Titanium Grade 5 CNC Machining Cost: A Comprehensive Engineering and Economic Analysis

Introduction: Navigating the Economics of Aerospace-Grade Precision

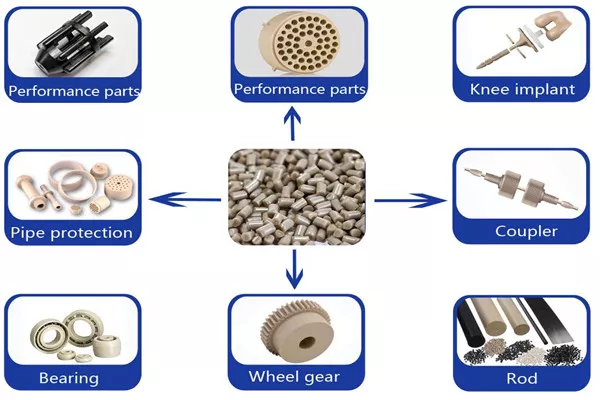

Titanium Grade 5 (Ti-6Al-4V) is not merely a material; it is a benchmark for high-performance engineering. As the most widely used titanium alloy globally, it offers an unparalleled strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility that makes it indispensable in aerospace, medical, and high-end automotive applications. However, these superior properties come with a significant challenge: Titanium Grade 5 CNC machining cost is notoriously complex to estimate and often represents a substantial portion of a project’s budget.

For engineers and procurement specialists at companies like JLYPT CNC Machining, understanding this cost is not about finding the cheapest supplier, but about partnering with a manufacturer who masters the intricate science of machining this “difficult-to-cut” material efficiently. The cost is a direct function of the alloy’s challenging behavior under the cutting tool: its low thermal conductivity, high chemical reactivity, and variable chip formation. An inexperienced shop will face broken tools, poor surface finishes, and scrapped parts, leading to exorbitant costs. A proficient partner like JLYPT leverages advanced strategies—specialized tooling, optimized cutting parameters, and multi-axis efficiency—to transform this challenge into a predictable, value-driven process.

This detailed analysis will dissect every component that contributes to the final price of your titanium component. We will move beyond generic quotes to explore the engineering decisions—from blank selection and tolerance strategy to finishing requirements—that truly govern cost. Through this lens, you will gain the expertise to design for manufacturability, evaluate supplier quotes critically, and ultimately achieve the optimal balance between the unparalleled performance of Ti-6Al-4V and your project’s financial constraints.

Deconstructing the Cost Drivers: A Multi-Factor Equation

The final invoice for a CNC-machined Titanium Grade 5 part is the sum of a series of interconnected cost centers. Understanding each is key to effective cost management.

1. Raw Material Acquisition and Preparation

The journey begins with the billet, bar, or forging.

-

Base Material Cost: Ti-6Al-4V is expensive. Prices fluctuate with aerospace demand, global sponge titanium supply, and mill quantities. A forged billet costs significantly more than a standard bar stock but may provide superior grain structure for critical components.

-

Stock Form and Wastage: The geometry of your raw stock directly impacts material utilization rate. A near-net-shape forging minimizes waste (and machining time) but has a higher upfront cost. Starting with an oversized rectangular block for a cylindrical part leads to high buy-to-fly ratio, where over 80% of expensive material may become chips. Strategic blank selection is the first major cost lever.

-

Material Certification: Aerospace (AMS 4928, AMS 6931) and medical (ASTM F136, ISO 5832-3) applications require full traceability and mill certification reports. This adds a premium over commercially pure grades.

2. The Machining Process: Time, Tools, and Technology

This is where engineering expertise most directly battles cost.

-

Machine Time (Cycle Time): Titanium’s low thermal conductivity (about 1/16th of aluminum) means heat concentrates at the cutting edge, not in the chip. This forces the use of much lower cutting speeds (Vc). A process that takes 1 hour in aluminum 7075 may take 3-4 hours in Ti-6Al-4V under optimal conditions, directly multiplying machine hourly rates.

-

Tooling Consumption: This is often the largest hidden cost. Titanium’s reactivity can cause diffusion wear and adhesion (built-up edge), leading to rapid tool failure. Using the correct substrate (micro-grain carbide), coating (AlTiN, TiAlN), and geometry (high helix, sharp edge) is non-negotiable. Tools must be changed proactively, increasing both tool cost and non-cutting time.

-

Machining Strategy: This is JLYPT’s core value-add. We utilize:

-

High-Pressure Coolant (HPC) Systems: Delivering coolant at 1,000+ PSI directly to the cutting edge to break chips, remove heat, and prevent re-cutting.

-

Trochoidal Milling & Dynamic Toolpaths: These strategies maintain a constant radial engagement, reducing heat buildup and lateral tool pressure, which extends tool life and allows for higher feed rates.

-

Multi-Axis Efficiency: Using 5-axis simultaneous machining to complete a part in a single setup reduces handling time, eliminates cumulative fixture errors, and often allows for more rigid, shorter tool extensions, enabling more aggressive cuts.

-

3. Post-Processing and Quality Assurance

The part off the machine is rarely the final product.

-

Deburring and Edge Breaking: Titanium’s toughness makes manual deburring labor-intensive. Automated processes like thermal energy method (TEM) or abrasive flow machining may be justified for complex internal channels.

-

Heat Treatment: Many aerospace components require solution treating and aging (STA) to achieve specific tensile and fatigue properties. This adds process cost and requires careful distortion management.

-

Surface Finishing: Common finishes include:

-

Vibratory Finishing: For general edge radiusing and stress relief.

-

Passivation: A chemical bath to enhance the natural oxide layer for corrosion resistance.

-

Anodizing (Type II or III): For wear resistance and identification (Type II) or enhanced corrosion protection (Type III, hardcoat).

-

Beam Blasting: For a uniform matte finish, often a precursor to coating.

-

-

Inspection and Certification: Verifying tight tolerances on complex titanium parts requires advanced metrology. Costs scale with the number of critical-to-quality (CTQ) dimensions, the need for first article inspection (FAI) reports (e.g., AS9102), and specialized equipment like coordinate measuring machines (CMM) with laser scanning or X-ray fluorescence (XRF) for material verification.

Table 1: Comprehensive Breakdown of Titanium Grade 5 CNC Machining Cost Factors

| Cost Category | Key Variables & Decisions | Impact on Final Cost | JLYPT’s Optimization Strategy |

|---|---|---|---|

| Raw Material | Buy-to-fly ratio; Mill certification (AMS, ASTM); Forging vs. Bar stock. | High. Can be 30-60% of part cost. Inefficient nesting wastes premium material. | Strategic Blank Sourcing & Nesting: We partner with certified mills and use CAM software for optimal nesting to minimize waste on multi-part orders. |

| Machine Time | Required cutting speed (Vc); Part complexity & thin walls; Number of setups. | Very High. Low Vc for titanium inherently creates long cycle times. Complexity multiplies this. | Advanced Toolpaths & Multi-Axis Machining: We employ trochoidal milling and 5-axis simultaneous machining to maximize material removal rate (MRR) and reduce setups, cutting time by up to 30%. |

| Tooling | Tool substrate/coating; Tool life expectancy; Required surface finish (Ra). | High. Premature tool failure increases cost and risk. Specialty tools (e.g., for deep pockets) are expensive. | Specialized Tooling & HPC: We use only premium, titanium-specific tools and integrate high-pressure coolant (1000+ psi) to extend tool life 2-3x, reducing cost per part. |

| Labor & Programming | CAM programming complexity; In-process monitoring; Skilled machinist oversight. | Moderate-High. Titanium requires expert programmers and attentive machinists to avoid costly errors. | Expert Process Engineering: Our engineers develop proven, stable processes, and use in-process sensors to monitor tool wear, minimizing scrap and manual intervention. |

| Post-Processing | Deburring complexity; Required surface finish (Anodize, Passivation); Heat treatment. | Variable. Simple passivation is low-cost; complex media blasting or cosmetic polishing is labor-intensive. | Integrated Finishing Services: Our in-house anodizing, passivation, and finishing provide single-source accountability and volume-based pricing advantages. |

| Quality Assurance | Dimensional tolerance (±); Surface finish spec (Ra); Documentation (FAI, CMM). | Variable. Tolerances beyond ±0.05mm and full CMM inspection reports add significant time and cost. | Design for Manufacturability (DFM) Feedback: We provide early DFM analysis to recommend tolerance relaxation where possible without compromising function, avoiding unnecessary cost. |

Case Studies: Cost Engineering in Practice

Case Study 1: Aerospace Structural Bracket (Low-Volume, High-Complexity)

-

Part: A primary flight control bracket with integral, thin-walled stiffeners and multiple interfacing datum surfaces.

-

Initial Challenge: The first-run quote from a standard machine shop was prohibitive. Their process used 3-axis machining with multiple fixtures, leading to a 28-hour cycle time, high scrap rate on the thin walls, and poor surface finish requiring extensive handwork.

-

JLYPT’s Cost-Optimized Solution:

-

DFM Collaboration: We recommended a switch from a rectangular block to a custom-drawn extruded profile closer to the final envelope, reducing material waste by 40%.

-

Process Innovation: The part was machined on a 5-axis mill in a single setup using a tombstone fixture. Dynamic milling toolpaths were used for the thin walls to maintain constant tool pressure and prevent chatter.

-

Tooling Strategy: We employed variable-helix end mills with AlTiCrN coating and used high-pressure through-spindle coolant for deep-pocket clearing.

-

-

Outcome: Cycle time reduced to 15 hours. Tool consumption dropped by 60%. The as-machined surface finish met Ra 0.8µm requirements, eliminating secondary polishing. The cost per part was reduced by 35%, while geometric conformity and mechanical properties improved, certified to AS9100 standards.

Case Study 2: Medical Implant Trial (Medium-Volume, High-Precision)

-

Part: A set of 5 orthopedic trial implants (femoral and tibial) used for sizing during knee replacement surgery. Required flawless, burr-free edges and a specific matte finish for visual contrast under OR lights.

-

Initial Challenge: The client needed several hundred sets at a cost point that made single-use trials viable. Previous supplier struggled with maintaining precise, rounded edges after vibratory finishing, often requiring 100% manual inspection and rework.

-

JLYPT’s Cost-Optimized Solution:

-

Design for Finishing: We collaborated to slightly adjust fillet radii to be more compatible with automated abrasive flow machining (AFM).

-

Integrated Production Cell: We set up a dedicated cell with a 5-axis CNC machine directly linked to an automated AFM deburring unit and a laser marking station.

-

In-Process Control: A vision system after the AFM process performed automatic inspection of critical edges, removing any defective parts from the line immediately.

-

-

Outcome: The integrated, automated cell reduced direct labor to loading blanks and packaging finished sets. The scrap/rework rate fell from 15% to under 2%. This allowed JLYPT to offer a 25% lower unit cost at the target volume, with guaranteed consistency and full traceability per FDA QSR requirements.

Case Study 3: Automotive Motorsport Component (Prototype, Extreme Conditions)

-

Part: A Formula Student connecting rod prototype from Ti-6Al-4V, requiring a perfect balance of ultimate tensile strength and fatigue life.

-

Initial Challenge: As a one-off prototype, traditional cost drivers like tooling amortization were irrelevant, but the need for perfect execution on the first attempt was paramount to avoid project delays. The student team had a fixed, low budget.

-

JLYPT’s Cost-Optimized Solution:

-

Value-Engineering the Process: We used a remnant piece of certified bar stock from another aerospace job, drastically reducing material cost.

-

Simulation-First Approach: Our CAM programmers used cutting force simulation software to optimize the toolpath for the delicate I-beam section of the rod, eliminating trial-and-error.

-

Targeted Finishing: We performed only the necessary operations: machining to print, hand deburring, and passivation. We provided a basic CMM report for critical bore centers and bypassed costly full-surface scanning.

-

-

Outcome: The part was delivered on time and on budget, performing flawlessly in dyno testing. The team received a detailed process sheet outlining the parameters used, giving them invaluable data for future design iterations and production planning.

Strategic Framework for Cost Management

Based on our experience, here is a strategic framework for managing your Titanium Grade 5 project costs:

-

Engage Early for DFM: Involve your machining partner during the design phase. A slight increase in a corner radius or a relaxation of a non-critical tolerance from ±0.02mm to ±0.05mm can dramatically reduce machining time and scrap risk.

-

Optimize the Blank: Challenge your partner to justify their blank selection. Ask for the calculated buy-to-fly ratio and explore alternatives like pre-machined stock or forgings.

-

Clarify Requirements: Be explicit about what is critical. Do all surfaces need Ra 0.4µm, or just the bearing faces? Is a full AS9102 FAIR required, or will a summary report suffice? Unspecified requirements lead to over-processing.

-

Consider Total Cost of Ownership (TCO): For high-volume parts, investing in custom tooling (form tools, specialty fixtures) or dedicated automation may have a high upfront cost but a lower TCO over 10,000 parts. Analyze the break-even point.

-

Partner, Don’t Just Purchase: A true engineering partner like JLYPT will work with you to solve cost problems, not just execute a print. Their expertise in process optimization is an asset that lowers your risk and total cost.

Conclusion: Mastering the Balance of Performance and Economics

Titanium Grade 5 CNC machining cost is a sophisticated equation balancing the material’s intrinsic challenges with advanced manufacturing solutions. It is not a commodity process. The lowest bid often reflects a supplier who underestimates these challenges, leading to cost overruns, delays, and quality failures downstream.

At JLYPT, we approach every Ti-6Al-4V project as an engineering collaboration. We transparently analyze all cost drivers—from strategic material sourcing to the application of proprietary high-pressure coolant and dynamic milling techniques—to build an efficient, stable, and predictable manufacturing process. Our goal is to deliver the exceptional performance of Titanium Grade 5 at the most responsible total cost, ensuring your project’s success from prototype through high-volume production.

To discuss your specific Titanium Grade 5 component and receive a detailed, engineer-to-engineer quote that breaks down the true value behind the cost, visit our service page at JLYPT CNC Machining Services.