8 Critical Advantages of Torque Motor for Robotics in Direct Drive Applications

Introduction: Revolutionizing Robotic Motion with Direct Drive Technology

In the rapidly evolving landscape of industrial robotics, the torque motor for robotics represents a paradigm shift in motion control technology, offering unprecedented performance characteristics that are transforming robotic system design. These advanced direct drive motors eliminate traditional transmission components, providing direct connection between the motor and the load, thereby revolutionizing torque delivery, positioning accuracy, and system reliability. The fundamental design principles of torque motor for robotics systems enable higher torque density, superior stiffness, and exceptional dynamic response compared to conventional servo systems with mechanical reducers.

As precision engineering specialists at JLYPT, we have developed extensive expertise in manufacturing critical components for torque motor for robotics applications. This comprehensive technical analysis explores eight fundamental advantages that establish torque motors as the preferred solution for advanced robotic applications, while examining the sophisticated manufacturing methodologies that ensure optimal performance in demanding operational environments.

1. Fundamental Principles of Torque Motor Technology

1.1 Direct Drive Architecture and Operating Principles

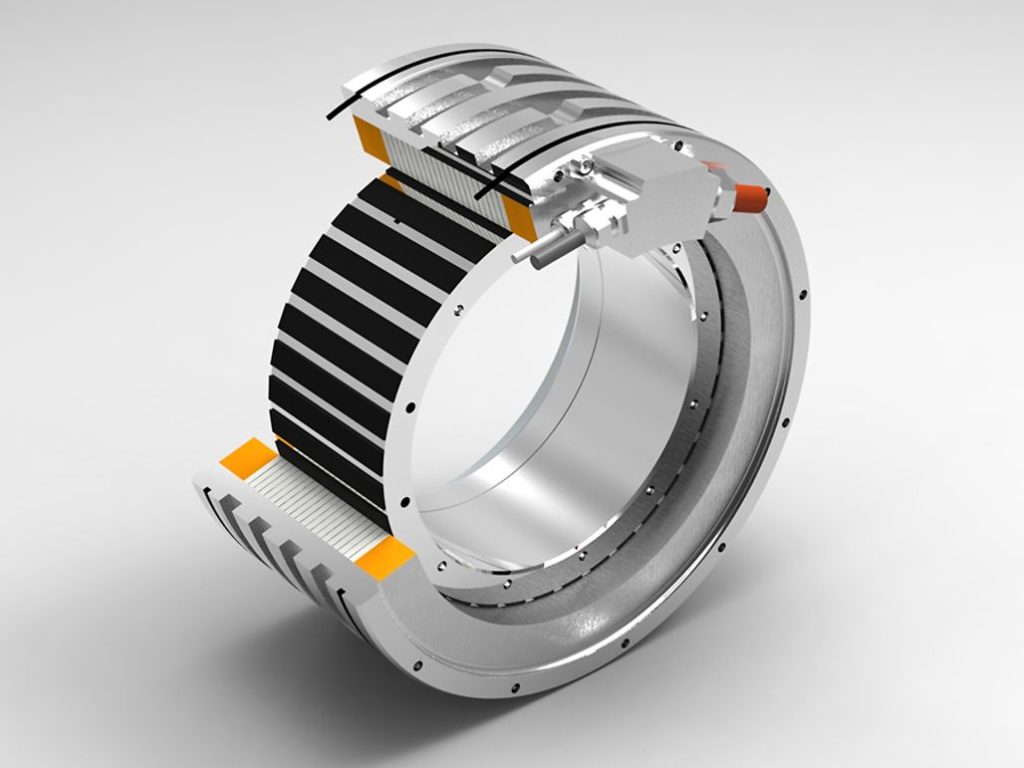

The torque motor for robotics operates on a fundamentally different principle than conventional rotary servo motors with gear reducers. These motors are characterized by their frameless design and direct drive capability, which eliminates mechanical transmission elements between the motor and the load.

Key Architectural Features:

-

Frameless Design: Separate rotor and stator components for direct integration into mechanical structures

-

High Pole Count: Typically 16-64 poles for smooth torque production and precise control

-

Large Diameter-to-Length Ratio: Optimized geometry for maximum torque generation

-

Zero Backlash Operation: Direct drive principle eliminates mechanical play and compliance

Operating Principle Fundamentals:

The torque motor for robotics utilizes a permanent magnet synchronous motor architecture with concentrated windings and high pole counts. The operational principle can be expressed through the fundamental torque equation:

T = k_t × I × sin(θ)

Where:

-

T = Torque output (Nm)

-

k_t = Torque constant (Nm/A)

-

I = Current (A)

-

θ = Electrical angle (radians)

This direct relationship between current and torque enables precise control and rapid response characteristics essential for advanced robotic applications.

1.2 Performance Classification and Applications

Torque Motor Performance Categories:

| Motor Category | Torque Range (Nm) | Speed Range (RPM) | Torque Density (Nm/kg) | Typical Applications |

|---|---|---|---|---|

| Standard Torque | 50-500 | 100-500 | 15-25 | Industrial robots, rotary tables |

| High Torque | 500-2,000 | 50-300 | 20-35 | Heavy-duty automation, machine tools |

| Ultra High Torque | 2,000-10,000 | 10-150 | 25-40 | Large gantry systems, wind turbines |

| Precision Torque | 10-200 | 200-1,000 | 10-20 | Semiconductor equipment, medical robots |

| Compact Torque | 20-200 | 300-800 | 18-28 | Collaborative robots, aerospace |

2. Critical Advantages of Torque Motor for Robotics

2.1 Exceptional Torque Density and Power-to-Weight Ratio

The most significant advantage of torque motor for robotics systems is their extraordinary torque density, which typically ranges from 15-40 Nm/kg depending on the motor design and cooling method.

Torque Density Comparison:

| Motor Technology | Typical Torque Density (Nm/kg) | Peak Torque Capability | Continuous Torque Rating |

|---|---|---|---|

| Torque Motor | 15-40 | 300-500% | 100% |

| Servo with Planetary | 8-15 | 200-300% | 50-80% |

| Servo with Harmonic | 10-20 | 200-400% | 60-90% |

| Conventional Servo | 3-8 | 150-250% | 30-60% |

Technical Factors Enabling High Torque Density:

-

Optimized Magnetic Circuit: Advanced finite element analysis (FEA) optimizes flux paths and magnetic utilization

-

High Energy Magnets: Neodymium iron boron magnets with energy products up to 52 MGOe

-

Advanced Cooling Systems: Liquid cooling capabilities dissipate 2-4 times more heat than air cooling

-

Compact Winding Design: Concentrated windings with high fill factors up to 75%

2.2 Zero Backlash and High Stiffness

The direct drive nature of torque motor for robotics eliminates all mechanical transmission elements, resulting in zero backlash and exceptionally high stiffness.

Stiffness Performance Metrics:

-

Torsional Stiffness: 1,000-5,000 Nm/rad for standard torque motors, up to 20,000 Nm/rad for high-performance models

-

Axial Stiffness: 500-2,000 N/μm depending on bearing arrangement

-

Radial Stiffness: 300-1,500 N/μm for standard configurations

Applications Benefiting from Zero Backlash:

-

Robotic machining and deburring operations

-

Precision assembly and testing equipment

-

Semiconductor wafer handling and processing

-

Optical positioning and alignment systems

-

Coordinate measuring machines and metrology equipment

3. Advanced Material Selection Strategies

3.1 Magnetic Materials and Core Components

The performance of torque motor for robotics is fundamentally dependent on advanced material selection for magnetic circuits and structural components.

Comprehensive Material Selection Guide:

| Material Specification | Applications | Key Properties | Thermal Characteristics | Cost Factor |

|---|---|---|---|---|

| Electrical Steel M19 | Stator laminations | Low core loss, high permeability | Curie temperature 740°C | 1.0x |

| Electrical Steel M15 | Premium stator cores | Superior core loss characteristics | Curie temperature 740°C | 1.3x |

| Neodymium N52 | Standard rotors | Maximum energy product 52 MGOe | Max operating temp 150°C | 2.5x |

| Neodymium N45SH | High-temperature rotors | High temperature stability | Max operating temp 180°C | 3.2x |

| Aluminum 6061-T6 | Structural components | Good strength-to-weight ratio | Thermal conductivity 167 W/m·K | 1.0x |

| Stainless 17-4PH | Shafts, fasteners | High strength, corrosion resistance | Thermal conductivity 18 W/m·K | 4.0x |

| Copper C10100 | Windings | Highest electrical conductivity | Thermal conductivity 391 W/m·K | 5.5x |

3.2 Specialized Material Processing

Lamination Manufacturing:

-

Laser Cutting: Precision cutting with kerf width 0.1-0.2mm and heat-affected zone <0.05mm

-

Heat Treatment: Stress relief annealing at 750-800°C for dimensional stability

-

Surface Insulation: C5 organic coating with thickness 3-5μm per side

-

Stacking Technology: Precision stacking with interlock features for mechanical integrity

Magnet Processing:

-

Magnet Segmentation: Strategic segmentation reduces eddy current losses by 40-60%

-

Surface Coating: Nickel-copper-nickel coating for corrosion protection

-

Precision Grinding: Tight tolerance grinding to ±0.02mm dimensional accuracy

-

Magnetizing Fixtures: Custom fixtures for optimal magnetic field orientation

4. Precision CNC Machining Methodologies

4.1 Multi-Axis Machining for Complex Geometries

The manufacturing of components for torque motor for robotics requires advanced CNC machining capabilities to achieve the required precision and thermal performance.

5-Axis Simultaneous Machining:

-

Complex Cooling Channels: Ability to machine intricate spiral and axial cooling passages

-

Precision Boring: Achieving bearing seat tolerances within ±0.005mm with surface finish Ra 0.4μm

-

Thin-Wall Machining: Manufacturing of delicate structural components with wall thickness down to 1.5mm

-

High-Speed Machining: Optimized tool paths for aluminum and steel components

Critical Machining Parameters:

| Operation | Material | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Depth of Cut (mm) | Tolerance (mm) |

|---|---|---|---|---|---|

| Roughing | Aluminum | 800-1,200 | 0.15-0.30 | 2.0-5.0 | ±0.10 |

| Finishing | Aluminum | 1,000-1,500 | 0.08-0.15 | 0.5-1.5 | ±0.025 |

| Roughing | Steel | 120-180 | 0.10-0.20 | 1.5-3.0 | ±0.15 |

| Finishing | Steel | 150-220 | 0.05-0.12 | 0.3-1.0 | ±0.015 |

| Hard Machining | Hardened Steel | 80-120 | 0.03-0.08 | 0.2-0.5 | ±0.010 |

4.2 Specialized Manufacturing Processes

Rotor Manufacturing:

-

Precision Balancing: High-speed balancing to G1.0 quality grade or better

-

Magnet Slot Machining: Precision slots with positional accuracy ±0.005mm

-

Surface Treatment: Electroless nickel plating or anodizing for corrosion protection

-

Thermal Management: Integration of cooling channels and heat transfer surfaces

Stator Manufacturing:

-

Winding Technology: Automated winding with tension control and precise layering

-

Impregnation Process: Vacuum pressure impregnation (VPI) for complete insulation

-

Termination Processing: Precision welding and brazing of electrical connections

-

Quality Verification: High-pot testing and partial discharge measurement

5. Thermal Management Solutions

5.1 Advanced Cooling Technologies

Effective thermal management is crucial for maintaining performance and reliability in torque motor for robotics applications, particularly during continuous operation at high torque levels.

Cooling Method Comparison:

| Cooling Method | Heat Dissipation (W/in³) | Thermal Resistance (°C/W) | Complexity | Cost Factor |

|---|---|---|---|---|

| Natural Convection | 0.5-2.0 | 1.5-4.0 | Low | 1.0x |

| Forced Air Cooling | 2.0-5.0 | 0.8-2.0 | Medium | 1.5x |

| Liquid Cooling | 5.0-15.0 | 0.2-0.8 | High | 3.0x |

| Conduction Cooling | 3.0-8.0 | 0.5-1.5 | Medium | 2.0x |

| Two-Phase Cooling | 10.0-25.0 | 0.1-0.4 | Very High | 5.0x |

5.2 Integrated Thermal Management Features

Advanced Cooling Solutions:

-

Spiral Cooling Channels: Optimized helical passages with calculated flow rates and pressure drop

-

Heat Pipe Integration: Passive cooling for localized hot spots in compact designs

-

Thermal Interface Materials: Advanced compounds with 3-8 W/m·K conductivity

-

Composite Materials: Thermally conductive polymers and metal composites

6. Precision Bearing and Alignment Systems

6.1 Bearing Selection for Direct Drive Applications

The bearing system in a torque motor for robotics must accommodate high torque loads while maintaining precise alignment and smooth operation.

Bearing Technology Comparison:

| Bearing Type | Speed Factor | Stiffness | Friction Torque | Life Expectancy |

|---|---|---|---|---|

| Deep Groove Ball | 1.0x | Medium | Low | 20,000 hours |

| Angular Contact | 1.2x | High | Medium | 30,000 hours |

| Crossed Roller | 0.8x | Very High | High | 25,000 hours |

| Hydrodynamic | 2.0x | Low | Very Low | 50,000+ hours |

| Magnetic Bearings | 3.0x | Low | Zero | 100,000+ hours |

6.2 Alignment and Installation Precision

Critical Alignment Parameters:

-

Runout Tolerance: 0.010mm maximum for standard applications, 0.005mm for precision applications

-

Parallelism: 0.015mm per 100mm for mounting surfaces

-

Concentricity: 0.008mm maximum between bearing seats and critical features

-

Flatness: 0.012mm per 100mm for mounting interfaces

7. Quality Assurance and Testing Protocols

7.1 Comprehensive Metrology Systems

The verification of torque motor for robotics components employs advanced measurement technologies and rigorous inspection protocols.

Dimensional Metrology:

-

Coordinate Measuring Machines: Volumetric accuracy to 1.8 + L/300 μm with temperature compensation

-

Laser Scanning: High-density point cloud capture for complex surface analysis

-

Roundness Measurement: Accuracy to 0.025μm with harmonic analysis capability

-

Surface Topography: 3D surface analysis with Ra measurement to 0.01μm resolution

Electrical Testing:

-

Hi-Pot Testing: Dielectric strength verification at 2U + 1000V for 60 seconds

-

Insulation Resistance: Minimum 100MΩ at 500V DC with temperature compensation

-

Winding Resistance: Four-wire measurement to 0.1% accuracy

-

Inductance Measurement: Ld/Lq measurement across electrical angle

7.2 Performance Validation

Dynamic Testing Protocols:

-

Torque Constant Verification: Measurement within ±2% of specified value across temperature range

-

Back-EMF Testing: Sinusoidal verification with THD less than 3%

-

Efficiency Mapping: Input-output power measurement with 0.2% accuracy

-

Thermal Performance: Temperature rise verification under continuous torque conditions

Environmental Testing:

-

Thermal Cycling: -40°C to +150°C for 500 cycles minimum

-

Vibration Endurance: Random vibration to 10Grms per MIL-STD-810

-

Humidity Testing: 95% relative humidity at 40°C for 240 hours

-

IP Rating Verification: IP65 standard, IP67 for harsh environments

8. Application Case Studies

Case Study 1: Robotic Machining Center

Challenge: An automotive manufacturer required high-torque direct drive motors for a new robotic machining cell performing precision milling operations on aluminum components. The existing systems with geared servos experienced backlash issues and limited stiffness.

JLYPT Solution: We developed custom torque motor for robotics systems with 400 Nm continuous torque and integrated liquid cooling. The manufacturing process incorporated precision machining of aluminum housings with spiral cooling channels and custom winding patterns optimized for low-speed, high-torque operation.

Results:

-

Achieved positioning accuracy of ±2 arc-seconds

-

Improved surface finish quality by 45% through elimination of transmission error

-

Increased material removal rates by 60% through higher torque capability

-

Reduced maintenance requirements by eliminating gearbox servicing

Case Study 2: Semiconductor Wafer Handling

Challenge: A semiconductor equipment manufacturer needed ultra-clean torque motor for robotics for vacuum-compatible wafer handling robots with minimal particle generation and exceptional reliability.

JLYPT Solution: Our engineering team designed specialized torque motor for robotics using stainless steel components and vacuum-compatible materials. The manufacturing process emphasized debris-free assembly techniques and specialized surface treatments. All components underwent rigorous cleaning and outgassing testing.

Results:

-

Achieved particle generation rates below Class 1 cleanroom requirements

-

Maintained torque ripple below 1% for smooth motion control

-

Enabled 25% faster wafer transfer cycles through higher acceleration

-

Achieved MTBF exceeding 50,000 hours in continuous operation

Case Study 3: Heavy Payload Material Handling

Challenge: A logistics automation provider required robust torque motor for robotics for palletizing robots handling 1,500kg payloads with high positioning accuracy and reliability.

JLYPT Solution: We implemented heavy-duty torque motor for robotics using high-strength steel components and advanced cooling systems. The design incorporated increased magnetic circuit volume and optimized winding configuration for maximum torque density. Precision machining ensured perfect alignment of critical components.

Results:

-

Achieved continuous torque of 2,500 Nm in compact form factor

-

Maintained positioning accuracy within ±5 arc-seconds under full load

-

Reduced energy consumption by 30% through higher efficiency

-

Extended service life to 25,000 hours between maintenance

9. Future Trends and Innovations

9.1 Emerging Technologies

The evolution of torque motor for robotics technology continues with several promising directions:

Advanced Materials:

-

High-Temperature Superconductors: Potential for dramatically increased power density

-

Nanocrystalline Alloys: Reduced core losses and improved high-frequency performance

-

Graphene Composites: Enhanced thermal management and structural performance

-

Magnetocaloric Materials: Advanced cooling technologies for extreme performance

Digital Integration:

-

Embedded Fiber Optic Sensors: Real-time temperature and strain monitoring

-

IoT Connectivity: Cloud-based performance monitoring and predictive maintenance

-

Digital Twins: Virtual modeling with real-time synchronization for performance optimization

-

AI-Driven Control: Adaptive control algorithms based on operational conditions

9.2 Manufacturing Technology Advances

The future of torque motor for robotics manufacturing includes:

Additive Manufacturing:

-

Complex Cooling Channels: Optimized thermal management geometries impossible with traditional machining

-

Integrated Structures: Combined multiple components into single pieces reducing assembly time

-

Customized Designs: Application-specific optimization through generative design algorithms

-

Lightweight Structures: Topology-optimized weight reduction with maintained stiffness

Sustainable Manufacturing:

-

Energy-Efficient Processes: Reduced environmental impact through optimized machining parameters

-

Recyclable Materials: Closed-loop material usage with 95% recycling rates

-

Green Manufacturing: Environmentally conscious production methods with carbon neutrality goals

-

Lifecycle Optimization: Design for extended service life and complete recyclability

Conclusion: Engineering Excellence in Direct Drive Technology

Torque motor for robotics technology represents the cutting edge of motion control in modern automation systems. The eight advantages explored—exceptional torque density, zero backlash, high stiffness, superior dynamic response, direct drive simplicity, high efficiency, compact design, and maintenance-free operation—establish torque motors as the preferred solution for demanding robotic applications where performance cannot be compromised.

As robotic technology continues to advance, the requirements for torque motor for robotics systems will become increasingly demanding, driving further innovation in manufacturing technologies and material science. The integration of digital technologies, advanced analytics, and sustainable manufacturing practices will ensure that torque motor technology remains at the forefront of industrial innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every torque motor for robotics component we produce meets the highest standards of performance, reliability, and efficiency. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of capability and performance in their automated systems.

For engineering teams seeking to enhance their robotic systems through superior torque motor solutions, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.