Resistance: Hardness exceeding most workpiece materials reduces flank and crater wear

-

Adhesive Wear Reduction: Low chemical affinity with ferrous materials minimizes built-up edge formation

-

Tool Life Extension: Typically 3-8× increase in tool life for cutting applications, up to 10× for forming applications

-

Consistent Performance: Reduced performance degradation over tool life compared to uncoated tools

Friction Reduction and Galling Prevention

The low coefficient of friction and chemical inertness of TiN provides significant benefits:

-

Dry Machining Enablement: Reduced heat generation and chip adhesion facilitates dry or near-dry machining

-

Galling Prevention: Non-reactive surface minimizes material transfer in sliding contacts

-

Power Consumption Reduction: Lower friction reduces cutting forces and energy consumption

Corrosion and Chemical Resistance

TiN provides effective protection in challenging environments:

-

Salt Spray Resistance: Typically withstands 24-48 hours salt spray (ASTM B117) without substrate corrosion

-

Chemical Inertness: Resistant to most acids (except HF), alkalis, and industrial chemicals

-

Oxidation Resistance: Protective oxide formation at elevated temperatures (up to 600°C)

Thermal Management Benefits

-

Thermal Barrier: Lower thermal conductivity than most metals reduces heat transfer to substrate

-

Thermal Stability: Maintains properties at temperatures where tool steels would soften

-

Reduced Thermal Cracking: Lower coefficient of friction reduces heat generation during cutting

Table 4: TiN Coating Performance Enhancement by Application

| Application Type | Primary Benefit | Typical Improvement | Optimal Thickness | Key Performance Metrics |

|---|---|---|---|---|

| Cutting Tools (HSS) | Wear resistance | 3-6× tool life increase | 2-4 μm | Flank wear, crater depth, cutting force |

| Forming Tools | Galling prevention | 5-10× tool life increase | 3-5 μm | Surface finish, material pickup, forming force |

| Plastic Injection Molds | Release improvement | 4-8× service life | 1-3 μm | Part release force, cycle time, surface quality |

| Medical Instruments | Biocompatibility + wear | Sterilization cycles >1000 | 1-2 μm | Sharpness retention, corrosion resistance |

| Precision Components | Friction reduction | 50-70% friction reduction | 1-3 μm | Coefficient of friction, wear volume |

| Food Processing | Corrosion resistance | Sanitization cycles >5000 | 2-4 μm | Chemical resistance, cleanability |

| Aerospace Components | Thermal barrier | Oxidation resistance to 600°C | 3-6 μm | Oxidation rate, thermal cycling life |

Quality Assurance and Performance Validation

Comprehensive testing protocols ensure TiN coatings meet stringent performance requirements.

Coating Characterization

-

Thickness Measurement: Ball cratering (Calotest), X-ray fluorescence (XRF), or cross-sectional SEM

-

Hardness Testing: Nanoindentation with Berkovich tip at loads of 10-50 mN to avoid substrate influence

-

Adhesion Assessment: Scratch testing (critical load Lc), Rockwell indentation (VDI 3198), or tensile adhesion testing

-

Residual Stress Analysis: X-ray diffraction sin²ψ method or substrate curvature measurement

Functional Performance Testing

-

Wear Testing: Pin-on-disc (ASTM G99) or micro-abrasion testing to determine specific wear rates

-

Friction Measurement: Reciprocating or rotating tribometers under controlled conditions

-

Corrosion Testing: Electrochemical impedance spectroscopy, potentiodynamic polarization, or salt spray testing

-

Thermal Cycling: Repeated heating and cooling to evaluate coating stability and interfacial integrity

Microstructural Analysis

-

X-ray Diffraction: Phase identification, preferred orientation, and crystallite size determination

-

Scanning Electron Microscopy: Cross-sectional imaging of coating microstructure and interface quality

-

Energy Dispersive Spectroscopy: Elemental composition analysis and distribution mapping

Application-Specific Testing

-

Tool Life Testing: Actual machining tests with standardized parameters and workpiece materials

-

Medical Device Testing: ISO 10993 biocompatibility, sterilization cycle resistance, and fatigue testing

-

Food Contact Compliance: FDA CFR 21 and EU 10/2011 testing for food contact applications

Table 5: TiN Coating Quality Standards and Testing Protocols

| Quality Parameter | Test Method | Standard/Equipment | Acceptance Criteria | Testing Frequency |

|---|---|---|---|---|

| Coating Thickness | Ball Cratering | Calotest CSEM | ±0.5 μm of specification | First article & batch sampling |

| Adhesion Strength | Scratch Test | Revetest, ISO 20502 | Lc > 40 N (cutting tools) | First article & periodic |

| Surface Hardness | Nanoindentation | Fischerscope H100 | 2000-2400 HV | First article |

| Wear Resistance | Pin-on-Disc | ASTM G99 | Wear rate < 5×10⁻⁷ mm³/N·m | First article & material change |

| Coefficient of Friction | Pin-on-Disc | ASTM G99 | 0.4-0.6 (dry against steel) | First article |

| Corrosion Resistance | Salt Spray | ASTM B117 | 24 hours to first red rust | First article & quarterly |

| Coating Composition | EDS/XRF | SEM-EDS, Fischer XDV | Ti:N ratio 1:1 ± 0.1 | First article & target change |

| Surface Roughness | Profilometry | Taylor Hobson Form Talysurf | Ra < substrate + 0.1 μm | First article & setup |

Application Case Studies

Case Study 1: High-Volume Automotive Component Stamping Tools

Challenge: An automotive manufacturer experienced premature failure of progressive die components due to galling and abrasive wear when stamping high-strength steel (HSS 380 MPa). Tools required replacement after 50,000 cycles, causing production downtime and excessive tooling costs.

Solution: JLYPT implemented a multilayer TiN/TiCN coating on critical die components:

-

Substrate: D2 tool steel hardened to 60 HRC

-

Pretreatment: Precision polishing to Ra 0.2 μm followed by argon plasma etching

-

Coating Architecture: 1 μm TiN adhesion layer + 3 μm TiN/TiCN multilayer (50 nm periodicity)

-

Deposition Method: Cathodic arc evaporation with filtered arc for smooth surface finish

Results: Coated components achieved 480,000 cycles before requiring maintenance—an 860% improvement. Galling was eliminated, and abrasive wear was reduced by approximately 90%. The multilayer architecture provided enhanced toughness that resisted chipping in high-impact areas.

Case Study 2: Medical Orthopedic Surgical Instruments

Challenge: A medical device company needed to improve the performance of stainless steel (17-4PH) surgical reamers used in orthopedic procedures. Instruments lost sharpness after 3-5 procedures and showed staining after repeated sterilization cycles.

Solution: We applied a precision TiN coating optimized for medical applications:

-

Substrate Preparation: Precision sharpening followed by electrophishing to Ra 0.15 μm

-

Coating: 1.5 μm stoichiometric TiN deposited via magnetron sputtering for maximum smoothness

-

Post-coating: Passivation and sterilization validation per ISO 17664

Results: Coated reamers maintained sharpness through 25+ procedures and showed no staining after 100+ autoclave cycles. The instruments passed ISO 10993 biocompatibility testing and received 510(k) clearance. Surgeons reported improved cutting efficiency and reduced bone necrosis due to sharper cutting edges.

Case Study 3: Precision Gear Cutting Tools for Aerospace Applications

Challenge: A gear manufacturer producing high-precision aerospace gears from Inconel 718 needed to improve hob tool life and reduce form errors caused by tool wear. Uncoated carbide hobs produced only 30-40 gears before requiring resharpening.

Solution: We developed a customized TiN coating for carbide gear hobs:

-

Substrate: Micrograin carbide (10% cobalt) with precision grinding to form tolerances

-

Interface Engineering: 100 nm chromium interlayer for enhanced adhesion

-

Coating: 3 μm TiN with controlled (200) preferred orientation for optimal wear resistance

-

Deposition: Hybrid arc-sputter process for dense, adherent coating

Results: Coated hobs produced 180-220 gears before resharpening—a 450% improvement. Gear form errors were reduced by 60%, and surface finish improved from Ra 1.2 μm to Ra 0.8 μm. The reduced tool changes increased machine utilization by approximately 18%.

Future Developments in TiN Coating Technology

Advanced Coating Architectures

-

Nanoscale Multilayers: Layer periods approaching 2-5 nm for maximum hardness and toughness

-

Functionally Graded Coatings: Continuous composition variation optimized for specific stress distributions

-

Smart Coatings: TiN-based coatings with embedded sensors for wear condition monitoring

Process Innovations

-

HiPIMS Evolution: Further increases in ionization and deposition rates for enhanced coating properties

-

Hybrid PVD-PECVD: Combining physical vapor deposition with plasma-enhanced chemical vapor deposition for unique coating chemistries

-

In-situ Process Monitoring: Advanced plasma diagnostics and coating property monitoring for real-time process control

Sustainability Improvements

-

Energy-Efficient Deposition: Improved power supplies and process optimization reducing energy consumption by 30-40%

-

Target Utilization Enhancement: Advanced magnetron designs increasing material utilization from 30% to 60%+

-

Green Chemistry: Alternatives to chemical pretreatment processes with environmental concerns

Conclusion: Engineering Excellence Through Surface Enhancement

TiN coating services represent more than a surface treatment—they are a comprehensive engineering solution that fundamentally transforms component performance across industries. From extending cutting tool life tenfold to enabling medical instruments to withstand hundreds of sterilization cycles, TiN’s unique combination of hardness, chemical inertness, and thermal stability provides solutions to some of manufacturing’s most persistent challenges.

The successful implementation of TiN coatings requires integrated expertise in materials science, plasma physics, surface engineering, and application knowledge. At JLYPT, we’ve built our TiN coating services on this comprehensive foundation, viewing surface enhancement not as an ancillary process but as an essential component of complete manufacturing solutions.

Ready to transform your components through advanced TiN coating technology? Contact our surface engineering team to discuss how our TiN coating services can address your specific performance challenges. From initial coating design through application and validation, we provide complete surface engineering solutions that enhance performance, extend service life, and reduce total operating costs. Begin your surface enhancement project at JLYPT PVD Coating Services.